What is Overspeed Trip, its types and how it works

- · Sudden removal engine load such as propeller coming out of water in rough weather, failure of clutch, fracture in a drive shaft of engine.

- · Stuck fuel control shaft.

Types of Overspeed Trips

Mechanical type overspeed trip.

Electro Pneumatic Overspeed Trip

Electronic Type Overspeed Trip

So this was all about the over speed trip that are used in the engines. If you want to add more info in to this topic ‘overspeed trips’, please feel free to comment below.

Related Articles

United States Coast Guard Cutter

If you are interested in learning more about the United States Coast Guard (USCG) and its fleet of vessels, you might have come across the term “cutter”. But what exactly is a cutter and what makes it different from other types of ships? In this blog post, we will answer these questions and provide some […]

Diesel Generator Alarms and Trips

Diesel Generator Alarms and Trips have been discussed in this article, which are common among all the generators. We will take some of the major alarms and trips. Also we will give reasons for such alarms occurring and troubleshooting to be done. Following alarms we will mention HT Water Temperature High High Low Lube Oil […]

How Can Women or Girls Join Merchant Navy

This article deals in the information as how can Girls Join Merchant navy, which covers most of the doubts and questions they have in their mind. So, let’s read it. A sector which is dominated by the men, giving a thought to join it as a woman, surely a tough and much of a thought giving […]

5 Replies to “ What is Overspeed Trip, its types and how it works ”

Hello, so the difference between the mechanical type overspeed trip and the electronical type overspeed trip is not the way that the turbine trips but taccuracy of speed sensing? in both systems the trip is achieved with the bolt ejecting out?

HI there all of the topics here are very important to us, how much it cost to subscribe or to buy a book from you.? GOD BLESS hope to hear from you soon.

- Pingback: Critical alarms and safety trips Critical alarms safety trips provided Safety

Hi everyone Please tell me how to do the main engine fuel pump plunger stuck during main engine operation in rough sea so can not stop ME Thanks in advance.

I think this is one of the most significant information for me. And i’m glad reading your article. But should remark on some general things, The web site style is perfect, the articles is really great : D. Good job, cheers

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Understanding Overspeed Trips

- Categories : Marine machinery, engines & controls

- Tags : Marine engineering

Introduction

The main aim of any diesel engine governor is to keep the speed of the engine within reasonable limits without getting affected by the changing load on the engine. In case the governor is not able to keep the speed of the engine within specific limits, the engine might speed up to such a level that it can damage the engine itself. In engines wherein the governor does not fail safe, over speed trips are used.

Overspeed Trip

The main function of an over speed trip is to cut the fuel supply to the cylinders in case the engine speed rises above the pre-set level. Generally fitted on steam turbo alternators or generators, over speed trip prevents the engine from getting damaged because of extremely high speeds.

How Does An Over Speed Trip Work?

The design of an over speed trip consists of a heavy bolt with a comparatively heavy head. The bolt is fitted at the forward end of the engine shaft where no engine torque is transmitted and is bored throughout the diameter of the shaft. Just like any other conventional bolt, the over speed trip bolt is held in place by using a nut and a spring.

At normal speeds, the bolt stays at the same position; however if the speed of the engine rises beyond the pre-set range, the centrifugal force generated by the heavy head of the bolt makes it fly out of the spring and nut’s compression pressure. The bolt eventually comes out of the bore, getting rid of the spring and washers.

Moreover, the arrangement is made in such a manner that the bolt head that comes out of the bore hits a trip lever which shuts the supply of fuel to the engine cylinders, eventually stopping the engine. The mechanism for stopping the fuel supply varies according to the type of the ship and engine. For e.g. in motor ships having steam turbo alternator, the over speed trip is controlled with the lubricating oil low pressure cut-out and the steam stop valve; whereas in few other ships the over speed trip is controlled using a system of levers and linkages that are connected by the turbine steam stop valve.

The steam stop valves actually controls the supply of fuel going to the cylinders. When the over speed trip operates, the pin holding the steam stop valve in the open position is released, closing the valve and stopping the flow of both, the steam and the fuel. The set speed for operating the over speed trip can be adjusted by adding washers below the spring and then adjusting their compression pressure.

Apart from over speed trips, permanent magnet alternators from engine camshafts along with rectifiers can also be used to prevent engine from racing at high speeds. However, this technique can only be used for electronic governors. As the speed of the engine crosses the pre-set speed, the voltage automatically increases, making the governor to reduce the fuel supply to the engine cylinder and lowering its speed.

Lambs Question and Answers - Stanley G. Christensen

Over Speed Trip in Diesel Engines & Types of Over Speed Trips

An over speed trip is a safety feature provided on the diesel engine of the ship to restrict uncontrolled acceleration of the engine, leading to mechanical failure or untoward accidents. In order to prevent the speed of a diesel engine to go beyond the pre-set speed range, an over speed trip is used in the diesel engines.

How Over Speeding can be Harmful?

A Diesel engine is designed for the mechanical stress associated with the centripetal and centrifugal forces of the moving parts inside it in a specified operational range. Centripetal force is directly proportional to the square of the rotational speed, stress increases rapidly with increase in speed. Mechanical connection strength can be overcome by the exceeding stresses due to the increase in operational speed. These can result in breaking of rotating parts or damage to the machinery itself. Over speed is thus a serious safety hazard and can lead to a fatal situation.

What does Over Speed Trip Does?

Due to sudden changes in the load on the diesel engine, the speed of the engine may vary. Though a governor is provided to control the speed of the diesel engine, the speed might go out of control, damaging the engine. Thus, for this reason over speed trips are used.

No matter what type of the over speed trip the engine uses, the main aim of the over speed trip is to cut the fuel supply to the engine cylinders in case the engine speed rises above a specific level.

Preventing Over Speeding of Engine

Reducing the likelihood of an uncontrolled and catastrophic over speed is essential and can be done by two methods:

a) Mechanical over speed trip

b) Electronic over speed trip

In this article we will have a look at the electronic over speed trip.

Electronic Over Speed Trip

To understand the electronic over speed trip, a normal lay out of the system is described below. The electronic over speed trip consists of

a) Fly wheel mounted speed sensor

Magnetic speed sensor is preferred in generator engines. Due to the discontinuity of actuator surface (gear tooth of flywheel) voltage is excited in the pick off coil of sensor, producing an electric analog wave. This cyclic wave created by the flywheel is read by the sensor.

b) Signal condition unit

This unit act as a receiver to the speed sensor. Basic function of the signal conditioner is to convert one type of electronic signal which may be difficult to read into another type into a more easily read format. This can be achieved by amplification, excitation and linearization of an electrical signal.

c) Detection and Comparison unit

There is a set value which is normally 10 % above the rated speed and acts as base value for this unit. Signal condition unit output is continuously detected and compared with the set value.

d) Trip signal unit

If the difference between the set value and detected value is above the limit, then this unit gives a trip signal which in turn shuts down the generator.

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

24 Comments

can you send to me mechanical over speed tripper journals and drawbacks…

hello sir, i want to know , how main engine overspeed trip is tested & what is the time duration of testing

Dear Pundari,

It is better to test the functioning of the over speed trip rather testing it at its real set speed. The set point is lowered then the required speed. once the generator reaches this lowered set point, it will trip. To run the generator in the actual overspeed condition is dangerous and long run in such speed can lead to problem in the bottom end bolts of the con rod.

anish, good day sir. im working in a ship, our aux generator is running but its not getting a load. the generator is running fast in 5sec then it will go slowly, what is the problem of this. tnx

The problem seems to be with governor of the AE. Check the droop setting of the same.

With thanks for all above information , kindly note recently we faced with aux engine over speed on one o our fleet vessel an led to total failure , explosion and fire in engine room.

Same aux engine was repaired/overhauled just 20 days back of accident in repair yards. Over speed trip were not activated and cause explosion.

Kindly advise possible factors which to be consider for such big accident.

With many thanks in advance.

i am working on CAT engine its many time show over speed alarm i change relay but the problem still there let me know what is the main problem and i can diagnose i

THIS SIGHT IS GIVING VERY VALUABLE INFORMATION

Its good to finally find a site like this. THUMBS UP!!!

Please assist me with this issue, my 5 cylinder Sulzer Harbor Generator is starting, only to be tripped by the over speed device when attempting to attain its rated RPM of 760. I suggested that the UG 8 governor might be faulty. Please what seems to b the problem?

rly a good rply by this site

How i can test overspeed alarm in generator vatepillar c-18. Answer please.

Please can you kindly help me, there is a cummins gen, and it has been tripping on over speed. Please can you kindly assist/give me a better idear to sort out this problem..

Please Sir, I need possible remedy or solutions to overspeed shutdown of Cummins power generator.What are the curses of that over speed?

Reasons have already been listed in the article. Overspeeding of engine is not healthy for rotational part of the engine (bearing housing bolts, crankshaft and its bolts etc.)

A nice site, I’m working on CT6 with overspeed issue… Have adjusted the Woodward the problem still persist, what really the possible causes?

We have created online forums for such technical discussions. Please visit: https://forums.marineinsight.com

You can contact any time related with all type of Woodward governing system and caterpillar engines related Quires, My contact Number is +91 9987396573

Good day Please is it possible test over speed from PLC

@Alan: in Many engine circuit, a test knob is provided. You can use that to test the overspeed trip.

How to reset mechanical overspeed trip

8 DK28 daihatsu generator engine .how to try out overspeed trip.i have a sensor in in flywheel so it may be a electronic type .how to carry outtests can somebody help sharing information?

@Benasher: Usually, the value of the speed sensor controller is reduced so that as the generator starts and reeatrip will operatoe ched the speed, the

Please comment on what to check in alternator…..

@Ankit: Please check this article- https://www.marineinsight.com/tech/generator/important-points-while-carrying-out-alternator-maintenance-of-ships-generator/

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

- Site Search Search Posts Find A Forum Thread Number Threads by Name Search FAQs

- ENGINEERING.com

- Eng-Tips Forums

- Tek-Tips Forums

Join Eng-Tips ® Today!

Join your peers on the Internet's largest technical engineering professional community. It's easy to join and it's free.

Here's Why Members Love Eng-Tips Forums:

- Notification Of Responses To Questions

- Favorite Forums One Click Access

- Keyword Search Of All Posts, And More...

Register now while it's still free!

Already a member? Close this window and log in.

Join Us Close

- Search Search

- Overspeed protection

- SpeedSys 200

- Istec SpeedSys 300

- SpeedSys T10

- SpeedSys T20

- SpeedSys T30

- Local partners

Mechanical overspeed protection or electronic overspeed protection?

10 April 2020 | Theme: Machine protection

In the past, overspeed turbine protection systems were often designed by the turbine OEMs themselves as part of the mechanical system. These mechanical protection systems are still in use, especially on medium-sized machines. However, electronic systems offer significant benefits and are becoming increasingly accessible, in both their economical and technical impact. This article explains the benefits of electronic protection over mechanical protection.

The principle of mechanical overspeed protection

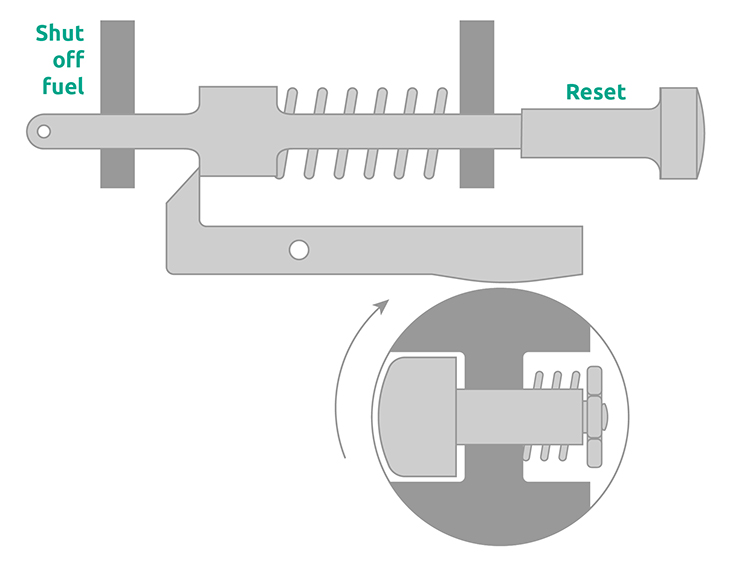

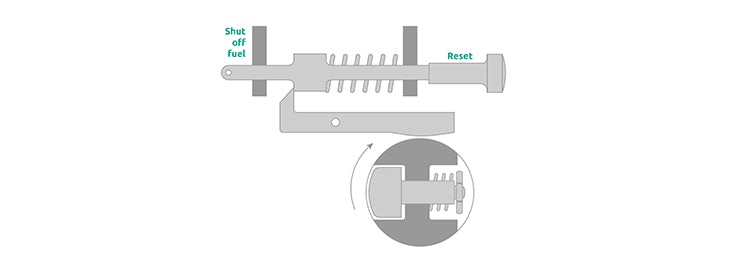

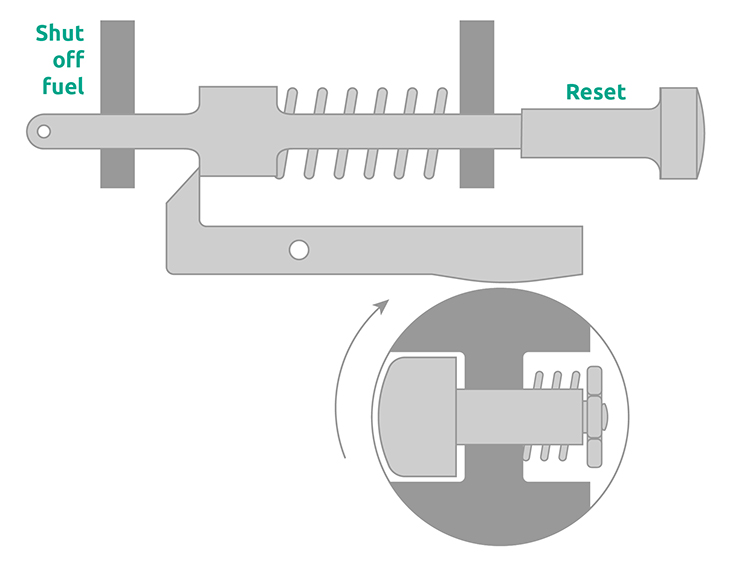

To understand the difference between the two types of protection, it is important to understand how mechanical overspeed protection works. Mechanical overspeed protection systems use a weight on a spring of which the spring force is known. Due to the centrifugal force as a result of the shaft rotation speed, the spring is stretched further and further and the weight moves out. As long as the rotational speed is still within the design specifications, the spring will not stretch too far and the weight will not protrude. However, if it exceeds its design specifications, the weight will run out and hit the trip bolt. This will release the pin and the trip will be activated.

The operation of a mechanical overspeed protection system.

The principle of electronic overspeed protection

Electronic overspeed protection consists of a gear or other measuring surface, speed sensors and a measuring system with trip logic and relay outputs. The speed sensors look at the measuring surface and give a sine or square wave signal, which the measuring system sees as pulses. The measuring system then counts the time between pulses to determine the rotation speed. The relay outputs are controlled by trip logic. In order to increase safety and availability, these protection systems are often built with redundant voting structures.

Why switch to electronic overspeed protection?

Switching from mechanical overspeed protection to electronic overspeed protection has significant advantages. Verifiable security is the primary argument. To illustrate: where mechanical overspeed protection systems have to be tested by actually overspeeding the machine (with all the risks involved!), an electronic overspeed protection system can be tested by simulating overspeed. In addition, a simulated test is quicker and easier to perform.

In this overview we compare both forms of machine overspeed protection:

Switching to electronic overspeed protection is not complex. Firstly, the mechanical trip lever and all associated system components are removed. Secondly, a measuring surface (gear) is mounted on the shaft if this is not already available, after which one or more sensors are placed around this measuring surface. The protection system can then be placed near the machine or in a cabinet.

Learn more about overspeed:

What does the API Standard 670 state about overspeed detection systems? »

The SpeedSys is a SIL-rated overspeed protection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint and low-impact installation enables advanced protection to a wide range of applications. SpeedSys is available in two versions. SpeedSys 200; for less demanding SIL 2 applications and SpeedSys 300 for demanding and critical SIL 3 applications.

SpeedSys 200 »

SpeedSys 300 »

What does the API Standard 670 state about overspeed detection systems?

5 speed-related failures with rotating machinery, sensors for speed measurements, knowledge & cases.

Learn more about speed measurements and overspeed protection on our blog.

18 November 2021 | Theme: Machine protection

Rotating machinery such as turbines, pumps and compressors are continuously subjected to major mechanical forces. As most of these machines are critical to the process, systems are implemented with protection…

The difference between SIL certification by design and proven in use

15 September 2021 | Theme: Machine protection

End-users that operate (critical) rotating machinery have a legal obligation to implement a suitable and verifiable safety instrumented system (SIS). Safety Integrity Level (SIL, IEC 61508), one of the more…

FT3000 announced obsolete by OEM, replaced by SpeedSys

18 October 2020 | Theme: Machine protection

The FT3000 overspeed protection system, formerly supplied by the Jaquet Technology Group (now: TE Connectivity), has been discontinued by the manufacturer. Its obsolescence affects many end-users as the Jaquet FT3000…

Istec International © 2024. All rights reserved

Istec International uses cookies. By clicking 'Accept cookies' or by using this website you confirm agreeing to this. Learn more about the used cookie.

Free bookazine Speed

Our bookazine Speed contains interesting and informative articles about speed measurements and overspeed protection on rotating machinery.

- Search Search

- Protection systems

- Monitoring systems / software

- Sensors & transmitters

- Engineering solutions

- Troubleshooting

- Turnaround service

- Machine safety consultancy

- Rotating equipment

- Wind turbines

- Speed protection systems

- Speed monitoring systems

- Speed sensors

- Manufacturer (OEM) solutions

- Book Vibration

- E-book: Wind Turbine Optimization

- Vibration Training (CAT1+)

- Speed sensors: Hall-effect

- Speed sensors: Eddy current

- Speed sensors: Variable reluctance

- About Istec

Mechanical overspeed protection or electronic overspeed protection?

10 April 2020 Theme: Machine protection

In the past, overspeed turbine protection systems were often designed by the turbine OEMs themselves as part of the mechanical system. These mechanical protection systems are still in use, especially on medium-sized machines. However, electronic systems offer significant benefits and are becoming increasingly accessible, in both their economical and technical impact. This article explains the benefits of electronic protection over mechanical protection.

The principle of mechanical overspeed protection

To understand the difference between the two types of protection, it is important to understand how mechanical overspeed protection works. Mechanical overspeed protection systems use a weight on a spring of which the spring force is known. Due to the centrifugal force as a result of the shaft rotation speed, the spring is stretched further and further and the weight moves out. As long as the rotational speed is still within the design specifications, the spring will not stretch too far and the weight will not protrude. However, if it exceeds its design specifications, the weight will run out and hit the trip bolt. This will release the pin and the trip will be activated.

The operation of a mechanical overspeed monitoring system.

The principle of electronic overspeed protection

Electronic overspeed protection consists of a gear or other measuring surface, speed sensors and a measuring system with trip logic and relay outputs. The speed sensors look at the measuring surface and give a sine or square wave signal, which the measuring system sees as pulses. The measuring system then counts the time between pulses to determine the rotation speed. The relay outputs are controlled by trip logic. In order to increase safety and availability, these protection systems are often built with redundant voting structures.

Why switch to electronic overspeed protection?

Switching from mechanical overspeed protection to electronic overspeed protection has significant advantages. Verifiable security is the primary argument. To illustrate: where mechanical overspeed protection systems have to be tested by actually overspeeding the machine (with all the risks involved!), an electronic overspeed protection system can be tested by simulating overspeed. In addition, a simulated test is quicker and easier to perform.

In this overview we compare both forms of machine overspeed protection:

Switching to electronic overspeed protection is not complex. Firstly, the mechanical trip lever and all associated system components are removed. Secondly, a measuring surface (gear) is mounted on the shaft if this is not already available, after which one or more sensors are placed around this measuring surface. The monitoring system can then be placed near the machine or in a cabinet.

Learn more about overspeed:

What does the API Standard 670 state about overspeed detection systems? »

SpeedSys 300 – Overspeed Protection System

The SpeedSys 300 is a SIL 3 rated electronic overspeed protection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint enables low-impact retrofitting and extends the range of machinery which can be protected.

Learn more about SpeedSys 300 »

What does the API Standard 670 state about overspeed detection systems?

5 speed-related failures with rotating machinery, sensors for speed measurements, learn more:.

12 July 2022 Theme: Machine protection

The API Standard 670 is an industry standard and describes the minimum requirements for a machine protection system (MPS). This includes, measuring radial shaft vibration, casing vibration, axial shaft position,…

22 November 2019 Theme: Machine protection

Rotating machinery such as turbines, pumps and compressors are continuously subjected to major mechanical forces. As most of these machines are critical to the process, systems are implemented with protection…

10 October 2019 Theme: Machine protection

Choosing the right speed sensor for an application is of crucial importance for an accurate and reliable measurement. After all, the signal of the sensor is the input for an…

Istec International © 2024. Alle rechten voorbehouden

Istec International uses cookies. By clicking 'Accept cookies' or by using this website you confirm agreeing to this. Learn more about the used cookie.

OR WAIT null SECS

- Do Not Sell My Personal Information

- Privacy Policy

© 2024 MJH Life Sciences ™ and Turbomachinery Magazine . All rights reserved.

How steam turbine protection system works

The function of the steam turbine protection system is often confused with the control system, but in fact the two systems are entirely separate. The protection system operates only when any of the control system set point parameters are exceeded, and the steam turbine will be damaged if it continues to operate.

A multi-valve, multi-stage turbine protection system incorporates a mechanical overspeed device (trip pin) to shut down the turbine on overspeed (10 percent above maximum continuous speed).

The protection system monitors steam turbine total train parameters and ensures safety and reliability by the following action:

Start-up (optional) provides a safe, reliable fully automatic start-up and will shut down the turbine on any abnormality

Manual shutdown

Trip valve exerciser allows trip valve stem movement to be confirmed during operation without shutdown

Rotor overspeed monitors turbine rotor speed and will shutdown turbine when maximum allowable speed (trip speed) is attained

Excessive process variable signal monitors all train process variables and will shutdown turbine when maximum value is exceeded

Centrifugal force resulting from high shaft speed will force the trip lever, which will allow the spring loaded handle to move inward. When this occurs, the port in the handle stem will allow the control oil pressure to drain and drop to zero. The high energy spring in the trip and throttle valve, normally opposed by the control oil pressure will close suddenly (less than one second). In this system there are two other means of tripping the turbine (reducing control oil pressure to zero) – manually pushing spring loaded handle and solenoid valve opening.

The solenoid valve will open on command when any trip parameter set point is exceeded. Solenoid valves are designed to be normally energized to close. In recent years, the industry has required parallel and series arrangements of solenoid valves to ensure increased steam turbine train reliability. Today, most speed trip systems incorporate magnetic speed input signals and two out of three voting for increased reliability. The devices that trip the turbine internally directly reduce the control oil pressure, causing a trip valve closure without the need of a solenoid valve (external trip method).

Two popular types of steam turbine shut off valves are available and both use a high spring force, opposed by control oil pressure during normal operation, to close the valve rapidly on loss of control oil pressure.

It is important to note that the trip valve will only close if the spring has sufficient force to overcome valve stem friction. Steam system solid build up, which increases with system pressure (when steam systems are not properly maintained), can prevent the trip valve from closing.

To ensure that the trip valve stem is free to move, all trip valves should be manually exercised on-line. The recommended frequency is once per month for High Pressure (40 bar) steam systems and daily for very high pressure (1000 bar +) steam systems. All the turbine trip valves should be provided with manual exercisers to allow this feature.

It can be hard to maintain VHP (very high pressure) steam systems, and to prevent contaminants (calcium, silica) from forming inside the turbine. Trip valve packing is essentially a filter that will trap any contaminants between the trip valve and the packing which can prevent the trip valve from closing.

Failure of the trip valve to close on command can cause catastrophic machine failure and expose personnel to safety issues. Periodic or infrequent exercise of trip valves can result in failure of the valve to move which, considering the plant safety requirements, will necessitate immediate turbine shutdown. Daily exercise of VHP trip valves will ensure freedom of movement of the trip valve and positively prevent unnecessary unit shutdowns.

This best practice has been recommended since the 1990s. When followed, it has resulted in zero lost time accidents and failure to trip incidents. When not followed, more than one catastrophic machine outage in critical (un-spared) machinery has occurred, that has exceeded three months in repair time.

Related Content:

Peoria Veterans honor 49th anniversary end of Vietnam War with trip to Washington

WASHINGTON (Gray DC) - 75 service members, and one service dog made the trek to Washington Tuesday.

Among them, Vietnam war veteran Jerry Wright.

“I was a draftee for two years, and I was not a supporter of the war,” said Wright.

He says his time abroad was a complicated one.

“I wouldn’t trade it for anything, but I wouldn’t want to do it again.”

For Vietnam Veteran Carl Lehman, it’s the first time he’s seen the memorials, and it’s bittersweet.

“I cannot stand the Vietnam War wall because I break down too bad, because I lost a few friends over there. And it’s kind of hard because I told them that I would take care of them,” said Lehman.

He says the war didn’t end when he came home. He’s carried the weight of war for almost 50 years.

Copyright 2024 Gray DC. All rights reserved.

2 arrested in high-speed motorcycle chase

Man arrested after shooting at cats in his yard

Gov. Justice declares State of Emergency due to FAFSA issues, delays

Man charged after repeatedly admitting to setting his trailer on fire

Lawsuit filed over middle school students refusing to compete against trans athlete in shotput contest

Latest news.

Ford recalls Maverick pickups because tail lights can go dark

Brothers say they lost everything but their dog after alleged act of arson set their home on fire

Dueling protesters clash at UCLA after police clear pro-Palestinian demonstration at Columbia

Arrests as campus protests erupt across country

Paul Auster, prolific and experimental man of letters and filmmaker, dies at 77

IMAGES

VIDEO

COMMENTS

An overspeed trip is required to ensure that fuel supply will be cut off from engine if its speed exceeds the predetermined value. Over speeding will result if there is. · Sudden removal engine load such as propeller coming out of water in rough weather, failure of clutch, fracture in a drive shaft of engine. · Stuck fuel control shaft.

Overspeed Trip. The main function of an over speed trip is to cut the fuel supply to the cylinders in case the engine speed rises above the pre-set level. Generally fitted on steam turbo alternators or generators, over speed trip prevents the engine from getting damaged because of extremely high speeds.

The overspeed governor is implemented on most marine diesel engines. The governor is a safety measure that acts when the engine is approaching overspeed and will trip the engine off if the regulator governor fails. It trips off the engine by cutting off fuel injection by having the centrifugal force act on levers linked to the governor collar.

An over speed trip is a safety feature provided on the diesel engine of the ship to restrict uncontrolled acceleration of the engine, leading to mechanical failure or untoward accidents. In order to prevent the speed of a diesel engine to go beyond the pre-set speed range, an over speed trip is used in the diesel engines.

Section 1.1 of API 616 does allow a vendor to offer alternative designs. Therefore, an overspeed trip setting higher than 5% may be acceptable. However, please be certain that the turbine is designed for an appropriate maximum speed. For example, a turbine with an overspeed trip setting of 110% may need to be designed for a maximum speed of 120%.

Overspeed range and an Emergency Overspeed trip occurs. Assuming the emergency trip system works as designed, it will prevent the turbine rotor from exceeding 120% (typical) of rated speed - which is the maximum design limit for most large utility turbines.

One is an electro-pneumatic type, featuring a trip setting for 15% above nominal speed. The other device, meanwhile, is a mechanical type that has a trip setting for 18% above nominal speed. Mechanical overspeed trip devices are fairly simplistic, often featuring a weighted spring loaded bolt that is set into the engine's rotating shaft.

In one case a boiler feedpump turbine (BFPT) was tested at less than full overspeed trip for years. The setpoint was dialed down for the test and then reset. A safety audit required a full speed test. At 8000 rpm the unit did not trip and an emergency trip was selected. Next year the trip failed again. The third year the controls group got ...

This video reviews an overspeed trip mechanism, how it works and illustrates what a trip looks like when it's triggered in a frame 5 accessory gearbox.This v...

Helooo friends in this video we explain what is overspeed protections of steam turbine & how many overspeed trip device used in turbine.Also explain mechanic...

#TurboMachinaery #OverSperdTripHello! fellow turbomachinery professionals and students in the technical field, If you are lovers of mechatronics, automation,...

Mechanical / hydraulic overspeed protection can fail during an overspeed test. These systems have failure modes which can only be tested when performing an actual over speed trip. When the system is stuck due to varnish or dirt the overspeed detection system will not shut down the machinery when required. I additional the back-up system.

The RAYAN-P10 Overspeed Protective Equipment is a product developed by HANI Energy Co. It is intended to be. used for rotating machines Overspeed protection. Overspeed Protection Device reads the frequency of input sensors by 3 independent Monitoring modules and trip two 2oo3. voters if at least two sensors detect over frequency (Electronic ...

Electronic overspeed trip protection consists of a 2 out of 3 voting configuration, where two of the speed probes need to sense an overspeed condition to trip the turbine. One out of 2 electronic overspeed protection systems are not recommended as per API 670 but are accepted by other international standards, and therefore, we believe, are widely

ELECTRONIC TRIP SYSTEM API recommends two speed sensors where: • "A" or "B" trip signal is seen, then the turbine trips. • "A" or "B" loss of signal or power, an alarm is given but the turbine remains running. • "A" and "B" loss of signal or power, the turbine trips. Figure 1 is the simplest system that can be used for a "special

This will release the pin and the trip will be activated. The operation of a mechanical overspeed protection system. The principle of electronic overspeed protection. Electronic overspeed protection consists of a gear or other measuring surface, speed sensors and a measuring system with trip logic and relay outputs.

6 Overspeed Trip Testing 101 6.1 Overspeed Trip Pre-test Checks 104 6.2 Uncoupled Overspeed Trip Test Procedure 106 6.3 Acceptance Criteria for Overspeed Trip Test 110 Questions 113 Answers 114 7 Centrifugal Pump and Centrifugal Compressor Start-ups with a Steam Turbine Driver 115 7.1 Centrifugal Pump and Steam Turbine Start-up 117

Risk exposures associated with a mechanical overspeed trip device: • The mechanical device has many moving parts that can malfunction. In some cases mechanical trip devices have failed to initiate a trip, resulting in an overspeed failure. • The mechanical trip device is not precise and trip initiation speed can vary.

This will release the pin and the trip will be activated. The operation of a mechanical overspeed monitoring system. The principle of electronic overspeed protection. Electronic overspeed protection consists of a gear or other measuring surface, speed sensors and a measuring system with trip logic and relay outputs.

A multi-valve, multi-stage turbine protection system incorporates a mechanical overspeed device (trip pin) to shut down the turbine on overspeed (10 percent above maximum continuous speed). The protection system monitors steam turbine total train parameters and ensures safety and reliability by the following action:

The automated fired shutdown overspeed trip test upgrade replaces the traditional 110% manual overspeed test with an automated test conducted at part speed during shutdown to prove protection-system operation. Test time is shorter as well as your install. A GE-qualified controls engineer will modernize and test the software on site, only taking ...

A turbine trip is the automatic safety shutdown of a power-generation turbine due to unexpected events. Due to the number of issues that may cause a trip, they are relatively common events. ... Many events can cause a turbine trip, including: turbine overspeed condition where the turbine accelerates over its design speed, typically by 10%; low ...

Mechanical overspeed trip mechanisms require periodic overspeed testing that stresses rotating components, extends outages and can cause failed starts with the need for manual resets. This solution includes additional speed sensors and a new main electronic overspeed trip (MEOST) system to replace existing mechanical systems.

WASHINGTON (Gray DC) - 75 service members, and one service dog made the trek to Washington Tuesday. Among them, Vietnam war veteran Jerry Wright. "I was a draftee for two years, and I was not a ...