FREE NEWSLETTER

Credit: Birkenstock

Birkenstock opens new factory in germany.

Construction began in April 2022, with the foundation stone laid in August of the same year. The new facility is the single largest investment in the company’s history at around €110 million.

The plant will begin with a team of around 200 people in production and administrative roles before expanding capacity and bringing in another 800 employees in the medium term.

Meanwhile, the company’s Görlitz plant will now focus entirely on cork-latex production. The new factory clears the way for Birkenstock’s “Made in Pasewalk” series of products.

Other articles of interest

- Footwear production moved away from Europe in the last 40 years

- Turnover up 79% for Valleverde in 2022

- Global issues drag down Brazilian footwear exports in May

- Billy Tannery collaborates with Grenson Shoes

International Leather Maker is a business information brand produced by Edify Digital Media Ltd

- Work & Careers

- Life & Arts

- Currently reading: Birkenstock: inside a $5bn brand

- Spring’s radical new menswear

- How to hold on to your hair

- What’s the flap about butterflies?

- Meet the Mozart of watchmaking – and his mentor

- Why hypebeasts are queuing for old New Balances

- Tailoring icon Gianluca Isaia’s guide to Naples

Birkenstock: inside a $5bn brand

- Birkenstock: inside a $5bn brand on x (opens in a new window)

- Birkenstock: inside a $5bn brand on facebook (opens in a new window)

- Birkenstock: inside a $5bn brand on linkedin (opens in a new window)

- Birkenstock: inside a $5bn brand on whatsapp (opens in a new window)

Jonathan Heaf . Photography by Daniel Stier

Simply sign up to the Style myFT Digest -- delivered directly to your inbox.

“As you can see, we have grown somewhat…” says Stefan Schulz, head of production final assembly. He is gesturing at hundreds of rows of industrial shelving units, 15m high, in Birkenstock ’s factory in Görlitz, eastern Germany, a town within borscht-spilling distance of Poland. The 36,000sq m factory – a corrugated modern block the colour of a dirty white Fiat – opened in 2009, runs 24 hours a day, five days a week, and employs around 1,900 workers.

Schulz is courteous, friendly and quick to share; but his affability cloaks the steely grip he has on shoe production efficiency. Need to squeeze more than 80,000 sandals a day out of a multinational, sometimes Covid-hit workforce in a factory that barely sleeps? You need a man like Stefan.

“We didn’t need this when I started nearly 10 years ago,” he explains of the spaceship-sized building before us. “Now we’re building a big new factory nearby. More capacity. More automation…” he says. “But I can’t tell you where.” Everything at Birkenstock is ringfenced with professional secrecy. “The Birkenstock story is one that is rising all the time. Rising, rising, rising .”

In its 248-year history, the orthopaedic-looking-shoe brand founded by Johann Adam Birkenstock has transformed from a family business plagued by infighting and efficiency squabbles into a global sandal sensation that last year went into partnership – for $4.87bn – with private equity firm L Catterton , a company created in part by Bernard Arnault and his family’s holding company, Financière Agache. Over the years its simple two-strapped shoes have enjoyed various iterations and maintained a reputation for dignified quality. But while the cork-based sandals were once derided as a fashion faux pas worn only by hippies and health professionals, the brand has lately been infused with high fashionability. In the financial year ending September 2019, the brand sold 23.8mn pairs of shoes and saw an 11 per cent increase in sales to €721.5mn.

The team at Görlitz crafts 50,000 cork sandals, and 30,000 ethylene vinyl acetate (EVA) pairs every day. Unlike many other big brands that outsource their manufacturing, Birkenstock owns each step of its production line – all of which is in Germany. This means that the business can quickly react to growing or shrinking markets, control and trademark each part of the shoe-making process, and protect its heritage as a German company.

The brand has four – soon to be five – factories in Germany, although only the Görlitz operation houses the complete assembly, crafting together the footbed, the leather sides, the straps and the buckles. It also partially produces Birkenstock’s higher-end range, 1774 (starting at £260), launched in 2020 and marking its evolution from a practical shoe brand into one offering luxury status symbols. A huge part of the Birkenstock rehabilitation, the 1774 line has elevated the brand to the realm of high fashion, and offered dozens of potential collaborations.

“Business is too good. Always. For 10 years we have been sold out. Managing the capacity with such demand, it’s a different kind of pain, but it is still pain. You know?” Oliver Reichert has been the Birkenstock CEO since 2012. We are sitting opposite one another at a huge wooden table in the brand’s Munich premises. A floor-to-ceiling photograph of Joseph Beuys hangs on the wall and I spy an original copy of The Face with Corinne Day’s famous shoot of a then-unknown Kate Moss wearing black Birkenstocks. Reichert’s belief and commitment to the brand are unequivocal. “We are in the century of quality – because people are sick and tired of all the cheap, quick, £8 trousers they wear once.”

Business remained strong even through the pandemic. “At the beginning of the situation it was pure fear for everyone,” says Reichert of the flux throughout the industry. “We don’t need to source anything, and we didn’t have worries about the impact on the global supply chain – everything we own can be moved around using trucks – but then when we saw the situation in Italy, we became very concerned for the people in our tanneries in this area.”

Everyone was at home – people cared about their desk, their chair, their jogging bottoms and, yes, their footwear. Birkenstock was a part of this self-reinvention” Oliver Reichert, CEO of Birkenstock

He decided to shut the production sites for two months, balancing the company’s responsibility towards its family-owned suppliers with the need to protect their workers. “And then, overnight, demand for our produce went through the roof.”

Reichert believes there was a psychological reason for Birkenstock’s sustained increase in sales. “Everyone was at home, and although there was no office people still cared about their desk, their chair, their jogging bottoms and, yes, their footwear. Birkenstock was a part of this self-reinvention; and the casualisation of workwear during the pandemic was mirrored by the mass casualisation of fashion.”

Reinvention is precisely the currency that Reichert spends his days pushing, not least when considering the 1774 line’s range of potential partners. “When you have a 250-year-old company – a very big beast – you have to be careful not to end up closed like the Catholic church, with everything locked away. Then you will die in your own greatness. The company will become a mausoleum. I want to keep the roof open. And this is what we do with 1774 – invite influential and creative people to come and have a picnic with us. I don’t need the money; I need their energy stream. Their view and interpretation of the brand.”

He gets up, walks over to a locked wood-and-glass cabinet and pulls out two seemingly standard blue-and-white Birkenstock shoeboxes. These house the brand’s recent collaboration – with Dior and its men’s artistic director, Kim Jones . They are a twist on the popular Tokio mule and Milano sandal, in Dior grey and felt and suede styles. First revealed at Jones’s AW22 show in January , they will arrive in stores in June. They are the perfect hybrid of ugly, comfy and desirable.

Much was made of the brand’s L Catterton deal last year. Before the LVMH-associated company was involved, another private equity firm, CVC Capital Partners, had been in talks for months . “It was a tactical thing,” explains Reichert. “If you want to convince somebody to love you even more, you probably have to talk to someone else as well. Look, the normal finance investor strongly believes that he is the predator. But the truth is they are not. It’s easy to spot the chicken trying to be the tiger in the room, you know?”

At the time of the agreement, Arnault commented: “Birkenstock was founded nearly 250 years ago and has grown to become one of the few iconic brands in the footwear industry. We truly appreciate brands with this long heritage.” According to Luca Solca, a luxury goods analyst at Bernstein, part of Birkenstock’s appeal is that it has captured the trend for fast growing informal footwear. “[These] brands are prized by investors as they promise significant future growth. Examples of this have been the recent IPO of Dr Martens and the private equity takeover of Golden Goose .”

How is Reichert’s relationship with Arnault now? “They [LVMH] have such an incredibly good track record; and the strength they have rests on giving space – whether to Celine or Kim Jones at Dior – to do their business.” Will the deal see more LVMH brands collaborating with Birkenstock?

“Not necessarily,” says the CEO firmly. “No one has talked to me about this. Of course, we are the new kid on the block, but this means that lots of people are calling.” Many brands have approached them, but others have produced their own sandal versions. “They decided to copy us,” says Reichert. “But if you are going to play remixes it should be a good one.”

Notwithstanding the success of the 1774 fashion collaborations, Reichert wants the future of Birkenstock to be more democratic. “In 10 years I want to give everyone access to the Birkenstock footbed. All this [1774] range is very high, but I want to go even deeper. I don’t want us to be misused as a fashion brand. We are like bread and water. So, for example, how do we get the footbed accessible to people in India? This needs a rough pricing of five to 10 euros. This is the challenge. But we don’t have a preference for serving kings. We want to serve people.”

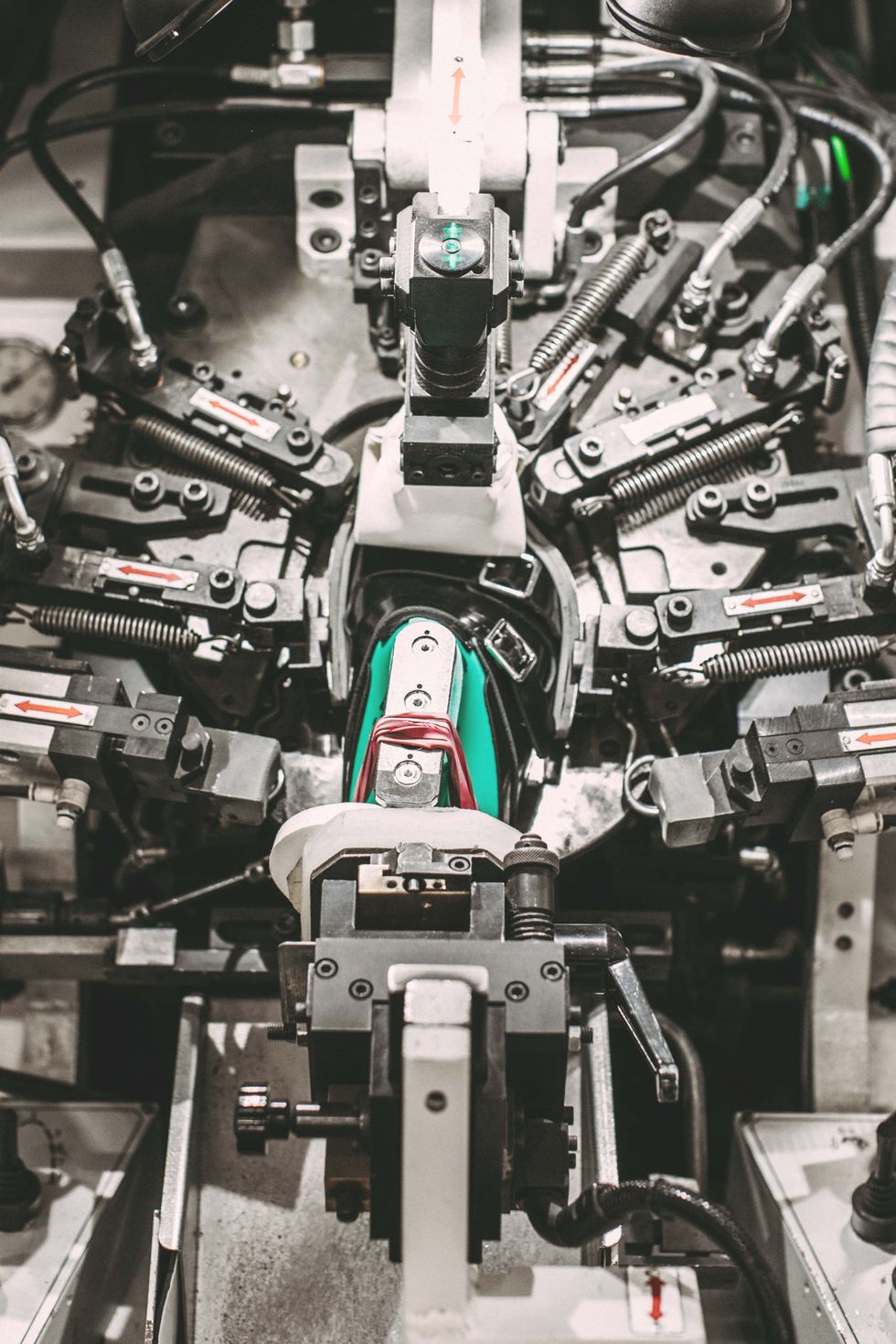

Back on the shop floor, I watch the making of an Arizona , one of the brand’s most popular models, which was relaunched last month in olive-green leather as part of the 1774 range. The production journey starts with big, pillowy brown bags filled with cork granules, part of which are a by-product of the making of wine corks, imported from Portugal. These are mixed with latex milk to make a sticky, unctuous paste, which is then fed into one of the footbed presses by a robot. The cork mixture is sandwiched between a thin lower sheet of jute and a leather inner sole, then baked in what looks like row upon row of individual waffle makers for around 10 minutes.

Belief in the Birkenstock footbed – or Fußbett , as it was coined by Konrad Birkenstock in 1896 – borders on cult-like. As well as being the brand’s true point of difference, it is also its DNA, its soul, and legally protected to the millimetre. Every raised bump and curve is designed to encourage a healthy gait. The general idea is that it stimulates the leg and foot muscles – big and small – much like walking on a sandy beach. Brands who want to collaborate with the company are encouraged, politely but firmly, not to touch it.

The inner sole and upper can be switched out with a vegan alternative or, in the case of the 1774 models, encased in a premium type of leather. The 1774 models also undergo a refining treatment known as “full exquisite”, which means none of the cork mixture can be seen around the edges. They also get fancier stitching and piping, with the details close to 80 per cent handmade, while the standard line is roughly 60 per cent.

With every stage come controls, beats in the production process where eagle-eyed employees both check for small faults and prep the shoes for the next stage of production. Control benches are distinguished by their harsh overhead lamps and laminated cheat sheets. “So much is still checked, of course, by the human eye,” explains Schulz. “At the end it is 1,000 per cent accuracy, rather than 100 per cent, that we require.” Every step is programmed for high quality at maximum capacity; whether that’s to add a layer of glue to the bottom of the footbed via a “waterfall” system or attach the leather straps via heat-activated glue tunnels and abrasion.

The whole process is a dance: part-metal, part-human. It ends when a friendly woman called Emily hands me a shiny white shoebox with 1774 Birkenstock branding on the outside. Inside are a gleaming pair of Arizona sandals and a centuries-old brand with one foot grounded in the past and the other – with its sense of collaboration and innovative spirit – firmly in the future.

Promoted Content

Explore the series.

Follow the topics in this article

- Menswear Add to myFT

- Fashion accessories Add to myFT

- Womenswear Add to myFT

- Style Add to myFT

- Fashion Add to myFT

International Edition

Birkenstock's new shoe factory starts up

Subscribe the World Footwear weekly newsletter

Get regular updates on your inbox: Subscribe the World Footwear weekly newsletter

Related news

Birkenstock files for IPO

Birkenstock invests 110 million euros in new shoe factory

Birkenstock names new Managing Director for Europe

Birkenstock sells majority stake to the company behind LVMH

Birkenstock, brand of the year

Birkenstock discontinuing Amazon deliveries in Europe

Related events, supreme w&m düsseldorf, neonyt düsseldorf, supreme w&m munich, related organizations.

PFI Germany - Test and Research Institute Pirmasens

IVO - International Association for Orthopaedic Shoe Technicians

ISC - International Shoe Competence Center Pirmasen

Messe Düsseldorf GmbH

Get the World Footwear news delivered to your inbox:

Subscribe the weekly Newsletter

Footwear Consumer 2030

A study reflecting on the main global consumer trends and the key changes for the footwear industry.

World Footwear Public Calendar

Click here to subscribe an updated version of the calendar displaying the footwear trade shows.

Next Events

Dallas apparel & accessories market, pitti immagine uomo, white milano resort, expo riva schuh, outdoor retailer, midwest buy mart, minse - international leather and textile exhibition, ispo shanghai, sicc- salão internacional do couro e do calçado, première vision, organizations, aicc - italian leather chemists' association, tomas bata univerzity in zlín (faculty of technology), cicur - chamber of the tanning industries of the state of guanajuato, kfma - kenya footwear manufacturers association, ichslta-the international council of hides, skins and leather traders associations, media partners.

Shoes Report

SHOES-MAGAZINE.COM

Revista del Calzado

Schuhkurier

We've detected unusual activity from your computer network

To continue, please click the box below to let us know you're not a robot.

Why did this happen?

Please make sure your browser supports JavaScript and cookies and that you are not blocking them from loading. For more information you can review our Terms of Service and Cookie Policy .

For inquiries related to this message please contact our support team and provide the reference ID below.

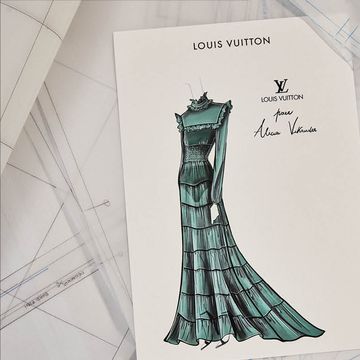

Inside The Atelier: The making of Birkenstock's 222 West

The label's new luxury shoe goes through 24 steps in production

The 222 West comes from Birkenstock's luxury 1774 collection, and is what Birkenstock describes as a combined upper, meaning it has the connecting the straps of the iconic Arizona sandal and the silhouette of the Boston Clog . The two are fused together to give the illusion of wearing two shoes at once, while also keeping recognisable elements of both styles.

Inspired by the vibrant creative heritage of downtown New York in the 1970s and 1980s, the style comes in a patent black, making it a great wear-everywhere shoe, whether teamed with denim at the weekend, tailoring for the office or dressed up for the evening.

To produce the style, there are 24 different steps involved, and the product will pass through the hands of 26 different individuals. First up is the baking of the footbed, which takes two days, before it can be wrapped in leather by hand.

Below, step inside the atelier and see how the 222 West comes to life. The shoe will be available to shop globally from Thursday 14th March.

Cork ready for production

Footbed baking

Orders ready for gluing of the footbed

Footbed exquisite finish

Leather cutting preparation

Skiving of the upper in lasting margines

Marking upper for glue position

Glue application on upper material

Gluing and activaion of parts of upper

Gluing and activaion of parts on upper

Both parts of upper glued together

Buckle application on the upper

Final control of upper before assembly

Pre moulding of upper before production

Hammering the sides of the glued upper

Gluing the sides of the upper

Lasting the shape of the upper over last

Shoes lasted ready for soling

The finished product

Inside The Atelier

Inside The Atelier: Jimmy Choo's crystal shoe

Inside The Atelier: Lily Gladstone's SAGs dress

The making of Claire Foy's glittering Armani gown

Inside The Atelier: Johnstons of Elgin's cashmere

The making of Adele's Louis Vuitton stage look

Natalie Portman's Golden Globes gown

The making of Oprah Winfrey's Golden Globes dress

Inside The Atelier: Emma Stone's crystal gown

Inside The Atelier: Alicia Vikander's sheer gown

Inside The Atelier: Prada's floral embroideries

Inside The Atelier: Manolo Blahnik Hangisi

- Flipboard icon Flipboard

- Newsletters

Birkenstock Nears Completion on New Shoe Factory in Germany

Stephen Garner

More stories by stephen.

- Shoe Brands at FFANY and FSNYE Shows Highlight a Positive Trajectory for Spring 2025

- Diane Sullivan Pledges $100K Donation to WiFi as the Caleres Chair Accepts Two Ten’s Bob Campbell Lifetime Achievement Award

- Cole Haan’s Cheryl Calegari on the Power of Resiliency and Trusting Your Intuition

- Show more sharing options

Birkenstock is getting close to completing its factory under construction in Pasewalk, Germany.

In August, the footwear company broke ground on the 120-million-euro ($127 million) project at the Berlin -Szczecin Industrial Park, located about an hour north of Berlin. As of today, Birkenstock said that the shell construction of the 36,000-square-meter, approximately 387,500-square-feet, building complex is nearly complete. The company on Wednesday held a “topping-out” ceremony at the new location.

Birkenstock added in a statement that it plans to open the facility for production in the third quarter of 2023.

Before the end of March, Birkenstock added that it will open an information office in the city center of Pasewalk, which will serve as a contact point for those who are interested in a job at the plant. Ultimately, more than 1,000 positions will have to be filled in Pasewalk in order to meet production capacity, Birkenstock said.

Birkenstock Is Bringing Back a Comfort Clog From 1995

Birkenstock raises guidance, cites strong consumer demand in q2, rose byrne goes relaxed in grey dior for birkenstock sandals for 'the view'.

At Wednesday’s ceremony, Birkenstock Group chief technical operations officer Mark Jensen thanked all those involved that helped to keep the project on track despite inflation and supply bottlenecks.

Watch on FN

“We are currently finishing the last groundworks and in the next few days we will start the interior fittings of the plant,” Jensen said. “In April we plan to get the installation of the first production machines underway. I am confident that we will be able to hold the first ‘Made in Pasewalk’ Birkenstock products in our hands in October at the latest, just as planned.”

In the next weeks and months, Birkenstock added that it is focused on the completion of several functional buildings, such as the employee office and the plant’s cafeteria, as well as installing and calibrating production machines.

This is the latest milestone for the popular footwear brand, which has continued to invest in retail stores in the U.S. in recent years. In December, the brand opened its fourth company-owned store in the States within the Marin Country Mart in Larkspur, Calif. It joined Birkenstock’s other owned stores in Brooklyn and SoHo in New York City and in Venice Beach, Calif.

In November, Birkenstock’s Boston Clog topped Lyst’s Year in Fashion report. The annual report that analyzes data from its 200 million users found that the Boston Clog is the hottest shoe of the year , with searches increasing 593% in the first six months of 2022.

The company was also honored late last year with the Collaboration of the Year award at the 36th annual FN Achievement Awards in New York City for its tie up with Manolo Blahnik.

This New Melissa x Marc Jacobs Collab Is Your Sign to Hop on the Jelly Sandals Trend for Summer

- Fashion News

- Celebrity Style

- Collaborations

- Outdoor Footwear

- Women’s Footwear

- Sneaker News

- Men’s Footwear

- Children Footwear

- Business News

- Executive Moves

- Mergers & Acquisitions

- Shoe Guides

- Sneaker Deals

- FN Gift Guides

- Foot Health

Access exclusive content

Alerts & Newsletters

By providing your information, you agree to our Terms of Use and our Privacy Policy . We use vendors that may also process your information to help provide our services. This site is protected by reCAPTCHA Enterprise and the Google Privacy Policy and Terms of Service apply.

Footwear News is a part of Penske Media Corporation. © 2024 Fairchild Publishing, LLC. All Rights Reserved.

Birkenstock Fachgeschaeft GmbH & Co KG

Top ways to experience nearby attractions

Most Recent: Reviews ordered by most recent publish date in descending order.

Detailed Reviews: Reviews ordered by recency and descriptiveness of user-identified themes such as wait time, length of visit, general tips, and location information.

Birkenstock Fachgeschaeft GmbH & Co KG - All You Need to Know BEFORE You Go (2024)

8 of the Best Factory Tours in Germany

Go behind the scenes of Germany’s most famous exports and find out how German cars , chocolate, and beer are made. Many factories in Germany open their doors to curious visitors and offer them a look at how their products are built, brewed, and sewed - from start to finish.

Before you go on a factory tour in Germany, make sure to call ahead or check their website and ask about reservations and tours in English. And don’t forget to check out the factory stores afterward for some great deals.

BMW Car Factory Munich

Chira Chirakijja / TripSavvy

For BMW fans, Munich offers no less than three points of interest, all in walking distance from each other:

The BMW Museum - Traces back the history of the famous car.

BMW World - An architectural masterpiece which is the delivery center for BMWs and also houses exhibition halls, design ateliers, and workshops for kids.

BMW plant - Offers fascinating tours: Put on your safety goggles and factory coats and watch how giant conveyors lift the 3-series BMW to be welded by computer-controlled robots.

- Where : Petuelring 130, 80809 Munich

Haribo Gummy Factory

Eckhard Henkel/Wikimedia Commons /CC BY-SA 3.0

The most famous gummy bears in the world come from Germany. Haribo Goldbären (gold bears) were born in 1920 in Bonn in West Germany .

Today, Haribo is the largest manufacturer of gummy sweets on the globe. Although you can’t enter the factory itself, you can visit the Haribo factory store, close to the original factory, which features an exhibition about Haribo and offers a wonderful variety of gummy bears for sweet prices.

- Where : Am Neutor 3, 53113 Bonn, North Rhine-Westphalia, Germany

Erdinger Brewery Munich

The world's largest brewer of wheat beer is located close to Munich and combines tradition and modern technology. At the Erdinger Brewery, the purest ingredients with age-old recipes make their way through a high-tech bottling plant.

On your tour, you will watch the brewing process from start to finish, explore the fermentation and filtration cellars, visit the computer-controlled warehouse, and learn how the beer is loaded and shipped around the world. More than one million bottles leave this brewery every day, but you can enjoy your fresh Hefeweizen in the brewery's beer garden.

- Where : Franz-Brombach-Str. 1-20, 85435 Erding

Chocolate Museum Cologne

Cologne ’s Chocolate Museum is home to a glass chocolate factory, where visitors of all ages can see how the cocoa bean turns into a chocolate bar. The machines in the small chocolate factory all have viewing windows, so you can get a detailed look at the individual production steps.

The exhibition tells you all about the rich history of chocolate, from the Mayan’s chocolate “drink of the gods” to today's commercials. If all this talk about chocolate made your mouth water, head to the 10-feet high chocolate fountain. The museum staff will be happy to dip a stick of waffle into the warm chocolate to give you a try.

Where : Am Schokoladenmuseum 1A, 50678 Cologne

Meissen Porcelain Factory

TripSavvy / Christopher Larson

300 years ago, Europe’s first porcelain was discovered in Meissen, close to Dresden . Today, Meissen porcelain ( Staatliche Porzellan-Manufaktur Meissen ) with its signature trademark, the crossed swords, is one of the most famous china manufacturers in the world.

You can tour various workshops that demonstrate the process of making the fine Meissen china by hand, from the modeling to the painting. There is also a museum, which holds a collection of 20,000 pieces from all periods, and an outlet store where you can hunt for some bargains.

- Where : Talstraße 9, 01662 Meissen

VW Factory and Autostadt Wolfsburg

Once again its cars - it is Germany after all. And the Volkswagen factory in Wolfsburg is just one hour away from Berlin and prides itself on being the largest auto plant in the world. There is a huge car museum, several pavilions dedicated to the various VW cars, driving courses for adults and kids, restaurants, a hotel, and of course the factory itself, which you can tour.

Another highlight: Embark on a glass elevator which takes you to the top of the 160 feet high glass Car Tower. They hold up to 800 custom-ordered cars, which are picked up by their buyers fresh from the factory.

Its adjacent “Autostadt” (car city) is a theme park dedicated to the automobile and offers everything car enthusiasts of all ages dream about.

Where : Stadtbrücke, 38440 Wolfsburg

Steiff Factory and Museum

Kids and collectors all over the world love the German Steiff plush toys with their signature “button in ear”. Created in 1880 by the German seamstress Margarete Steiff, the plush animals are made only out of the finest materials, such as felt, mohair, or alpaca.

You can visit the birthplace of the famous toys, Giengen, 90 miles west of Munich. After stopping by the largest Steiff shop in the world, make sure to check out the interactive toy museum and the workshops where the plush toys are still created by hand.

Where : Margarete-Steiff Platz 1, 89537 Giengen an der Brenz

Jagermeister Factory Tour

Not just fit for Frat boys, discover the German liquor of Jagermeister with a visit to its headquarters in Wolfenbuttel (about 200 km west of Berlin).

Tours are 1.5 hour and while you won't find out all the secret ingredients (there are 56!), English or German guides take visitors through production, into the herb cellar and through a tasting.

Where : Wolfenbuettel, Germany

Car Lover's Guide to Germany

The Best UNESCO Sites in Germany

Where to Go With Kids in Germany

15 Fun Things to Do in Dusseldorf, Germany

The Top 23 Things to Do in Munich

New Year's Celebrations in Germany: The Complete Guide

Germany Guide: Planning Your Trip

Germany's 500-Year-Old Beer Purity Law

The Best Time to Visit Cologne

The 7 Best Islands to Visit in Germany

Regensburg: Planning Your Trip

Is It Safe in Germany?

How to Visit Munich on a Budget

As Seen on Screen: The Hunger Games - Mockingjay Movie Locations

The Top 11 Things to Do in Stuttgart, Germany

Gifts and Souvenirs from Germany

BIRKENSTOCK IS EXPANDING ITS PRODUCTION SITE IN GÖRLITZ

BIRKENSTOCK is preparing for further growth at its production site in Görlitz.

- BIRKENSTOCK’s largest location in the world continues to grow

- Adjacent property purchased in the Ebersbach industrial park

- Creation of additional rooms for employees to take breaks and socialize as well as new parking spaces

BIRKENSTOCK is preparing for further growth at its production site in Görlitz. In this context, Germany’s largest shoe manufacturer has acquired a property with a production hall adjacent to its existing premises in the Ebersbach industrial park. To company plans to create 200 additional parking spaces on the 17,660-square-meter property by the end of the year. In addition, the company will add additional rooms for employees to take breaks and socialize. New plans regarding the use of the acquired production hall, which is currently leased to an external company, will be drawn up in the coming weeks. The plans include opening a factory outlet on the site.

Project planning for the new parking spaces is already underway, and construction could begin as early as the beginning of November. As such, the parking spaces could be completed before Christmas, weather permitting. The preparations for expanding the spaces for employees to take breaks and socialize are also in full swing. This project will be kicked off at the end of October. The structural work should be completed by March 2017, with construction fully completed by the end of September 2017. Further investments in expanding the site will follow. As in the previous year, an investment valued in the high two-digit million euros has been budgeted for this purpose.

BIRKENSTOCK operates two production sites in the German state of Saxony – one in Görlitz and another in Bernstadt. ALSA GmbH in Görlitz is by far the BIRKENSTOCK Group’s largest location, and not only in Saxony, but worldwide. Nearly one out of every three of the long-established, family-run company’s 3,600 employees now works in Görlitz. Thanks to its size, convenient location, and the site’s potential for further development, the production facility in Görlitz has particularly benefited from the group’s dynamic growth – BIRKENSTOCK has nearly doubled its production since early 2013. Recently, further expansion at the Görlitz location had increasingly been limited by a lack of space. By acquiring the neighboring property, however, the company has now paved the way for further growth. It plans to fill a number of open positions in the coming weeks. The company is primarily looking for qualified skilled technicians, such as mechatronics engineers, metal workers, and electrical engineers.

BIRKENSTOCK is now one of the largest private employers in the Upper Lusatia region of Germany (Oberlausitz in German). As a result of BIRKENSTOCK’s rapid growth, eastern Saxony has developed into a center of the German and European shoe industry – a development which has gone largely unnoticed by the general public. Approximately 11,600 people work in the industry in Germany, including 1,800 employees at BIRKENSTOCK’s two locations in Saxony. As such, today nearly one out of every six of the industry’s employees works at one of BIRKENSTOCK’s locations in Saxony.

Press contact

Jochen Gutzy Chief Communications Officer

Birkenstock Group B.V. & Co. KG Burg Ockenfels 53545 Linz

Postal address: Sedanstraße 4 D-50668 Köln

About BIRKENSTOCK

BIRKENSTOCK is a global brand which embraces all consumers regardless of geography, gender, age and income and which is committed to a clear purpose - maintaining foot health. Deeply rooted in studies of the biomechanics of the human foot and footed on a family tradition of shoemaking that can be traced back to 1774, BIRKENSTOCK is a timeless «super brand» with a brand universe that transcends product categories and ranges from entry-level to luxury price points while addressing the growing need for a conscious and active lifestyle. Function, quality and tradition are the core values of the lifestyle brand which features products in the footwear, sleep systems and natural cosmetics segments. BIRKENSTOCK is the inventor of the footbed and has shaped the principle of walking as intended by nature (“Naturgewolltes Gehen”).

With around 6,200 employees worldwide, we believe how things are made matters as much as the product itself. To ensure these quality standards, we operate a vertically integrated manufacturing base and produce all our footbeds in Germany. In addition, we assemble over 95% of our products in Germany and we source over 90% of our materials and components from Europe. We process our inputs to the highest environmental and social standards in the industry by operating state-of-the-art scientific laboratories for materials testing.

BIRKENSTOCK runs operational sites in Germany, in the states of North Rhine-Westphalia, Rhineland-Palatinate, Hesse, Bavaria, Saxony, and Mecklenburg-Western Pomerania. Headquartered in Linz am Rhein, the BIRKENSTOCK Group also operates its own sales offices in the United States and Canada as well as in Brazil, Japan, Denmark, Poland, Switzerland, Sweden, Spain, the United Kingdom, France, Norway, the Netherlands, Dubai, Singapore and India.

Birkenstock Group B.V. & Co. KG Burg Ockenfels, Linz am Rhein, Germany

You can find our online shop at www.birkenstock.com

BIRKENSTOCK INTRODUCES SHINJUKU

BIRKENSTOCK INDIA OPENS ITS FIRST FLAGSHIP STORE IN MUMBAI

BIRKENSTOCK EXPANDS ITS RETAIL PRESENCE IN JAPAN WITH A CONCEPT STORE IN SHINJUKU, TOKYO.

BIRKENSTOCK INAUGURATES ITS FIRST OFFICE FOR THE BENELUX IN AMSTERDAM

BIRKENSTOCK celebrating the archive

Back to Overview

BIRKENSTOCK Group

Birkenstock group – immense growth thanks to görlitz location.

From February 2019

The BIRKENSTOCK Group is showing rapid company and location growth. There are currently around 1000 employees working in Görlitz, making the location the largest in the entire group worldwide. The heart of the world-famous Birkenstock sandals, the anatomically shaped cork-latex footbed, is produced here. In the meantime, over 100,000 pairs of sandals and components are manufactured in Görlitz in three shifts every day.

The border location of the European city Görlitz/Zgorzelec also helps: the global brand benefits from the workforce on both sides of the border. In view of the strong growth, it is becoming increasingly difficult to meet the need for qualified and motivated employees. The local workforce consists mainly of Germans and Poles who come from the region of the two border towns. Current investments are flowing into a new social building, which cost around 3 million euros (commissioning July 2019). For Sean Harris, Chief Administration Officer of the BIRKENSTOCK Group, this is an important signal to the region: “As one of the three largest and growing employers in the Görlitz area, Birkenstock has become an important stabilizing economic factor. We are aware of the responsibility that results from this. With the new building, we are not only upgrading our production location, but also consciously increasing our footprint in the region.” The fact is: no other location has benefited as much from the positive development of Germany’s largest shoe manufacturer in recent years than the BIRKENSTOCK plant in Görlitz.

In the last 18 months alone, the company has invested millions of euros in strengthening and expanding the plant. BIRKENSTOCK just opened a factory outlet in June 2017.

As one of the largest employers, BIRKENSTOCK is also involved in civic life. For example, the company is the main sponsor of the annual Europamarathon and also supports various youth teams in the region of its production sites.

New Central Laboratory near Görlitz

Only a few kilometers away from the Görlitz plant, the BIRKENSTOCK Group will also set up its new central chemical laboratory by the end of 2019. The plant in Bernstadt concentrates entirely on the manufacture of the so-called “components”. These are the shafts, buckles and rivets, for which mainly materials such as leather, textiles, metal and plastics are processed. Therefore, the need for laboratory capacities is particularly high here.

With the creation of its own chemical central laboratory, BIRKENSTOCK is taking a different approach in Europe, if not worldwide. Because the fact is: most global shoe brands have their products mainly manufactured in Southeast Asia. Most of the chemical analysis are usually carried out there as well. Not so at BIRKENSTOCK: the materials for the sandals are not only processed at our production sites in Germany, but will also be tested in the company’s own laboratory in Germany in the future. This is likely to be largely unique, at least in the dimensions in which production takes place – BIRKENSTOCK manufactured and sold around 25 million pairs of shoes last year. With the creation of its own laboratory capacities on a large scale, BIRKENSTOCK is broadening the value chain in the procurement area and at the same time setting an example against the business model of the European shoe industry, which is essentially based on the principle of contract manufacturing in low-wage countries, and all of the associated problems.

- Environment

- Road to Net Zero

- Art & Design

- Film & TV

- Music & On-stage

- Pop Culture

- Fashion & Beauty

- Home & Garden

- Things to do

- Combat Sports

- Horse Racing

- Beyond the Headlines

- Trending Middle East

- Business Extra

- Culture Bites

- Year of Elections

- Pocketful of Dirhams

- Books of My Life

- Iraq: 20 Years On

Germany's luxury footwear maker Birkenstock set to go public

The company, which plans to list its shares on the new york stock exchange, will continue to be controlled by private equity firm l catterton.

More than half – 54 per cent – of the company’s customers are in the Americas with Europe accounting for 36 per cent. AFP

Birkenstock has filed for an initial public offering, in another sign of the allure US equity markets hold for European firms seeking a valuation uplift.

The German footwear maker , whose iconic sandals are worn by hippies and preppies alike, will continue to be controlled by private equity firm L Catterton, a filing on Tuesday revealed. The company will disclose the proposed terms of the share sale in a later filing with the US Securities and Exchange Commission.

The IPO could value Birkenstock at more than $8 billion, Bloomberg News reported previously.

Goldman Sachs Group , JP Morgan Chase and Morgan Stanley are leading the offering, which comes more than two years after L Catterton and the family investment company of billionaire Bernard Arnault acquired a majority stake in Birkenstock, valuing it at about €4 billion ($4.3 billion).

The US market for IPOs looks like it’s finally coming back to life after 18 months in the doldrums. Birkenstock’s IPO filing comes hot the heels of others from SoftBank Group's semiconductor designer Arm , grocery delivery firm Instacart and marketing and data automation provider Klaviyo.

Founded nearly 250 years ago, Birkenstock developed a contoured insole for greater comfort. The modern, cork-lined sandals took hold in the 1970s, as shoppers from the US Southwest to Europe became enamoured with the comfy style. Birkenstock has since become a high-fashion brand, launching collaborations with luxury names such as Dior, Manolo Blahnik and Valentino, and spawning variants from labels including Celine and Givenchy.

More than half – 54 per cent – of the company’s customers are in the Americas with Europe accounting for 36 per cent, according to Tuesday’s filing. While women make up 72 per cent of Birkenstock customers, the footwear has broad cross-generational appeal, led by millennials with 31 per cent of sales, followed by baby boomers with 30 per cent, Gen X with 27 per cent, and Gen Z with 12 per cent.

A shopper visits a Walmart in Rosemead, California. Stock markets were down again on the last trading day of 2022, a year that has been marked by record inflation. AFP

A listing would cap off a successful run for the company, whose family heirs stepped back from management duties about a decade ago. Since then, it’s streamlined strategy, launched high-profile collaborations and experienced explosive growth in demand.

“We see ourselves as the oldest start-up on earth,” chief executive Oliver Reichert said in a letter to investors included in the filing.

“We are a brand backed by a family tradition of a quarter of a millennium with the resilience, timeless relevance, and credibility of a multi-generational business.”

Sales have been boosted of late by the blockbuster Barbie movie, whose star Margot Robbie sports a pair of pink Birkenstocks in one scene.

For the six months ended March 31, the company had a net profit of €40 million on revenue of €644 million, as indicated by the filing. That compares with €73 million on revenue of €543 million during the same period a year ago.

Birkenstock has also been investing heavily in building out its production sites in Germany, including a new €120 million factory in Pasewalk, a town north of Berlin.

The company, which will become Birkenstock Holding Ltd, plans to list its shares on the New York Stock Exchange under the symbol BIRK.

Energy This Week

Expert analysis on oil & gas renewables and clean energy

Early access to products and promotions

Member Exclusive Products

Birthday Surprise

Tradition - Innovation - Fascination

Two and a half centuries of experience.

BIRKENSTOCK is an exceptional phenomenon in a clothing industry characterized by short-lived fashion trends. The company’s roots can be traced back to 1774. Our brand identity is based on a solid foundation of two and a half centuries of corporate history.

Global brand with German roots

BIRKENSTOCK is a global brand. BIRKENSTOCK is not only one of the top five global footwear brands, it is also one of the most well known German brands in the world. With around 5,500 employees, this tradition-rich, sixth-generation family-owned business is also the German footwear industry’s largest employer. About one in four employees in the industry works at BIRKENSTOCK. More than 3,000 new jobs have been created since the beginning of 2013, almost all of them in Germany. This is because BIRKENSTOCK produces most of its products at its own production facilities in Rhineland-Palatinate, North Rhine-Westphalia, Bavaria, Hesse and Saxony.

BIRKENSTOCK has been a global player since the 1970s. Our products are sold in some 90 countries on all continents. And our organization is becoming increasingly international as well. BIRKENSTOCK has 16 locations in Germany. Internationally, we are represented with sales offices in the United States, Brazil, China, Singapore, Hong Kong, Japan, Denmark, Poland, Slovakia, Spain, France, Norway, Dubai, India and the United Kingdom.

Inventor of the footbed

We create products that make the lives of our customers easier and better. Our core products is our unique, anatomically shaped footbed. BIRKENSTOCK invented the footbed and has also shaped the meaning of the term "footbed", which is so common today. The footbed is not only a unique, revolutionary product concept that paved the way for a completely new market. It's also a core idea and a reference point for everything that we do. Now and in the future. Everyone should have access to our footbed.

BIRKENSTOCK stands for excellent comfort, high functionality and extraordinary quality. The high level of quality is the result of carefully selected, high-quality materials from sustainable sources that are processed under what are for our brand typically demanding conditions. Our products promote wellbeing. They literally do good. So they stand out from the flood of cheap products that dominate large parts of our consumer world today.

COMMENTS

Birkenstock has opened its manufacturing sites in Bernstadt and Görlitz to the public for the first time ever. Lifting the veil on how the brand's famous leather and cork sandals are made, FashionNetwork.com reports about the shoe company's expansion strategy and vision for the future. For the first time ever, visitors are allowed inside Birkenstock's production facilities in Germany ...

The day before, BIRKENSTOCK had invited representatives of the state government and the city of Pasewalk, including Reinhard Meyer, Minister for Economy, Infrastructure, Tourism and Labor, to a tour of the plant. There has been a lot going on at the Berlin-Szczecin Industrial Park since BIRKENSTOCK laid the foundation for the new plant last ...

The BIRKENSTOCK buckle is a masterpiece of simple design by Karl Birkenstock. The production facility in eastern Germany's Markersdorf is home to a highly ev...

The opening hours of BIRKENSTOCK Factory Outlet Görlitz, which is located on the 2nd floor of the Gewerbering 6 building, are as follows: 11:30 a.m. to 6 p.m. on weekdays and 10 a.m. to 2 p.m. on Saturdays. Due to its excellent transport links in the German-Polish border region, the new store is set to attract visitors from the tri-nation ...

https://youtube.com/playlist?list=PL08a_WSkwXOMiAJgkzZ87q82Bx5L7UWqZ&si=v42v3bPMWMJILQDyWelcome to the Director's Cut of our 'Made in Germany' series. Take a...

1966 - Birkenstock is introduced into the U.S. market. 1988 - Environmentally-friendly adhesives are used in production - setting a new standard for environmental awareness worldwide. 1990 - Production is expanded and modernized to reduce energy consumption by over 90%. 2009 - A new and bigger footbed production facility becomes ...

With around 6,200 employees worldwide, we believe how things are made matters as much as the product itself. To ensure these quality standards, we operate a vertically integrated manufacturing base and produce all our footbeds in Germany. In addition, we assemble over 95% of our products in Germany and we source over 90% of our materials and ...

With around 6,200 employees worldwide, we believe how things are made matters as much as the product itself. To ensure these quality standards, we operate a vertically integrated manufacturing base and produce all our footbeds in Germany. In addition, we assemble over 95% of our products in Germany and we source over 90% of our materials and ...

Footwear manufacturer Birkenstock has begun operations at its new production facility in the Berlin-Szczecin industrial park near Pasewalk, Germany. Construction began in April 2022, with the foundation stone laid in August of the same year. The new facility is the single largest investment in the company's history at around €110 million.

Birkenstock 2019. About 30 minutes away at Birkenstock's Görlitz factory, some 1,350 employees work daily to produce Birkenstock's iconic fussbett from cork and EVA, using some 5,952 pounds ...

He is gesturing at hundreds of rows of industrial shelving units, 15m high, in Birkenstock's factory in Görlitz, eastern Germany, a town within borscht-spilling distance of Poland. The 36,000sq ...

Sep 22, 2023 Germany. The new Birkenstock production facility, located in the Berlin-Szczecin industrial park near Pasewalk, has started operations on the 5 th of September according to schedule. It was the largest single investment in the history of the company, at a cost of almost 110 million euros. The facility will initially employ around ...

The Scions of Sandals. The seven generations who brought hippies and hypebeasts their favorite ugly shoe. From Carl's failure, today's Birkenstock was born. His son, Karl, cracked the code in ...

For this iteration, Birkenstock invites us into its factory in Germany to see how its brand new 222 West shoe has been made. The 222 West comes from Birkenstock's luxury 1774 collection, ...

Birkenstock is getting close to completing its factory under construction in Pasewalk, Germany. In August, the footwear company broke ground on the 120-million-euro ($127 million) project at the ...

Bonn and Bad Godesberg hop-on hop-off tour in a double-decker bus. 18. ... Excellent quality products and customer service at Birkenstock store in Bad Honnef, Germany. ... this is the " outlet or sonderpreis" section, factory seconds- small flaws on most where some great savings can be made.

Address. Am Neutor 3, 53113 Bonn, Germany. Phone +49 228 90904440. Web Visit website. The most famous gummy bears in the world come from Germany. Haribo Goldbären (gold bears) were born in 1920 in Bonn in West Germany . Today, Haribo is the largest manufacturer of gummy sweets on the globe.

LINZ, Germany , March 8, 2023 /PRNewswire/ -- After BIRKENSTOCK laid the foundation of its 120-million-euro lighthouse project in Pasewalk only last August, the next milestone was celebrated with ...

As a result of BIRKENSTOCK's rapid growth, eastern Saxony has developed into a center of the German and European shoe industry - a development which has gone largely unnoticed by the general public. Approximately 11,600 people work in the industry in Germany, including 1,800 employees at BIRKENSTOCK's two locations in Saxony.

Birkenstock Holding plc is a German shoe manufacturer known for its sandals and other shoes notable for contoured cork footbeds (soles), made with layers of suede and jute, which conform to the shape of their wearers' feet.Founded in 1774 by Johann Adam Birkenstock and headquartered in Neustadt (Wied), Rhineland-Palatinate, Germany, the company's original purpose was to create shoes that ...

The fact is: no other location has benefited as much from the positive development of Germany's largest shoe manufacturer in recent years than the BIRKENSTOCK plant in Görlitz. In the last 18 months alone, the company has invested millions of euros in strengthening and expanding the plant. BIRKENSTOCK just opened a factory outlet in June 2017.

Birkenstock has opened its manufacturing sites in Bernstadt and Görlitz to the public for the first time ever. Lifting the veil on how the brand's famous leather and cork sandals are made, FashionNetwork.com reports about the shoe company's expansion strategy and vision for the future. For the first time ever, visitors are allowed inside Birkenstock's production facilities in Germany ...

Birkenstock has also been investing heavily in building out its production sites in Germany, including a new €120 million factory in Pasewalk, a town north of Berlin. The company, which will become Birkenstock Holding Ltd, plans to list its shares on the New York Stock Exchange under the symbol BIRK.

BIRKENSTOCK has been a global player since the 1970s. Our products are sold in some 90 countries on all continents. And our organization is becoming increasingly international as well. BIRKENSTOCK has 16 locations in Germany. Internationally, we are represented with sales offices in the United States, Brazil, China, Singapore, Hong Kong, Japan ...