Exclusive Look Inside the Camaro Assembly Plant – Cool Cars Are Built Here!

David Hakim Writer Aug 18, 2016

See All 67 Photos

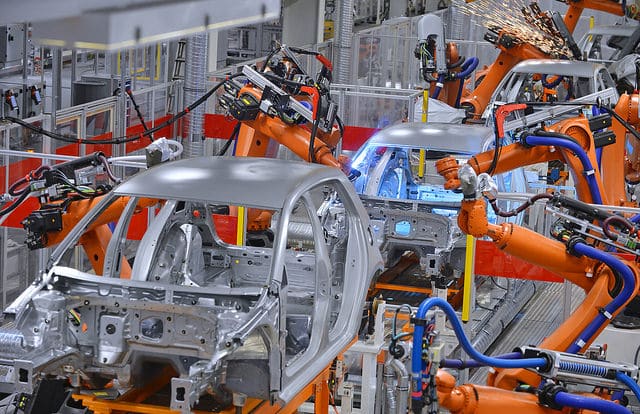

With this being the week of the annual Woodward Dream Cruise, Chevrolet is going all out to celebrate the Camaro's 50th birthday. That's when they invited us to check out the Lansing Grand River Assembly plant and see the shiny 2017 Camaros being born and rolling off the line. We couldn't wait, and let's face it; we're suckers for assembly plants, feeling like kids at an amusement park. We pointed the 2017 Camaro SS 50th Anniversary Special Edition we'd been driving all week west, and headed along interstate 96 towards Lansing. The 455-horse, direct-injected, 6.2L LT1 was eating up the highway mile-markers like Pac-Man on steroids.

In celebration of the Camaro's 50th Anniversary, the fine folks at Chevrolet had also arranged plant tours for hundreds of Chevy enthusiasts. There were Camaros from all six generations from owners all over country who were in town for the Woodward Dream Cruise. They proudly displayed their rides in the parking lot outside of the Lansing Grand River Assembly Plant. Chevy also showed off the 2017 ZL1 and 2016 COPO models for all to drool and have fantasizes over when driving home.

So, check out our awesome behind-the-scenes photo gallery from the Chevy Camaro plant and see the care, passion, and love these individuals put into every car that rolls off the line.

Also, make sure to watch the video of 2017 Camaro SS come together. We also caught a LT1 as it barked to life for the first time.

A Quick History of Camaro Production

Starting with the Fourth Generation models in 1993, the Camaro was built north of the border. First, it was the Sainte-Thrse Assembly in Quebec, but after production was halted in 2002, this chapter in the Camaro's (and its cousin the Firebird's) long, storied career closed. When the Fifth Generation Camaro came out in 2009, production was moved to the Oshawa assembly line in Ontario. By 2015, the last Canadian-built Camaro came off the line and it signaled an end of over a decade of Canadian production of one of America's most popular pony.

When the Sixth Generation was being developed, the plan to bring production back to the US was already in place. Now, the 2016 Camaro is made in Lansing, Michigan, just a few miles from the state capital building. The reason was simple: By moving the Camaro to the General Motors' Lansing Grand River Assembly, GM was able to reduce costs and have better operating efficiencies, since the plant builds other rear-drive vehicles such as the Cadillac CTS and ATS. The facility is also GM's second newest plant, as it was totally refurbished and opened in 2001. Lansing Grand River Assembly engulfs over 2.5 million square feet on 111 acres. For you history buffs, the Lansing plant was the same site that made Oldsmobiles for many decades. So many a Cutlass, 442, and other models powered by Rocket V8 engines came from these same grounds.

MotorTrend Recommended Stories

Freaks and Oddities of the 2024 HOT ROD Power Tour—Huge, Weird Gallery!

Steven Rupp | Jun 21, 2024

Hot Engine Bays of the 2024 HOT ROD Power Tour! Huge Gallery!

Steven Rupp | Jun 20, 2024

What Is the 1988 Callaway Sledgehammer Corvette and Why Is It So Dang Fast?!

Johnny Hunkins | Jun 20, 2024

HOT ROD Power Tour West Returns in 2024: Route and Schedule Inside!

HOT ROD Staff | Jun 20, 2024

The Breaking Point: Converting Your Hot Rod to Disc Brakes

Gray Baskerville | Jun 20, 2024

Shell Rotella SuperRigs 2024: ENORMOUS GALLERY Hot Rod Trucks Show off at the Big Rig Beauty Pageant in Texas

KJ Jones | Jun 19, 2024

Lansing Grand River Assembly / Stamping

Lansing Grand River Assembly is GM’s second-newest U.S. assembly plant. Constructed in 1999.

920 Townsend Street Lansing, MI 48933 Map

Year Opened: Assembly – 2001 / Stamping – 2016 Size: 3.4 million sq. ft. on 111 acres Union: UAW Local 652 Social: @MFG_GM , Facebook

We proudly build luxury and performance models including:

Cadillac : CT4 and CT5

LGR is designed around GM’s Global Manufacturing System and focuses on maximum performance in safety, people systems, quality, customer responsiveness, cost and environment.

Visiting our campus? Please view our guide for protocols, dress code and other information before visiting.

US Operations Impact Numbers

Photos & Videos

Join Our Team

We’re looking for adventure seekers and imaginative thought leaders to help us transform mobility and advance an all-electric future.

Chevy Camaro fans tour GM Lansing plant

Lansing — Chevrolet Camaro fans from across Michigan, the U.S. and Ontario drove their favorite muscle car here Thursday for a special celebration and factory tour honoring the 50 th year of the Camaro.

General Motors Co. opened the doors of its Lansing Grand River Assembly Plant for a rare public peek inside the factory that builds the Camaro and Cadillac ATS and CTS variants. The plant has been building the car since last year when the sixth generation launched.

The company estimated up to 1,300 would come through the doors Thursday. Tours were self-guided with dozens of people along the plant floor answering questions at different build spots as workers wore Camaro Fifty T-shirts as part of the celebration.

Attendees had a chance to listen to a tech talk from some GM employees who work on the car including chief engineer Al Oppenheiser and a kickoff that featured UAW Local 652 President Mike Green, Lansing Mayor Virg Bernero and GM officials.

“We’re excited to meet so many Camaro enthusiasts, customers and supporters that in some cases have traveled extremely far to celebrate this milestone and share in the passion of the vehicle that we get to build every day,” Plant Manager Steve Notar Donato said.

Young and old Camaro fans brought their Camaros, including Lerick Chissus, 4, of Novi who drove his red Camaro Power Wheels with his sister, Lorelai, 1, in the passenger seat.

“He got it ready for the car show,” mom Jennifer Chissus said. Dad Lerick Chissus is an engineer on GM’s Camaro team. “He washed it and polished it.”

Mike and Barb Gerish of Kawkawlin near Bay City drove their 1968 burgundy Camaro to the celebration, a car they’ve had since 1969 and they bought for $2,389. They were excited to see inside the plant.

“It was our honeymoon car,” said Barb.

Jim Wozniak, 62, of Hubbard, Ohio, drove his black 1977 Z/28 and was busy polishing it in the parking lot for the car show.

“I bought it new,” he said. He was 23 and paid about $5,600. “It was my first new car and I still own it. I always wanted a Camaro and I saved up and bought one.”

He wants to bring the car onto Woodward for Saturday’s official Dream Cruise day.

On Friday, hundreds of Camaros are expected to participate in a police-escorted cruise from Detroit onto Woodward in Ferndale and north.

Chevy announced the Camaro name during a press conference on June 28, 1966, and the 1967 model car arrived in dealerships in September of that year. The car took a seven-year production break when the fourth generation ended production in 2002. The fifth generation returned in 2009 as a 2010 model.

(313) 222-2319

- Car News By Brand

- Chevrolet News

- Hyundai News

- Celebrity Car News

- Just for Laughs

- Motorsports

- Product Reviews

12 Must-Visit Automotive Factory Tours in the United States

Keep the following in mind before you schedule:

- Most don’t allow cameras or recording devices on the tours

- Minimum ages of visitors around typically between 8 and 12 years old

- Nearly all of these visits require reservations in advance

- Adhere to the dress code guidelines, including closed-toed shoes

- Some tours involve extensive walking, so call ahead if you need special accommodation

Furry Friends: How to safely travel with pets

12. Nissan North America – Smyrna, Tennessee

Limited tours of this vehicle assembly plant near Nashville are offered–only Tuesdays and Thursdays–but a motorized, narrated ride through the assembly of these renowned Nissan vehicles is worth the waiting list. You’ll get to see everything from the Pathfinder to the Altima and the Leaf rolling off the production line. More information.

11. BMW U.S. Factory – Spartanburg, South Carolina

Those interested in getting an inside perspective on the “Ultimate Driving Machine” will love touring the only American BMW factory, which is near Charlotte, NC. For a $10 fee, visitors will get to see the modern engineering marvels of the German brand at work within the production plant. Afterward, swing by the Zentrum museum to see the history of BMW at your own pace. More information .

10. Hyundai Motor Manufacturing Alabama – Montgomery, Alabama

If you want to watch the construction of a car you probably own, check out this factory within the historic Montgomery city limits. After watching a prep video and donning your headsets, you’ll be taken on a guided tram tour of the assembly of the Hyundai Sonata and Elantra . The experience is free and occasional evening tour times are offered too. Check out the gift shop after your tour for some Hyundai swag! More information .

9. Toyota Motor Manufacturing Kentucky – Georgetown, Kentucky

Welcome to Toyota’s assembly plant in Georgetown, Kentucky!

In the heart of the bluegrass region, not far from Lexington, is a massive Toyota manufacturing plant that has given tours to hundreds of thousands of people since 1990. Visitors can take a free guided tram tour through the inside of the facility while listening to friendly guides over headphones explain the work being done. An 11,500-square-foot Visitor Center includes displays and a Toyota gift shop. More information .

8. Subaru of Indiana Automotive (SIA) – Lafayette, Indiana

If you’re headed to Chicago sometime, swing by the home of North American Subaru production that’s southeast of the Windy City. A free, mile-long walk on an elevated catwalk through the facility offers a unique perspective on production operations, but skirts are highly discouraged for that reason! You’ll be accompanied by a knowledgeable Subaru tour director on your walk. More information .

7. Ford Rouge Factory – Dearborn, Michigan

The assembly area is only one portion of this thorough five-part, self-guided tour. Apart from seeing the new aluminum F-150 produced in the assembly floor, learn more about the plant’s innovations at the Legacy Theater, Manufacturing Innovation Theater, and Legacy Gallery. Tickets are a bit pricey but it’s one of the few facilities open for weekend tours. More information .

6. Mercedes-Benz US International – Tuscaloosa, Alabama

Get a close-up look at the most luxurious auto brand around by seeing the Visitor Center Museum and taking a guided tour along the assembly floor, which produces such greats as the M-Class . Despite the tour costing a small fee, the experience is highly memorable–and the two mile walk will give you a workout too! More information .

5. Bowling Green Corvette Plant – Bowling Green, Kentucky

Welcome to the home of the Chevy Corvette!

This place halfway between Louisville and Nashville received a lot of attention after a sinkhole appeared in its adjacent National Corvette Museum. Now that it’s being repaired, visitors are flocking to see the Chevy building and tour the assembly plant. For a small fee, you can take an hour-long guided walking tour of the Corvette sports car’s actual construction, from the initial steel structure to the final drive off the line. More information .

4. Honda Heritage – Marysville, Ohio

The Honda Heritage Center in Marysville, Ohio

Although you can’t actually tour the factory here near Columbus which has been producing vehicles for over 50 years, the facility recently opened up a stellar museum on its grounds . You’ll learn about the role the factory has played in the history of the Honda, as well as see fascinating models on display. The best part of the experience is the hands-on activities! More information .

3. General Motors Fairfax Assembly Plant – Kansas City, Kansas

This GM assembly and stamping facility in the heart of barbecue city offers free walking tours on certain days. If you follow the strict set of safety guidelines, you’ll get to see the process of metal being molded into body panels and attached to vehicles like the Buick LaCrosse and the Chevrolet Malibu . More information .

2. Shelby American Inc – Las Vegas, Nevada

The legacy of Carroll Shelby lives on! This facility has been modifying and selling Ford vehicles for 50 years. If you still have time after seeing the numerous cars on display on the showroom floor, you can get a free tour of the garage (donations accepted). More information .

1. Harley Davidson – Multiple Locations

Harley Davidson powertrain assembly in Kansas City

Multiple Harley Davidson plants offer tours in the US. A free, hour-long walking tour of the manufacturing plant in York, PA is offered, but most visitors prefer the Steel Toe Tour which–for a decent price–gets you entrance to special areas, a commemorative pin, a group photo, a safety vest, and $5 toward the gift shop. A Kids Corner makes this facility suitable for your whole family.

In the heart of Harley history, Menomonee Falls, WI has the northwest plant. You’ll love the interactive museum in downtown Milwaukee and the grand tour of the production facility. Staying overnight? Consider the unique Iron Horse Hotel.

Finally, observe the powertrain operations in Kansas City, MO with a free factory tour of some of the brand’s most beloved models. More information on all three tours .

Safety Tips: Reduce distracted driving and save lives

Aaron is unashamed to be a native Clevelander and the proud driver of a Hyundai Veloster Turbo (which recently replaced his 1995 Saturn SC-2). He gleefully utilizes his background in theater, literature, and communication to dramatically recite his own articles to nearby youth. Mr. Widmar happily resides in Dayton, Ohio with his magnificent wife, Vicki, but is often on the road with her exploring new destinations. Aaron has high aspirations for his writing career but often gets distracted pondering the profound nature of the human condition and forgets what he was writing… See more articles by Aaron.

GM Resumes Camaro Production In Lansing

General Motors has resumed production of the Chevrolet Camaro at its Lansing Grand River Assembly Plant after a parts-related shutdown.

The temporary shutdown began on May 10 th due to a semiconductor shortage plaguing the auto industry this year.

The Grand River Assembly Plant produces the Camaro, along with the Cadillac CT4 and CT5. While UAW Local 652 workers returned to work on the Camaro on Monday, the Cadillac models are still expected to be sidelined by the parts shortage until August 9 th .

Lansing Grand River spokesperson Erin Davis issued a statement saying that GM’s supply chain, engineering and manufacturing teams are finding “creative solutions” and “making strides to maximize production of high-demand and capacity-constrained vehicles.”

LGR will continue to support limited Cadillac Blackwing production.

CRG Research Report - © 2003-2024, Camaro Research Group

The First-Generation Camaro Assembly Process

Process Overview

Fisher body - body shop operations, fisher body - paint shop operations, fisher body - trim shop operations.

- Chevrolet Assembly - Body Bank & Trim Line & Front Sheet Metal

- Chevrolet Assembly - Engine Dress Line & Chassis Line

- Chevrolet Assembly - Paint Shop & Sheet Metal Subassembly

Chevrolet Assembly - Final Line Operations

Introduction.

Norwood was a very old plant that was typical of the old standard model for Fisher Body/Chevrolet assembly facilities; the Fisher Body plant and the Chevrolet assembly plant were on the same piece of property, but were operated by two separate GM Divisions. Fisher Body built the body shell from the firewall back, and shipped it through a hole in their common wall to the Chevrolet plant, fully painted and trimmed, including the interior, minus the instrument panel, dash and floor-mounted components, and front carpets. Chevrolet then assembled all the rest of the trim, chassis, and final assembly components, including all the front end sheet metal, and shipped the finished cars to the dealers. Fisher Body had a huge Paint Shop for the body, and Chevrolet had their own separate Paint Shop for all the front end sheet metal. Norwood ran two shifts, and produced 57 cars per hour, or 912 per day, and produced only the Camaro until mid-April, 1969, when the Firebird (previously built at Lordstown) was added to their mix.

Van Nuys had been a traditional separate Fisher Body/Chevrolet assembly operation for many years, similar to Norwood, but was one of the first Fisher/Chevrolet plants to be consolidated under GMAD (GM Assembly Division) management in 1967-68, replacing the formerly separate Fisher Body and Chevrolet managements with a single GM Division in charge of the entire operation. By 1969, the former Fisher Body Paint Shop had been expanded so it also accommodated the Chevrolet front end sheet metal, and the former Chevrolet Paint Shop was abandoned. Trim Shop operations were also consolidated, with some formerly separate Fisher Body and Chevrolet Trim operations combined on the existing trim lines. Van Nuys also ran two shifts, and produced 35 cars per hour, or 560 per day, but only half of those were Camaros in 1969 - the other half of their schedule was full-size Chevrolet Impala and Caprice models.

Fisher Body Overview

Paint Shop : Cleans, phosphates, primes, seals, and topcoats the body shell, including stripes, and sends it on to the Trim Shop.

Trim Shop : Installs wiring, glass and moldings, weatherstrips, door and deck lid hardware, interior and exterior trim, taillights, moldings and emblems, headliner, seats and rear carpets, water tests, and ships the trimmed body to Chevrolet.

Chevrolet Overview

Trim Line : Installs VIN plate, dash mat, heater or A/C system, wipers, pedal support, instrument panel, cluster and wiring, steering column, front carpets, console, brake booster, rear bumper and guards, and the rear shocks and fuel tank; at Norwood, the body continues to the Final Line for Body Drop, Van Nuys also installs the complete front sheet metal assembly and sends the body to the Final Line for Towveyor chassis-to-body marriage.

Engine Line : Receives engines and transmissions from six different supplier plants and joins them, stamps VIN derivatives, fully dresses and wires/plumbs the engine, engine and trans oil fill, and sends the completed assembly to the Chassis Line.

Chassis Line : Starts with the bare subframe mounted to a carrier truck, and to this is added the front suspension, steering gear and linkage (caster/camber set in a machine), rear axle and springs, fuel and brake lines, exhaust system, master cylinder (brake system bled/tested), engine/transmission, and propeller shaft. The power steering (if applicable) was then filled and the assembly sent to the Final Line on a pedestal conveyor for Body Drop at Norwood. At Van Nuys, the chassis is built-up on the Towveyor line for chassis-to-body marriage.

Paint Shop : Takes the raw front end sheet metal panels (hood, fenders, header panel, front valance, inner fenders, radiator support) from the stamping plants, welds the fender reinforcements to the fender skins, and cleans, phosphates, primes, seals, and topcoats the outer panels; cleans, phosphates and dip-primes the inner fenders and radiator support. After painting, all panels are conveyed to the Sheet Metal Line. Also has a low-temp paint system for grilles, consoles, steering columns, ashtray and glove box doors for delivery to the Trim Line, and a wheel system that primes and paints wheels and conveys them to the wheel & tire assembly area.

Sheet Metal Line : All the painted front sheet metal panels are assembled into complete front end assemblies, including fenders, header, wiring, radiators and shrouds, inner fenders, grilles, and headlights, which are conveyed to the sheet metal installation station after Body Drop at Norwood, or to the front sheet metal installation area near the end of the Trim Line at Van Nuys. Both plants installed the front end sheet metal as a pre-assembled unit (less the hood), followed by assembly of the hood.

Final Line : At Norwood, the body is dropped on the pedestal conveyor-mounted-chassis, then the front sheet metal and hood are installed. At Van Nuys, the chassis is raised up to the body and secured. The rest of the Final Line process is similar at both plants - the subframe and rear springs and shocks are bolted-up, master cylinder is attached to the body or booster, mount/balance and install wheels/tires, front bumper, battery, fill cooling system, evacuate and fill A/C system, gas fill, car start, auto trans top-off, window sticker and P-O-P, drive off, toe-in set, roll-test, final inspection and repair, deliver to truck or rail shipper.

The preceding covers the basic sequence of assembly operations; now we'll cover each individual department of both Fisher Body and Chevrolet Assembly in more detail, starting again with Fisher Body, and continuing in order to completion of the car.

Fisher Body Operation Details

Subassemblies: Many major subassemblies were built up in precision off-line fixtures and conveyed to the side frame or body framing lines, including:

- Rear compartment pan - trunk floor and rear frame rails.

- Front floor pan - main floor pan, seat and subframe mount reinforcements, floor shift piercing, cutouts and reinforcements.

- Cowl & dash - dash, air intake plenum, cowl top, side panels, upper and lower instrument panel.

- Windshield and backlite upper headers.

- Rear wheelhouse assembly (inner and outer) with quarter inner panel.

- Front body hinge pillar/windshield side frame inner and outer and reinforcements.

- Side roof rail assembly (inner and outer).

- Rear shelf panel with deck lid hinges, torsion rods and rear seat bulkhead panel.

Underbody: The rear compartment pan, front floor pan, cowl and dash, and rear shelf panel subassemblies were welded together to form a complete underbody after being loaded to a precision steel body carrying truck on wheels with locators for each subassembly; this "build truck" carried the body all the way through the body framing line, and then returned on its continuous-loop conveyor to pick up another group of subassemblies.

Side Frame: Large assembly fixtures the length of the body were suspended vertically from a continuously-moving overhead conveyor; these were continuous-loop conveyors, one for the RH side, one for the LH side, across the aisle on both sides of the body framing line. All the body side components were loaded outside-first, in car position, and welded sequentially as the conveyor moved along, including the outer rocker, outer quarter, wheelhouse and quarter inner, front body hinge pillar, roof rails, rocker inner, and miscellaneous brackets and reinforcements depending on the body style. Separate side frame fixtures were scheduled for coupes and convertibles. At the end of the side frame line, the assembly was a one-piece body side panel, ready to be transferred into the body framing line and joined to the finished underbody assembly.

Body Framing: As the body build truck entered the framing line carrying the completed underbody, the side frame fixtures shuttled in from each side and were locked in place against locators on the build truck; two pairs of diagonal crossbars were added to tie the side frame fixtures together at the top, the upper windshield and backlite headers were loaded, and hundreds of spotwelds were made to tie the side frame assemblies to the underbody. After the headers were welded, the crossbars were removed, the cowl tag was installed, and the roof skin, tulip panel (the panel between the backlite and the deck lid opening), and rear end panel were loaded and welded. At the end of the framing line, the body was lifted and transferred to a simpler, lighter carrying truck, and the precision body build truck returned on its loop conveyor back to the underbody line.

Body-In-White Final Operations: The side shroud ("saddlebag") outer panels and the doors and deck lid were installed and fitted, followed by soldering and metal-finishing the roof-to-quarter joint, metal-finishing exposed spotweld flash, stud-welding for windshield and backlite and vinyl top molding retainers, option and spoiler drilling, mig-welding the dual exhaust hanger (for 1969's, if applicable), final metal-finish, body cleanup, and inspection. Once complete, the body and loose cowl vent panel were shipped upstairs to the Paint Shop.

Most Body Shop repairs were handled on-line (dings, dents, metal-finish, solder repairs, missing weld studs, missing welds, etc.), but there were off-line stalls for major metal repairs, panel replacement, and similar issues that required the body to be stationary for an extended period.

Phosphate System: The raw body shell passed through a seven-stage phosphate system, where it went through a series of enclosed high-pressure hot spray stages where it was washed to remove all the oils and debris from stamping, welding, brazing, soldering, and grinding operations, then the body was coated with a hot iron phosphate solution which "etched" the metal and provided "teeth" for paint adhesion. The final stage was a de-ionized hot water rinse and blow-off, followed by a drying oven on the way to the prime booth.

Prime System: In the first prime booth, the entire body, inside and out, was manually sprayed with primer, and confined areas subject to corrosion were given a second coat of heavier primer material; this prime coat was then baked at 390F for 30 minutes. In the second prime booth, the instrument panel and rear of the shelf area (and the upper door and quarter areas of 1967-68 models) were painted interior color, and another coat of air-dry flash primer was sprayed from the belt line down. The interior color areas were masked, and the entire outer body was sprayed with gray primer-surfacer and the body was baked again at 285F for 45 minutes. The cowl vent panel was hung in the side window opening on wire hooks all the way through the paint process.

After baking, the entire outer surface was wet-sanded, wiped down, and the body went through a short infra-red dry-off oven on its way to the sealer deck.

Sealing: The primed and baked body passed through a long series of platforms where vinyl plastisol sealer was applied to all joints; floor pan drain hole plugs were installed and sealed, and the sealers were manually dressed in exposed areas. Floor pan deadener pads were then installed, which "melted" into place later in the color reflow oven. The body then went through a sealer oven to "set" the sealers on its way to the color booth.

Color System: The bodies were sequenced to "batch-paint" by color as much as the build schedule allowed, to minimize the waste of thinner required to clear paint guns between colors. The interior was masked off, the body exterior was tacked-off, and it then entered the main color booth, where it got three coats of acrylic lacquer, sprayed automatically with vertical and horizontal reciprocating spray guns, with a 3-minute "flash" between coats, followed by a 10-minute bake at 200F to "skin" the surface prior to sanding. In the next stage, any surface defects were power- and hand-wet-sanded with mineral spirits, then wiped off prior to entering the final "reflow" oven. This bake lasted 30 minutes at 275F, where the lacquer surface softened and "re-flowed" to a uniform gloss.

The last process for a non-stripe car was the blackout booth, where the firewall was blacked-out, the trunk was sprayed with spatter paint, and sound-deadening undercoat material was sprayed in the rear wheelhouses. The rear "cocktail shakers" on convertibles were suspended in the trunk for spatter painting, but weren't bolted in place until later in the Trim Shop, after the taillights and marker lights were installed.

If the car required Z28, Z10, or Z11 stripes or a black rear end panel or rockers, they were masked and manually sprayed in the in-line repair booth/oven system after the reflow oven, including the cowl vent panel; spoilers were painted body color separate from the body, and were final-installed to the deck lid just prior to the repair booth. The rear window filler panel, deck lid and spoiler were masked and sprayed stripe color in the repair booth, and baked in the repair oven before the body went back downstairs to the Trim Shop. The paint guns in the repair booth were fed from manifolds that were part of the main color circulating system so that the repair booth used exactly the same paint the main color booths were using.

If a unit required a major paint repair that couldn't be accommodated in the normal in-line cycle time, it could be diverted off the main line at the end of the repair booth into a parallel loop that ran in the opposite direction and fed the unit back into the main line ahead of the main repair booth; the re-run loop could accommodate about 20 units.

Paint System Information

Paint came from DuPont in 500-gallon tote tanks, with paint mixed from the same lot distributed to both the Fisher and Chevrolet paint shops to minimize color match and gloss issues between the body and the front sheet metal.

Special order paint colors were done by dragging 5-gallon pressurized paint pots through the booths and manually spraying everything; if there was a fleet or special order large enough, they charged one of the spare circulating systems, but that didn't happen very often - it didn't pay to charge a spare system for less than 100 cars.

Scheduling

Wiring and the roof insulator went in first, followed by the headliner and sail panel and shelf trim and garnish moldings (and rear speakers or defroster if ordered), and the windshield and backlite opening flanges had the molding clips installed and were primed for later glass installation (vinyl tops went on ahead of this so the rear edge could be trimmed in the backlite opening before glass priming). Convertible windshield frame trim moldings and latch hardware were installed, along with the power top mechanism, plumbing, and wiring.

Convertible tops were built up on an off-line merry-go-round fixture, then carried to the line where the installation was completed; a protective shipping cover was installed over the top skin after final inspection before the body was shipped to Chevrolet.

Door and deck lid locks were installed. The lock/key package was a Fisher Body item picked at random out of a bin - it came in a 2-part bag; Fisher tore open the half with the door and deck lid cylinders and installed them, and taped the other half of the bag to the instrument panel; the Chevrolet Body Bank entry clerk tore the label off the bag (which had the key numbers on it) and input those numbers (along with the body number that associated the body to the ident number and dealer order) to the program that generated the Broadcast Copy, which had the key numbers on it when it was printed. When the body got to the Chevrolet Trim Line, the glove box cylinder was installed with the (Chevrolet-painted and assembled) glove box door, and the ignition cylinder was inserted when the steering column was installed. The second set of keys was placed in the ash tray.

Door and quarter panel interior hardware and side glass went in and glass was set to gage blocks on the windshield pillar and roof rail, and roof rail and door opening weatherstrips and drip moldings went in next. After verifying side glass fit, door and quarter trim panels and kickpads were installed. The windshield and backlite glass was cleaned, primed, and had the dam and Thiokol adhesive bead applied, and were installed in the openings, followed by "bear grease" sealer between the bottom edge of the glass and the edge of the opening, and the reveal moldings were installed; the gage-located cowl vent panel was used to locate the ends of the lower windshield reveal moldings, and was left secured by one screw. Taillights, marker lights and emblems were installed (followed by the rear "cocktail shakers" on convertibles), sealing fixtures were clamped over the firewall holes, and the body went through a 3-minute water test booth and inspection area. The seats for that car were delivered from the "Cushion Room" where they were built, and the rear carpet and seats were installed last, followed by a final inspection (at Norwood, but not Van Nuys, "P", "T", and "B" ink stamps were applied to the body for Paint, Trim, and Body inspection OK), and the body was shipped up the ramp to Chevrolet.

Chevrolet Assembly Operation Details

Chevrolet assembly - body bank operations.

Order reference: When the body entered the area, the clerk entered the body number from the cowl tag and the newly assigned VIN into the computer, which cross-referenced back to the "ident number" and dealer order number. This data resulted in generation of the precise specifications and all the Chevrolet parts required for that particular car and prepared the file that would generate the "Broadcast Copy" when the car was released.

Scheduling: There were usually six lines in the schedule bank - one for RS, one for A/C, one for SS and Z/28, and three for high-volume standard cars, so cars could be scheduled without having situations like three A/C's in a row, three consoles in a row, three RS's in a row, etc., as these had higher work content vs. the standard cars and scheduling two or three of them in a row would over-cycle certain line operations.

Releasing: When the clerk at the end of the body bank selected the next body based on the scheduling "rules" and released it from its line into the main conveyor to the Trim Line, the computer released the "Broadcast" file with the next sequence number, and it was sent to many teletype printers throughout the plant where subassemblies were built and sequenced for delivery to the Main Line to meet up with that particular car. The same computer program also generated the end-of-line paperwork for that car - the price sticker, car shipper, and other internal documents. Note that as the bodies were released from the six lines in the body bank, the bodies were not in VIN order.

The "Broadcast Copy" (often called the "build sheet" today) included the sequence number, VIN, identification number, dealer code, order number, and selection codes for virtually every part that went on that car. There were two types of Broadcast Copies: the Body Broadcast Copy (BBC) was used on the Trim Line and Final Line, and the Chassis Broadcast Copy (CBC) was used on the Engine Dress, Chassis, and post-marriage overhead Chassis Line. There was some level of duplication on both Broadcast Copies, which were standard Chevrolet forms used in most Chevrolet plants. (Vega assembly at Lordstown was a notable exception - the teletype printers couldn't print a full sheet at 103 per hour, so the Vega Broadcast (designed by yours truly) was only a half-sheet, 8-1/2 by 5-1/2 inches, so the printers could stay ahead of the line.) By the time the car got to the Final Line there were Broadcast Copies all over it, under it, and inside it, as all the various feeder lines used them too. Each installation point for conveyor-delivered components had a trash barrel to pitch the copy that came taped to the subassembly, and there were several at the end of the Final Line.

The car was now officially released for production, and was locked permanently in sequence as it headed for the Trim Line. At Norwood, the body was on a Trim Truck, and at Van Nuys it was in an overhead conveyor clamshell carrier (the low ceilings in the old Norwood Trim Shop building weren't high enough to accommodate overhead conveyors).

Chevrolet Assembly - Trim Line Operations Details

Completion of body trim.

Next came the Z87 wood-grain trim plate and assist handle, parking brake bracket, dimmer switch, speedo cable and grommet, accelerator pedal and lever, and the pedal support assembly (and booster with power brakes), plus the clutch pushrod and pushrod seal on manuals, followed by the A/C air distribution and outlet ductwork and the upper instrument panel pad. The instrument cluster was subassembled in an off-line conveyor system, including the instrument panel wiring harness and fuse block, and was installed next, followed by routing the wires, securing the fuse block to the dash panel, and attaching the heater or A/C control head to the cluster. Subsequent operations included the radio, ash tray assembly, and glove box and door, followed by the steering column with the wheel already subassembled to it, then the front carpet and sill plates. Holes were drilled for the console, automatic floor shifter and cable, the riv-nuts were set, and the shifter was installed. The floor console went in next, less the upper trim plate, shift boot, and retainer for manuals, which were installed on the Final Line after Body Drop. The cowl vent panel was retrieved from the back seat, its front seal was added, and it was final-installed on the cowl, followed by the wiper arms and blades.

The rear bumper and guards, RS backup lights, license door and license light were installed, followed by the heater hoses, fuel tank, rear shocks, pinion bumper, and rear spring front U-nuts and rear shackles and upper shackle bushings, and the trim operations were complete.

FRONT SHEET METAL PROCESSES IN GM PLANTS

In GM assembly plants in the 60s and 70s, there were three different processes for installing the front sheet metal to the body. This depended on the plant's history and the type of vehicles it produced.

Most plants (including Norwood) installed the front sheet metal on the Final Line after body drop, although two different methods were employed. Some plants (including Norwood) installed the front sheet metal as a complete one-piece "buck-built" assembly after body drop, then installed the hood last. Other plants installed the front sheet metal "piecemeal" after body drop - radiator support and header/grill first, then the fenders, then the hood. Lordstown used this "piecemeal" process for their combined Impala/Caprice/Firebird build.

The Van Nuys partial-frame "F" body and full-frame "B" body front sheet metal installation was laid out following their pattern of previously building fully-unitized bodies. They also buck-built the front sheet metal assembly as a single unit, but installed it to the body on the Trim Line, with the body supported in an overhead carrier. The hood was fitted last, prior to their Towveyor chassis-to-body marriage operation.

As passenger car frames disappeared and fully unitized body construction became the norm in the 80s, 90s and beyond, all of the front sheet metal was installed in the Body Shop.

Camaro Front Sheet Metal Installation

The "buck-built" front clip was lowered into place with an overhead hoist; two operators guided it into position, pulling the rear of the fenders outboard to clear the side shroud "saddlebags" on the body as the assembly moved rearward. The hook was then released and the hoist went back upstairs to pick up the next assembly. At this point, operator skill became critical as the shim packs were made up and stuffed in place for the top, front, side, and bottom fender-to-body attachments to achieve the correct gap and flush fits between the fenders and the body.

Establishing a perfectly square hood opening was critical, as the hood was "trapped" on all four sides by the header, fenders, and cowl vent grille; a special "hood squaring fixture" (similar to this fixture on a Monte Carlo ) was dropped in place. It had two pins at the rear that went into the two holes in the cowl just inboard of the fenders (the ones with the little black plastic plugs in them), two pins at the front that engaged the two holes in the top of the radiator support just inboard of the diagonal brace attachments, and locator blocks on the sides for the fenders. Once the fender fit points at the rear were properly shimmed and secured, the squaring fixture was removed, and the front end was ready for the hood.

The last step prior to hood installation was to retrieve the antenna body from the R.H. hinge pillar and install it to the fender.

Hood Installation

From this point, the body was conveyed to the Final Line, where it would meet the chassis.

Chevrolet Assembly - Engine Dress Line Operations Details

In the engine schedule area, the operator grabbed the next Broadcast Copy from the printer, verified the sequence number, noted the engine code required for that car, and moved an air-powered overhead hoist on traveling bridge rails over the correct engine rack. The specified engine was hoisted out of the rack and transferred to the next hook on the overhead engine dress line conveyor, where the throwout bearing (on manuals) was greased and installed, along with the clutch fork boot. Another operator on the other side of the line repeated the process with the specified transmission, which was then installed and bolted to the engine; on automatics, an air tool was used to rotate the flexplate, and the converter bolts were driven, followed by the lower cover.

The VIN derivative numbers were stamped in the next operation on both the engine pad and the transmission, using a gang-stamp holder and a hammer. From here on, all the detail dress items were added (plug wires, coil, engine harness, battery cables, carburetor, pulleys, alternator, starter, fan and clutch, A/C compressor, power steering pump, transmission cooler lines and fill tube, A.I.R. pump, diverter valve and air manifolds, drive belts, dipstick and tube, oil filter, engine and transmission mounts, PCV plumbing, vacuum fittings, fuel pump and fuel line, radiator hoses, and (if applicable) the transmission-mounted 4-speed manual shifter and linkage was installed and adjusted (3-speed manual floor shifters were mounted on the cross-member and adjusted later on the Chassis line). Engine oil and transmission lube were added, and the completed engine/transmission assembly was conveyed to the Chassis Line for installation in the subframe. The engine line inspector wrote the engine, transmission, and carburetor codes on the Broadcast Copy and put the sheet in a box for pickup by a Scheduling clerk (needed to create the P-O-P at the end of the Final Line).

Chevrolet Assembly - Chassis Line Operations Details

The subframe was built up separately on a feeder line; the bare subframe was loaded on a conveyor, where the frame-side engine mount brackets were installed. Next, the upper and lower control arms and stabilizer bar were loose-installed, followed by the front springs and hub/spindle/brake caliper assemblies. It was then loaded into the "Geo-Machine", which set caster and camber. The machine clamped the subframe down solid against locators, and a swiveling head on each side was bolted to the front hub lug studs; when the machine was cycled, the machine heads compressed the hubs to design suspension height and positioned the wheel mounting face of the hubs to the correct caster and camber angles, which created gaps between the upper control arm shafts and the bracket on the subframe. The operators stuffed both gaps on each side with shims positioned over the studs, and torqued the nuts on both sides and the bushing bolts through the lower control arm bushings, plus the stabilizer bar bushing and end link bolts; the machine then lowered the suspension to full rebound against the upper control arm bumper, the nuts were removed holding the machine heads to the hub faces, and the subframe was transferred out of the machine, flipped upside-down, and the steering gear, pitman arm, idler arm, and steering linkage were installed. The subframe was then flipped right-side-up and loaded on the chassis carrier truck.

The rear axle, rear brake pipes, and rear springs (including the front mounting bracket, bushings, and fully-torqued through-bolt) were subassembled (and the diff lube was added) on another feeder line, and that unit was then loaded on the chassis truck, followed by the front shocks, prop shaft, brake pipes, valves, hoses, and master cylinder, transmission control and backdrive linkage, fuel and vapor lines, and the engine/transmission assembly was installed and all mounts were torqued. The power steering hoses and fuel/vapor lines were connected, the clutch cross shaft was added, manual floor shift linkage was installed and adjusted, and the heat riser valve and complete exhaust system was installed.

The chassis then passed into the fluids area, where the power steering system was evacuated and filled automatically, and the brake system was evacuated-and-filled automatically through the master cylinder - the bleeders on the master cylinder and at each wheel were never touched. Another machine head was then clamped to the back of the master cylinder which pushed on the rear piston to bring the brake system to 1200 psi and held it there for 20 seconds; any pressure decay or movement of the piston indicated a leak. When the leak test was complete, the machine automatically topped-off the fluid level, the test head was removed, and the master cylinder cap was installed. The inspector then wrote the axle number on the Broadcast Copy and set it aside for later pickup by Scheduling, and the complete chassis moved on to the Final Line Body Drop station at Norwood or to the Towveyor lift station at Van Nuys.

Chevrolet Assembly - Paint Shop Operations Details

Raw Metal: The front fender outer skin and the long inner fender reinforcement were received separately from the stamping plant in order to get more pieces in a standard rack; these two parts were spot-welded together in special fixtures which established the "crown" of the fender so it matched the contour of the hood, and the raw welded assembly was then sent to the primer "Flow-Coat" line.

Sheet Metal Painting: All raw parts (wheels, brackets, etc.) and the front end sheet metal (hoods, fenders, lower fender extensions, header panels, front valances, radiator supports, inner fenders, etc.) went through a cleaning, degreasing, and hot phosphate system, then through a flow-coat booth where it was deluged with black primer from all directions and then baked. The sheet metal parts that got exterior color were pulled off the prime conveyor and loaded on another conveyor buck, in car position, for finish painting; it got a coat of primer-surfacer that was baked and lightly wet-sanded, then got three coats of lacquer, a short bake to "skin" it over, a light wet-sanding and wipe-down, then it went through the final re-flow oven at 275F for 30 minutes. Next was an in-line repair booth where Z-10/Z-11/Z-28 and D-90/DX1 stripe masking, spraying, and de-masking was done (including lower fender blackout when required), followed by another oven. After cooling, the conveyor delivered the buck carrying the color-coated parts, in the same sequence as the cars on the main assembly line, to the sheet metal subassembly area. Exterior color lacquer was supplied by DuPont, and both Fisher Body and Chevrolet Paint Shops at the same assembly location were supplied from the same DuPont-mixed lot in order to minimize any color-match problems. This wasn't an issue at Van Nuys, as their recently-consolidated Paint Shop had each car's front sheet metal on a buck just ahead of the body shell so the entire exterior of the car was painted at the same time with the same paint; that set of sheet metal eventually met up with that same body again after Body Drop on the Final Line.

Wheel Painting: The wheels were removed from the prime conveyor and placed in another conveyor system that took them through a booth where their faces were sprayed with color wheel enamel, then through an oven, and the conveyor continued to the wheel & tire assembly area where the wheels were picked off.

Small Parts Paint: All the miscellaneous brackets and small parts that only got black primer were picked off the prime line after cooling and were placed in individual containers by part number for delivery to the engine, chassis, and final line areas where they were installed.

Low-Bake Paint: Small plastic and metal parts that required color (grilles, consoles, steering columns and covers, N34 steering wheel hubs, ashtray and glove box doors, stereo speaker grilles, etc.) were received in prime from the suppliers and were painted in yet another paint system, in build sequence, baked at 150F in a short infra-red oven, and conveyed to their point of use on the Trim Line and the sheet metal subassembly area.

VE3 Front Bumpers: These optional front bumpers were received already painted from the supplier, as they required a special flexible paint and a unique process not available in the assembly plants.

Final Paint Repair: There were no paint operations of any kind after the finished car came off the Final Line, unless it needed a repair that couldn't be finished in the Paint Shop or if it got scratched during the assembly process after paint. If a spot color repair was required, it was done in an off-line prep area and spray booth with an infra-red oven which only heated the repaired surface to about 150F ("low-bake"), and final gloss of the repaired area was achieved by compounding and polishing.

Chevrolet Assembly - Front Sheet Metal Subassembly

The radiator support was built up first and placed on the conveyor fixture, including the radiator, A/C seals, baffles, condenser and plumbing, center grille support, hood latch assembly, horns, header panel, voltage regulator, horn relay, headlights, and RS headlight door assemblies; the lower radiator-to-subframe mount cushions and bolts were installed, retained by zip-nuts so they wouldn't fall off. The seals were stapled to the inner fenders which were then subassembled to the fenders off-line along with the lower fender extensions, A/C dehydrator bottle, Z21 wheel opening moldings, RS vacuum tank, emblems and marker lights, then those fender assemblies were brought to the buck and joined to the header panel and radiator support with the diagonal braces while fixtured at the rear of the buck to establish a perfectly square hood opening. The front valance panel, license plate bracket and parking lights went on, the forward lamp harness and RS vacuum harness was routed and connected to all components, the grille and headlight bezels went on, the washer bottle bracket and battery tray were installed, and the "cocktail shakers" were installed on convertibles. The front clip (less the hood) was now ready for assembly to the body after body drop at Norwood or at the end of the Trim Line at Van Nuys, prior to chassis-to-body marriage.

The hood was hung separately from the conveyor; the pad and latch striker assembly was installed, along with SS louvers and the ZL2 air valve and solenoid assembly, underhood lights, etc.; ZL2 hoods for Z/28's were drilled and had the "302" emblems installed. Hood hinges were installed later on the fenders, just prior to hood installation.

Wheel And Tire Assembly

Pre-marriage.

BODY DROP PROCESSES IN GM PLANTS

In GM assembly plants in the 60s and 70s, there were two different processes for joining the body and chassis. This depended on the plant's history and the type of vehicles it produced.

The most common body-to-chassis joining process was the "body drop", where the trimmed body was picked up off its body truck with an overhead "body drop tackle" device, which then "dropped" the body vertically on the chassis, which was being carried on a pedestal conveyor. The body mount bolts were then driven (4 on a partial-frame Camaro/Firebird "F" body, 10 on a full-frame "A" or "B" body), and the body/chassis was set down on its wheels on a flat-top Final Line conveyor. This process was employed at Norwood.

Plants with a history of building fully-unitized bodies installed the front sheet metal back on the Trim Line and used a "Towveyor" system to join the body and chassis. The body (including the front sheet metal) was in an overhead "clamshell" carrier six feet off the floor. The chassis was built-up and carried on a "Towveyor" device pulled by a conveyor chain in the floor that was synchronized with the overhead body conveyor. Each Towveyor had a hydraulic unit that raised the chassis up to the body so the body bolts and all other chassis-to-body attachments could be made. The Towveyor was then lowered and returned in a continuous loop to have another chassis assembled on it. This process was employed at Van Nuys, which built both partial-frame "F" bodies and full-frame "B" bodies on the same line.

As passenger car frames disappeared, fully unitized body construction became the norm and the front sheet metal was installed in the Body Shop. At that point, the Towveyor method became the process of choice for joining the chassis and the body.

Chassis-to-Body Marriage at Norwood

Chassis-to-body marriage at van nuys.

Subsequent operations in the Final Line center pit were the same in both plants: the speedo cable was connected, fuel and brake line clips were secured to the underbody, the rest of the exhaust hangers were attached, the main fuel line was attached to the hose from the fuel tank, and the parking brake cables were secured and adjusted. Automatic shift linkage and clutch linkages were adjusted, the backdrive linkage was connected and adjusted, and the convertible floorpan brace was installed.

Up top, the steering column flange was connected to the rag joint, followed by securing the loosely-installed column to the dash and at the toe plate with its trim cover, manual floor shift levers, boots, and retainers were installed along with console trim plates. The master cylinder was pulled rearward and attached to the dash studs or the booster, and final wiring and plumbing connections were made.

Other Operations

Four or five gallons of gas were pumped into the tank, the carburetor was primed by filling the float bowl through the vent tube, and the car was started for the first time; idle speed was adjusted, automatic transmissions were topped-off, the air cleaner was installed, and the car was ready for drive-off.

The Scheduling clerk had already produced the P-O-P from the Broadcast Copies picked up at the Engine and Chassis lines, the window sticker, car shipper, and final order copy had been produced, and these were placed in the glove box with the warranty folder and owner's manual while the window sticker was applied to the door glass. The car was then "de-papered" by removing all the extra Broadcast Copies, supplier labels, etc. that were taped all over the car as assembly information, and trashing them. Each car and its scheduled subassemblies picked up about twenty Broadcast Copies at it progressed through the Chevrolet assembly system, but it was strictly an internal plant information document and none were shipped with the car's paperwork package to the dealer, although many 1969 Van Nuys units had a Broadcast Copy glued to the top of the gas tank.

A team of inspectors gave the car a once-over, and a roll-tester drove the car off the end of the line into the toe-in machine. Here the driver used a fixture that rested on the window opening to hold the steering wheel level while the machine operator in the pit adjusted the tie rod sleeves until toe-in was in spec and tightened the tie rod sleeve clamps. The driver then returned the steering wheel fixture to the pedestal, and drove ahead onto the roll-test machine.

The roll-tester drove the car on the rollers at speeds up to 60 mph or so, checking mechanical operation, instruments, speedometer accuracy (a large master speedometer was suspended overhead in the driver's view), upshifts/downshifts, clutch, brakes, wipers, horn, turn signals, radio, acceleration, A/C operation, and listened for any unusual noises. One side of the rollers was smooth and round, and the other side were eccentric, to mimic driving the car on a rough road - the driver moved the car over to the rough side and listened for any squeaks or rattles, and when the rollers stopped, he drove the car ahead and parked it on another dual-strand flat-top conveyor, noted any discrepancies on the inspection ticket, and returned to pick up another car.

Final Process

The shipping line was another flat-top conveyor, which carried the now-finished car "out the door" to the shipping contractor; the car got one more once-over here, and all extraneous labels, stickers, and inspection tickets were removed. At the end of the line, the contractor drove the car away to his shipping yard adjacent to the plant where loads were made up for loading on haulaway trucks or rail cars to begin the journey to the ordering dealer.

Generally, cars to be delivered within several hundred miles of the plant left on haulaway trucks; those destined for dealers further away were shipped by rail, then unloaded at the nearest GM railhead to the dealer and transferred to haulaway trucks for final delivery.

Author Introduction / Biography

Chrysler 1985-2001: Retired Plant Manager - Conner Avenue Assembly Plant (Viper & Prowler). Chief Engineer - Project Liberty. Chief Engineer - Advanced Process Development. Director - Advanced Manufacturing Engineering.

GM 1964-1985 (Chevrolet and GM Assembly Division): Production, Production Engineering, Vehicle Engineering, Product Promotion Engineering, Process Engineering, Pilot Operations, New Model Pre-Production & Launch.

BSME, Michigan State.

Where Are Chevrolet Camaros Made? (Solved & Explained)

The Chevrolet Camaro is one of the most popular mid-size muscle cars in the auto market.

It made its debut in 1966 and was designed to compete with Ford’s Mustang for the 1967 model year.

The Chevrolet Camaro, since its debut, has evolved through five generations into its current sixth (which kicked off in 2016). Within that time, the Chevy Camaro has been sauced with landmark innovations and the latest technology.

If you have ever been curious about where these classic Camaros are made, this article will walk you through it in detail.

Table of Contents

Where Are Chevrolet Camaros Being Made?

The first-generation Chevy Camaros (1967-1969) were manufactured at two American assembly plants.

One was at Norwood, in the state of Ohio, and the other at Van Nuys, California.

There were also non-American plants in countries that require domestic assembly. The countries include the Philippines, Belgium, Peru, Venezuela, and Switzerland.

The second-generation Camaros were also produced at the assembly plants in Norwood and Van Nuys.

This was the case with the third-generation (1982-1992) models, too, until 1987, when GM restricted production to the GM Van Nuys plant in California.

However, General Motors took a different turn with the fourth generation Camaro models. GM moved production from its American base in Van Nuys to Saint Therese, Quebec, Canada.

The Chevrolet Camaro was on a hiatus of some sort between 2002 until its return with the fifth-generation model in 2009.

GM also built the fifth-generation in Canada but at a different location; Oshawa Car Assembly, Oshawa, Canada.

The sixth-generation Chevrolet Camaros were manufactured in 2015, which marked a return to production on American soil.

GM built the model at the Lansing Grand River Assembly, Lansing, Michigan, the main production plant of the Chevy Camaros.

Here are some important facts on our article on How Long do the Chevrolet Camaros Last?

Are Camaros For the US Market Produced in the US?

Chevy Camaros for the US market were produced in the US until 1992, when production moved to Quebec, Canada.

The assembly plant for the Chevy Camaro remained in Canada for over a decade until the sixth generation launched in 2015.

In 2015, production moved to the Lansing Grand River Assembly, Lansing, Michigan.

The Grand River Assembly in Michigan, US, remains the assembly plant for Camaros made for the US market.

It also supplies Chevy Camaros for international auto markets, making it the Chevy Camaro’s only production plant.

Are They Being Assembled in the US?

The Chevy Camaros are built and assembled in the US, which has been the case since 2015.

The move of the assembly plant from Canada to Lansing, Michigan, was well-received and positively impacted the American economy.

How Can You Check Where A Specific Camaro Was Produced?

Here’s how to check a Camaro’s country of origin:

The first thing you need to do is figure out your Vehicle Identification Number (VIN).

In case you aren’t very familiar with VIN, it is a code with encrypted characters representing information about your vehicle.

This includes vehicle history, past recall, country of origin, production date, etc.

You can find the VIN in various locations in your car, including the windscreen on the driver’s side, the driver’s door, and the steering column. Another option is to check your insurance card or the vehicle’s title records.

There are several VIN decoders on the internet that you could use, including Vehicleidentificationnumber.com and National Insurance Crime Bureau.

Please remember that certain Chevy Camaro models were produced in Canada and not the US. If the VIN decrypt reveals the country origin as Canada, it could mean you own a fourth-generation or fifth-generation Camaro.

Please also read our article about 11 Chevrolet Camaro facts and statistics you should know .

Are Japanese or European Built Camaros Better?

As of now, there are no assembly plants for the Chevy Camaros in Japan or Europe. The Grand River Assembly in Lansing, Michigan, handles production and assembly for local and international markets, including Japan and Europe.

Where Is the Camaro Designed?

Chevy Camaros are designed at Chevrolet’s design studios in the US.

The Chevy Camaro has spanned through six generations with several models. This explains why the vehicle has been through several designs over the years.

Where Are Camaros Made for the Australian Market?

Chevrolet Camaros are built for local and international markets at the Grand River Assembly.

The Camaro is imported by General Motors’ partner company named Holden Special Vehicles for the Australian market.

HSV converts the Camaro models to right-hand-drive in line with the Australian auto market standard.

However, HSV has announced retirement after rolling out the last few units of the Camaro ZL1 and the Camaro SS.

In response to this, GM launched the General Motors Specialty Vehicles (GMSV) as a replacement for the HSV.

The GMSV is slated to launch the Silverado pickups and Chevrolet Corvette in Australian markets in late 2021.

There is nothing official yet, but it makes sense to expect that the GMSV will also launch Chevy Camaros in Australian markets soon.

That’s because there are reports GM plans to race the car at the 2022 Super Cars Championship in Australia.

Also read our article about where Chevrolet Trailblazers are made .

Where Are Chevy Camaros Made for the Canada Market?

Chevrolet Camaros have a strong presence in the Canadian auto market. The Grand River Assembly in Lansing, Michigan, supplies both the US and Canada markets.

Between 1992 and 2015, the assembly plants for Chevy Camaros were located in Quebec and, later, in Oshawa, Canada.

During this time, the plants supplied both American and International markets.

From 2015 till now, Chevy Camaros for the Canada auto market are made at the assembly in Lansing, Michigan.

Where Are Chevy Camaros Made for the U.K. Market?

The Grand River Assembly Plant supplies Chevy Camaros for international markets, which obviously includes the U.K.

However, General Motors effectively pulled Chevys out of the UK market when it sold the Vauxhall-Opel to PSA.

Currently, the sales of Chevrolet models, including Camaros, are handled by Ian Allan Motors, the only approved U.K. dealership.

Make sure to also read our article about where the Chevrolet Traverse is made .

Is Chevrolet Planning to Move Its Production?

During its life-time, production of the Camaro has been moved multiple times, so it’s not odd to expect another move in the coming years.

However, a move out of the US is highly unlikely in the nearest future as it would imply taking away American jobs.

And with the state of the economy, GM doesn’t want that kind of reputation.

Is Chevrolet Hiring or Firing in the US?

Several online job search platforms like Indeed and Glassdoor are filled with job postings from Chevrolet.

If you are looking to land a job with the company, be on the lookout for job ads on these platforms.

Is Chevrolet An American Company ?

Chevrolet is an American company, through and through.

Founded in 1911 in Detroit, Michigan, Chevrolet has grown to be one of the top and most popular American brands.

The GM company has a reputation for building most of its cars in American plants and with American-made components.

The brand has topped several American-made year-end lists, including the American-made Index.

Click to share...

If you see the Last Norwood Camaro in person rest assured that every detail of the restoration was supported by the hundreds of Norwood Plant employees that VHS taped and photographed the car forever capturing its real time assembly condition. The restoration of the last car is therefore a fitting and lasting tribute to the men and women of the General Motors Norwood Assembly plant- all made possible because history was captured through the captivating power of the lens.

Last Norwood Camaro - Last Norwood Unit - Last Norwood Car. - Forever

All of the Vehicles produced by the former General Motors Corporation at its long expunged Norwood, Ohio factory are all existing trademarks of the new General Motors Company-and while the Company is on record as being supportive of this work and its research - any and all historical marks as used here are used for identification, descriptive or illustrative purposes only. This site is not affiliated with General Motors Company.

Content copyright 2024 Philip Borris. All rights reserved. Contact: 686 Eastern Ave PMB-205 Chillicothe Ohio 45601 e-mail: [email protected]

Copyright © 2024 CHEV-STAR LLC. ECHOES OF NORWOOD

The Last Norwood Unit is very likely the most photo documented GM unit build ever produced. This distinction is certain due to the unprecedented decision made by GM management to allow employees to bring cameras and video recorders into plant at the very time when the "last unit" "last car" was being built. Every aspect of the unit was photographed along with every assembly detail of the build. All captured right down to exact decal, emblem placement, paint over spray, paint break points and even production flaws. This level of unbiased third party photographic documentation greatly simplified the restoration task making the completion of the car essentially academic. This car has one of a kind provenance. It was the first car to be given away to an employee when a GM production facility closed. It was the only vehicle awarded by GM with zero cost-including tax liability. It was the very last car assembled in the birthplace of the "F" car-the Norwood GM Assembly Plant. This red IROC-Z is a fitting end to Ohio "F" Body production from 1967-1987, meaning this car shares an unbroken production linage with the first 1967 Camaro, the great Z/28's the SS cars, 427 COPO's and the ZL-1.

- Echoes of Norwood

- Visions of Norwood

- August 26, 1987

- Last Norwood Camaro

- Forum Listing

- Marketplace

- Advanced Search

- Team Camaro

- Team Camaro Cruiz-Ins

Janesville, WI GM PLANT TOUR... YES or NO?

- Total voters 9

- Poll closed Oct 8, 2007 .

GM Plant Tour

- Add to quote

Ok guys. I am taking a poll on who may be interested on taking a plant tour through General Motors Assembly Plant in Janesville, WI to see what the production line is like. They build the Full Size SUV's (Tahoe, Yukon, Denali, etc), along with the Medium Duty Trucks. If there is enough interest, we will then work on a date to set it up. At least 10 people and I can get a guided tour on a tram. Less than that, and I would have to give the tour personally, which wouldn't be bad either. (I can show you more than a tram ride could) Would be a weekday, Monday through Thursday. Once again... GM Plant Tour Janesville, WI Date and Time to be set later

let me know im there.

I'd be interested, depending on date and my availability... Where I work sent Radiator supports to the Janesville plant for the last 7-8 years. Let me know if it gets planned. Russ

I will let this run through Sunday to see what kind of response I get. Then I will come back and see what date and time works for everybody. Thanks guys.

Ya know there is hardly a picture of the place , I found a couple. Wish they still build Camaros there.

Plant tour is really cool. i took the tour when they were building Corsicas and Barretas in NJ.

Dave Watson. I do know of him, only from older friends, stories and books. He is from the Milton, WI area... about 10 miles North of the Janesville Plant. Many fans of his around here though. So far, from some PM's I have received, it looks like most would like to see a Tuesday around 12:30 or 1:00 PM. This would give us about 2 hours to walk through the plant, which is more than enough time. I will be checking with Security and Communications on Monday to make sure what date is ok. We have some ISO and OSHA Inspections coming up, and they don't like tours being given at same time for safety reasons. I will post Tuesday the date and time, then we'll see who can make it. Thanks guys.

Yes Dave Watson was from Milton... he is now in florida I guess, with Corp. NASCAR doing some admin stuff. I was in his pit in the 1978 Atlanta 500 race, when he ran of of gas and locked up on a run into the pits, he lost power to his brakes and hit his jackman who later died from the accident. That pretty much stopped his career. He never was the same. Mark Martin and he were friends and very competitive with each other.

bump up

OK GUYS !!! Here's the Scoop. The two best dates for the plant and myself are both Tuesdays. Either... Tuesday October 16 or Tuesday October 23 . The 16th would be better, but I will leave it up to you guys to decide. The other option is time. I think a 1:00 PM tour start would be best. The shift ends at 3:48 PM, so this would be plenty of time to see things in action. Could even possibly meet for lunch at 11:30 - 11:45 to fill up, then proceed to tour. Otherwise, we would need a 9:30 meet time to start tour. I know "Click" would prefer the later time, as would others who had PM'ed me. So, from what I see it looks like this... Tuesday October 16, 2007 GM Assembly Plant Janesville, WI 1:00 PM Tour Start Time Optional... Lunch @ 11:30 (Fuddruckers, Red Robin, Texas Roadhouse) Please let me know for sure who will be attending. Thanks guys.

TazJr800 said: OK GUYS !!! Here's the Scoop. The two best dates for the plant and myself are both Tuesdays. Either... Tuesday October 16 or Tuesday October 23 . The 16th would be better, but I will leave it up to you guys to decide. The other option is time. I think a 1:00 PM tour start would be best. The shift ends at 3:48 PM, so this would be plenty of time to see things in action. Could even possibly meet for lunch at 11:30 - 11:45 to fill up, then proceed to tour. Otherwise, we would need a 9:30 meet time to start tour. I know "Click" would prefer the later time, as would others who had PM'ed me. So, from what I see it looks like this... Tuesday October 16, 2007 GM Assembly Plant Janesville, WI 1:00 PM Tour Start Time Optional... Lunch @ 11:30 (Fuddruckers, Red Robin, Texas Roadhouse) Please let me know for sure who will be attending. Thanks guys. Click to expand...

if possible for the others,,, the 16th would work best for me (time doesn't matter). The 23rd will leave me out, unfortunately. Either way, thanks for making the offer. PM sent to you Taz.

I'm interested, could make either day possibly. Impossible to say for sure, this is our busy season at work, and I never know what each day will bring.

As of today, the 23rd looks better, but the 16th may be doable(I should know in the morning). 1PM works, or 11:30.

The 16th works for me. I may be able to make the 23rd work as well if needed. I would like to see as many TC'ers as possible so whichever. I'm all in for the lunch then tour idea as well works for me.:thumbsup:

browsing the GM plant website and found this about tours... are we getting a special time alotment? Tour Length One hour. Tours will be offered Mondays, Tuesdays, Wednesday and Thursdays at 9:15am and 10:45am. Groups must have a reservation that is made at least 48 hours in advance. All reservations are to be made over the telephone at 608-756-7681 where you will leave your name and number and GM will call you back to schedule a tour. No cameras, video equipment, backpacks or purses will be allowed in the facility.

- ?

- 84.2K members

Top Contributors this Month

Media professionals: We created an all-new experience just for you. Visit the new Chevrolet Pressroom .

Latest in News

IMAGES

VIDEO

COMMENTS

Now, the 2016 Camaro is made in Lansing, Michigan, just a few miles from the state capital building. The reason was simple: By moving the Camaro to the General Motors' Lansing Grand River Assembly ...

The GM Lansing Grand River facility, sometimes abbreviated LGR, is located in Lansing, Michigan, United States. It currently produces the Chevrolet Camaro as well as the Cadillac CT4 and CT5 ...

Lansing Grand River Assembly is GM's second-newest U.S. assembly plant. Constructed in 1999. Location. 920 Townsend Street Lansing, MI 48933 Map . Facility. Year Opened: Assembly - 2001 / Stamping - 2016 Size: 3.4 million sq. ft. on 111 acres Union: UAW Local 652 Social: @MFG_GM, Facebook. What We Do.

Up to 1,300 expected to tour Lansing Grand River Assembly Plant as part of Camaro's 50th anniversary. ... Chevy Camaro fans tour GM Lansing plant. Melissa Burden. The Detroit News.

We leave the adjacent question and answer conference room (Parts 1 & 2)...and head out to the shop to begin to see the Camaro's in various stages of construc...

Production of the 2021 Chevy Camaro has resumed at GM's Lansing Grand River Assembly Plant following a production halt resulting from the chip shortage. ... Take A Detailed Exterior Tour Of The ...

Lansing Camaro Plant. 4,143 likes · 3 talking about this. Facebook Fanpage dedicated to the 6th Gen Camaro being built at LGR. Pictures, sharing, networking and exclusive photos of this awesome plant...

Lansing Grand River Assembly (LGR) is a General Motors owned and operated automobile assembly facility located in Lansing, Michigan, United States.Lansing Grand River Assembly produces vehicles built upon the GM Alpha platform including the Cadillac CT4, Cadillac CT5, and Chevrolet Camaro.. The Lansing Grand River Assembly facility includes a body shop, paint shop, general assembly and central ...

Curt Collins, Chevrolet Performance Manager, continues to lead us through the part storage and second assembly area to see various stages of construction. We...

50th Anniversary Chevrolet Camaro SS features orange trim, including brake calipers. Activities at the assembly plant include a Camaro-only parking area for as many as 500 cars, presentations by Camaro team members including chief engineer Al Oppenheiser, and 45-minute assembly-line tours starting at 7 a.m. and running through 3:30 p.m.

Tonawanda engine plant tour of LT1 and LT4 assembly video 2016+ Camaro: 6th Gen Camaro general forum. You are browsing camaro6. Homepage: Garage: Wiki: Register: Community: Calendar: Today's Posts ... Tonawanda engine plant tour of LT1 and LT4 assembly video User Name: Remember Me? Password Post Reply Thread Tools: 02-27-2015, 06:54 PM ...

Added on April 15, 2015 Aaron Widmar Assembly Plant, Assembly plant tour, car tours, factory, factory tour, Ford assembly plants, Kansas City Assembly Plant, Michigan Assembly Plant, Nissan's ...

The Grand River Assembly Plant produces the Camaro, along with the Cadillac CT4 and CT5. While UAW Local 652 workers returned to work on the Camaro on Monday, ...

The First-Generation Camaro Assembly Process. Author - John Hinckley. Reviewed by the CRG Last Edit: 17-Feb-2024 ... exactly how a car was built in a typical GM assembly plant in this time frame, including any significant differences in the process between the Van Nuys and Norwood assembly plants. The detail discussion will focus on the 1969 ...

Chevy Camaros for the US market were produced in the US until 1992, when production moved to Quebec, Canada. The assembly plant for the Chevy Camaro remained in Canada for over a decade until the sixth generation launched in 2015. In 2015, production moved to the Lansing Grand River Assembly, Lansing, Michigan.

Expand user menu Open settings menu. Log In / Sign Up

The 2019 Camaro is produced at the GM Lansing Grand River assembly plant located in Lansing, Michigan, USA. The Lansing Grand River plant is the only facility in the world that produces the Camaro ...

It was the very last car assembled in the birthplace of the "F" car-the Norwood GM Assembly Plant. This red IROC-Z is a fitting end to Ohio "F" Body production from 1967-1987, meaning this car shares an unbroken production linage with the first 1967 Camaro, the great Z/28's the SS cars, 427 COPO's and the ZL-1.

Production of the 2022 Chevy Camaro was originally set to begin Monday, June 14 th, but that date was later pushed back. Updates and changes over the 2021 model year include the addition of two ...

Plant tours? 2016+ Camaro: 6th Gen Camaro general forum