HOW TO FIX EXCESSIVE BRAKE PEDAL TRAVEL

What Is Excessive Brake Pedal Travel?

Excessive brake pedal travel happens when you feel your pedal sinking rapidly while braking, or sitting lower than usual when activating your vehicle’s brakes. This can happen due to wobbly discs knocking pistons back or air in the braking system.

Performing DIY brake repair to fix excessive brake pedal travel can be a tedious task. Follow the steps below to diagnose and repair your sinking brakes.

How to Fix Excessive Brake Pedal Travel

1. Diagnose the Problem . To diagnose issues with the master cylinder, the first thing you need to do is remove the lines, install brass or plastic plugs into the outlets, and apply the brakes. What happens when you apply the brakes will tell you what issue your vehicle is having. You can continue this process of elimination by isolating each wheel.

2. Use Your Parking Brake. If you don’t typically engage your parking brake, the parking brake can be key in figuring out if your car is suffering from excessive brake pedal travel. If the parking brake doesn’t properly engage, that generally means a low pedal.

3. Bleed the Brakes. Bleeding your brakes is an important step in brake pedal travel repair and other brake issues. Use a jelly jar half full of brake fluid and a short hose to depress your brake pedal.

While depressing the pedal, rotate the star wheel to lose up the clearance. Then, go back one click when the wheel scrapes. It’s best to have a partner on hand when bleeding your brakes.

4. Bleed the Master Cylinders . After bleeding the brakes, bleeding the master cylinders is the next step. In traditional systems, you begin with the longest line in the circuit first, and go from the right rear, left rear, right front, and left the front. In diagonally split systems, the order is right rear, left front, left rear, and right front. Flush out the bleeder valves, and finally, remove the air from your master cylinder.

If you’re not sure which type of system your vehicle is or are unaware of the proper tools needed to fix excessive brake pedal travel, it’s best to bring your vehicle into Brake Works.

With two convenient locations with great weekend hours, getting proper brake maintenance is simpler than you think. Contact our team of certified specialists to schedule an appointment.

Erika Suarez

Previous post what problems can old power steering fluid cause, next post best brake pads for trucks, leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

Brake Works is a family owned and operated brake and auto repair business, established in 1989 by Ray and Eddie Gruetzner. We are committed to providing the highest quality brake and auto repair service possible at affordable prices.

Our Services

Best Brake Shop In San Antonio Suspension Repair San Antonio Car AC Repair - San Antonio Auto Repair Shop San Antonio

Hours of Operation

14950 Nacogdoches | 210-657-3300 | San Antonio, TX | [email protected]| Copyright © 2023. Brake Works. All rights reserved.

- Brake Repair and Replacement Service

- Suspension Repair Service

- Car AC Repair Service

- Auto Repair Service

CALL US TODAY (210) 657-3300

Get an appointment

CONTACT FORM

Free shipping over $249.00

Buy with monthly payments

Learn More - Get a real-time decision.

Free Shipping over $249!

TBM Brakes Brake Calculator

There are 3 key components to effective pressure delivery to your calipers in order to have adequate braking performance potential at the caliper. Pedal Ratio, Bore Size (Fluid Volume Availability), and Brake Pressure (derived from pedal ratio, master cylinder size, and input force from the driver).

Below are calculators to help you plan a proper brake setup.

*Note: these calculators do not take into account or verify that your caliper style/design, pad compound or rotor size are adequate to achieve your goals*

Calculate Pedal Ratio

*Factory Pedal Ratios on vehicles equipped with power brakes are typically 4:1. For manual brake conversions we typically target between 6:1 or 7:1. Note, different length pushrod and master cylinder placement may need to change to accommodate.

Note: making sure your master cylinder pushrod does not have preload at neutral is important to proper system function. Watch this video to learn more: Click Here

Measurement A:

Measurement B:

Effective Pedal Ratio= 0 : 1

Calculate Master Cylinder Area (sq. in.)

Bore Diameter:

Master Cylinder Area: 0.00 sq. in.

Calculate Effective Pressure at your Master Cylinder

*We recommend a normal operating pressure of 7-800 psi*

*Recommended max achievable pressure of 1200psi*

*Typical input force is 100pounds by average weight and size driver. Input force can vary from 70 lbs to 150+ depending on driver. See This Video (link) to understand how to calculate this.

Input force:

Pedal ratio:

Master Cylinder Area of System:

Line Pressure at Master Cylinder: 0.00 psi

Calculate Master Cylinder and Pedal Travel

*Note: for reference a larger master diameter results in a harder feeling pedal with less travel, this allows for less modulation of pedal feel for driver.*

*Note: smaller bore master cylinder results in softer feeling pedal with more modulation but a longer pedal throw to achieve pressure*

Fluid Requirement

Master Cylinder Diameter:

Master Cylinder Travel Distance (Inches): 0.01 in

Pedal Ratio:

Pedal Travel (Inches): 0.00 in

Calculate Master Cylinder Fluid Output (Cu. In.)

*Note compare this to your fluid requirement to determine adequate fluid volume is available for your braking demands. Output needs to be greater than requirement below*

Master Cylinder Travel Distance:

Master Cylinder Area:

Available Fluid Volume by System: 0 cubic inches

Fluid Requirement By Your Brake System

*Note: if you have varying size pistons, it may require you to do this calculation for each caliper separately and add the results together for overall Fluid Requirement*

*Note: pad movement may change depending on style of caliper and system being used. Typically this number can be between .01 and .03 after a system is bled, consult your brake manufacturer if needed* For reference, piston size and quantity are here for our drag racing calipers. Many aftermarket calipers run different sizes pistons, consult your manufacturer.

DR1: (2 pistons: 1.75" Diameter)

F1: (2 pistons: 1.75" Diameter)

F3: (4 pistons: 1.75" Diameter)

Piston Size

# of pistons

Inches of Pad Movement:

Fluid Requirement: 0.00

- Choosing a selection results in a full page refresh.

- Opens in a new window.

- Savings Central

- Shop by Brands

- News & Events

- Help Center Home

- Order Status

- Knowledge Base - Home

What is brake pedal ratio?

Pedal ratio is an important but often overlooked part of your braking system. It tells you how the force you apply to the pedal is multiplied and transferred to the Master Cylinder . It also affects how far the pedal travels.

Why is it important?

The average person can press on the brake pedal with about 70 lbs. of force. However, to stop a moving vehicle, disc brakes require 800-1,200 psi at the calipers. The force you put on the pedal is amplified by all the parts of the system. The pedal ratio is one thing that helps.

How is it calculated?

- This is measurement “A” in the diagram.

- This is measurement “B” in the diagram.

- “A” divided by “B” equals the pedal ratio.

For Example

Assume the following:

- Measurement “A” = 12 in.

- Measurement “B” = 3 in.

12 divided by 3 = 4. In this case, the pedal ratio is 4:1.

How does it affect performance?

Using the numbers from the examples above shows how the force is multiplied:

- 70 lbs. of force applied to the pedal

- A 4:1 pedal ratio

- Equals 280 lbs. of force applied to the master cylinder pushrod

For power brake systems, the Brake Booster increases the force even more. This makes stopping easier and driving more enjoyable.

Also, take note of the pedal travel:

- A master cylinder with a 1.10 in. stroke

- The pedal needs to travel 4.40 in.

It's important that the master cylinder bottoms out before the pedal hits the floor. This ensures the master cylinder moves enough fluid to stop the vehicle.

What should the pedal ratio be?

Pedal ratio is not something that is easily changed. However, it is something to consider during a custom build. It also comes into play when converting from manual to power brakes or vice versa.

The right pedal ratio depends on the brake system design. The pedal ratio needs to work with:

- Manual vs. Power Brakes

- Disc vs. Drum Brakes

- Master Cylinder Diameter

- Wheel Cylinder Diameter

- Caliper Piston Diameter

The chart below lists some basic guidelines. With some fabrication, your pedal ratio can be fine-tuned to meet your needs.

Behling Racing

Brake Pedal Set-up and Guidelines

Brake pedal guidelines.

Wilwood pedal assemblies and integrated balance bars have been designed specifically for racing applications. Properly set-up, this assembly will allow for the precise adjustment of front-to-rear brake bias. The advantages of an adjustable balance bar and dual master cylinders are:

- Brake proportioning can be adjusted by use of different size master cylinder bores for front and rear brakes.

- Front to rear brake balance can be fine tuned by adjusting the balance bar.

- With two independent hydraulic systems, should one master cylinder fail, the other system may remain functional.

Brake pedals should be mounted securely. When possible, keep the master cylinder reservoir level higher than the horizontal plane of the calipers to prevent excessive fluid drain back which can result in double pumping of the pedal. If this is not possible, a two pound residual pressure valve should be plumbed into the brake line at the exit of the master cylinder to prevent fluid drain back (do not confuse the two pound valve with the ten pound version; the ten pound valve is for use with drum brakes only).

Brake pedals should be free to return when no pressure is being applied, allowing the master cylinder pushrod to return to its undepressed position. In some cases, the master cylinder spring (internal) may not be strong enough to fully return the pushrod; in this case an additional pedal return spring can be used. There are two important items for consideration:

1. The brake pedal should have an adjustable return stop on it when a strong pedal return spring is used. This prevents the master cylinder from excessively banging the snap ring stop inside the master cylinder bore (visible under the rubber boot). Adjust the stop so the pedal stops returning at the point when the master cylinder piston retracts against the snap ring, Figure 1 .

1. Master cylinder pedal stop and return hole position.

2. The master cylinder piston must fully retract. If the master cylinder piston is not allowed to fully retract when the brake pedal is not applied, the primary inside seal will not return past the small pressure relief hole (visible within the master cylinder reservoir on some master cylinders). This can cause excessive residual line pressure and contribute to brake drag and an overheating condition, see Figure 1 , Detail “A”.

Balance Bar Adjusting

The balance bar is an adjustable lever (usually a threaded rod), that pivots on a spherical bearing and uses two separate master cylinders for the front and rear brakes. Most balance bars are part of a pedal assembly that also provides a mounting for the master cylinders. When the balance bar is centered, it pushes equally on both master cylinders creating equal pressure, given that the master cylinders are the same size bore. When adjusted as far as possible toward one master cylinder it will push approximately twice as hard on that cylinder as the other.

To set up the balance bar, thread the master cylinder pushrods through their respective clevises to obtain the desired position. Threading one pushrod into its respective clevis means threading the other one out the same amount. Sometimes this will lead to a “cocked” balance bar when the pedal is in the relaxed position, see Figure 2 , “no pedal effort”. This is acceptable as long as each master cylinder pushrod is completely free of pressure when the pedal is relaxed.

Note: The pushrod adjustment depicted in the figure is representative of a typical asphalt application. That is, large caliper pistons in front, small caliper pistons in the rear.

It is important that the operation of the balance bar functions without interference by over adjustment. This can occur when a clevis jams against the side of the pedal or the lever (bolt) hits the pedal bore during any point of pedal travel, Figure 3 .

Lever movement should be unimpeded throughout pedal travel. In the neutral position, clevises should have between .20” - .25” total clearance between the side of the pedal. The large washers between the pedal and clevis should remain loose. Make sure that the master cylinder pushrods remain true in relationship to the cylinder during entire pedal travel; pushrods should not be pushing master cylinder pistons at an angle. See Figure 4 .

NOTE: In its non-depressed position, the pedal and balance bar should allow the pushrod of the master cylinders to fully return. This can be checked by feeling pushrods for very slight movement, not loose movement. Master cylinder pistons should be against the retaining snap ring (under boot).

Balance bar lever interference.

Example of pushrod alignment.

Pedal Ratios / Mechanical Leverage

Pedal ratio, or mechanical leverage is the ratio calculated from the length from the pivot point of the pedal to the center of the foot pedal (A), divided by the length from the pivot point to the master cylinder pushrod (B). Refer to the figures below.

Mechanical leverage is simply a means of increasing the brake force without increasing your leg effort. As “A” gets longer and “B” gets shorter, the mechanical leverage increases brake force without pushing harder on the pedal. The disadvantage is that the pedal stroke also increases, requiring you to push the pedal further.

If uncertain about which pedal ratio is right for your application, a 6:1 ratio is an excellent starting point.

A = Distance form pivot point to middle of push / pull point

B = Distance form pivot to point of push on master cylinder

P = Pivot point

F = Force or push

Copyright Wilwood

- CREATE ACCOUNT

- TERMS OF USE

- PRIVACY POLICY

- RETURN POLICY

- COMPANY INFO

MON-FRI 9AM - 6PM

SAT 9AM - 1PM

5170 N 125th St. Butler, WI 53007

- Summit Racing Equipment

Search Form

Recent searches.

- Hot Rods and Muscle Cars

- Old Motorcycles

Trending Searches

- Ford Bronco

- Record Setting

- Fuel Injection

Pedal Pushers: How to Figure Out Pedal Ratio & Master Cylinder Bore Size

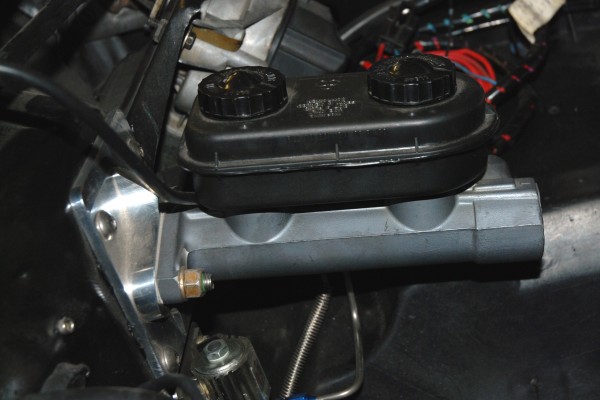

This manual master cylinder is one of the most common you’ll find at a drag strip and it’s also perfect for many hot rod applications. It is a Mopar master cylinder, often found on applications such as Dodge mini vans and Chrysler Cordoba’s (Summit Racing offers them through Strange Engineering, Mopar Performance, Wilwood, Cardone, Dorman and others). These master cylinders are available in at least two different bore sizes: 1-1/32-inch and 1-1/8-inch. They’re manufactured with an aluminum body along with a relatively large capacity plastic reservoir with dual outlet bores (which correctly face the driver side fender when mounted on the firewall).

The Mopar-style master cylinder has one shortcoming: the size of the outlet fittings. The front fitting is a 9/16-20-inch inverted flare while the rear is a 1/2-20-inch inverted flare. What’s so difficult about that? You’ll have trouble finding the right fittings. Both Lamb Components and Strange Engineering manufacture special adapters specifically for these master cylinders, which allow an easy hook up to -3 AN fittings. See the Summit Racing catalog for Strange master cylinder fittings.

In this case, the brake master cylinder is adapted to the car with a billet piece from the folks at TRZ Motorsports. If you have a Mopar, Summit Racing offers several special adapters from Mopar Performance that enable you to mount the later model tandem master cylinder to your car.

The typical Detroit pedal assembly looks like this. This vintage Chevy hanging arrangement is designed to accept the brake pedal assembly, and if equipped with a clutch, that too. If you take close look at this pedal, you can see two different master cylinder pushrod mount holes--one is for a booster-equipped application, while the other is for a non-boosted brake arrangement. For a late model, non-boosted manual application, many fabrication shops modify the pedal assembly by creating a mount that is higher (up the pedal) than the original. By moving the mount position higher, the pedal ratio is improved.

When it comes to reworking the brakes on your car, two things seldom come into consideration: your master cylinder and pedal ratio. And those are two factors that are absolutely critical to your brake system performance. The brake pedal acts as a lever to increase the force the driver applies to the master cylinder. The master cylinder, in turn, forces fluid to the disc brake caliper pistons or drum brake wheel cylinders.

Take a close look at a brake pedal . You’ll find that the pivot point (where the pedal swivels) and the mounting point for the master cylinder pushrod are often rather different. If the length of the pedal or the distance between the pushrod mount–or a combination of both–is changed, then there is a change in the amount of (leg) force required to energize the brake master cylinder. This is the mechanical advantage of the lever or in simpler terms, the “pedal ratio.” There is a mathematical equation that helps you figure it out:

Input Force X Pedal Ratio / Brake Piston Area = PSI

The formula essentially figures out the amount of force exerted by you through your leg times the pedal ratio divided by the area of the brake piston(s). The force is measured as pounds per square inch (PSI), and we’re told that the average adult male can exert roughly 300 pounds of force (maximum) with one leg. That’s a whole bunch! Something in the order of one-third or one-half that figure is certainly more relaxed, even in a bad-to-the bone hot rod.

Let’s look at how all this applies to activating your master cylinder. A typical manual master cylinder usually requires something in the range of 600 to 1000 PSI to function properly. You have to figure out how to transform the 100 or so pounds of relaxed leg pressure (roughly one-third of the 300 PSI as we mentioned above) into pretty big PSI figures. This is accomplished by way of a lever (the brake pedal). In order to arrive at the pressure required, changing the overall length of the pedal is possible, although it’s probably a bunch easier and usually far more practical to simply shorten the distance between the pivot point and the master cylinder pushrod mount location. That’s how fab shops modify brake pedals.

But we’re not done yet.

There’s something else to think about: brake line pressure. This pressure is a totally different thing than the force you apply to the pedal. That force acts in one direction and is addressed in pounds. Pressure, on the other hand, acts in all directions and is addressed in PSI (pounds per square inch). As we pointed out above, varied (pivot length) brake pedals can be used to change the force. Inside the hydraulic system, the surface area of the piston is what is affected by pressure. Decreasing the bore size of the master cylinder increases the pressure it can build.

Pistons in master cylinders are specified by bore size, but there’s a catch. The area of a circle (or bore) is Pi–R-Squared. The area of the piston surface increases or decreases as the square of the bore size or diameter. The area of something like a common 1-1/8-inch master cylinder is approximately 0.994-inch. The area of an equally common 1.00-inch bore master cylinder is approximately 0.785-inch. Switching from the larger master cylinder to the smaller version will increase the line pressure approximately 26.5 percent assuming that pedal ratio hasn’t changed.

When the pedal force is increased or the pedal ratio is increased (or perhaps both at once), the stroke of the master cylinder is shortened (brake line pressure is unaffected). When the master cylinder piston size is increased, the output pressure of the master cylinder is decreased. A master cylinder with a smaller piston will exert more line pressure with the same amount of force (pedal ratio) than a master cylinder piston with a larger piston area. Because the brake line fluid pressure is working against the surface of the wheel cylinder (or disc brake piston), increasing the area of the cylinder will increase brake torque.

So, if your car needs some help in the stopping power department, or if there’s a need to reduce the pedal effort, you have a few options: A) decrease the master cylinder bore size; B) increase the pedal ratio; or C) increase the wheel cylinder bore size. If the pedal ratio is increased, there will be more travel at the master cylinder piston. If the master cylinder bore size is decreased, the piston has to travel further to move the same amount of fluid. Typically, a master cylinder has approximately 1-1/2-inch to 1-3/4-inch of stroke (travel). What you have to do is coordinate the pedal ratio with the bore size to arrive at approximately half of the stroke (roughly 1-inch) in order to make the brakes feel comfortable and stop the car safely.

Wayne Scraba is a diehard car guy and regular contributor to OnAllCylinders. He’s owned his own speed shop, built race cars, street rods, and custom motorcycles, and restored muscle cars. He’s authored five how-to books and written over 4,500 tech articles that have appeared in sixty different high performance automotive, motorcycle and aviation magazines worldwide.

22 responses to “Pedal Pushers: How to Figure Out Pedal Ratio & Master Cylinder Bore Size”

I have been told, by so called experts, that the larger the master cylinder bore size would give more stopping power with less leg pressure on the peddle. If I understand this artical, my information is incorrect and a smaller bore master cylinder will give more stopping power with less leg pressure. Is this correct? Thanks

With the same pressure applied (by your leg), the smaller bore piston will have more pressure at the caliper.

right, would you walk thru mud on a soup can or coffee can? soup can provides more psi.

[…] If you still can’t diagnose the problem, then step up to a larger master cylinder bore size (we recently covered bore size in this article). A new set of brake drums and metallic shoes will also improve braking power, but you’ll […]

I have 15/16 bore MC. I have converted to 4 wheel disc brakes (67 barracuda) right stuff on the rear wilwood on the front. Cannot get a decent pedal. I feel I have a volume issue & intend to go to a 1″1/8 bore MC. Am I on the right track. If isolate front or rear lines pedal comes up good.

If volume was a thing you would have huge lines similar to fuel lines. Hydraulics is pressure. If you go to a bigger bore you lose pressure (according to the article). I too have the 15/16 MC. But I want to add a vacuum power booster to assist in my efforts.

This article is spot on!!! It has good understanding of basic hydraulics. Going on the comments, don’t people get taught anything anymore? I had this in 7th grade science.

I have a 1938 chevy pickup with 1 1/4 & 1 3/16 wheel cylinders. I converted to a dual resivor 1 ” bore master cylinder. The problem is the pedal travels to the floor before engaging the brakes. I have the shoes adjusted up far enough you can hear them drag. Do I need a larger bore master to displace more fluid ?

Sounds like you need to bleed them properly.

What is your MC stroke?

IF you have zero air in the lines and no spongy pedal then yes, you need to increase the m/c bore size to move more fluid volume to be able to move the pistons in each wheel cyl

I have the exact same issue on my 38. How did you finally fix the problem? I have 3-1/2″ of foot travel and 1/2″ of booster travel.

I am building a 4 door 32 plymouth hotrod. 560 hp want it to stop… All steel, heavier than most rods with disc brakes all around. Conversion disc brakes using 69-77 gm calipers on 11″ discs. Would like to go with manual brakes but vac assisted a possibility. Deciding on master cylinder- 1 or 1-1/8″? Pedal I have is 4 to 1 (power brake set up) Can change ratio if need be. Any input would be appreciated THANKS

Follow up question- how does a power booster affect the 600- 1000 PSI required to function properly?

I have 67 nova on grand national chassis g body every thing new stock every thing drake related rear drum new dual booster 78 blazer m/c won’t slide a tire 1/4 rear line Help. I can’t drive my 35000.00car.

I have a 97 mustang Gt with hydroboost and 1 inch bore oem master cylinder with Wilwood Big brake kit up front.The issue I have is that mine brake pedal feels to soft to Low. I will change the master cylinder to 1 1/8 bore size and hopefully it will help with the brake pedal feel. I want mine brake pedal to be more firm not soft like it is now.

i like to customize the single piston master cylinder can u help me for it to be build?

Howdy, you should reach out to the Summit Racing tech folks. They’ll be able to spec-out exactly what you need for your brake system. Click here for their contact info.

Ma car has 1 pot floating caliper 48mm diameter for a total area calculated 3619mm2, I bought 4 pot from old Jaguar xjs with 4x48mm pot, total area calculated 7239 exactly double, standard master cylinder is 22.2mm diameter, how can I calculate the new master cylinder? The pedal still remain the same, thank you

I have a 1933 Singer with a 5 to 1 pedal ratio a 1inch bore m/c 1 inch bore rear w/cyl on single leading shoes 15/16 inch front w/cyl on twin leading shoes, should this give the right balance.

I have a wilwood 7/8 bore master cylinder with 3/16 brake line and chevy meteric 2.5 inch front calipers and ford 9 inch rear drum brakes the brake pedal feel is good with one pump but gets higher when pumping the pedal but even then the vehicle does not lock up the brakes and only slowly stops can not panic stop . I have manual proportioning valves front and rear the adjustment of them makes no difference what is my problem? do I need to change the master cylinder bore?

this might just be the worst article I have ever read. caliper piston size effects line pressure? that is only the beginning. you guys really should take this down. it is only going to confuse people?

the article states master cylinder bore size affects pressure and is 100% accurate

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Similar Stories

Understanding the different types of shock absorbers—plus the 7 signs of worn or blown shocks, how to diagnose front suspension shakes, shimmies, or noises—and what parts will fix them, how alignment settings affect driving performance.

Calculator for PEDAL STROKE CHANGE

• A negative percentage indicates a decrease in stroke. • A positive percentage indicates an increase in stroke.

- A shorter stroke requires a higher pedal effort to generate the same hydraulic pressure. - A longer stroke will reduce the effort required to generate the same hydraulic pressure.

The numbers already entered are just examples and can be overwritten.

Stroke of brake pedal will change %

To predict pedal stroke before you install different master brake cylinders, do the following: » measure current stroke » compute predicted change » add calculated percentage to current stroke

This calculator calculates the change in brake fluid displacement after changing the Master Brake Cylinder(s).

Not all pedal travel is related to brake fluid displacement and therefore will not change with different master cylinders. Here are some examples: - Travel to pick up slack between the pedal, pivot point, push rod and master cylinder, etc. - Travel to make up for flex in the pedal assembly and fire wall.

Here are some actions that require pedal travel AND brake fluid displacement: - Closing the gap between pads and rotors. [a bigger than normal gap while driving, can be caused by worn wheel bearings or warped rotors] - Expansion of brake lines. [minimize the number of curves and replace rubber lines with SS braided lines to limit this] - Flex in calipers. [monoblock calipers usually are stiffer than halves bolted together] - Aligning sliding calipers on worn bushings or with tapered worn pads. [you can replace rubber bushings with brass ones to reduce these problems]

• For this Pedal Travel Calculator (that only calculates the difference in stroke between the "old" and "new" situation), it does not matter whether you are dealing with a tandem M/C or a dual M/C set-up.

• If you are working on a vehicle with one single M/C operating all four brakes (most cars of the 60's and older), than fill out either the "front" fields or the "rear" fields (leaving the other two empty).

How Car Brakes Work and How to Tell When They Go Bad

B rakes are your vehicle's most important safety system. Under normal conditions, a driver exerts about 70 pounds of force on the brake pedal (about the same amount of effort it takes to bite into a steak) to bring thousands of pounds of moving metal and plastic to a quick and controlled stop. A flawless brake system is absolutely crucial to driver, passenger and pedestrian safety.

Read on to learn how a modern automotive brake system works and some of the most common brake system problems .

What Are the Different Types of Car Brakes?

- All modern vehicles come with hydraulic brakes. Hydraulic brake systems pressurize and transfer brake fluid to the wheel brakes assemblies. The brake assemblies (disc or drum) use the pressurized fluid to apply the brake friction material that generates the friction needed for braking.

- Anti-lock brakes use wheel speed sensors, a computer control module and an electro-hydraulic actuator to prevent hydraulic brake systems from locking up during hard braking.

- Working in conjunction with hydraulic brakes, hybrid vehicles feature a regenerative braking system that uses the electric driveline to initially slow a car. The hydraulic brakes ultimately bring the vehicle to a stop.

- Parking brakes , independent of the hydraulic or regenerative braking system, are used to apply rear brake assemblies.

What Are the Main Parts of the Hydraulic Braking System?

Master cylinder.

When you press the brake pedal, the brake linkage (rod) pushes on the master cylinder's internal piston seals, pressurizing and forcing brake fluid into the brake lines, brake calipers and wheel cylinders. This causes the brake pads to press inward against the rotors and force the brake shoes to press outward against brake drums.

Power brake booster

Brake boosters assist drivers by multiplying the force they apply to the brake pedal. These boosters use engine vacuum, an electric pump (diesel engines produce little or no engine vacuum) or hydraulic pressure (usually the pressure of the power steering pump). This increases braking performance while decreasing pedal effort, making driving safer and more pleasurable.

Brake lines and hoses

Made of double-walled steel and multi-layer rubber and synthetic compounds, brake lines and hoses transfer pressurized fluid from the master cylinder to the brake wheel assemblies.

Disc brake assemblies

A disc brake assembly consists of a brake caliper, brake pads, disc rotor and mounting hardware.

Drum brake assemblies

A drum brake assembly consists of a backing plate, wheel cylinder, brake shoes/linings, hold-down and pull-back springs, brake drum and an automatic self-brake adjusting mechanism.

Brake switches

Modern brake systems include a brake warning lamp switch that tells the driver if the master cylinder is low on brake fluid, or there is a problem with the brake system. There is also a parking brake warning light that lets you know if the parking brake is engaged.

Parking brake

Applying the parking brake mechanically locks the rear brake assemblies to keep a car stationary when parked on a hill. It also helps stop a vehicle due to a hydraulic system failure.

A hybrid's hydraulic brakes includes all the same parts as a standard hydraulic brake system.

How Does the Braking System Work?

Hydraulic brake systems convert mechanical energy (the spinning wheels) into heat energy by transforming and amplifying the force exerted on the brake pedal. The brake pedal acts like a lever. Along with the brake booster, it greatly multiplies the force applied on the brake fluid in the master cylinder.

The master cylinder also increases brake fluid pressure, then sends pressurized brake fluid, via brake lines and hoses, to the brake calipers and wheel cylinders. The pressurized fluid acts on the caliper piston, squeezing the disc brake pads inward, clamping the pads against the brake rotors .

On drum brakes the wheel cylinders slide outward, forcing the brake shoes against the drum using a wedging, jamming action — similar to how a bicycle coaster brake works. The energy of the pads clamping against the rotors and brake shoes pushing against drums generates friction and heat. This heat-friction, along with friction generated between the tire and road surface, slows rotor and axle (and wheel) rotation and ultimately brings the car to a stop.

On a regenerative braking system, stepping off the accelerator or pushing on the brake pedal causes a hybrid car's electric drive motor to run backward. The drive motor spinning backward places a drag on the wheels and slowing the car, while also producing electricity that recharges a hybrid's high-voltage batteries. While regenerative braking provides practically all the initial stopping power, the hydraulic system engages during panic stops or hard stopping at high speeds.

Signs the Braking System Isn't Working Properly

Grinding (metal-to-metal), noisy brakes.

- Worn or damaged brake pads or shoes (possibly digging into and scoring the disc rotors or brake drums), or brake pad wear indicator rubbing against the rotor.

- Worn, rusted, missing or broken brake hardware, excess brake dust accumulation, rust build-up on rotors or drums, or a stone, rust or some other foreign object jammed between a rotor and pad.

Steering wheel or brake pedal vibrating when stopping

- Excess rotor "run-out" (thickness varies across the face of the rotor) or drums are "out-of-round," badly rusted rotors or drums, contaminated brake linings, cracked, damaged or glazed rotors or drums.

Spongy or fading brake pedal

- Low brake fluid, air trapped in the brake fluid or a leak in the hydraulic system.

Low brake, excess pedal travel

- Brake self-adjusting mechanism not working, low brake pads or shoe linings, misadjusted master cylinder push rod.

Pulling to one side when stopping

- Seized or leaking brake calipers or wheel cylinders, contaminated brake linings, faulty self-brake adjusting mechanism, build-up of excess brake dust or a front-end alignment out of adjustment.

Dragging brakes

- Weak, damaged or rusted brake hardware, seized brake calipers or wheel cylinders, collapsed brake hose, misadjusted parking brake cables or misadjusted master cylinder push rod.

Grabbing or locking brakes

- Sticking or binding brake hardware, failing or failed anti-lock wheel speed sensors, brake lining friction surfaces contaminated by grease or brake fluid or bad brake booster.

Excessive brake pedal effort

- Seized brake calipers or wheel cylinders, clogged or collapsed brake hoses, contaminated brake linings or defective master cylinder, or power brake booster vacuum, mechanical or electrical problems.

A regenerative braking system has a unique pedal feel but can exhibit all of these same symptoms.

Brakes are one of your car's most essential safety systems. Never dismiss a brake warning light or brake system problems. Disregarding brake issues can be dangerous and lead to much more expensive repairs. When it comes to your car's brakes, it's always better to be safe than sorry.

- Forum Listing

- Marketplace

- Advanced Search

- General Service and Repair

Brake pedal travel

- Add to quote

Have a 2011 Heritage The rear brake pedal has way to much travel , I know this is a problem but what is the fix for it.

Does your bike have ABS ?

no it don't have ABS

My 2011 Heritage has ABS Sent from my SM-G900V using Tapatalk

OK then I would try bleeding the rear brake at the caliper.

was thinking of that but don't know how air would get in unless fluid is low I don't see a leak Going to switch out the fluid when I try this I see it is needed every 2 years

Someone could have changed the brake light switch and gotten air in the system.

Plenty of material left on the rear pads? Is the caliper freed up and operating normally?

Check your pad thickness. It can be done on the bike with a flashlight and some contortion or mirror. I forgot the spec. HD uses for min. thickness, but it is about the thickness of a credit card! I replace mine way before that.

I don't know if you bought a used or new Bike or how many miles the Breaks have on them. Most people use the Rear Break to stop. Me I use the Front because it's a lot easier to replace the PADS in the Front. Anyway to much travel is the first sign you need to check the Brake Pads. Probably your a few miles away from hearing the Rotors grinding. First I would Pull those Pads off and check them. When Harley assembles the bikes they put the right amount of Fluid in the Reservoirs, as the Break Pads ware the Fluid level will go down in the Reservoir causing Travel. If you fill up the Reservoir and you need new brake pads, you will not be able to compress the Brake Caliper Hydrophilic Plunger. Also to accomplish that task use a big C Clamp. That's what I would do, Good Luck!

Ok I changed the fluid in the rear brakes and used a brake bleader pump on it. I have brakes I did notice when the pump was sucking out the old fluid that a single air bubble Had to be the problem How it got in there thow I have no clue. Thanks guys It a easy fix and now ill be changing the fluid out once a year The fluid was bad looked stringy I know I have never changed it in the 3 years I had the bike. Now should the front fluid be changed also It works fine but is old fluid also. Thanks again for the advice and tips

Yes do the front and avoid problems down the road.

Harley spec is to change fluid every 2 years. There's even a note about it related to the abs recall, that if brakes are not flushed every 2 years, the abs recall is basically voided (may have this wrong, so check the info for yourself). If you've owned the bike for 3 years, then change the front fluid and check pads while you're down there. From my 2014 service manual, min pad thickness is 16 thousandths. Eff that, that's way too thin! Sent from my SM-G950U using Tapatalk

- ?

- 98.7K members

Top Contributors this Month

- Forum Listing

- Marketplace

- Advanced Search

- 2016+ Mercedes-Benz Metris Tech Section

- Engine and Technical Discussion

Brakes, modulation and pedal free travel

- Add to quote

Overall I like my van, but one thing very hard to get used to is the brake pedal modulation. It isn't too bad once you actually get to braking, but there is a LOT of pedal travel before that happens. The other two cars I drive have very little travel before braking begins. Switching between them can almost be dangerous for the first couple of stops. Is there an adjustment for brake pedal free travel?

I’m curious about this too. This anomaly is confusing and uncomfortable, and not a good scenario for the tours we conduct. Hoping someone will have some clever tips to fix this.

madsry said: I’m curious about this too. This anomaly is confusing and uncomfortable, and not a good scenario for the tours we conduct. Hoping someone will have some clever tips to fix this. Click to expand...

Check this thread. https://www.metrisforum.com/threads/2020-126-cargo-van-with-spongy-brake-pedal.11204/post-128013

Yeah, not fading, not spongy, not sinking. Stops fine. Just a lot of free travel before something happens. You can get used to it if the van is all you drive, but it is different than other cars. Different even than other Mercedes cars. But seemed to be the same on the 2 vans I have driven.

My brakes seem really touchy when compared to my other vehicle a 4Runner. I also had to put red tape around the gear shifter on the Metris as if it started to rain, I would go it as it's where the wipers are on the 4runner. Overall, I like the van except for the sun visors, they are at an angle to the road when used?

I'm not a fan of the brake feel. I have posted about it in the past. I do find that regular brake fluid service is noticeable. More so than any vehicle I have owned.

Good tip. I've got a Service B coming up so I'll check the brake feel after the flush. No complaints presently. I think there's more than just good or bad brake feel going on here. My van is generally driven close to fully laden -- as designed, I presume. I find Metris has an extremely wide range of pedal sensitivity, as pointed out by @RocketVan above, and I like being able to modulate precisely. Like a big rig, in traffic I find that avoiding coming to a complete stop through good following distance and careful brake modulation gives me the smoothest, cheapest, and lowest wear and tear drive (both on me and the van). The problem is that this driving style requires a lot of discipline and concentration -- it's not intuitive to think three moves ahead while driving, and the Metris brakes are indeed very touchy, so that modulation requires a fair amount of skill. Out here in Cali, many drivers "drive it like they stole it," meaning what I consider to be fairly mindless rapid acceleration and very hard last minute braking. Smaller, sportier cars tolerate that driving style way more than our highly efficient vans -- efficient because they are designed to give a high load capacity with a small engine and relatively small overall volume. So I think Daimler made the choice to design braking around the maximum intended workload of Metris. Anyway, FWIW (which ain't much), I am at peace with Metris' brake feel, though I totally get the problems folks have related.

DDW said: It isn't too bad once you actually get to braking, but there is a LOT of pedal travel before that happens. Click to expand...

It is a personal preference thing, and also a training yourself thing. The problem with both of those is if you frequently drive another car with very different brake pedal characteristics, it is hard to retrain driving out of the driveway. And the Merc is definitely the outlier. Associated with this at least on my van: you can get the brake pressed just a little, enough so it lets you shift into neutral but not into reverse. This seems odd, should be the same switch, so maybe it is just that the pedal came up just enough as you hit the shift lever that it permitted it to go into neutral, then slightly more travel up and blocked going into reverse. Anyway the result of that is you are backing up now in neutral. You are also looking back or at the camera, not at the warning which appears on the small console display. If you are backing down a hill you are now somewhat out of control. This happens quite frequently in my van. All made possible by the little shift lever with no tactile feedback (which every other shift lever on the planet has) and the long brake pedal travel. This is not possible on any other car, if the brake interlock is active you can't move the lever and you know it instantly, even if looking in the mirrors or rear view camera. Also, there are distinct positions of the lever for fwd, neutral, and rev so it is non-modal. Mercedes needs to hire some good man-machine interface experts. I've gotten two SUV type loaners from them when they were dealing with warrantee issues on the van, and both were abysmal in this aspect. The high end one truly appalling. It isn't a German thing, both the Porsche I own and the VW van I owned are perfectly acceptable for the most part.

I think this is due to excessive kick back of the pads. Maybe excessive runout of the discs or bearings, but much more likely how the calipers were designed. With the van turned off, pressing the brake pedal by hand, it goes down nearly 3 inches on the first stroke. But on the second and subsequent strokes, half or less than that. Even if left until the next day, still the shorter stroke. The pads are getting kicked back by driving, so each new application has to recover that lost motion. I wonder if any of the aftermarket calipers fix this problem. It is a known problem with disc brakes. Way back on the Pontiac Fiero, the master cylinder had a two stage piston to address exactly this issue. The larger piston pushed fluid into the smaller one to lessen the initial stroke, then the smaller one applied the braking pressure.

- ?

- 40.1K posts

- 6.4K members

Top Contributors this Month

- Escape Manuals

Ford Escape: Brake System - General Information / Diagnosis and Testing - Brake System

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart(s)

Symptom Chart: Brake System

Symptom Chart: NVH

Pinpoint Tests

- Road test the vehicle. At highway speeds of 89-97 km/h (55-60 mph), apply the brake using a moderate to heavy pedal force.

NOTE: During normal operation, brake pedal is not connected to brake callipers, instead, it is connected to a pedal feel simulator inside the EBB thru brake fluid, the pedal feel simulator is a springing system which provides feedback to driver’s foot. Pedal pulsation will not be felt during ABS operation.

- Road test the vehicle and apply the brakes on a dry, firm surface, then apply the brakes on a wet, snowy or loose surface (such as gravel).

- Check the front suspension.

- Inspect the front brake discs. REFER to: Specifications (206-00 Brake System - General Information, Specifications). INSTALL new brake discs as necessary. REFER to: Brake Disc Machining (206-00 Brake System - General Information, General Procedures). REFER to: Brake Disc (206-03 Front Disc Brake, Removal and Installation).

- Road test the vehicle.

- Check the rear suspension.

- Verify that there are no damaged components, uneven tire wear.

- Check the suspension components.

- Check suspension alignment.

- Inspect the system for leaks. Bleed the brake system.

- Ignition ON.

- Using a diagnostic scan tool, perform the ABS self-test.

- REFER to: Specifications (206-00 Brake System - General Information, Specifications). .

- Install new front brake pads as necessary, REFER to: Brake Pads (206-03 Front Disc Brake, Removal and Installation).

- Install new rear brake pads as necessary, REFER to: Brake Pads (206-04 Rear Disc Brake, Removal and Installation).

- Inspect the brake calipers and guide pins.

- Inspect the brake flexible hoses during brake application.

- Inspect the brake pads.

- Inspect anti-rattle clips or springs for missing or damage.

- Inspect brake disc shield and bolts.

- Perform a road test and confirm the concern.

Specifications

General procedures - brake disc machining, other information:, ford escape 2020-2024 service manual: general procedures - supplemental restraint system (srs) repowering, ford escape 2020-2024 service manual: removal and installation - power transfer unit actuator motor.

- Manuals Home

- 4th Generation Ford Escape Owners Manual

- 4th Generation Ford Escape Service Manual

- Adjusting the Headlamps

- Electric Parking Brake

- Locating the Pre-Collision Assist Sensors

- New on site

- Most important about car

Fastening the Seatbelts

IMAGES

VIDEO

COMMENTS

3. Bleed the Brakes. Bleeding your brakes is an important step in brake pedal travel repair and other brake issues. Use a jelly jar half full of brake fluid and a short hose to depress your brake pedal. While depressing the pedal, rotate the star wheel to lose up the clearance. Then, go back one click when the wheel scrapes.

I understand that there should be a little bit of travel in the pedal so that the pressure is off the master cylinder when at rest. But how much?

Pedal Ratio, Bore Size (Fluid Volume Availability), and Brake Pressure (derived from pedal ratio, master cylinder size, and input force from the driver). Below are calculators to help you plan a proper brake setup. ... Calculate Master Cylinder and Pedal Travel *Note: for reference a larger master diameter results in a harder feeling pedal with ...

A 4:1 pedal ratio. Equals 280 lbs. of force applied to the master cylinder pushrod. For power brake systems, the Brake Booster increases the force even more. This makes stopping easier and driving more enjoyable. Also, take note of the pedal travel: A 4:1 pedal ratio. A master cylinder with a 1.10 in. stroke. The pedal needs to travel 4.40 in.

A: On average, brake pedal ratio should range from 5.1:1 to 7.1:1. To calculate your ratio, measure the distance from the pivot point of the pedal to the center of the pedal pad (measurement A), and then the distance between the pivot point and the master cylinder pushrod hole (measurement B). Next, divide measurement A by measurement B.

1. The brake pedal should have an adjustable return stop on it when a strong pedal return spring is used. This prevents the master cylinder from excessively banging the snap ring stop inside the master cylinder bore (visible under the rubber boot). Adjust the stop so the pedal stops returning at the point when the master cylinder piston ...

Note that the brake pressure —and the consequent vehicle deceleration— that is achieved, for a similar force level, has been slightly diminished because of the reduced pedal ratio. But most importantly, the pedal is significantly shortened: the initial dead stroke is attenuated and the stiffness (travel / deceleration ratio), enhanced.

3. First of all, if you worried about brakes have a proffesional check them out. That said, I've had the same problem after replacing pads before. Jumped in the car and pressed the pedal down hard, thinking I was simulating a hard braking situation. I was convinced that the pedal didn't normally do that, but the reality is that in a normal ...

So, if your car needs some help in the stopping power department, or if there's a need to reduce the pedal effort, you have a few options: A) decrease the master cylinder bore size; B) increase the pedal ratio; or C) increase the wheel cylinder bore size. If the pedal ratio is increased, there will be more travel at the master cylinder piston.

Sep 30, 2022 at 14:43. With four disc brakes, calipers and pads have very little piston travel by relying on the piston seals to retract pads slightly with slight drag on rotors. This translates to less brake pedal travel after finalizing brake flush/bleeding procedures. The calipers, pistons, piston seals, rotors and pads must be clean and ...

To predict pedal stroke before you install different master brake cylinders, do the following: » measure current stroke » compute predicted change » add calculated percentage to current stroke. This calculator calculates the change in brake fluid displacement after changing the Master Brake Cylinder (s). Not all pedal travel is related to ...

BMW 3-Series (E90 E92) Forum > E90 / E92 / E93 3-series Technical Forums > Suspension | Brakes | Chassis > Brake Pedal Travel Distance Thread Tools: Search this Thread 05-15-2014, 11:06 AM ... Mine goes about 1/2 inch lower than the gas pedal when depressed. Is this acceptable? Appreciate 0 Quote Bookmarks: twitter; Facebook; Digg; Google ...

When you press the brake pedal, the brake linkage (rod) pushes on the master cylinder's internal piston seals, pressurizing and forcing brake fluid into the brake lines, brake calipers. and wheel ...

Pedal travel is influenced by the ratio between the brake master diameter and the brake piston diameters: go bigger (or more) on the brake pistons and travel will increase but you will have more brake control aswell. So I have a few options then and would like your opinion. 1: deal with it as is.

What is Acceptable for Brake Pedal Travel? Thread starter Scooter_NE; Start date Sep 17, 2019; Tags brakes Scooter_NE New Member. Joined Sep 17, 2019 Messages 1 Location Maine. Sep 17, 2019 ... just to see if that makes a difference with the brake pedal travel. Reply. Goatman TJ Expert. Supporting Member. Joined Apr 23, 2019 Messages 5,041 ...

The size of the brake chamber determines maximum allowable push-rod travel. See chart to know if your air brakes are in adjustment. The size of the brake chamber determines maximum allowable push-rod travel. ... truck, or truck and trailer brakes. In other words, the brake pedal brings the vehicle to a stop when it it depressed. SHOULD KNOW The ...

Acceptable Pedal travel is 6" with all 4 disk brakes. Reference is in the 'Service Manuals, the Brake section 5, pages 5-32 and 5-33. Link to manuals (large .pdf files): Workhorse Technical Info You may have a 2003 P32 chassis under your 2004 motorhome. There is a VIN decode chart in the manual. These beasts don't stop nearly as well as a car ...

Brake pedal travel. Jump to Latest Follow 5K views 12 replies 8 participants last post by azglocker Sep 16, 2018. REDWON11 Discussion starter 4 posts · Joined 2018 Add to quote; Only show this user #1 · Sep 11, 2018. Have a 2011 Heritage The rear brake pedal has way to much travel , I know this is a problem but what is the fix for it. ...

where the pushrod exits the brake chamber or the chamber mounting bracket. Note where the pushrod mark started and where it ends up, then measure the difference in the next step. See Figure 1. Step Three - Have the other person press and hold the service brakes (pushing the brake pedal all the way down until it stops) while

Brake Pedal Travel. Hello Everyone.. Need some input on my recent problem.. My brake pedal travel too far or at least I think so. It travels about a 1" before it make contact. If you pump the brake once or twice it brings the pedal up. Should add that pedal is spongy also, it's not firm at all.

164 posts · Joined 2023. #1 ·Apr 11, 2024. Overall I like my van, but one thing very hard to get used to is the brake pedal modulation. It isn't too bad once you actually get to braking, but there is a LOT of pedal travel before that happens. The other two cars I drive have very little travel before braking begins.

Excessive brake pedal travel (low/spongy pedal) GO to Pinpoint Test E Erratic brake pedal travel GO to Pinpoint Test F Brake drag GO to Pinpoint Test G ... Some squealing noise from the brake system is acceptable under certain conditions such as cold start or low speed brake application. Under all other general driving conditions, the vehicle ...

There are times when a brake pedal can have a longer travel whenever you change your brake pads because the brake pedal is still adjusting. However, there are times when the issue can be due to having excessive air in the brake lines. If that is the case, you should bleed the brakes to remove the excess air.

There is an intermittent problem with excessive brake pedal travel. Most of the time, the brake pedal is fine. It isn't super firm, but it's acceptable. However, sometimes the brake pedal has excessive travel. When this occurs, the brakes will not engage until the pedal is nearly to the floor! The intermittent nature of this problem is what ...

The force feedback controller is substantially similar to the hybrid controller with the commanded brake pedal position omitted, leaving only the commanded brake pedal force application. ... of one vehicle striking a vehicle ahead in the same travel lane. In a ... speeds while permitting contact at higher speed if acceptable speed reductions ...