Factory Tours

Get a good look at american manufacturing.

Factories are one of the many reminders of our state’s prized industrial heritage. From coins and motorcycles to potato chips and chocolate, many Pennsylvania factories offer tours and are the perfect places to find Made-in-PA keepsakes.

Get trip ideas

City Life Best Things to Do in the Pocono Mountains What do scenic hiking trails, thrilling waterparks, and premier casinos have in common? You can find them all in the Pocono Mountains! If you're traveling to northeast Pennsylvania and want to know wh ... Read More

City Life Best Things to Do in Philadelphia Planning a visit to Pennsylvania's largest city? If you're wondering what to do in Philadelphia, your options are truly endless! Explore America's constitutional history, reenact an iconic movie scene ... Read More

City Life Best Things to Do in Lancaster, PA History, culture, art, city life, and delicious food all come together in Lancaster, Pennsylvania. Whether you're a longtime fan who visits often or are crossing state lines to explore the area for th ... Read More

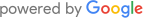

Factory Tour Destinations

Results are limited to a 25-mile radius

Altoona, PA Benzel's Pretzel Bakery

Lebanon, PA Weavers-Kutztown Bologna Inc

Souderton, PA Asher's Chocolates Factory

Mercer, PA Wendell August Forge

Lititz, PA The Julius Sturgis Pretzel Bakery

Pottsville, PA Yuengling Museum & Gift Shop

Tyrone, PA Gardner's Candy Museum

Nazareth, PA C.F. Martin & Co.

Lakeville, PA Sculpted Ice Works Factory Tour & Natural Ice Harvest Museum

Geigertown, PA Joanna Furnace Historic Site

Hanover, PA Snyder's Of Hanover Factory Outlet

Thomasville, PA Martin's Potato Chips Inc.

Mount Joy, PA Wilton Armtale Factory Store

Saint Marys, PA Straub Brewery

Philadelphia, PA U.S. Mint

Scranton, PA Lackawanna Coal Mine Tour

Mountainhome, PA Callie's Candy Kitchen

Brookville, PA BWP Bats, LLC

Nottingham, PA Herr's Snack Factory Tour

Cresco, PA Callie's Pretzel Factory

Hershey, PA Hersheypark

Hershey, PA Hershey

Hershey, PA Hershey's Chocolate World

Lewistown, PA Asher's Chocolates Factory - Lewistown

York, PA Harley-Davidson Vehicle Operations Factory Tour

Columbia, PA Turkey Hill Experience

Easton, PA Crayola Experience

York, PA Wolfgang Confectioners

Hanover, PA Utz Quality Foods

We use cookies to ensure that we give you the best experience on our website. If you continue to use our website, we will assume that you are happy to receive all cookies (and milk!) from visitPA.com. Learn more about cookie data in our Privacy Policy

Pepperidge Farm Tour

03 Jan Pepperidge Farm Tour

Still the leader Pepperidge Farm continues to invest in the latest robotics and other cutting edge systems to boost production efficiency, capacity and flexibility at its flagship Denver, Pa., plant.

By Dan Malovany

When the Denver, Pa., plant started up in 1991, the newest Pepperidge Farm player on the roster had all of the equipment to be an all-star operation for years to come. Built at 611,000 sq. ft. at an almost unheard of cost of $180 million, the Denver plant was seven years in the making and a start of technology that incorporated the most comprehensive, computer-integrated manufacturing (CIM) capabilities of its time.

However, like any rookie, the Denver facility needed a little seasoning before it could really show its potential. The first steps toward big-league success involved training the employees on the new computers and automation, then creating an operational structure that allowed its workers to harness that technology. Initially, more than half of the employees came down from the aging Downingtown, Pa., bakery that Denver had replaced and located 34 miles down the Pennsylvania Turnpike. While many of these employees had valuable, hands-on baking experience, they needed almost as much training as many of the additional employees that Pepperidge Farm eventually hired off the street as the plant got up to steam in the mid-90’s.

That’s because Denver’s state-of-the-art equipment made it one of the new breed of bakeries where performance is determined less by baking experience and more by understanding programmable controls and adhering to statistical controls. To improve the plant’s performance over the years, the Denver team has had to devise new systems that not only raised the learning curve of the workforce, but also required thinking totally out of the box to improve production capacity as well as line efficiencies.

Using data gathered from the plant’s statistical process controls, teams on each line meet weekly to analyze ways to reduce loss, increase production consistency, minimize changeovers, enhance throughput, reduce new product startup issues or improve safety. In some cases, such rethinking of the process involved a tweak here and there, such as determining that the flatness of the band on the Milano oven was a critical factor in producing consistently oval sandwich cookies. In other cases, such rethinking has forced Pepperidge Farm to challenge how it traditionally produces its top-selling icons as the company has continued to invest in new emerging technology.

“We know that as technology changes, we have to change with technology,” notes Dean Moll, Denver’s plant manager. “When this plant was built, we were well-positioned for the 90’s. Every day, we’re making sure that we’re prepared for the 2000’s. I think we are. Just in the last three years, for example, we have doubled the throughput on two key lines – Goldfish and Milano.”

The Denver plant is the featured tour at this year’s B&CMA Technical Conference. Today, the facility is divided into two operations areas – a 351,000-sq.-ft. area for biscuit production and 260,000 sq. ft. for bread and roll production. Overall, the plant has 12 lines, including three bakery lines producing sliced breads, French (string line) breads and rolls. The nine biscuit lines produce Goldfish crackers as well as a variety of premium cookies, ranging from Soft Baked and Chocolate Collections to Milanos, Brussels and more.

The improvements on Goldfish Line 7 and Milano Line 3 that Moll refers to are classic examples on how Pepperidge Farm has transformed the Denver plant from an engineering milestone where technology controlled people to a facility where it’s now people over machine.

Previously, it would have been heretical to even consider tinkering with the Goldfish process. Today, however, the plant uses radio frequency drying equipment that has doubled the line’s throughput. In the past, Pepperidge Farm could not increase the oven’s throughput dramatically on the Goldfish line because it would significantly increase the amount of moisture in the final product, which affected the cracker’s texture. Because the dryer reduces moisture of the snack cracker in half, without impacting color, size or other baking characteristics, the plant is able to double production capacity without having to put in a new oven or additional Goldfish line. It also has allowed Pepperidge to produce a variety of new line extensions, such as its giant Goldfish crackers, which has higher moisture levels.

“That’s an example of technology that was not there when the plant was built,” Moll notes. Overall, he adds, “It’s not a questions of what we would do differently if the plant were built today. It’s about how technology has changed, and how we have changed with it.”

Moreover, on the Goldfish line, Pepperidge Farm has added seasoners, which are similar to those used in potato ship plants, for its flavor-blasted snack crackers. To meet the burgeoning number of marketing needs over the years, Team Goldfish designed a maze of conveyors that lead from lines to multiple packaging stations from any one line.

Pepperidge can produce a kaleidoscope of Goldfish packaging configurations ranging from 1-oz. single serve or standard 6-oz. bags to flavor-blasted milk cartons, 31-oz. foodservice or 38-oz. club store size.

On the Milano line, the plant has changed the way it deposits the batter. Previously, the company had two depositors – one as a backup if the other needed cleaning or if it broke down. By slowing depositor speeds and synchronizing them, engineers have increased throughput by 50% without adding another piece of equipment, notes Paul Brooker, manager of engineering.

“If one of the depositors goes down, we can still run the line with one depositor and kick up production to speeds like we ran before,” Brooker says. “It really gives us flexibility. We can use the two depositors to maximize capacity or we can use them as a backup if something goes wrong. These are the little things that get you over the hump to improve your yields.”

With the increased depositor speeds, Denver in 1998 moved to install a faster, second-generation robotic cookie sandwiching system that picks and places cookies at a rate of 1,320 a minute compared with 880 a minute on the older system, which was initially installed in 1988.

The new system’s 12 robotic arms can pick and place at speeds of 120 per minute, which is nearly double the speed of the “old” robotic system that has 20 arms working at a rate of 60 to 75 per minute. Brooker says the new system is faster because, with four servo devices, it was designed for light payloads at faster cycle speeds while the older system had been designed for heavier payloads and slower cycle speeds for assembling automobiles and other heavy machinery.

Because robotics are becoming more sophisticated, more adept and increasingly affordable, the payback has become shorter, says Dave Watson, Pepperidge’s director of corporate engineering, who was the lead engineer and one of the key architects in the start up of the Denver plant a decade ago.

Watson notes that the first-generation robotic system cost $3.5 million, resulted in annual savings of $1.1 million in direct labor and worker compensation costs and has a 3.9-year payback. That’s an internal rate of return (IRR) of 20.2%. The new system cost $2.0 million, resulted in annual savings of $1.3 million in direct labor only and has a cash payback of 1.5 years or an IRR of 41.3%, Watson adds.

The increased capacity has prompted Pepperidge Farm to further justify an investment in a prototype, robotic cookie cupping system that picks individual cookies from a moving belt and loads them with paper cups in multiple orientations at a rate of 120 cups a minute.

“If you don’t have these robotics, you couldn’t even put enough people on the line to keep up with the speed of production,” Brooker says. “Until we hit these speeds and dedicated this line [to Milano production], we could not justify the investments that we made on it. We need to run this every shift,” which is currently 15 shifts per week.

The system, which became operational just this summer, features two robotic cuppers that each pick and place 660 cookies – or 100 bags – a minute. The system cost $3.2 million, will provide $1.2 million annual savings in direct labor only and has a cash payback of 3.26 years or an IRR of 27.8%.

Automation improvements have allowed the Denver facility to put together a career season as far as statistics, with the number of cases of products for the entire plant rising 26% to more than 12 million this year.

That’s nearly 60% more than the 7 million cases of product produced in 1997 and triple the amount produced during its first full year of operation in 1992.

At the same time, the plant has reduced its waste by 50%, saving the company millions of dollars. It’s not surprising to learn, then, that Denver won the equivalent of the MVP award when the team received the Margaret Rudkin Award, named after Pepperidge’s founder, for plant of the year.

“We were fortunate enough to start as a premier facility, and we have invested over the years to keep it on the cutting edge,” says Moll, who notes Denver received ISO 9002 certification this year. “We want to keep it a leading-edge facility, but it will only be a leading edge, and state of the art if we have our people take us there.”

What’s been driving Pepperidge Farm’s growth over the last few years has been the company’s switch to an icon strategy, where the company puts it marketing muscle behind the biggest and best products in its portfolio, including Goldfish, Milano and Swirl breads. By increasing these product sales, line volumes grow, which improves production efficiencies. Meanwhile, part of the money saved by increased efficiencies is being funneled into marketing and R&D programs to create new packaging, boost advertising budgets or roll out new products, such as the successful debut of chocolate-enrobed Milanos that will be produced seasonally later this year.

Production typically runs 24 hours a day, five to seven days a week. Bulk flour is stored in 10, 120,000-lb. silos. Two, 120,000-lb. silos hold sugar. Flour is transferred to 20,000-lb. use bins to ensure accurate scaling and quicker cycle times. The plant has 50,000-lb. tanks for shortening, corn syrup, canola oil, blended oil and an 80,000-lb. chocolate tank. Six manually-filled bins hold minor ingredients, such as rye flour, starch and wheat gluten. Micro ingredients are hand measured, then put in carts that each hold one batch.

On the mezzanine level, the control room for Denver’s CIM system looks like Houston Control where central supervisory computers oversee a network of more than 100 industrial-hardened PC’s linked by fiber optic lines. Each line has its own supervisory computer, as does ingredient handling and mixing. Pepperidge Farm has replaced its initial IBM 386s PC/2s with IBM 486s, which use generally available software and hardware, not proprietary, which makes upgrading more affordable.

On the mezzanine level on the biscuit side, five 1,300-lb. cookie and two 1,500-lb. cracker mixers control formulation and mixing time. All come with CO2 systems to control dough temperature. After mixing, batches fall through 20-ft. chutes, which are hoisted through slots on the floor, to the first level.

On six cookie lines, three produce chocolate bottom-coated or enrobed cookies. Others produce soft-baked, shortbread, assortment packs or a variety of chocolate chip and other wirecut cookies. Line 1 also produces Goldfish Graham snacks. Oven sizes range form 150 to 300 ft. on the biscuit lines.

Perhaps most unique are the Milano lines. There, after makeup, cookies travel through a 150-ft. oven to a 60-ft cooling tunnel. To ensure proper cooling, Pepperidge used a device similar to an oven “mole” to measure the tunnel’s temperature, air velocity and other variables. After the mini-bottomer applies orange, mint or chocolate coating, Milanos travel to the robotic sandwiching systems. Double chocolate-filled Milanos receive another coating by a second bottomer before sandwiching. Because they have twice the filling, the double chocolate-filled Milanos receive a second cooling to ensure the product is sealed.

Next, the Milanos then race toward the robotic cupper at a rate of 1,320 a minute. Using a counter-flow principle, five cookies at a time head into the front system while six cups at a time are denested from the rear. One photo eye ensures that the cups have been denested while a second makes sure the cookie is properly topped. If it sees dark chocolate, as in the filling, and not white vanilla, as in the cookie, the system will assume the cookie isn’t sandwiched. Overall, the system is programmed to fill the cups. If the cookies aren’t picked up, they are conveyed to the end and recycled later or discarded.

After filling, the filled cups loop around 180° to the stuffers, which place them in the bag, which are sealed, then cased and sent to warehousing.

On the Goldfish line, the freshly mixed, yeast-raised dough receives an extended fermentation before being dumped from the mezzanine level to the first floor, where it’s laminated, die-cut and baked. After moving through the radio frequency dryer, which reduces the product moisture in half to its proper level, the Goldfish travel through a seasoner and a new larger-sized accumulator, which was installed when the line’s capacity was doubled.

From the accumulator, the Goldfish head into bucket conveyors to one of many scalers, which place the exact weight of product into the package below. After sealing, the filled bags of Goldfish travel single file to case packers.

On the line, sophisticated sensors meticulously monitor color, moisture, height and the amount of oil or salt. QA personnel routinely take samples of the line for scoring and testing.

In the vast warehouse, employees break down product off conveyors by depot. Each day, about 40 tractor trailers are filled at Denver, whose biscuit operation services 120 mid-Atlantic and New England depots. Typically, the warehouse holds one week of inventory of cookies and crackers.

Streamlining changeovers are two areas which the company is seeking to improve on the biscuit side. Previously, Denver conducted changeovers after every 8-hour shift. Now the plant’s making them in mid-shift “to whittle our inventory down next to nothing,” Moll says.

“We’re learning from the bakery side how to change on the fly,” Moll explains. “Our goal is to take that thought process over to the biscuit side.”

New product development is another area where Pepperidge Farm and its Denver plant are striving to streamline. Previously, it normally took 4-6 months to introduce a new product. Under a new program called “Project Lightening,” the company wants to go from idea concept to production in two months.

Such challenges to reduce costs, enhance quality, improve throughput and increase safety, along with the 20 strict standards of ISO 9002 certification, have prompted Moll to reorganize the management structure at the plant. Today, to oversee production, Denver has three product managers – one for bakery, cookie, and cracker – reporting to operations manager, William Livingstone. To oversee incoming ingredients and outgoing product, planning, receiving, warehousing and shipping managers report to supply chain manager Stephen Lieb.

“Part of the reason for systematic changes that we have made is due to the growth of the company over the years,” Moll says. “And as we had to bring new people in, we need a strong system to consistently produce products that live up to our company’s standards.”

Asked what he would do differently if he had a chance to rebuild the Denver facility again from scratch, Moll replies, “I don’t think it’s a case of what we would have done differently. We did a good job. It’s a wonderful plant. Our charge is – as technology changes – to improve on what we have here and make it better.”

With such a mandate, it’s safe to say, for Pepperidge Farm “there’s never an ordinary day” in Denver, Pa.

No Comments

Sorry, the comment form is closed at this time.

Search this Site:

Pennsylvania factory tours | see it made in the usa.

Some of the links on this page may be affiliate links. As an Amazon associate, I earn from qualifying purchases. There is no additional cost to you when you make a qualifying purchase via an affiliate link. Click here for the full affiliate disclosure.

Take a Made in America Pennsylvania Factory Tour

Pennsylvania is a great place to see how potato chips and snack foods are made , tour a brewery or candy factory , visit a dairy farm , or learn something new about American manufacturing on one of these educational Pennsylvania factory tours.

Pennsylvania Factories That Offer Tours

Harley Davidson | York, PA

Journey through the facility that produces the Sportster ® , Softail ® , Touring, and CVO ™ families of motorcycles and LiveWire ™ electric motorcycles.

#Harley Davidson

Cornwall Iron Furnace | Cornwall, PA

Visit America’s most complete charcoal-fueled ironmaking complex where all of the raw materials necessary for the smelting process were found in this self-contained iron plantation. Cornwall Iron Furnace is the only surviving intact charcoal cold blast furnace in the Western Hemisphere. Tours are available Friday-Sunday.

#Cornwall Iron Furnace

George’s Furniture | Marietta, PA

See how George’s Furniture is handcrafted by skilled craftsmen on a guided tour of the woodshop and showroom.

#George’s Furniture

Ken Smith Basses | Perkasie, PA

Visitors to the factory are awestruck by what is probably the largest collection and variety of musical-grade woods in the world. Smith Basses brings Old World Tradition and Modern Innovation together to craft the highest quality playable handmade bass guitars. Ken Smith pioneered, developed, and introduced many of the features used on today’s Basses that are now industry standards.

#Ken Smith Basses

Martin Guitar | Nazareth, PA

Guided, one-hour factory tours depart from the Visitor Center where you can visit the Martin Museum and 1833 Shop. You’ll experience first-hand the handmade craftsmanship that goes into every instrument Martin Guitar makes while learning about the nearly 200-year-old history of American-made Martin guitars.

Visit the Official Martin Guitar Amazon Store

#Martin Guitar

New Holland Haytools Plant | New Holland, PA

The expertise of engineering, research and development, sales, marketing, and manufacturing operations come together to produce the world’s top hay equipment in New Holland, PA. The campus is 341 acres with a 150-acre test farm and a 700,000-square-foot manufacturing plant. Tours can be scheduled on Tuesdays and Thursdays.

#New Holland

Sculpted Ice Works | Lakeville, PA

The Sculpted Ice Works factory tour and museum offers fun and educational tours of the working manufacturing facility for school groups, bus tours, scout groups, and more.

#Sculpted Ice Works

SnapCab | Warrington, PA

SnapCab manufactures elevators and invites individuals and groups to learn about SnapCab’s lean culture through a free tour of the facility. The free tour includes classroom training, a facility tour, and conversation with SnapCab frontline members.

United States Mint | Philadelphia, PA

More than 1,600 employees work at six United States Mint facilities with production in Philadelphia, PA, San Francisco, CA, Denver, CO, and West Point, NY. Free in-person tours of the Philadelphia and Denver facilities are available to learn about coin manufacturing and the history of the Mint.

Zippo & Case Knives Museum | Bradford, PA

It’s not a factory tour, but Zippo and Case Knives has a museum where visitors can explore 15,000 square feet of attractions. Guests will learn about Zippo’s contributions to the American effort in WWII, glance into Zippo’s famous repairs center, and more.

Visit the Official Zippo Amazon Store

Visit the Official Case Amazon Store

#Zippo #Case Knives

More Tours in Pennsylvania

Pennsylvania Chocolate & Candy Factory Tours

Made in the USA Matters has a complete directory of United States chocolate and candy factories that offer tours . Check out the chocolate and candy factory tours in Pennsylvania .

Pennsylvania Cheese Factory Tours

Made in the USA Matters has a complete directory of United States cheese factories that offer tours . Check out the cheese factory tours in Pennsylvania .

Pennsylvania Dairy Farm Tours

Made in the USA Matters has a complete directory of United States dairy farm tours . Check out the dairy farm tours in Pennsylvania .

Pennsylvania Distillery and Brewery Tours

Made in the USA Matters has a complete directory of United States distilleries and breweries that offer tours . Check out the distillery and brewery tours in Pennsylvania .

Pennsylvania Potato Chip & Snack Factory Tours

Made in the USA Matters has a complete directory of United States potato chip and snack factories that offer tours . Check out the potato chip and snack factory tours in Pennsylvania .

USA Factory Tours

Did we miss a Pennsylvania factory tour? Please share it with our community in the comments below.

American Dairy Farm Tours | See Dairy Products Made in the USA

American Cheese Factory Tours | See Cheese Made in the USA

American Chocolate & Candy Factory Tours | See Chocolate & Candy Made in the USA

American Potato Chip Factory Tours | See Snack Foods Made in the USA

American Distillery & Brewery Tours | See Spirits Made in the USA

Pin it pennsylvania factory tours.

Your saves and shares help other Americans find products that are Made in the USA. Thank you!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Made in the USA Product Categories

Baby & Toddler

Clothing & Shoes

Electronics & Accessories

Farm & Ranch Equipment

Food & Drinks

Hobbies & Leisure

Home Furnishings

Household Essentials

Patio & Garden

Personal Care

School & Office

Sporting Goods & Recreation

Tools & Home Improvement

© 2024 madeintheusamatters.com

- Share on Facebook

New! Made in the USA Matters Facebook Group

Join the Made in the USA Matters Facebook Group where you can ask for USA-made product recommendations, request we find an American-made product you're looking for, and help others find Made in the USA products they need.

We welcome Made in the USA consumers and manufacturers!

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Frugal Lancaster

Helping You Live a Frugal Life in Lancaster County, PA

Pepperidge Farm Community Store in Denver, PA

Did you know that the Pepperidge Farm plant in Denver, PA has a discount store open to the community on Saturday and Sunday mornings from 8am to 12noon? It is located at Rt 272 and the Turnpike exit.

This store accepts cash only!

Some of the best deals I found

You’ll find everything from 6.6oz bags of goldfish to 30 oz cartons , ranging in price from about $1.50 to $5.00. Campbell’s cooking soups , spaghettios and other canned items are available as well. In the freezer section there is bread, soups, turnovers and cakes.

I took some pictures below to show you a glimpse of what you’ll find and the prices. These photos were taken in November 2017.

They also had the Piourette Wafers at a discounted price. Please note that people who want the best cookies, start standing in line around 7:15am.

If you take your kids with you, the ladies at the checkout desk are really kind and often give a small bag of chessman cookies to the kids as a special treat!

FYI. Sometimes they have discounted cases of food in the hallway as you enter. In November 2017 they had cases of goldfish for just $3.00 because they had a sell by date in mid-December 2017.

You might also be interested in:

Did you love this post?

Want to receive more posts like this one in your inbox—and be the first to know about local deals, ways to save money and fun things to do in Lancaster PA?

Check your email right away. We just sent you a welcome letter with direct links to our most helpful resources in Lancaster County. And tomorrow you’ll get a neat little freebie from us. (Add [email protected] to your address book if you’re having trouble getting the emails!)

- Classical Conversations

Family Movie Nights for Classical Conversations Cycle 2 (Medieval History & Astronomy)

- Lancaster County

Young Artist classes a la carte is back for 2022: Build your own art camp at the Center for Creative Exploration (PA College of Art and Design)

Africa: Morning Time Guide, Read-Aloud List and Family Movie Ideas

Shopping Lancaster County Etsy Stores

Refreshing mountain christmas lights & family escape room experience.

- Local Events

7 Summer Theater Camps in Lancaster County

How We Save on Gas

How to Live Off Of Your Pantry for a Month

80+ Etsy Gifts for Classical Conversations Tutors

Our Family’s Top 10 Favorite Sourdough Recipes

Frugal Lancaster posts may contain affiliate links, which means we might make a small percentage of sales made through our links (at no extra cost to you!) Please read our privacy policy for more details.

- Denver Tourism

- Denver Hotels

- Denver Bed and Breakfast

- Denver Vacation Rentals

- Flights to Denver

- Pepperidge Farm Incorporated

- Things to Do in Denver

- Denver Travel Forum

- Denver Photos

- All Denver Hotels

- Denver Hotel Deals

- Last Minute Hotels in Denver

- Things to Do

- Restaurants

- Vacation Rentals

- Travel Stories

- Rental Cars

- Add a Place

- Travel Forum

- Travelers' Choice

- Help Center

Awesome Factory Outlet Store - Pepperidge Farm Incorporated

- United States

- Pennsylvania (PA)

- Lancaster County

- Denver

- Denver Restaurants

“Awesome Factory Outlet Store” Review of Pepperidge Farm Incorporated

Great selection and value of Pepperidge Farm products. Store opens early and was well stocked with favorites and special values.

- Excellent 14

- Very good 3

- All languages

- English (18)

- English (18)

17 - 18 of 18 reviews

Every Saturday and Sunday morning from 8 am until noon the outlet shop is open. You can find some extreme bargains. It is not very easy to find the entrance. There is only a VERY tiny sign at the entrance to a long driveway. Ask locally where it is.

Travelers who viewed Pepperidge Farm Incorporated also viewed

Been to pepperidge farm incorporated share your experiences, owners: what's your side of the story.

Own or manage this property? Claim your listing for free to respond to reviews, update your profile and much more.

Browse nearby

Pepperidge Farm Bakery Outlet – NOW LOCATED IN SUITE 1718

Pepperidge Farm® makes your favorite cookies, crackers, breads and rolls.

Pepperidge Farm® has been making exceptional cookies, crackers, breads and more for 75 years. At Pepperidge Farm, we bake the products you love. Goldfish® crackers, Swirl bread, and Mi lano®, Chessmen® and Sausalito® cookies, just to name a few.

Pepperidge Farm was founded in 1937 by Margaret Rudkin, an entrepreneurial homemaker who began by baking fresh, all-natural bread for her allergy-afflicted son. We still take care to bake every day using the best ingredients, so that it’s more than just a cookie, cracker or slice of bread…it’s the best moment of your day

Store Information

Suite number:, store hours.

Mon - Sat 10am to 8pm Sunday 11am to 6pm

Phone Number:

(717) 393-3989

For The Preferred Shopper

Free 6.6 oz. bag of Goldfish with a $10 or more purchase. Limit one free item per purchase.

The Hottest Deals from Pepperidge Farm Bakery Outlet – NOW LOCATED IN SUITE 1718

Discount Days

$4.99 with purchase of $10 or More

Pepperidge Farm

Baking is our passion. It’s the driving force behind everything we do and will be for generations to come.

Modal Title

Print some form of CTA FORM here

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Aliquam amet blanditiis, dicta dolor dolore doloribus eaque earum eveniet excepturi harum inventore ipsam laudantium magnam nemo perferendis rem sint sit. Corporis.

Accesory Area for CTA Modal

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Consectetur deserunt dignissimos dolorem doloremque error et eveniet, laboriosam? A adipisci cum dolore expedita laboriosam praesentium repellat voluptate voluptatibus. Ea, fugiat nesciunt!

Factory Tours

Celebrating american imagination and industry, 44 tours in pennsylvania.

- {{keyword}}

- {{$parent.googlePlacesAutocompleteEnabled ? location.description : location}}

View All Routes at Pepperidge Farm

discover pepperidge farm

Discover Pepperidge Farm

- Be your own boss --> Realize Your Full Potential

- Owning a distributorship --> Owning A Distributorship

- About us --> About Us

- All Routes for Sale

- Featured Routes

Search For Routes

- Pepperidge Farm

- United States

^corrected_spelling^

^original_spelling^, 273 routes at pepperidge farm.

- Title (A-Z)

- Title (Z-A)

- Company Name (A-Z)

- Company Name (Z-A)

- Date Posted (Newest to Oldest)

- Date Posted (Oldest to Newest)

- Distance (Furthest to Closest)

- Distance (Closest to Furthest)

Don't See What You're Looking For?

to receive job recommendations and notifications about new jobs that meet your skills.

Narrow Search

Not ready to apply.

Joining our Distributor Network will enhance your route search and application process. Whether you choose to apply or just leave your information, we look forward to staying connected with you.

Where To Buy

Get connected.

Need to find products near you? We can help.

Monday – Friday 8 a.m. to 8 p.m. (EST)

If you have a question or feedback, we'd love to hear it.

Please enter the information below to send us an email

Please tell us more about yourself and your experience with this product. Or, if you are contacting us on behalf of someone else, please respond based on that person’s information and experience. Thanks!

Allowed types: jpg, png, pdf. Max size: 10MB.

Looking for products details or nutritional info?

Looking for a media contact?

Connect with Us

IMAGES

VIDEO

COMMENTS

Just off I-76 in Denver, Pa., a 450,000-square-foot Pepperidge Farm bakery churns out cinnamon swirl bread, Milanos, and dark chocolate chip cookies by the thousands. It's also on pace to produce 55 million pounds of Goldfish this year, or about 20% of the national supply. Advertisement.

Wendell August Forge. Saint Marys, PA. Straub Brewery. Lakeville, PA. Sculpted Ice Works Factory Tour & Natural Ice Harvest Museum. Lewistown, PA. Asher's Chocolates Factory - Lewistown. Lebanon, PA. Weavers-Kutztown Bologna Inc.

03 Jan Pepperidge Farm Tour. Pepperidge Farm continues to invest in the latest robotics and other cutting edge systems to boost production efficiency, capacity and flexibility at its flagship Denver, Pa., plant. By Dan Malovany. When the Denver, Pa., plant started up in 1991, the newest Pepperidge Farm player on the roster had all of the ...

Kreider Farms Dairy Tour. Get a 360° view of farming on our tour from our 100ft Silo Observation Tower. Drive through our Moo-ternity Barn, Calving Corner and watch our girls get milked on our milking Cow-rousel. Plus, see the newest addition to our farm, the Kreider Valley Ranch, where we have Texas Longhorn Cattle! Visit Website.

Pepperidge Farm, owned by Campbells Campbell Soup Co, has a Denver, PA bakery which makes 55 million pounds of Goldfish crackers a year.Learn more about the ...

Explore all. Moist & Savory Stuffing. Choco-Mint Marshmallow Goldfish Treats. BBQ Bacon Sliders Made Easy. Thanksgiving Leftover Turkey Sandwiches. Holiday Brie en Croute. Chessmen® Sandwich Cookies. Pepperidge Farm® has been making exceptional cookies, crackers, breads and more for 75 years. We bake with passion using the best ingredients.

More than 1,600 employees work at six United States Mint facilities with production in Philadelphia, PA, San Francisco, CA, Denver, CO, and West Point, NY. Free in-person tours of the Philadelphia and Denver facilities are available to learn about coin manufacturing and the history of the Mint. Zippo & Case Knives Museum | Bradford, PA.

Pepperidge Farm Incorporated. Review. Share. 18 reviews #1 of 1 Specialty Food Markets in Denver $ Specialty Food Market. 2195 N Reading Rd, Denver, PA 17517-9112 +1 717-336-8500 Website Menu. Closed now : See all hours.

Pepperidge Farm Tour. Denver, PA October 23, 2015 . ... Pepperidge Farm's $2 billion portfolio includes the top-selling Goldfish crackers, delicious Milano and Sausalito cookies, frozen Puff Pastry and Texas toasts, and more than 50 varieties of fresh baked breads including Pepperidge Farm Swirl, Farmhouse and Whole Grain and Ecce Panis artisan ...

Did you know that the Pepperidge Farm plant in Denver, PA has a discount store open to the community on Saturday and Sunday mornings from 8am to 12noon?It is located at Rt 272 and the Turnpike exit. This store accepts cash only! Some of the best deals I found. You'll find everything from 6.6oz bags of goldfish to 30 oz cartons, ranging in price from about $1.50 to $5.00.

Pepperidge Farm's factory near Denver is giving away thousands of bags of goldfish crackers. ... Lancaster, PA 17603 717-291-8611 Facebook; X-Twitter; LinkedIn; YouTube; TikTok; Pinterest;

About Our Brands. Our commitment to DSD began in 1961 with the acquisition of Pepperidge Farm. With their commitment to quality and fresh baked goods, Pepperidge Farm built a network of independent distribution partners who made sure the store shelves were full of bakery items every day. DSD became the way we do business when we chose to expand ...

Pepperidge Farm Incorporated. 2195 N Reading Rd, Denver, PA 17517-9112. +1 717-336-8500. Website. Improve this listing. Ranked #1 of 1 Specialty Food Market in Denver. 18 Reviews. Patricia E. Elkridge, Maryland.

Pepperidge Farm. 97,049 likes · 3,045 talking about this. Holding baked goods to a higher standard since 1937. #HaveALittleTaste

For prices between $3.50 and $7.50, day-trippers can "grab a pint to take on the tour.". The ambiance is further enhanced by three highly polished copper brew-kettle domes suspended over the bar area. Vintage Pennsylvania breweriana, encased in glass, draws attention to the opposite wall. Rather than a robotic, self-guided tour with ...

Store Information Suite Number: 1718. Store Hours. Mon - Sat 10am to 8pm Sunday 11am to 6pm . Phone Number: (717) 393-3989. View In Directory Website Google Map

Self-guided multimedia tours of our new state-of-the-art facility are open to the public and are fun for all ages. The tours are free and access is available for our physically challenged visitors. Groups of 10 or more, please phone (215) 721-3276 to arrange your visit.

Fourteen years later, Margaret was a 40-year-old-mother of three young sons, living in Fairfield, Connecticut on a beautiful property called Pepperidge Farm—named for an ancient Pepperidge tree that grew there. The Rudkins had moved into Pepperidge Farm in 1929 —the same year as the great Stock Market Crash.

For screen reader problems with this website, please call 1-844-995-5545. Looking for a particular Pepperidge Farm® product in your area? Our easy-to-use store locator should do the trick.

neither pepperidge farm nor any of its employees or representatives makes any representations with respect to the information contained herein, including without limitation the fair market value of any existing pepperidge farm distributorship offered by its independent distributors, or the tax, financial, operational or legal outcomes of any ...

GMO is short for "genetically modified organisms.". It is sometimes called genetic engineering and refers to a process where desirable traits or characteristics are introduced into an organism. In America many farmers who grow canola, corn, soybean and sugar beet choose to use genetically modified seeds and have done so for nearly twenty ...

Pepperidge Farm. 595 Westport Ave Norwalk, CT 06851 United States. Call Us 1-888-737-7374. Monday - Friday 8 a.m. to 8 p.m. (EST) Email Us. If you have a question or feedback, we'd love to hear it. Send an email. Close modal. Please enter the information below to send us an email.