- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

- Slip, Trip, and Fall Hazards Listed

- Clarifying OSHA Standards

- Prevent Workplace Slips, Trips, and Falls

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace . This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

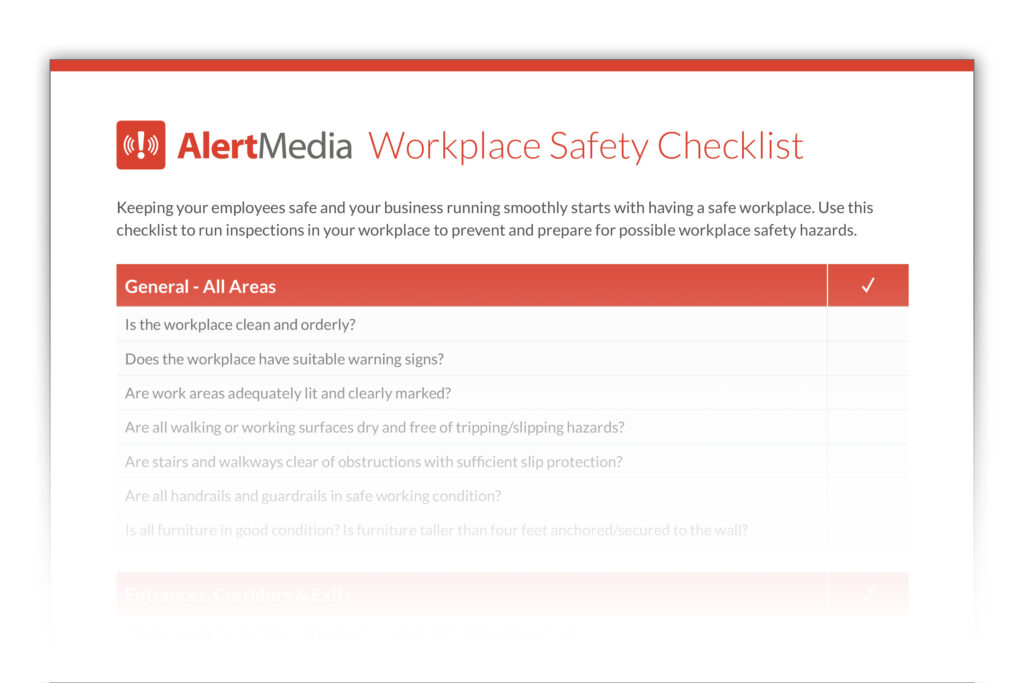

Download Our Workplace Safety Checklist

What are slip, trip, and fall hazards in the workplace.

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations .

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training , so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.

More Articles You May Be Interested In

Workplace Safety Checklist

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

- Skip to main content

- Skip to site information

- Departments

Language selection

- Français

Scheduled maintenance - Thursday, July 12 at 5:00 PM EDT

We expect this update to take about an hour. Access to this website will be unavailable during this time.

Prevention of Slips, Trips and Falls

On this page, how do falls happen, how to prevent falls due to slips and trips, what can you do to avoid falling at work.

Statistics show that the majority (67%) of falls happen on the same level resulting from slips and trips. The remaining 30% are falls from a height. This document will summarize information on "falls on the same level" (slips and trips). Falls from an elevation, such as falls from ladders, roofs, down stairs or from jumping to a lower level, etc., is discussed in other documents since each type of fall must be assessed as part of a fall prevention program .

Slips happen where there is too little friction or traction between the footwear and the walking surface. Common causes of slips are:

- wet or oily surfaces

- occasional spills

- weather hazards

- loose, unanchored rugs or mats

- flooring or other walking surfaces that do not have the same degree of traction in all areas

Trips happen when your foot collides (strikes, hits) an object causing you to lose balance and, eventually fall. Common causes of tripping are:

- obstructed view

- poor lighting

- clutter in your way

- wrinkled carpeting

- uncovered cables

- bottom drawers not being closed

- uneven (steps, thresholds) walking surfaces

Both slips and trips result from unintended or unexpected change in the contact between the feet and the ground or walking surface. This fact shows that good housekeeping, quality of walking surfaces (flooring), selection of proper footwear, and appropriate pace of walking are critical for preventing fall incidents.

Housekeeping

Good housekeeping is the first and the most important (fundamental) level of preventing falls due to slips and trips. It includes:

- cleaning all spills immediately

- marking spills and wet areas

- mopping or sweeping debris from floors

- removing obstacles from walkways and always keeping walkways free of clutter

- securing (tacking, taping, etc.) mats, rugs and carpets that do not lay flat

- always closing file cabinet or storage drawers

- covering cables that cross walkways

- keeping working areas and walkways well lit

- replacing used light bulbs and faulty switches

Without good housekeeping practices, any other preventive measures such as installation of sophisticated flooring, specialty footwear or training on techniques of walking and safe falling will never be fully effective.

For more information about effective housekeeping, visit the OSH Answers document on Workplace Housekeeping - Basic Guide .

Changing or modifying walking surfaces is the next level of preventing slip and trips. Recoating or replacing floors, installing mats, pressure-sensitive abrasive strips or abrasive-filled paint-on coating and metal or synthetic decking can further improve safety and reduce the risk of falling. However, it is critical to remember that high-tech flooring requires good housekeeping as much as any other flooring. In addition, resilient, non-slippery flooring prevents or reduces foot fatigue and contributes to slip-prevention measures.

In workplaces where floors may be oily or wet or where workers spend considerable time outdoors, prevention of fall incidents should focus on selecting proper footwear. Since there is no footwear with anti-slip properties for every condition, consultation with manufacturers is highly recommended.

Properly fitting footwear increases comfort and prevents fatigue which, in turn, improves safety for the employee. For more information on footwear visit the OSH Answers document on Safety Footwear .

You can reduce the risk of slipping on wet flooring by:

- taking your time and paying attention to where you are going

- adjusting your stride to a pace that is suitable for the walking surface and the tasks you are doing

- walking with the feet pointed slightly outward

- making wide turns at corners

You can reduce the risk of tripping by:

- keeping walking areas clear from clutter or obstructions

- keeping flooring in good condition

- always using installed light sources that provide sufficient light for your tasks

- using a flashlight if you enter a dark room where there is no light

- making sure that things you are carrying or pushing do not prevent you from seeing any obstructions, spills, etc.

- Fact sheet last revised: 2023-03-28

Healthy, safe and productive lives and enterprises

- Accident and Dangerous Occurrence Reporting

- Accreditation

- Introduction

- Justification

- Irish Legislation, EU Directives & Standards

- Delivery Guide

- Design-Construction-Handover

- Functional Safety

- EPD Guidance

- International/European Committees

- National Projects

- Useful Links

- Useful Tools

- ATEX Regulations - Frequently Asked Questions

- What are Biological Agents?

- Classification of Biological Agents

- Biological Agents Frequently Asked Questions

- Good Occupational Hygiene

- Disinfectants

- Vaccination - Frequently Asked Questions

- Transporting Biological Agents

- Biological Agents and Reproductive Health

- Relevant Legislation

- Code of Practice

- Notification

- Accident, Incident and Disease Reporting

- Avian Influenza

- Blood Borne Viruses

- SARS-CoV-2 and COVID-19

- Legionellosis

- Leptospirosis

- Lyme Disease

- Tuberculosis

- Microbiological Safety Cabinets

- Health Surveillance

- Occupational Exposure Lists

- Personal Protective Equipment

- Useful Resources

- Brexit and Access of Products to the EU Market

- Chemicals Export / Import Regulation

- Market Surveillance – Industrial Products

- Selling Goods on the EU Single Market after Brexit

- Transportable Pressure Equipment

- Further information

- Employer Policy

- Are You Being Bullied

- Codes of Practice

- Bullying Employer Perspective

- Bullying Employee Perspective

- Accident/Incident Reporting

- ADR and TPED

- Biological Agents

- Construction

- Other Licensing Agencies

- All Notification Forms

- Classification and Labelling

- Confined Spaces

- Consultation

- Display Screen Equipment

- Managing Safety in Schools

- Teacher Support and Resources

- Teacher Training

- Initiatives in Education

- Electrical Fatality Statistics

- Electricity in the Workplace

- Overhead Power Lines

- Underground Cables

- Video - Dangers from Power Lines on Farms

- Role of the Commission for Regulation of Utilities

- HSA & Other Organisations

- IS 10101 National Rules for Electrical Installation

- Works Needing Certification

- Employees Duties

- Fire Detection and Warning

- Emergency Escape and Fire Fighting

- Fire Prevention

- First Aid Frequently Asked Questions

- Electricity

- Pedestrian safety

- Manual Handling Hazards

Slips, Trips and Falls

- Working at Height

- Lone Workers

- Myth 1: Inspections and Fines

- Myth 2: Health and Safety is Expensive

- Myth 3: Red Tape Hindering Business

- Myth 4: Manual Handling Training

- Myth 5: Everything Banned

- Horticulture

- Human Factors

- Illness Reports

- HSA Inspections

- Recording Inspections

- What to Expect When the Inspector Calls

- Actions of Inspectors

- Powers of Inspectors

- Workplace Fatalities

- The Appeals Process

- Prosecutions 2018

- Prosecutions 2017

- Prosecutions 2016

- Prosecutions 2015

- Prosecutions 2014

- Prosecutions 2013

- Prosecutions 2012

- Prosecutions 2011

- Prosecutions 2010

- Prosecutions 2009

- Prosecutions 2008

- Prosecutions 2007

- On Indictment

- Liquid Petroleum Gas (LPG)

- Safety, Health and Welfare at Work Act 2005

- Safety and Health Management Systems

- Safety Representatives and Consultation

- Safety Statement and Risk Assessment

- Manual Handling Guidance Documents

- Manual Handling Case Study Video Series 1

- Manual Handling Case Study Video Series 2

- Manual Handling FAQ's

- Manual Handling Research reports

- Selling Goods on the EU Single Market

- Joint Market Surveillance Action on HARmonised Products 2021 Omnibus (JAHARP2021 Omnibus)

- Motor Factors

- Respiratory Protective Equipment

- Noise at Work

- Noise - Frequently Asked Questions

- Safe Maintenance - Reducing Noise

- Health Surveillance – Noise

- Vibration at Work

- HAV Risk Assessment

- Optical Radiation at Work

- Electromagnetic Fields

- Agency Roles

- Posted Workers

- Prosecutions

- Public Consultation

- Remote Working

- Safety Alerts

- Frequently Asked Questions

- Safety Signs

- General Simple Safety

- Simple Safety in Food and Drink

- Simple Safety in Retailing

- Simple Safety in other Languages

- STF Online Courses

- Further Information

- Mapping Hazards

- Stairs and Steps

- Slippery Surfaces

- Identify Risks

- Measuring Slip Resistance

- Selecting Surfaces

- Information with Flooring

- Metal and Profiled Surfaces

- Communicate

- Housekeeping

Shoes, Footwear

- Communication

- Sample Risk Assessment

Over-used Signs

- Fatal Injury

- Non-Fatal Injury and Illness

- Agriculture, Forestry and Fishing

- Mining and Quarrying

- Manufacturing

- Electricity; Gas, Steam and Air Conditioning Supply

- Water Supply, Sewerage, Waste Management and Remediation Activities

- Wholesale and Retail Trade; Repair of Motor Vehicles and Personal Goods

- Transportation and Storage

- Accommodation and Food Service Activities

- Information and Communication

- Financial and Insurance Activities

- Real Estate Activities

- Professional, Scientific and Technical Activities

- Administrative and Support Service Activities

- Public Administration and Defence; Compulsory Social Security

- Human Health and Social Work Activities

- Arts, Entertainment and Recreation

- Other Service Activities

- Annual Review of Workplace Injury, Illness and Fatality Statistics

- Other Statistical Reports

- European Statistics on Accidents at Work

- CSO Labour Force Survey Data

- Sun Protection

- Ventilation

- Guidance on Managing the Risk of Work-Related Violence and Aggression

- Overview / Introduction

- Risk Assessment

- What We See

- Control Measures for Workplace Violence and Aggression

- Reporting of Incidents and Legislative Requirements

- Additional Information

- Vulnerable Workers

- Welfare Payments

- Winter Readiness

- Work at Height

- Work Positive Project 2008/2009

- Work Positive Project 2005-2007

- Stress in the Workplace

- Legal Requirements

- Work Related Vehicle Statistics

- Vehicle Risks

- Forklift Trucks

- Transport of Dangerous Goods by Road (ADR)

- Managing Health and Safety

- Liabilities of Directors

- Protecting your Workplace's Reputation and Assets

- Benefits of Creating a Positive Safety Culture

- Organising Safety and Health in your Workplace

- Safety and Health Monitoring

- Roles and Responsibilities for Directors

- Precautions & Risk Assessment

- Legislation & Enforcement

- Agriculture Code of Practice

- Online Risk Assessment FAQs

- Updated Agriculture Safety Videos

- Farm Safety Partnership Advisory Committee

- ATVs / Quad Bikes

- Guidance on the Safe Handling of Cattle on Farms

- Safe Handling of Cattle on Farms Information Sheet

- Cattle Handling in Marts and Lairages

- Children's Book 'Stay Safe on the Farm with Jessy'

- Farm Safety During Lambing

- Sábháilteacht Feirme le linn Breith Uain

- Farm Safety During Calving

- Sábháilteacht Feirme le linn Breith Lao

- Using Petrol Driven Chainsaws

- Chainsaw Felling of Large trees

- Selecting & Monitoring of Contractors

- Mechanical Harvesting

- Extraction by Forwarders

- Electricity at Work

- Chainsaw Snedding

- Cross Cutting & Manual Stacking

- Chainsaw Clearance of Windblow

- Felling & Manual Takedown

- Chainsaw Safety Training Advice

- Forest Owners & Managers who intend to fell trees - Info Sheet

- Code of Practice for Managing Safety & Health in Forestry Operations

- Child Tractor Safety

- Farmers over 65 Years

- Falls & Collapses

- Farmer Health

- Fire Electricity & Chemicals

- Manual Handling Slips & Trips

- Timber Work

- Video Index

- Online Farm Safety Course

- FarmFamilyCPD.ie

- Hospitality General

- Leisure Areas

- Larger Machinery

- Simple Safety

- Role Finder Tool

- Chemicals A-Z

- BeSmart Risk Assessment Tool

- Chemicals Act Guidance

- ECHA Guidance & FAQs

- ECHA Website

- ECHA Webinars

- E-Bulletin Archive

- Helpdesk Information

- Pesticides Control

- Poison Centre

- ADR - Carriage of Dangerous Goods by Road

- What is Asbestos

- Asbestos Surveys

- Latest News

- Safety Alert

- Asbestos FAQs

- Asbestos risks in safes and fire resistant cabinets

- E-Learning Course

- Asbestos Legislation

- Restrictions and Exemptions

- Guidance Document

- Asbestos Removal

- Analysts and Laboratories

- Asbestos Notifications

- Asbestos Waivers

- Other Agencies with Responsibility for Asbestos

- The Chemicals Act

- What are Chemicals Agents?

- What are Carcinogens, Mutagens and Reprotoxic Substances ?

- Hazardous Medicinal Products (HMPs)

- Roadmap on Carcinogens

- REACH Restriction

- Information for Suppliers and Retailers

- Training Requirements

- Posters (Available in Several Languages)

- Health Surveillance and Monitoring

- Introduction to Welding

- Welding Risk Assessment

- Case Studies

- Chemical Agents Legislation

- Carcinogens, Mutagens and Reprotoxic Substances Legislation

- Chemical Weapons

- Classification

- Introductory Guidance on the CLP Regulation

- CLP Regulation (EC) No 1272/2008

- Understanding CLP

- Publications and Guidelines

- External Resources

- Health Hazards

- Environmental Hazards

- Notification to NPIC

- Notification to the C&L Inventory

- Roles and Duties

- Introduction to COMAH

- Legislation

- Inspections

- Useful Links on Major Accidents

- Notifications

- MAPP and Safety Management

- Safety Report

- Timelines for Submission of COMAH Documentation

- Significant Modifications

- Reporting COMAH Accidents

- Information to the Public Overview

- List of all Establishments by Tier

- Lower Tier Establishments by County

- Upper Tier Establishments by County

- Objectives of Emergency Plans

- Testing and Review of Emergency Plans

- Local Competent Authority Annual Report

- Internal Emergency Planning

- External Emergency Planning

- Role of the HSA in Land-use Planning

- Consultation Distance

- Societal Risk

- Request for Technical Advice

- HSA Approach to Land Use Planning

- COMAH Regulations 2015

- Guidance on Technical Land-use Planning Advice

- MAPP Guidance for Lower Tier Operators

- Intermediate Temporary Storage

- LCA Annual Report on Activities

- Electronic Notification

- Request for TLUP Advice

- Schedule 7 Notifiable Incident

- LCA Annual Report of Activities

- MAPP Assessment form for Lower Tier Establishments

- News Updates

- What are Detergents

- Detergent Regulations

- Detergent Labelling & Packaging requirements

- Using and Storing Detergents

- Ingredient Data Sheets

- Liquid Laundry Detergent Capsules

- Biocidal detergent products

- EU Derogation for Surfactants

- EU Chemicals Strategy for Sustainability Conference 2023

- DNAs in Ireland

- Obligations of EU Exporters

- Obligations of EU Importers

- Chemicals Subject to Export/Import Notification

- The Role of the Authority

- Nanomaterials

- Roles and duties under REACH

- SVHCs and Authorisation

- How does a chemical get onto Annex XVII of REACH

- Annex XVII Updates of REACH

- Information in the Supply Chain

- Notification of Substances in Articles

- The registration process

- Only representative

- Duty to inquire

- Downstream users

- Questions and Answers

- EU enforcement projects to check poison centre notifications & online sales

- New CLP hazard classes will be included in IUCLID

- European Commission adopts criteria for essential uses of harmful chemicals

- HSA Inspectors checking compliance of imported chemicals as part of an EU wide REACH enforcement project

- HSA finds high non-compliance rate for scented products for sale on Irish market

- Have Your Say - ECHA seeks comments on proposals to identify 2 more chemicals as substances of very high concern under REACH

- ECHA provides advice on new hazard classes for substances and mixtures

- PFAS restriction proposal

- New obligations for sale of Diisocyanate products from 24th August 2023

- HSA information sheet on regulatory obligations of EU candle and reed diffuser producers

- Selling chemical products online

- Poison Centre Notification

- Obligations for producers of candles/diffusers

- Safety Data Sheets

- Keep your registration up to date

- Chemical Risk Assessment

- Read the back

- REACH Authorisation List

- REACH Candidate List

- Paint containing MEKO

- Candles and reed diffusers containing LILIAL

- ECHA & EU Consultations

- HSA Consultations

- Project Supervisor Design Process (PSDP)

- Project Supervisor Construction Stage (PSCS)

- Contractors

- Create a Site Specific Safety Statement

- Create a Construction Stage Safety and Health Plan

- Risk Assessment Method Statement (RAMS) Template and Guidance

- Create a Construction Site Traffic Management Plan

- Information for Employees

- Other Useful Resources

- hsalearning.ie for Construction

- Construction Skills Certification Scheme (CSCS)

- Duties as a Designer

- Good Design Practice

- Construction Site Traffic Management Plan

- Safe use of Dumpers

- The Lighthouse Club

- Construction Workers Health Trust

- CAIRDE On Site. In Mind.

- Construction Safety Partnership Advisory Committee

- Construction Regulations Amendment 2019

- Auxiliary Devices

- Safety File

- Excavations

- Diving at Work

- Hiring Diving Contractors

- Diving Methods

- Dive Team Size

- Diving Training

- Compression Chambers

- Emergency Equipment

- Diving Medicals

- Fitness to Dive

- Mutual Recognition

- Diving and Pregnancy

- Reporting Accidents and Dangerous Occurrences

- Underwater Heritage Orders

- Health and Safety Management

- Emergency Plans

- Docks Code of Practice

- Common Hazards

- Container Terminals

- Dry Bulk Terminals

- Roll On Roll Off (Ro-Ro) Terminals

- Useful Websites & Publications

- Legislation and Enforcement

- Who's Who in Fishing Safety

- Maritime Legislation

- The Sea Fishing Sector

- Top 10 Tips

- Management of Health and Safety

- Emergency Contacts

- The Safety Statement

- Safe Systems of Work

- Instruction, Training and Supervision

- Injuries and Ill Health

- Slips and Trips

- Manual Handling

- Dangerous Chemicals

- Instability

- Publications and Useful Websites

- Lifejackets

- Regulations

- Information and Guidance

- The Health and Social Care Sector

- Health and Social Care Regulators

- Health and Social Care Illness and Injury Statistics

- Sharps Directive and Regulations

- Healthcare Waste

- Specific Biological Agents

- Chemical Agents

- Electricity and Healthcare

- Musculoskeletal Disorders

- Slips Trips and Falls in Healthcare

- Work Related Stress

- Violence and Aggression

- Work Equipment

- Emergency Department

- Ambulance Services

- Outpatients

- Stores / Warehouse

- Technical Services

- Maintenance Workshop

- Lounge / Activity Room

- Sluice Room

- Garden / Grounds

- Nurse's Station

- Hallway / Corridor

- Mining Legislation and Notifications

- Promotional Activities

- Disused Mines and Shafts

- Mines Rescue

- Mining in Ireland

- Mining Techniques Used in Ireland

- Managing for Health and Safety

- Health and Safety in Education Sector

- Heath and Safety in Healthcare Sector

- Health and Safety in Central Government

- Health and Safety in Local Government

- HSALearning

- Healthy Ireland

- State Claims Agency

- Chemical Exposure

- Dust Including Silica Dust

- Noise in Quarries

- Whole Body Vibration

- Muscoskeletal injury

- Quarry Accident and Inspection Statistics

- What to Expect from an Inspection

- HSA Quarry Sector Resources

- Safe Quarry Guidance

- Statutory Notifications

- Quarries Legislation and Guidance

- Quarry Workers Guide

- Other Quarry Industry Groups

- Publications and Videos

- Quarry Safety Week

- All Island Seminar 2018 Exhibitors Info

- All Island Seminar 2018 Delegates

- Vehicle Access

- Driver Selection and Training

- Construction of Haul Roads

- Reversing and One-way Systems

- Selection of Equipment

- Inspection of the Working Face

- Significant Hazards

- Overburden Stripping

- Trespass, Boundary Fencing and Prevention of Drowning

- Drilling of Shotholes

- Danger Zones

- Disposal of Surplus Explosives

- Blast Specification

- Duties of Shotfirer

- Face Profiling and Drill Hole Logging

- Edge Protection during drilling and loading

- Management of Lagoons and settling ponds

- Management of Tips and Stockpiles

- Inspection, Appraisal and Geotechnical assessment

- Asphalt Plant Safety

- Machinery and Conveyor Initiative 2020

- Work Permits and Isolation of Equipment

- Tyre Changing and Repair

- Workshop Safety

- Maintenance Work at Height

- Guarding Return Idler Rollers

- Mobile Crushing and Sizing

- Conveyor Guarding and stops - pull wires

- Clearing Blocked Crushers

- Batching Concrete, Block and Asphalt Plants

- Renewable Energy

- Taking Care of Business

- Getting Started

- Safety Statement

- Recommended Publications

- Micro Business

- Vehicle Incident Trends

- Work Related Vehicle Safety

- Workplace Transport Safety

- Working on or near a road

- Driving for work

- Vehicle Maintenance

- Chemical Agents and Carcinogens

- Information to the Public

- Export / Import

- Nanotechnology

- Chemicals Acts 2008 and 2010

- Chemical Weapons Act 1997

- Organisation of Working Time Act 1997

- Safety Health and Welfare (Offshore Installations) Act 1987

- Safety in Industry Act 1980

- Dangerous Substances Act 1972

- European Communities Act 1972

- Factories Act 1955

- Code of Practice for the Chemical Agents Regulations

- Code of Practice for Preventing Injury and Ill health in Agriculture

- Farm Safety Code of Practice - Risk Assessment document

- Code of Practice for the Design and Installation of Anchors

- Code of Practice for Working in Confined Spaces

- Working on Roads Code of Practice - for contractors with three or less employees

- Code of Practice for Avoiding Danger from Underground Services

- Code of Practice for Safety in Roofwork

- Code Of Practice for Biological Agents

- More Codes of Practice

- Online Complaint Form

- Agriculture

- Chemical and Hazardous Substances

- Docks and Ports

- General Application Regulations

- Health and Social Care Sector

- Information Sheets

- Latest Publications

- Machinery and Work Equipment

- Manual Handling and Musculoskeletal Disorders

- Mines and Quarries

- Occupational Health

- Physical Agents

- Research Publications

- Safe System of Work Plan (SSWP)

- Safety and Health Management

- Slips Trips and Falls

- Work Related Vehicles

- EU Weekly RAPEX Alerts

- The Benefits

- Risk Assessments Made Easy

- Safety Statements Made Simple

- hsalearning.ie

- Work Positive

- Publications, Top Tips and Videos

- Workplace Health Toolkit for Businesses

- Simple Safety Series

- Safety Representatives

- New Publications and Resources

- Resources in Different Languages

- Post-Primary Guidelines

- Post-Primary Guidelines - Safety Statement Checklist Word Documents

- Post-Primary Guidelines - Safety Statement Checklist PDFs

- Post-Primary Guidelines - Part B - FAQs

- Post-Primary Guidelines - Part C - Risk Assessment Templates

- Primary Schools Guidelines - Short Guide

- Primary Schools Guidelines

- Video on Primary School Guidelines

- Interactive Risk Assessments – Primary

- Treoirlínte ar Bhainistiú Sábháilteachta, Sláinte agus Leasa i mBunscoileanna

- Treoirlínte maidir le Bainistiú Sábháilteachta, Sláinte agus Leasa in Iar-Bhunscoileanna

- 'What's Under the Sink?' Household Chemicals SPHE Presentation – Primary students

- 'What's Under the Sink?' – Primary teacher guidelines

- Farm Safety Presentation - Primary teachers

- On the Farm Videos - Primary students

- Choose Safety / Get Safe Work Safe - Transition Year teachers / students

- Choose Safety – Post Primary / Further Education

- Keep Safe on the Farm – Post Primary students

- Graduate.ie – Post Primary students

- Roghnaigh an tSábháilteacht

- Post Primary

- Choose Safety

- Courses for Apprentices on hsalearning

- Workplace Health and Safety Induction hsalearning course

- Get Safe Work Safe hsalearning course

- Mainstreaming

- Only a Giant can Lift a Bull

- Too Cold for Sharks

- Health and Safety Training Providers

- Online Course for Schools

- Online Courses for Students

- Your Safety, Health and Welfare in Healthcare - Online Course

- Online Course Information Leaflets

- Safety, Health and Welfare Induction

- New Resources

- Translated Resources

- Work Related Vehicles Safety Program Plan and Priorities for 2016-2018

- Public Consultation on new Code of Practice - Safe Industrial Truck Operation

- Vehicle Related Accident Trends

- Falls from Vehicles

- Vehicle Overturns

- How to Manage Work Related Road Risks

- Online Vehicle Risk Management Resource (EU Commission)

- Winter Driving Tips

- Grey Fleet Driver Declaration Form

- Managing Grey Fleet Information Sheet

- HSA and UCD joint webinar on Work Related Road Fatalities

- Employer Responsibilities

- Online Course

- Driver Health

- Driver Handbook

- Road Safety Law

- Managing Your Employees

- How to Manage Driving for Work

- Evaluating Road Safety Risks Movie

- Benefits for the Community

- Vehicle Safety Pre-Checks

- Vehicle Risk Management Business Case Studies

- New Guidance – Safe and Efficient Goods Reception for Road Freight

- Managing Workplace Priority Risks

- Workplace Transport E-Learning Courses

- Managing Pedestrians at Work

- Warehousing Safety

- Guidance and Publications

- Load Securing Videos

- Working on Roads Guidelines

- Safety in Road Work Zones - PRAISE Report 2011

- Guidance and Information

- Transport & Storage Sector Incident Trends

- Behaviour Based Safety Guide Part 1

- Behaviour Based Safety Guide Part 2

- Top Ten Tips for Behavioual Safety - Factsheet

- Are you being Bullied ?

- Bullying - Employer Perspective

- Bullying - Employee Perspective

- Ergonomic Risk Assessment Tools

- Manual Handling Videos Series 1

- Manual Handling Videos Series 2

- BeSMART Videos

- Miscellaneous Videos

- Infographics

- Display Screen Equipment FAQs

- Manual Handling FAQs

- Manual Handling Training System FAQs

- Other Links

- Further Reading and Information

- Occupational Dermatitis Frequently Asked Questions

- Occupational Asthma Frequently Asked Questions

- Pregnant at Work Frequently Asked Questions

- Workplace Stress (AKA Work-Related Stress)

- The Role of the HSA

- What is WorkPositiveCI

- What Workplace Stressors does WorkPositiveCI Measure

- How to Implement WorkPositiveCI in your Workplace

- Guidance - Work-related Stress a Guide for Employers

- Guidance - Work-related Stress Information Sheet for Employees

- Managing Psychosocial Hazards in the Workplace Information Sheet

- Healthcare - Work-related Stress Webpage

- Homeworking - Managing Stress whilst Working from Home

- Podcast - Questions and Answers on Stress and Bullying at Work

- HSE (UK) Management Standards on Work-related Stress

- Job Stress and Working Conditions Report (2019) ERSI

- Healthcare - Work Related Stress Mental Health Promotion in the Healthcare Sector (EU OHSA)

- Practical Advice for Workers on Tackling Work-Related Stress and its Causes (EU OSHA)

- Critical Incident Stress Management Network Ireland

- Grade III Inspector – Dublin

- Board Vacancies

- General Information for Applicants

- Working with the HSA

- Recruitment Policy

- About the HSA

- Social Media

- Webinar Recordings

- Previous Events

- Workers' Memorial Day

- Press Releases 2024

- Media Queries

- Newsletters & Bulletins

- Focal Point Network

- European Healthy Workplaces Campaign 2023-2025

- European Healthy Workplaces Campaign 2020-2022

- European Healthy Workplaces Campaign 2018-2019

- European Healthy Workplaces Campaign 2016-2017

- European Union Senior Labour Inspectors Committee (SLIC)

- HSA on Facebook

- HSA on YouTube

- HSA on LinkedIn

- HSA on Twitter

- Press Releases 2023

- Press Releases 2022

- Press Releases 2021

- Press Releases 2020

- Press Releases 2019

- Press Releases 2018

- Press Releases 2017

- Press Releases 2016

- Press Releases 2015

- Press Releases 2014

- Press Releases 2013

- Media Campaigns

- Board Member Profiles

- Organisational Structure

- Vision, Mission and Mandate

- Strategic Priorities

- Prompt Payment Details

- Purchase Orders in Excess of €20,000

- Financial Statements and Reports

- Why Contact the HSA Contact Centre

- HSA Contact Centre Service Levels

- Make a Complaint

- Protected Disclosures Annual Report

- HSA Contact Centre

- Protected Disclosures

Please Note

Our website uses cookies to enhance your browsing experience and to collect information about how you use this site to improve our service to you. By not accepting cookies some elements of the site, such as video, will not work. Please visit our Cookie Policy page for more information on how we use cookies.

- News, Events & Media

- Customer Service

- RSS News Feed

- Follow HSA on Twitter

- Subscribe to our newsletter

- Bullying at Work

- Business Licensing and Notification Requirements

- Health and Safety Myths

- Market Surveillance

- Personal Protective Equipment - PPE

- Slips Trips Falls

- Workplace Stress

- Work Safely

- Agriculture & Forestry

- Catering and Hospitality

- Flammable liquids and Fuels Retail Stores - NEW

- Public Sector

- Small Business

- Publications

- Employer and Employee Supports

- New Publications and Translated Resources

- Managing Safety and Health in Schools

- Teacher Support And Classroom / Student Resources

- Safety and Health Initiatives in Education

- Health and Safety Courses Online

- Driving for Work

- Load Securing

- Working On or Near a Road

- Transport and Storage

- Accidents and Behaviour

- Manual Handling & Display Screen Equipment

- Occupational Asthma and Dermatitis

- Sensitive Risk Groups

Every working day seven people are hurt in work slips, trips and falls (STF)

- See a systematic approach to Slip Risk Assessment and Prevention

- See our online training on Slips, Trips and Falls and Safer Stairs and Steps

- See our Information Sheets on Preventing Work STF , Safer Work Stairs and Steps , Preventing Vehicles STF and Choosing Slip-resistant Footwear

- See our internet sections on STF Info , High-risk Areas , Spills , Pedestrian Surfaces , Environmental Cleanliness , Footwear , Ice and Over-used Signs

Submission completed, thank you!

Slips trips falls info, high-risk areas.

Pedestrian Surfaces

Environmental cleanliness.

- Floor Wet Cleaning

Snow and Ice

Subscribe to hsa publications, subscribe to hsa chemicals publications.

Facility slip hazard solutions

How can i maintain safety and sure footing in a messy, manufacturing environment with an abundance of slip/fall factors such as oil mist from machining or air tools, hydraulic fluids, etc..

Responding is Tim Brennan, sales and marketing manager, Wooster , Wooster, OH.

Manufacturing plants can be messy places.

Hydraulic fluids that allow machinery to function properly can leak onto floors, be tracked through the facility on shoes (regardless of how vigorously they’re wiped) and then transported to other surfaces, creating potential slip/fall incidents. Oil mist, which is pervasive in factories, poses similar problems.

Couple this with the fact that some machinery requires operators to step up to access maintenance or operational areas, and safety can quickly be compromised. Anti-slip stair treads and nosings are a simple and inexpensive way to resolve this problem. Treads typically cover much of the step surface, while nosings cover the front third, but aside from that the construction is the same. These products are often applied on stairwells and landings but can also be installed on machinery steps to enhance safety and create a more sure-footed environment.

A heat-treated, corrosion-resistant aluminum base is filled with diamond-hard aluminum oxide filler that provides a high coefficient of friction for sure footing, even when wet. The filler should include a minimum of 65% virgin aluminum oxide to attain the desired coefficient of friction and anti-slip properties desired, as well as long service life. The higher the coefficient or friction, the more “stickiness” of the surface and less slippage potential.

Many manufacturers offer contrasting colors to draw attention to the leading edge of the nosing or tread. Photoluminescent or glow-in-the-dark technology is also available to light the way in the event of a power outage. This should be strongly considered for egress pathways (and is part of the building code for new structures more than seven stories tall). Renovation treads and nosings are available in varying widths to suit the project at hand and can be cut to length at the factory to simplify installation. Safety treads include a mill finish extruded aluminum base, with a beveled edge, and countersunk holes as standard. Anchors available include Tapcon screws, wood screws, machine screws or expansion screws. Using the desired anchors, the treads or nosings are fastened in place, allowing fast and easy installation over existing surfaces, such as diamond plate, mesh, wood, metal and concrete. Once installed, the project is complete. The surface now boasts a much higher coefficient of friction, which enhances its non-slip properties, regardless of the condition of the manufacturing environment. Service life of the anti-slip nosings and treads will vary depending on traffic pattern and use.

Care should be taken to ensure the non-slip surfaces are clean, especially when using contrasting colors for the leading edge. They’re easily cleaned with common household cleaners/degreasers, although a small section should be cleaned first to ensure colorfastness of the surface. Manufacturer warranties vary but typically are five years.

Machinery surfaces that don’t lend themselves to the installation of treads can benefit from the application of non-slip tape. Available in multiple widths, colors and coarseness, and as die-cut shapes, non-slip tape provides a simple and cost-effective solution to improving safety when treads and nosings can’t be used. Care must be taken to thoroughly clean the surface before application, as any residual oil or debris will impede the tape from sticking and cause premature peeling.

Manufacturing is often a messy process, but it doesn’t have to be an unsafe one, thanks to the non-slip products available.

Editor's note: This article represents the independent views of the author and should not be considered a National Safety Council endorsement.

Related Articles

Anti-slip coating, post a comment to this article.

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)

Report Abusive Comment

Find Info For

- Current Students

- Prospective Students

- Research and Partnerships

- Entrepreneurship and Commercialization

Quick Links

- Laboratory Safety

- Researcher's Guide

- Employee Safety

- Building Safety

- Waste Management

- Compliance Programs

- Staff Listing

- Customer Service Phone Number

- environmental-concerns

- Slips, Trips, and Falls

Standard for Testing Hard Surface Flooring

REPORT HAZARDOUS GROUND or FLOOR CONDITIONS

Slips, trips, and falls are the leading cause of occupational injuries at Purdue University. Minimize the number of slip, trip, and fall occupational injuries at Purdue! Call (765) 494-3087 to report exact location inside or outside of any building on the Purdue campus that may cause a slip, trip, or fall.

Did you know that surface conditions are the biggest contributing factor to slip, trip, and fall injuries?

- Indoor Air Quality

- Indoor Water Quality

Campus Safety Contacts

If you see something, say something.

Purdue Police Phone: (765) 494-8221

Purdue Fire Phone: (765) 494-6919

REPORT A SAFETY CONCERN

Sign up for Emergency Text Messages

Do you want to recognize one of our staff for a job well done? Nominate the staff member(s) for a Bravo Award here !

Communication

- OneCampus Portal

- Brightspace

- BoilerConnect

- Faculty and Staff

- Human Resources

- Colleges and Schools

- Purdue Police

- Purdue Fire

- Fire Protection Engineering and Special Services

- Environmental Health and Safety

- Environmental Health and Safety Regulatory Compliance

- Campus Emergency Preparedness Office

Purdue University, 610 Purdue Mall, West Lafayette, IN, 47907, 765-494-4600

© 2019 Purdue University | An equal access/equal opportunity university | Integrity Statement | Copyright Complaints | Brand Toolkit | Maintained by Administrative Operations

Contact Administrative Operations for accessibility issues with this page | Accessibility Resources | Contact Us

Understanding OSHA Regulations for Trip and Fall Hazards in the Workplace

Workplace safety isn’t just a good idea-it’s the law. In industries where the risk of trip and fall hazards is substantial, strict regulations exist to safeguard employees.

The fines for non-compliance can be hefty, but more importantly, adherence to these rules saves lives and prevents injuries. Below are the key OSHA-mandated practices your organization needs to have in place to prevent falls and protect your team.

Table of Contents

Uneven Surfaces

Spills and clutter, poor lighting, improper footwear, fines and penalties, worker’s compensation, productivity loss, routine hazard assessments, barrier installation, safety training, maintenance protocols, immediate response, medical referral, incident investigation, understanding your rights, filing a claim, maximum settlements, reputation and experience, local expertise, client testimonials, proactive prevention, follow this guide to adhere to osha regulations for trip and fall hazards in your workplace, identifying common hazards.

The first step to a safer workplace is to carefully find potential hazards. Below are some of the most frequently encountered dangers:

Hazards, like cracked sidewalks, uneven floors, and loose tiles, can easily cause trips. They can trip even the most cautious employees. Proactively identifying and promptly repairing these surfaces is crucial for preventing accidents.

Spills in the break room and unattended boxes in hallways are commonplace. But, they pose significant trip hazards.

These are among the most preventable risks that, surprisingly, occur frequently. Implementing strict cleanliness and storage policies can help mitigate these dangers.

Areas with inadequate lighting can hide hazards that are noticeable in well-lit conditions. Ensuring regular maintenance and conducting thorough lighting audits can help mitigate these risks.

Employees need the right footwear for their jobs. These might be non-slip shoes for wet areas or steel-toed boots for construction sites. Good footwear reduces falls.

The Cost of Negligence

Knowing the cost of workplace accidents can motivate people to follow safety rules and OSHA guidelines. Here are key considerations:

Violations of OSHA standards , especially those related to fall hazards, can lead to hefty fines and penalties. Adherence to these regulations is not only a matter of legal compliance but also a financial imperative to avoid such costs.

Injuries resulting from falls can lead to significant worker’s compensation claims. This creates financial strain on the company’s resources and negatively affecting the bottom line.

The direct costs of accidents are often accompanied by indirect costs such as:

- downtime for investigations

- recovery periods for injured employees

- decline in team morale

All these can adversely affect overall productivity.

Fall Safety Protocols

Following OSHA’s fall safety rules through practical steps can greatly improve workplace safety. Here are some strategies:

Regular walk-throughs and safety inspections are good proactive approaches. They help find and fix hazards before they cause accidents.

Installing safety measures can prevent falls and save lives. They include:

- safety nets

- skylight screens

These measures are installed proactively in areas identified as high-risk.

Offer comprehensive education to employees about the risks associated with their specific roles. They must understand the importance of adhering to safety protocols. This can dramatically reduce the likelihood of accidents.

Develop and maintain a consistent schedule for the repair and upkeep of workplace infrastructure. This is vital in ensuring a safe and hazard-free working environment.

What to Do After an Accident

Preventing falls is crucial, but it’s only one aspect of a comprehensive safety strategy. Equally important are the procedures followed after a fall. These are critical to ensuring employee well-being and meeting legal requirements.

It’s vital that all staff are well-versed in the immediate actions to take following a fall. These steps include:

- securing the area to prevent incidents

- providing first aid if qualified

- reporting the incident to the appropriate personnel

After an accident, providing clear and accessible processes to receive medical help is essential. This not only aids in their recovery but also supports any potential workers’ compensation claims .

Conducting a thorough investigation into the cause of a fall is crucial. It’s not just about fulfilling a legal requirement. It’s an opportunity to uncover and address underlying issues, preventing future incidents.

The Role of Legal Representation

The complexities of navigating the aftermath of a slip-and-fall incident can be overwhelming. This makes legal representation a valuable resource. Here’s why:

A qualified legal team can provide invaluable guidance on your rights after a slip and fall injury. Their expertise ensures that you’re aware of your entitlements and the obligations of your employer.

The process of filing a claim can be daunting, with many legal intricacies. Legal experts can simplify the process, allowing you to focus on your recovery while they handle the legalities.

If a settlement succeeds, legal help is crucial to ensure you get the full slip and fall settlement amounts you’re due. This includes medical expenses and lost wages.

Find a Personal Injury Attorney

Finding the right legal support after an injury is paramount. Here’s how to find a reputable attorney:

Seek out attorneys with a proven track record in personal injury law, especially those with experience in slip and fall cases. Their past successes can give you confidence in their ability to handle your case.

Choosing local attorneys can have significant advantages. They bring a deep understanding of state regulations and local legal nuances, which can be beneficial in navigating your case. For instance, if you work in Virginia, or specifically in Virginia Beach, then you should work with personal injury attorneys near Virginia Beach .

An attorney’s reputation can offer valuable insights into their dedication and effectiveness. Good reviews and referrals show their commitment. They aim for the best outcomes for their clients.

Viewing OSHA regulations as the minimum standard, not the goal, is key to creating a safer workplace. Proactive measures include regular safety meetings to discuss new measures and best practices.

Cultivating a safety-first culture transforms the workplace, with everyone committed to security. Encourage employees to voice concerns for a collaborative safety approach, making it a collective responsibility.

Following OSHA’s trip and fall rules avoids penalties. It also creates a secure, productive work environment for your team.

By understanding these rules and tailoring them to your organization’s needs, you show a commitment to safety. This commitment resonates with your team and stakeholders. Remember, a fall shouldn’t be the first sign you need to reinforce your safety measures-it should be the last.

For more insights and guidance on a range of other topics, we invite you to browse our blog.

Lost Your Password?

Reset Password

Common Triggers of Slips, Trips, and Falls – And How To Avoid Them

Slips, trips, and falls are some of the most common causes of workplace injuries in the US, accounting for over 8 million emergency room treatments every year. While not all these incidents are severe, some will have serious consequences, such as bruises, strains, sprains, fractures, and head injuries.

In many cases, a slip or fall can make it difficult for you to move around, do everyday activities, or live as independently as you used to. It could even force you to take a few days or weeks off work, which will affect your income and productivity.

“Slips, trips, and falls can be frustrating, embarrassing, painful, and costly to you and your family. These accidents often leave victims hospitalized for days or weeks while the utility bills, medical bills, and other expenses collect at your doorstep,” says Alex Bouganim and Joseph Capetola, slip and fall lawyers in NYC .

What To Do If You Slip, Trip, Or Fall

Sometimes, no matter how careful you are, accidents can still happen, and it is crucial that you know what to do in this kind of situation so you can manage it in the best way possible. One of the first steps is to immediately seek medical attention, especially if the fall was quite hard and you are feeling pain anywhere in your body.

Injuries may not always be apparent, and a doctor can help determine specific problems and recommend the proper treatment. Aside from this, a trip to the doctor can help establish credibility if you decide to file a personal injury case or claim compensation against whoever was liable for the accident.

However, if you experience difficulty moving around, do not force yourself to get up right away and look for someone to help you instead. For severe trauma or injury, it is best to call an ambulance and stay in place until they arrive since any sudden movement could aggravate the damage to your body.

Finally, remember to report the incident to the property owner or manager or get someone to do it for you if you cannot move around freely, and make sure that there is proper documentation to help you establish evidence when you claim compensation. It is also a good idea to consult with a legal expert for specific guidance on what to do after a slip and fall accident since the actual steps to do may vary depending on the location and circumstances of the accident.

Common Causes And How To Avoid Them

Awareness is vital in preventing you from becoming a victim of these accidents. When you know the causes of slips, trips, and falls, it becomes easier to avoid them and you can even prevent them from happening to others. Take a look at these common triggers of slips, trips, and falls and what you can do about them:

1. Poor Lighting

Poor lighting can make it difficult to see hazards and other dangers, such as stairs, curbs, or wet and slippery surfaces, increasing your risk of slipping or falling. If you have poor vision, this is even more of a problem because the dim and dark surroundings can hide any obstructions in your path and prevent you from taking evasive action to avoid getting tripped.

To prevent slip and fall accidents due to poor lighting, ensure that all walkways are well-lit, especially in areas with high foot traffic or potential hazards. Install adequate lighting sources, such as overhead lighting or task lighting in darker areas, and immediately replace light bulbs when they burn out.

2. Slippery Or Uneven Surfaces

One of the most common triggers of slips, trips, and falls are slippery or uneven surfaces because they can cause you to lose your footing easily. These are often caused by ice, snow, water, oil or grease, sand, mud or dirt, loose gravels or stones, and man-made causes like waxed floors, which could become slippery due to spills or leaks.

Fortunately, there are many ways you can avoid falling victim to these triggers, and wearing proper footwear is at the top of the list. Shoes with good traction and non-slip soles can help prevent slips and falls, while smooth or worn-out soles can increase your risk. Take extra precautions by immediately cleaning up any spills or wet areas, using non-slip mats in areas prone to getting wet, such as bathrooms or kitchens, and being careful when walking on freshly cleaned or waxed floors.

3. Mats And Rugs

When not correctly displayed or maintained, mats and rugs can result in a slip or trip, especially for an unsuspecting passerby. For example, curled-up edges or lumps in the middle of a rug could entangle your feet and cause you to lose your balance. It is also highly possible for a loose and unsecured rug to slip out of place right when you step on it, leading to a nasty fall and an injury.

To prevent rugs and mats from becoming a tripping hazard, ensure they are properly secured and maintained. Regularly inspect them for signs of wear and tear, and immediately replace any rugs that are frayed, have holes, or are lumped in certain parts. Keep them completely flat, with no bumps or curls on the edges, and use non-slip pads underneath so they stay firmly in place.

4. Excessive Clutter

Aside from being a tripping hazard, clutter can also cause fires, which is why it is essential to do regular housekeeping to prevent these incidents from occurring. Excessive clutter like books, shoes, toys, cords, loose rugs, and stacks of newspapers on the floor create environmental hazards that impede movement and result in blockages that hinder people from walking safely.

You can minimize the occurrence of these incidents by making sure that all walkways, hallways, and stairways are always clear of clutter. Keep your space organized, secure loose cords, and use storage solutions such as shelves, cabinets, or drawers to keep items off the floors and tables.

5. Uneven Or Poorly Built Stairs

Stairs that are damaged or not built according to safety standards can lead to serious injuries, especially if you fall from a higher level. This includes stairways with no handrails covered in dirt and debris or have broken, loose, uneven, or missing steps. Aside from these, obstructions like boxes or clutter on the steps can also cause people to trip and fall.

You can reduce the risk of slipping firstly by ensuring that your stairs are built according to strict guidelines , with the stair slope maximum range being from 30 to 50 degrees. As an additional preventive measure, you can install non-slip surfaces on the stairs, such as rubber or slip-resistant paint, and ensure that stairways are well-lit and have a clear path by removing any items left on the steps like shoes or work equipment that can create potential hazards. Carpeted stairs should also be in good condition with no noticeable deterioration, excessive wear, or missing treads.

The post Common Triggers of Slips, Trips, and Falls – And How To Avoid Them appeared first on What's Trending .

A .gov website belongs to an official government organization in the United States.

A lock ( ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

- Falls in the Workplace

- Ladder Safety

- Aerial Lift Safety

- MCWP Safety

- Aerial lifts raise workers to complete work-related tasks exposing workers to fall hazards.

- Using an aerial lift requires training.

- Proper safeguarding can reduce or eliminate aerial lift fall injuries.

Aerial lifts are powered mobile platforms that elevate workers to various heights. This exposes workers to fall hazards. The term 'aerial lifts' is an overarching term to capture multiple types of lifts like scissor lifts and boom lifts.

Some common tasks aerial lifts are used for include:

- Drywall installation

- Maintenance

Aerial lifts are mobile. This makes aerial lifts easy to get to many jobsites with minimal setup time. For these reasons, aerial lifts are often used instead of scaffolding.

Aerial lifts are popular at various jobsites, including:

- Construction

- Telecommunication

- Warehousing

- General building maintenance

Other industries use aerial lifts to move materials, change lightbulbs, store boxes, and other tasks.

Slips, trips, and falls are the leading cause of death for construction workers. In 2022, slips, trips, and falls killed more than 400 U.S. workers. 1

Between 2011-2014, 1,380 workers were injured as a result of operating an aerial lift or scissor lift. 360 of these injuries were a result of slips, trips, and falls from one level to another. 2

Between 2011-2014, 87 workers died as a result of operating an aerial lift or scissor lift. 48 of these deaths were a result of slips, trips, and falls from one level to another. 3

Safety risks

Aerial lifts are mobile, used as elevating equipment, and considered a restricted workspace. These aerial lift characteristics raise the risk of fall injuries.

Aerial lifts are used in a number of different conditions, such as adverse weather conditions and high-traffic, continually-changing worksites. These conditions create other hazards that expose workers to injury, including:

- Crushing/trapping hazards

- Electrocutions

Best practices

Training is necessary for anyone using aerial lift work platforms and equipment.

Recommended safe work practices for aerial lifts are included in ANSI Standards and OSHA Requirements.

American National Standards Institute (ANSI) Standards

Occupational Safety and Health Administration (OSHA)

Note: Both OSHA and ANSI standards vary for different types of lifts.

What CDC is doing

In an effort to create awareness about common workplace hazards when using aerial lifts, NIOSH has developed educational tools and products. Employers, trainers, safety and health professionals, and aerial lift operators can use this information to prevent work-related falls.

NIOSH Aerial lift hazard recognition simulator

The Simulator is designed to help potential aerial lift operators acclimate to operation and identify the common occupational hazards during use. There are multiple hazards including depressions (potholes), crushing hazards, tip over hazards, etc.

Using the Simulator is not a substitute for required training to operate an aerial lift.

Aerial lift simulator

Use the simulator from the safety of a computer to refresh existing knowledge or become familiar with hazards you may encounter on the job.

To launch the simulator

- Click on the Launch Aerial Lift Hazard Recognition Simulator button below to download the Simulator. Note: The files for the Simulator may take a few minutes to download.

- Click Open on the menu

- Double click LiftSimulator Application

- Click Extract All

- Click Browse to select or create a folder location on your computer's hard drive. Do not select a networked shared drive.

- Select "Extract" (one folder and one application file will download).

- Open the LiftSimulator Folder that was created.

- Double click Lift_Simulation Application to run the Simulator.

- If on a newer version of Windows 10, you may get a pop up stating that "Windows protected your PC." Click "More info" and then click "Run anyway."

- Enable the audio on your computer. Directions are provided audibly.

- Select which Aerial Lift Simulation you would like to play!

To use the simulator

- Select the screen resolution and graphics quality if needed by clicking "Settings" in the menu.

- Once launched, you the will be prompted to position the lift in the appropriate area while avoiding hazards.

- To maneuver the lift use your keyboard. Press "h" if you require assistance.

- Follow the green arrows and align the lift with the transparent platforms visible at various locations in the work area.

- You will be notified when you have reached each target area successfully.

- To finish the scenario, park the lift at the final location.

Pan C.S., Chiou, S., Kau, Y., Wimer, B., X. Ning, and Keane, P. (2017) "Evaluation of Postural Sway and Impact Forces during Ingress and Egress of Scissor Lifts at Elevations," Applied Ergonomics , 65, pp. 152-162.

Pan C.S. (2016) "NIOSH Aerial Lift Safety Research and Practice," Hsiao, H. (Editor), Fall Prevention and Protection: Principles, Guidelines, and Practice, Chapter 16, pp. 271-290.

More on aerial lifts

- Us Department of Labor, Bureau of Labor Statistics TABLE A-1. Fatal occupational injuries by industry and event or exposure.

- US Department of Labor, Bureau of Labor Statistics Survey of Occupational Injuries and Illnesses (nonfatal data) .

- US Department of Labor, Bureau of Labor Statistics Census of Fatal Occupational Injuries query system (fatal data) .

National Institute for Occupational Safety and Health (NIOSH)

The Occupational Safety and Health Act of 1970 established NIOSH as a research agency focused on the study of worker safety and health, and empowering employers and workers to create safe and healthy workplaces.

.png)

1-888-326-9244

Create an Account

- Sign in or Register

- PRINTERS & SUPPLIES

- FLOOR MARKING

- SAFETY SIGNS

- PIPE MARKERS

- Free Samples

National Safety Month: Custom Signage to Combat Workplace Hazards

Resource Navigation

- Resources Home

- Infographics

--> 13 May, 2024 4 MINUTE READ

When we think about workplace accidents, it’s hard not to think about the most dramatic, worst-case scenarios like fires, amputations, or forklift hazards. However, workplace slips, trips, and falls should be added to the list as they are the third leading cause of workplace safety hazards , often resulting in death or serious injury.

The Bureau of Labor and Statistics reported in the 2021-2022 calendar year 674,100 cases related to workplace slips, trips, and falls injuries and 700 of those resulted in death.

What Can Result in a Slip, Trip, or Fall Injury?

Many factors can contribute to the likelihood of a slip, trip, or fall. Footwear and environmental factors are a couple of the main contributors to these types of workplace hazards. Here is a list of incidents where a hazard may result in a slip, trip, or fall:

- Water, ice, snow, mud, grease, oil

- Loose or irregular surfaces like gravel or unanchored flooring

- Sloped walking surfaces without slip- or skid-resistance

- Uncovered hoses, cables, wires, or cords across walking surfaces

- Unmarked steps or ramps

- Thresholds, gaps, and other irregularities in walking surfaces

- Speed bumps and curb drops

The Occupational Health and Safety (OSHA) standard for slip, trip, and fall hazards in a General Industry, defined as all industries not included in agriculture, construction or maritime, Walking-Working Surface standard (29 CFR 1910 Subpart D).

A walking-working surface is defined as any horizontal or vertical surface on or through which an employee walks, works, or gains access to a work area or workplace location. OSHA’s standard requires employers to identify and evaluate slip, trip, and fall hazards and provide proper personal protective equipment (PPE) and training to employees so they can recognize the hazards and minimize their occurrence.

How Can Trips, Slips, and Falls be Prevented in the Workplace?

OSHA currently does not have a formal requirement for training on slips, trips, and falls, however, workers need to receive some type of training and reoccurring refreshers in OSHA regulations to be able to decrease the occurrence of these types of incidents in their workplace.

One of the easiest and most effective ways to keep the workforce fresh on this topic is to craft a training plan where employees can learn:

- OSHA’s regulations for walking/working surfaces

- Slips, trips, and falls and what causes them

- How to avoid slips, trips, and falls in the workplace

The amount of training can be done at the worker’s own pace or in a more formal setting. Once training is set up, visual communication can help retain the information.

How Can Visual Communication Be a Preventative Method for Workplace Safety?

Most workplace accidents are preventable, including accidents that involve slips, trips, and falls. Most of these types of incidents are caused by obstructions in walkways, while the rest are a result of uneven surfaces.

Preventing these accidents is often simple and cost-effective. Many visual communication methods can reinforce safety training in any work environment. Here are some visual communication methods that can work in any facility:

Floor marking