- Search forums

- Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

- Earthmoving Equipment

which way do i travel the excavator when on slopes?

- Thread starter instructor gus

- Start date Mar 11, 2015

instructor gus

- Mar 11, 2015

Sprockets downhill?:beatsme

Charter Member

Convention (Scrub Pullers words) dictates sprockets downhill.You will get some other opinions on this but I have never read otherwise in any operators manuals,Caterpillar included.That should be the digging or operating profile too.Pull against the idlers.The direction of travel would be intuitive then,rock them forward to travel forward,if an obstruction should enter the cab with the window open while traveling forward it would push the stick,foot treadle to the rear inhibiting the forward motion of the track train and possible injury to the operator..Ron G

Thanks Ron G! It seems like a "old school" method, meaning it's the traditional way to travel downhill but was wondering if it is something still practiced.

Garrie Denny

Senior member.

- Mar 17, 2015

You calling Scrub old ?

I think it was the school he was talking about.....LOL.Ron G

Scrub Puller

Yair . . . Fellers, I just put in about six hours knocking out wattle bushes with a little wheel tractor . . . I'm old and aching and got a crick in my neck. Cheers.

- Mar 18, 2015

I was only kidding RonG

- Apr 18, 2015

- Apr 23, 2015

Does this rule of thumb also apply to smaller excavators ? Say 5-6-7-8-9-ton with blade attachment at the opposite end to the drive gears, the blade is right in front of the Idlers ?

Well-Known Member

- Apr 26, 2015

Garrie Denny said: Does this rule of thumb also apply to smaller excavators ? Say 5-6-7-8-9-ton with blade attachment at the opposite end to the drive gears, the blade is right in front of the Idlers ? Click to expand...

- Apr 29, 2015

cdm123: Iagree with you on the idlers and blade being down hill for the reasons you have stated,seems like a no brainer to me.

Also the extra weight of your blade would be a lot more on a smaller machine than that of the finals.

- Find a Machine

Search the Blog

Excavator safety tips for before, during, and after operation.

While there are many safety features on John Deere excavators , there’s no guarantee they will always get the job done. Good judgment is always required to make full use of the features and ensure the safety of yourself and others around you.

Access the top performing equipment on the market. Explore our inventory of John Deere machinery!

How to Safely Operate An Excavator

Any time you operate equipment, it’s important to understand how you can maintain a safe work environment for yourself and those around you. Here are some excavator safety tips you should consider when putting the equipment to work.

How to Improve Excavator Safety

To ensure you are safely operating an excavator, check that the excavator is outfitted with sufficient visibility to enable drivers to have a clear view of areas where people could be in danger due to the operation of the equipment. Preparing and checking any and all safety features before operating an excavator is key to improving overall safety.

5 Excavator Safety Tips: Before Operation

Before starting your excavator, consider the following safety tips to ensure you are fully prepared for operation:

- Tip #1: Seat belts are provided for comfort and security.

- Tip #2: Before going to work, be sure the mirrors are clean and set properly.

- Tip #3: Make a quick check of the controls. Be sure the control levers are operating properly.

- Tip #4: Check the propel system. It’s better to do this before operating so you can prevent accidents on the job.

- Tip #5: Call the area’s utility services to have the job site marked for underground lines or structures.

18 Excavator Safety Tips: During Operation

Once you’ve completed the before-operation excavator safety tips, continue with the following:

- Tip #1: Never permit riders in the bucket, cab, or anywhere else on the machine. Excavators only have one seat, which is meant for the operator.

- Tip #2: Never attempt to operate the excavator unless you are sitting in the seat and in full control.

- Tip #3: Reduce the excavator’s speed when working on rough terrain or within congested areas.

- Tip #4: Carry the bucket low to the ground during transport. This will increase visibility and machine stability.

- Tip #5: When moving the excavator around the job site, select a route that is as flat as possible. Steer the machine as straight as possible and only make small gradual changes in direction when turning is needed.

- Tip #6: Travel directly up slopes vertically instead of diagonally.

- Tip #7: When propelling up slopes, the boom and the arm should be extended with the bucket carried low and rolled out. This will allow you to drop the bucket and prevent the equipment from sliding if necessary.

- Tip #8: When propelling down a slope, the bucket bottom should be low and parallel to the ground.

- Tip #9: In very steep or slippery conditions, you can use the boom and arm to help move up and down the slope. When going up a steep slope, extend the boom and arm, and when needed, lower the bucket and retract the arm to help pull the machine up. When traveling down a steep slope, position the bucket with the flat surface resting on the ground. While retracting the arm, raise the boom and propel the machine until the front of the tracks reach ground level.

- Tip #10: When using the excavator for trenching, make sure the machine is level by placing dirt underneath the tracks. Being level will make the trench vertical and will help to avoid cave-ins.

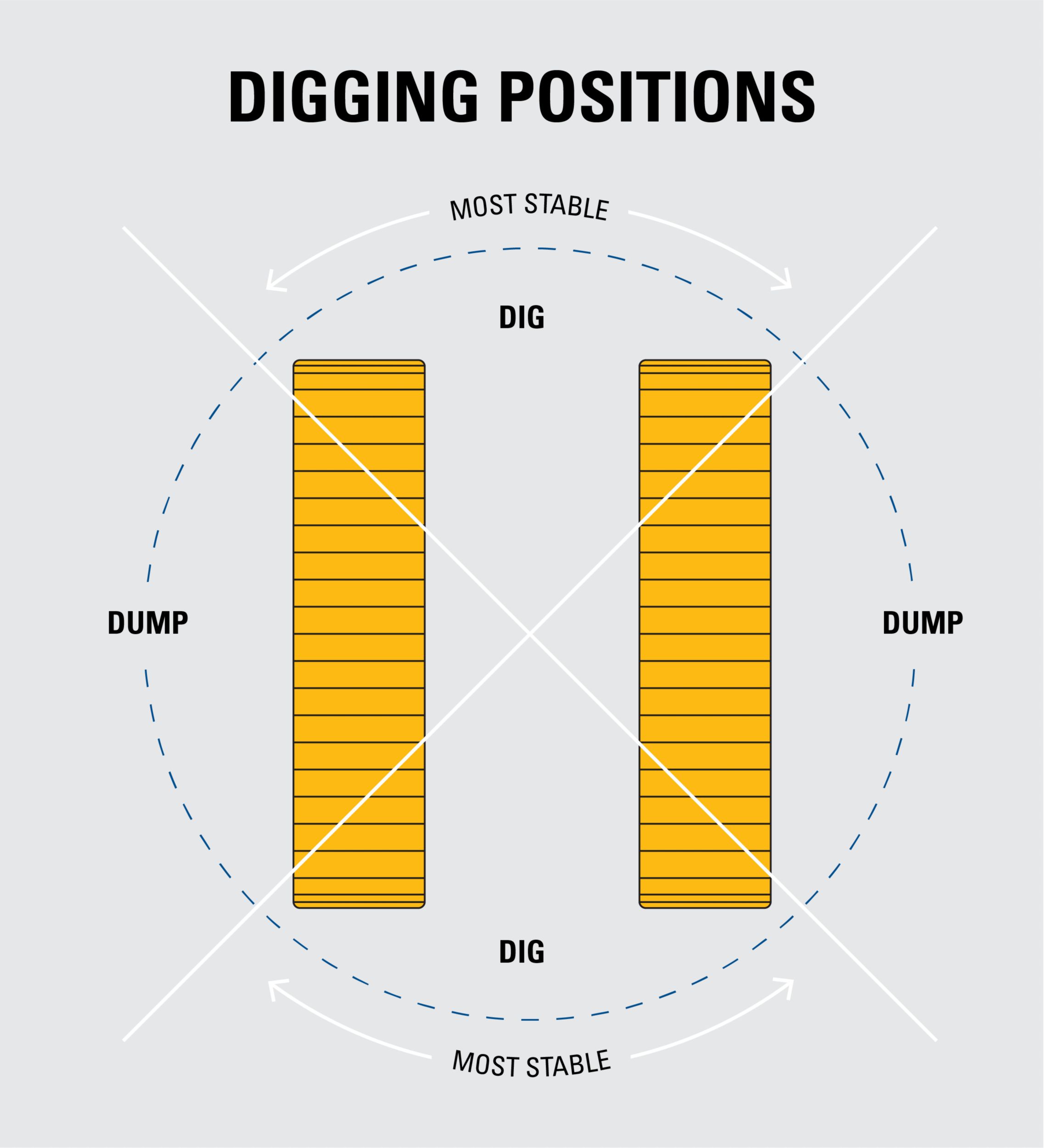

- Tip #11: For better stability, work with the propel motors to the rear of the machine.

- Tip #12: Dump spoil piles as far away from the excavation as possible to avoid cave-ins.

- Tip #13: When doing excavation jobs on slopes, level the machine by digging a shelf (or bench cut). Material removed from the upper slope can be used to build up the lower slope and create a level surface.

- Tip #14: On steep bench cuts, cut enough away from the upper bank to allow for adequate swing clearance when casting downslope.

- Tip #15: Never dig underneath the excavator.

- Tip #16: When backfilling a cave-in, the excavator’s tracks should be at a 90-degree angle to the excavation with the propel motors to the rear of the machine.

- Tip #17: When loading trucks, never swing the excavator bucket or the truck cab. By swinging over the rear of the truck, any loose materials will fall on the ground or in the bed, rather than on the cab.

- Tip #18: Never attempt tothe clean the excavator’s bucket by striking it on the ground or against another object.

4 Excavator Safety Tips: After Operation

Finally, once you’ve safely performed your day of work, consider the following post operation safety tips:

- Tip #1: When shutting down the unit, be sure it’s parked on a level surface with the bucket attachment lowered to the ground.

- Tip #2: Turn off the auto-idle switch and run the engine at half throttle without load for a few minutes to help cool the turbocharger down.

- Tip #3: Set the RPM to low idle before shutting the engine off with the key switch.

- Tip #4: Don’t forget to lock up the cab when exiting the equipment.

Final Thoughts

Don’t forget to keep these safety tips in mind the next time you start up your excavator for a day of work. For more information about John Deere excavators and operating them safely, contact your local John Deere dealer today.

If you enjoyed this post or want to read others, feel free to connect with us on Facebook , or Twitter !

Excavator Safety , john deere construction , John Deere excavators , John Deere safety , john deere tips

You might also like:

5 Tips for Operating an Excavator on a Slope

Operating machinery on smooth, straight and stable terrain is not as common as you may think. Work and construction sites are full of holes, hills, dirt piles and steep edges. Because of this, it is common to operate equipment such as an excavator on a slope.

Why Does Slope Matter for Operating an Excavator?

There are two main reasons that slope matters when operating an excavator. The first is the center of gravity. As the machine turns sideways, the center of gravity shifts. The steeper the slope, the higher the chance of tipping. Tipping a large excavator down a hill can be extremely dangerous.

The second is lubrication. As the engine turns and shifts on a slope, lubrication, oil and fuel all shift within the machine. Different excavators have different holding containers for lubrication. If they tilt too far, it could impact the engine’s ability to use the liquids. This can cause engine failure or damage.

Here are some safety tips and tricks for operating an excavator on an incline or slope .

1) Use the Right Machine

When operating a machine on a slope, or when operating a machine in general, always make sure you are using the correct machine. For excavator operation, a long reach excavator may work well for slopes and angled digging. This way, the actual machine can remain on stable ground while the extra long digging arm maneuvers the hill. If you don’t have one you can always rent a long reach excavator for a short period of time. Other specialty machines such as spider excavators can help the machine reach odd spaces and work over unique terrain.

2) Follow the 70% Rule

An excavator should not be operated on a slope of over 70%. 70% slope grade is a term used instead of angles or gradient. 70% slope is equal to a 35-degree angle.

How to Find the Slope of a Hill

A surveyor on a construction site should be able to help the operator determine the slope or grade of a hill. By using the elevation at the top and bottom of the hill, the surveyor can find the rise of the hill. If the hill is steep enough to make you question it, take the time to find someone with site plans or who can measure the slope to ensure that you and the machine are safe to operate.

3) Examine the Condition of the Hill

Rain, melting snow, ice, mud and loose rocks can impact the integrity of the hill. Even if the machine is well below the 70% rule, unstable terrain could cause a large machine such as an excavator to slip or shift under its own weight. Overturns can be dangerous with such large equipment.

If the weather has been bad or if the slope does not look secure, consider waiting a day or two for conditions to improve. If loose debris is causing the danger, consider clearing the space to make it safe for operation.

4) Be Aware of Equipment Positioning

When driving up a slope, the front attachment should be kept out and low to the ground to keep a lower center of gravity. The excavator boom can be used in your favor to maintain proper weight balance and distribution. It is easier to balance the weight of an excavator driving up a slope versus driving sideways across it.

5) If You Aren’t Comfortable, Don’t Operate

At the end of the day, operating an excavator on a slope is a skill acquired with experience, expertise and knowledge. If you aren’t comfortable, always feel like you can say “no” to the job. Ask for help or to get further instructions before trying something new on a whim. A 20 ton excavator isn’t just a class. 20 tons is the weight of three elephants, a loaded coach bus, and a whale shark. You would not think lightly of three elephants or a whale shark falling on top of you so don’t do the same when it comes to potentially tipping an excavator.

Safe Operation of an Excavator on a Slope

Operating on slopes can sometimes be necessary. However, all jobs should be taken seriously and done safely. By being aware of the terrain, following the 70% rule, watching the equipment poisoning and using the right machine can help make operating on a slope safe. However, if you ever aren’t safe, you should not operate. That way, everyone gets home safe and sound at the end of the day.

Set Job Site for Accurate Rates

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

- Personal Details

- Preferred Dealer

Site Settings

- Unit of Measure

- Industry & Role

- search Search

Open Till 5PM

We need more information to finish setting up your account. Would you like to do that now?

Yes, Let's Get Started

- Explore Products

- Find Used Products

- Rent Products

- Manage My Equipment

- View Finance Solutions

Find Dealer

Need help finding a Cat dealer near you? Our dealer locator provides the most up-to-date information on Cat dealers close to you. Simply enter your address and select the type of equipment you're looking for. Or, if you already know the name of the dealer you're searching for, you can type in the dealer's name for a list of locations.

Filter Dealer Results By:

Dealer Type

Equipment Type

CAT Vocational Trucks are currently available only in the United States and Canada. If you search for vocational trucks elsewhere you will not get any results.

Your dealer has been set close

You're Leaving Cat.com

Note that by entering data in this application for purposes of obtaining driving directions, you are providing such data directly to Google LLC and/or its affiliates. By clicking "I Agree" or by using the Google Maps functionality to obtain driving directions, you acknowledge and agree that use of Google Maps is subject to the then-current Google Maps/Google Earth Additional Terms of Service at https://developers.google.com/maps/terms-20180207#section_9_3 and Google Privacy Policy at https://policies.google.com/privacy

- Products & Services – North America

- Info for Owners

- Tips For Digging And Trenching With Your Excavator

TIPS FOR DIGGING AND TRENCHING WITH YOUR CAT® EXCAVATOR

Learning best practices for digging with your Cat® hydraulic excavator can save you time and money. These basic tips for digging and trenching can help you get the most out of your excavator while staying safe , increasing efficiency and reducing fuel costs.

POSITIONING YOUR EXCAVATOR

The larger the platform on which your excavator sits, the more stable your machine will be. An optimum setup would allow you to dig to the front or the rear, then dump to the sides. This lets a truck or spoil pile to get close to the side of your excavator and cuts down on the distance of each pass, saving fuel.

Need to make repeated long reaches? The most stable positions to dig are diagonally across each corner of your tracks.

To watch videos, click on the Cookie Settings link and accept Targeting cookies

OPTIMIZING YOUR DIGGING RANGE

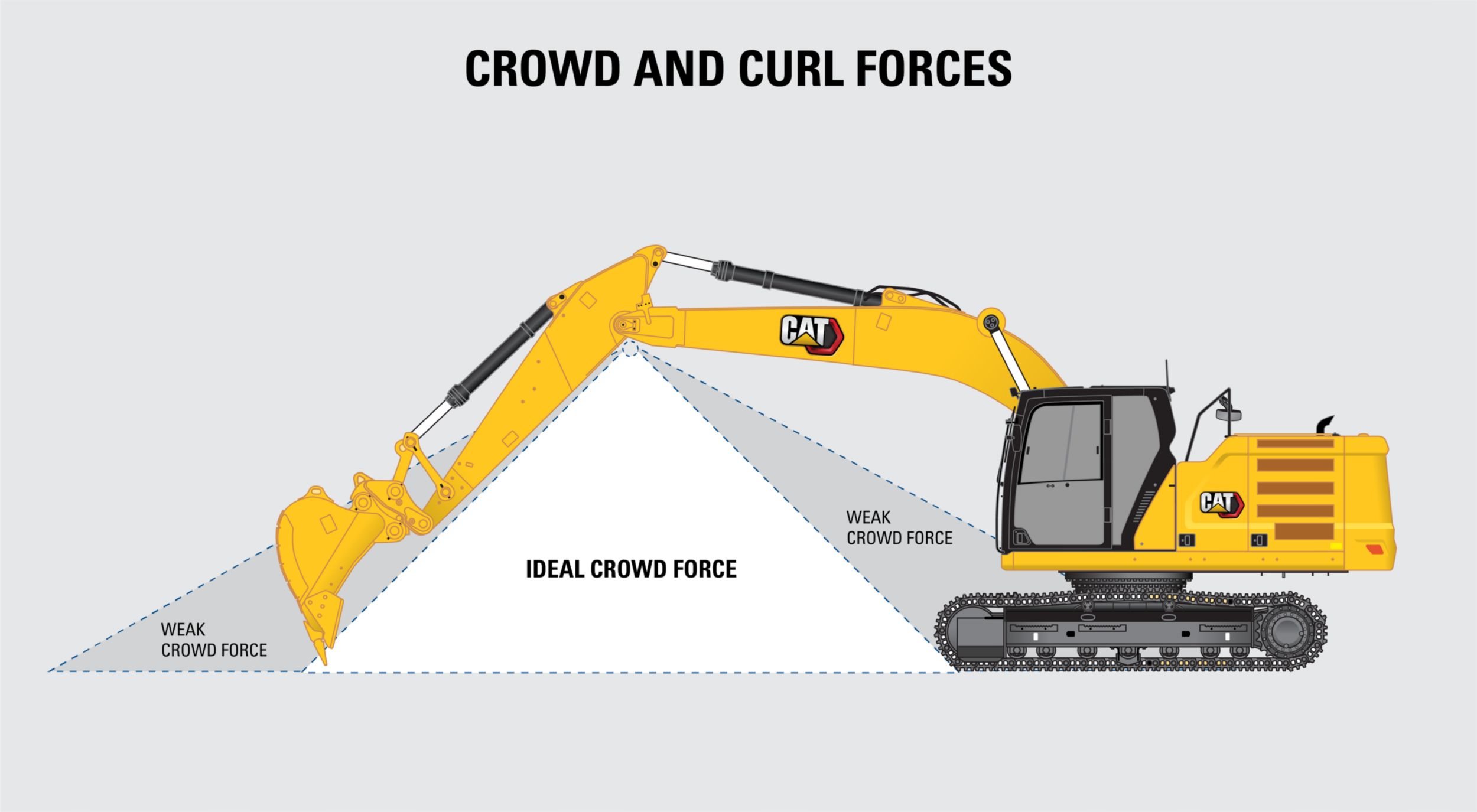

The optimal digging range for your stick starts about 35 to 45 degrees from vertical back to a vertical position. Digging outside this range lowers your efficiency, lengthens cycle times and may make your excavator’s position less stable.

Ideally, the bucket should be loaded by the time your stick returns to the vertical position. As you dig, continue to move the machine undercarriage forward (or backward) between passes to maintain this 35- to 45-degree range.

Use the stick crowd force and bucket curl force to give you breakout power without burning through additional fuel. Your stick crowd force is generated when digging by moving the stick inward. The bucket curl force is generated by the bucket cylinder and linkage. Ideally, the bucket curl force should be 10% to 15% greater than your stick crowd force to maintain good performance. That’s why bucket design and ground engaging tools can make a big difference in the performance of your excavator. Talk to your Cat ® dealer about the buckets and bucket tips that might be best suited for your jobsite.

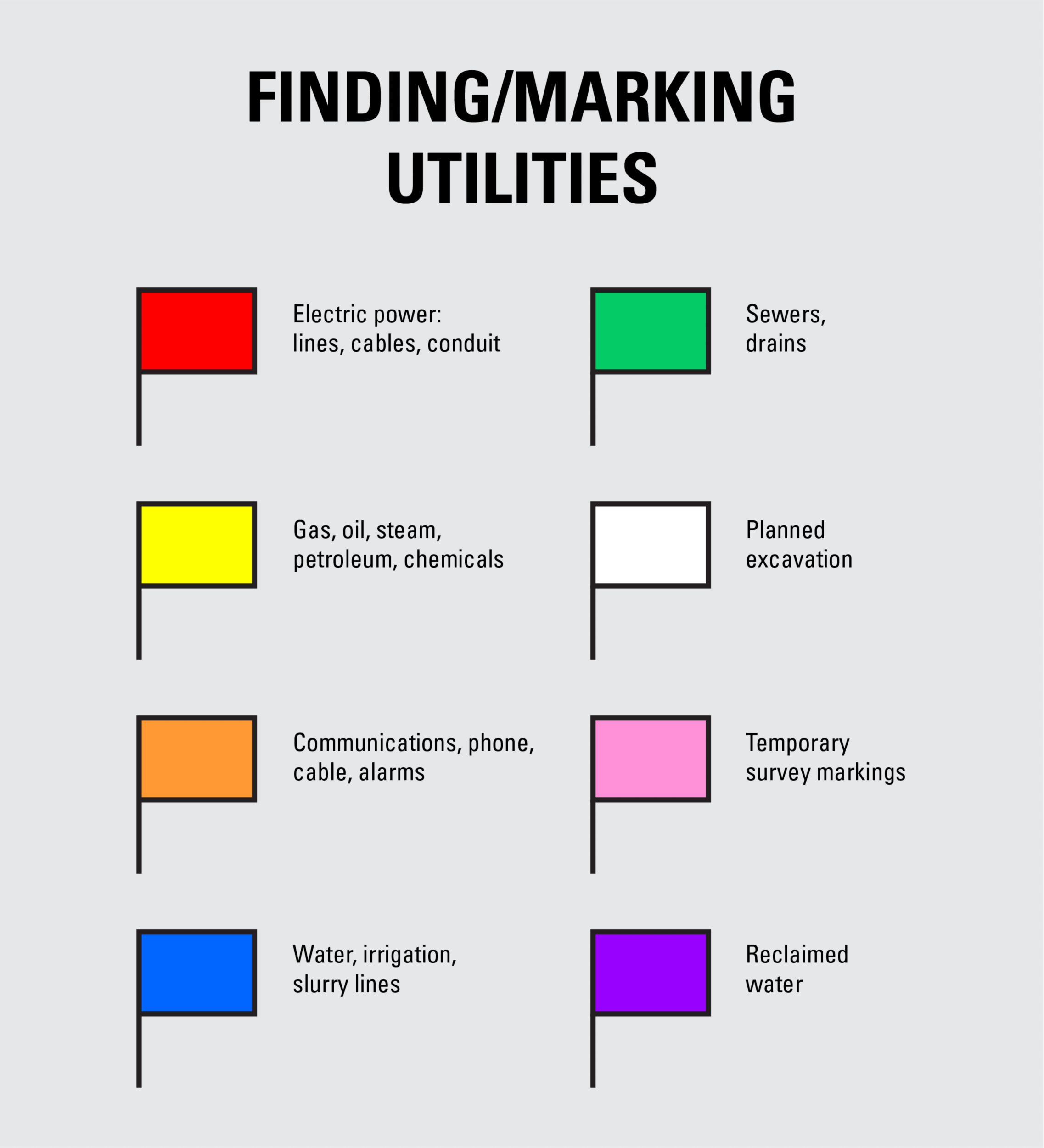

FINDING AND MARKING UTILITIES

It is extremely important that you call the local One Call System in your region before you begin digging. This is required by law and will save you the hassle and massive fines of damaging underground utilities. Make a call at least 48 hours before you plan to start digging and identify the time and place of your excavation. Your information will be logged, and local utilities will be alerted to come to your dig site and mark their facilities.

Markings are approximate and there is a tolerance zone between 18 and 36 inches to either side of the mark. Don’t dig inside the tolerance zone and risk rupturing utilities.

Markings are made by flags that are color coded based on which utility is buried on your site:

- Red flag: Electrical power lines, cables, conduit or lighting cables.

- Yellow flag: Natural gas, oil, steam, petroleum, chemicals or other gas.

- Orange flag: Communications, phone lines, alarm lines, signal lines or cable TV.

- Blue flag: Water, irrigation or slurry lines.

- Green flag: Sewers or drains.

- White flag: Planned excavation.

- Pink flag: Temporary survey markings.

- Purple flag: Reclaimed water.

Never assume someone else has made the call to the One Call System. Remember: It’s better to call twice on the same job than to arrive for work and find that nothing has been marked.

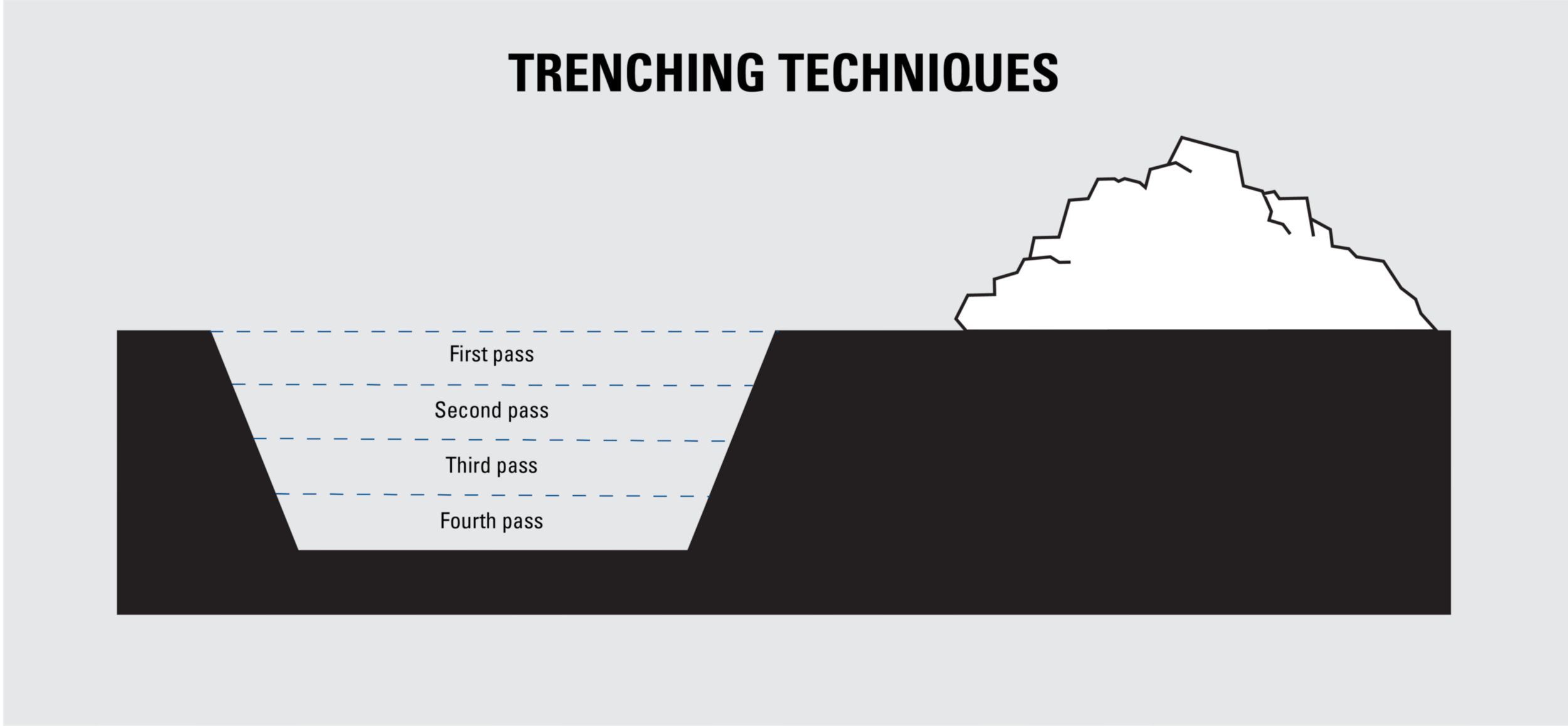

TRENCHING TECHNIQUES

When trenching, start at the top and work down in layers. Don’t dig from the bottom and fill your bucket by raking up the face. Digging from the bottom up is much harder and extends your cycle, because you’ll be going all the way to the bottom of the trench on each pass.

Set your excavator facing the work area. Avoid digging over the side.

Every excavator has a maximum digging envelope. Within that is a working range that is the most efficient. Work in this range to maximize your digging forces and use the force of the stick and bucket to get full bucket loads with every pass.

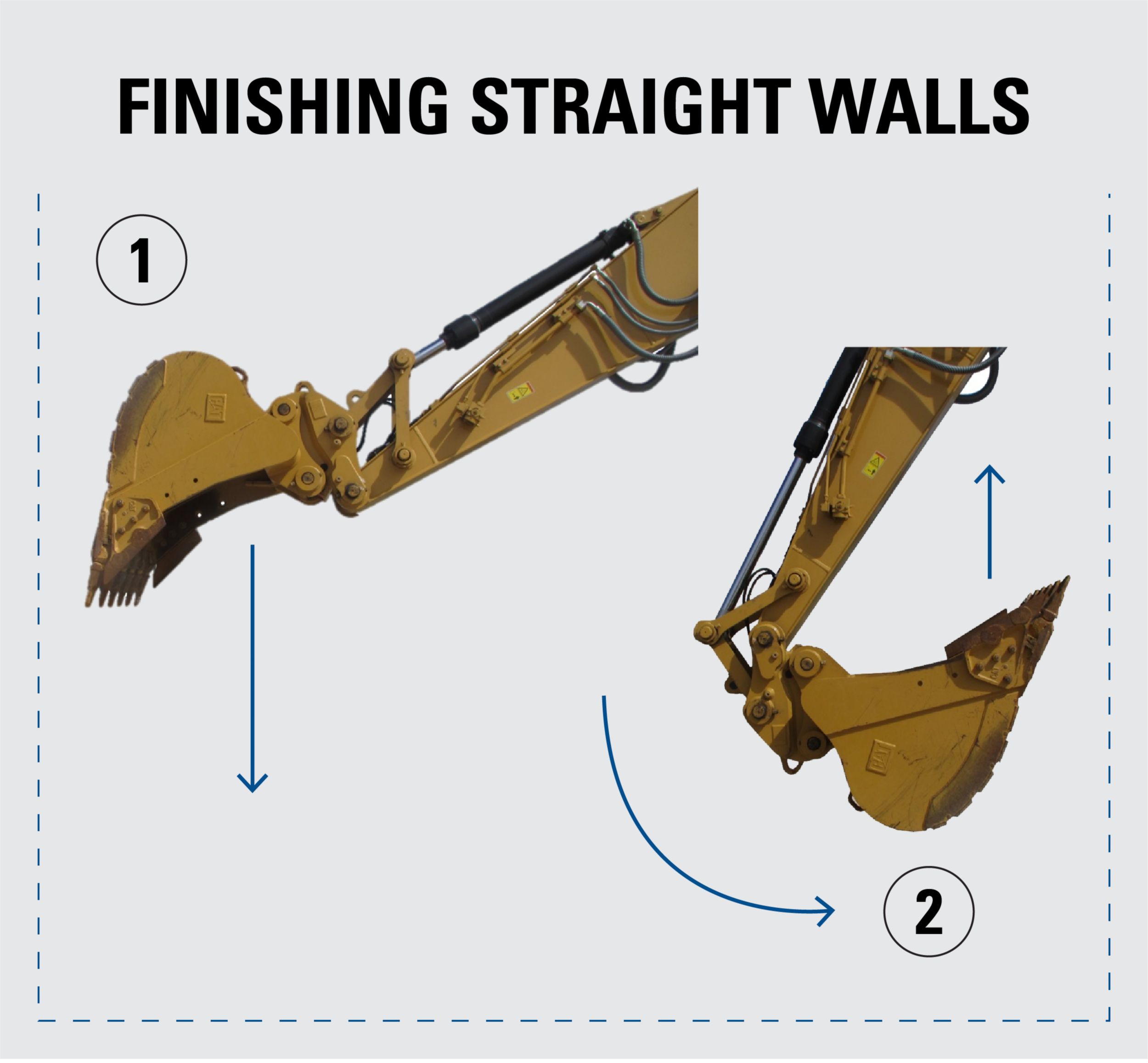

To finish the straight walls of your trench, finish the far wall first. To move your bucket in a straight line, move the stick out while you move the bucket down. Hold the bucket open and vertical. Then move to the closest wall. Lift the bucket upward and keep the cutting edge vertical.

Need additional tips for digging and trenching with your hydraulic excavator? Caterpillar offers extensive operator training through Equipment Training Solutions. Learn more here .

MORE EXCAVATOR CHOICES

No matter your focus, there’s a Cat excavator with your name on it.

Popular Articles About Excavators

Get the most from your excavators with operating tips, safety advice, maintenance help and much more.

The "Value" in a Customer Value Agreement

Check out these 4 ways a Customer Value Agreement helps your equipment and your business.

Mobile Goes Mainstream

Cat mobile apps make it easy to track equipment location, use, health and more.

Your Equipment Is a Reflection of Your Brand

Keep your equipment in good running condition to maximize uptime and reduce operating costs.

Eight Ways to Attract and Keep Top Talent

Hiring and retaining workers can be a challenge. Use these tips find the people you need.

View Articles

Once you own, you’re in.

Get unlimited access to must-know information about your machine. Find ideas you can put to work on the job right away, including business insights.

- Attachments

- Power Systems

Industry Solutions

Services & support.

- Financing & Insurance

- Maintenance

- Safety Services

- Technology & Solutions

How Can We Help?

- Find Rental Equipment

- Find Used Equipment

- Find Your Dealer

- Register Cat Warranty

- Shop Merchandise

Company Info

- Corporate Press Releases

- Product & Services Press Releases

Connect with Cat

- Caterpillar Foundation

- Social Media

- Visitors Center & Museum

public North America ‧ English edit

To enable this feature, you must accept the use of targeting, functional, and performance cookies.

Caterpillar Brands

- Cat Financial

- The Cat Rental Store

- Cat Lift Trucks

- Progress Rail

- Solar Turbines

- SPM Oil & Gas

- Turner Powertrain Systems

- Caterpillar.com

- My Marketing Preferences

- Cookie Settings

- Do Not Sell or Share My Personal Information

- Accessibility Statement

- © 2024 Caterpillar. All Rights Reserved.

Internet Explorer users may experience issues with certain features of our site. Please try a current version of an alternate browser (i.e. Google Chrome, Microsoft Edge, Mozilla Firefox) for the full Cat.com experience.

Issue 6-1 - Jan/Feb 2024

Issue 5-6 - Nov/Dec 2023

Issue 5-5 - Sep/Oct 2023

Issue 5-4 - Jul/Aug 2023

Issue 5-3 - May/Jun 2023

Issue 5-2 Mar/Apr 2023

Issue 5-1 Jan/Feb 2023

Issue 4-6 Nov/Dec 2022

Issue 4-5 - Sep/Oct 2022

Issue 4-4 - Jul/Aug 2022

Issue 4-3 - May/Jun 2022

Issue 4-2 - Mar/Apr 2022

Issue 4-1 - Jan/Feb 2022

Issue 3-6 - Nov/Dec 2021

Issue 3-5 - Sep/Oct 2021

Issue 3-4 - Jul/Aug 2021

Issue 3-3 - May/Jun 2021

Issue 3-2 - Mar/Apr 2021

Issue 3-1 - Jan/Feb 2021

Issue 2-6 - Nov/Dec 2020

Issue 2-5 - Sep/Oct 2020

Issue 2-4 - Jul/Aug 2020

Issue 2-3 - May/Jun 2020

Issue 2-2 - Mar/Apr 2020

Issue 2-1 - Jan/Feb 2020

Issue 1-6 - Nov/Dec 2019

Issue 1-5 - Sep/Oct 2019

Issue 1-4 - Jul/Aug 2019

Issue 1-3 - May/Jun 2019

Issue 1-2 - Mar/Apr 2019

Issue 1-1 - Jan/Feb 2019

Operating Excavators on Slopes

Inspection, environmental hazards, bucket operation, and more.

View the complete article here.

Working on slopes is challenging for even the most experienced excavator operators. Although your boss loves and appreciates you, they are also concerned for the safety of the equipment. Even used excavators are expensive. Follow these tips to safely operate an excavator on even the steepest slopes.

Experience Counts

Working on a slope is not for the faint-hearted – or an inexperienced trainee. Only highly experienced operators should use an excavator on a slope. Working in this environment requires specialized knowledge of terrain, navigating tight spaces, and determining what equipment is needed to ensure traction and stability.

Inspect Your Equipment

Doing something as simple as making sure the windows are clean before you start your engines can save life and limb. You always need to see what you are doing, but especially when working on a slope. Make sure seat belts and harnesses are in good working order. Remember that oil will not circulate as readily to the top of the engine while operating on a slope. Ensure that the oil is topped off.

Hold on Tight

Use single-bar grousers for adequate traction. Like dozer tracks, a single-bar grouser will dig deep into the ground and keep the excavator close to the slope. This is not a job for triple-bar grousers which are designed for flat or gentle slopes.

Get on the Right Track Direction

You want more weight behind you to counter-balance the heavy motor drive. Point your tracks up and down; not sideways. Idlers should be forward heading uphill. The opposite applies heading downhill – point the idler down the slope. Idlers bear the brunt of the energy generated while digging. Through-axles on one side of the frame distribute that energy across the frame.

Boom, Boom

Use the boom in your favor. By stretching out the arm and keeping the boom low to the slope, you’ll keep the weight of the bucket and the boom ahead of the machine. This allows you to walk your way up the slope. You can use the arm to assist you in pulling up if you place the bucket teeth in the ground. Always stop the machine before repositioning the boom and arm.

You must remain focused while operating on a slope. You’re using your feet to run the travel motors while simultaneously using your hands for the controls. Further, you need to make adjustments to the effort you are putting into the controls while digging. That’s one of the reasons why only experienced excavator operators should work on slopes. There is a lot of hand-eye coordination involved. You must be heads up at all times.

Don’t Fill It Up

Working along a mountain road is particularly treacherous. For example, when installing a pipe downhill of a mountain road, do not bring in fill to extend the road out. Allowing one track to rest on the fill while the excavator digs is dangerous. As the tracks rock, they are compressing and loosening the fill zone. The risk is that the fill will collapse, and the excavator will tumble over the slope.

A smaller machine, such as a compact excavator with a dozer blade, provides more stability on a slope. In fact, a dozer blade can be lowered below you on the slope. This helps stabilize the footing making it less likely that the machine will tip or slide. Some smaller machines have frames that allow you to adjust the track angle up to 15 degrees. The advantage is that you can sit on a mild slope with the top of the machine level.

Do the Math

Actually, the manufacturer has done the math for you. Consult the operator’s manual to determine safe operating ratios for working directly on a slope with your particular excavator. Do not exceed these ratios! You may get away with pushing the limit until something gets in your way – like a stump or a big rock. Lose your footing and you will likely slide and maybe even roll right over the hill. (Remember the scenario where you’re working on the side of a mountain? Not a good time to risk rolling.)

Environmental Hazards

When you drive a car in snow or rain, you want to slow down. Same applies to excavating on a slope. Wet conditions mean you cannot safely work on very deep slopes. Even if the operating manual says you can. You must also consider the type of soil the machine will have to move upon. According to the Occupational Safety and Health Administration (OSHA), type C soil is the least stable. This soil classification includes gravel and sand. It also includes any soil with water seepage. OSHA recommends testing the soil before and even during excavation, as you may encounter multiple types of soil as you dig.

Keep Close While Slewing

Keep the bucket as close to the ground and to the machine as possible when slewing material. Carefully control your speed as you bring the bucket around. Moving material from the top of the slope to the bottom at too high a speed will gather unwanted momentum. Slewing over the side engages the swing motor; not the boom. You are then stressing the swing motor, which is actually weakest part of the machine. Go slow and steady, with less material in the bucket than you would pick up on level ground.

Easy Does It

When operating an excavator on a slope, you want to ease up on everything. Your speed, your swing, and the amount of material you pick up. Make sure your machine is ready to not roll by checking all safety features like seatbelts and harnesses before you begin. Keep the windows and the cab clean and the operating manual close at hand. Be aware of your environment. Take weather and soil into consideration when determining how big of a slope the machine can handle. Your mission is to keep you and your machine upright.

Why should only highly experienced operators handle excavators on slopes?

Operating on slopes demands specialized knowledge of terrain, tight spaces, and equipment requirements for traction and stability, making it suitable only for highly experienced excavator operators.

What are some key tips for safe excavator operation on slopes?

Ensure thorough equipment inspection, use single-bar grousers for traction, position tracks up and down the slope, strategically utilize the boom, maintain focus, and consider environmental factors such as soil stability and wet conditions

Related Articles

Trenchers vs Excavators

View the complete article here. Surgeons use a scalpel when they operate. They could use any sharp object – but a scalpel provides the needed precision. It’s a similar choice between trenchers and excavators. But […]

Fleet Management Guide

View the complete article here. Fleet management is the administrative approach referring to the purchase, organization, and coordination of work vehicles for a company. Implementing a good fleet management system plays an integral role […]

Hitting Pay Dirt in the Soil Blending Business

What do you do with a bunch of dirt you’ve just excavated? You can haul it away yourself to dump somewhere. Or you can pay someone to take it away. The better answer is to […]

Latest from Steel Giant Market

2021 Hitachi ZW310-6 Wheel Loader

2010 CAT 336DL Excavator with Digging Bucket

(4ea) Double Drum Reverse Waterfall Anchoring and Mooring Hydraulic Powered Timberland Winches

(8ea) Timberland A1250 Single Drum Hydraulic Snubbing Winches

Copyright © 2023 | EquipmentAndContracting.com | West Palm Beach Website Design | Privacy Policy

- Directional Drills

- Rock Drills

- Surface Exploration Drill Rig

- Water Well Drill

- Geotechnical Drill Rig

- Diaphragm Wall Piling Rig

- Piling Accessories

- CFA Piling Rig

- Hammer Piling Rig

- Rotary Piling Rig

- Vibratory Piling Rig

- Truck Mounted Piling Rig

- Micro Piling Rig

- 100T – 500T

- Lattice Mobile

- Tower Crane

- Cone Crusher

- Impact Crusher

- Jaw Crusher

- Slow Speed Shredders

- Medium Speed Shredders

- High Speed Shredders

- Material Handlers

- Motor Grader

- Road Planer

- Soil Stabilizer

- Asphalt Plants

- Backhoe Loader

- Telescopic Loader

- Track Excavator

- Wheel Loader

- Wheeled Excavator

- Underground Excavators

- Underground Loaders

- Underground Rock Drills

- Underground Dumpers

- Underground Concrete Equipment

- The Omnia Machinery App

- Manufacturers

- Exhibitions and Events

- Recent Shipments

- Case Studies

- Sell a Machine

Operating Excavators on a Slope

Working on slopes can be a challenging operation even for the most highly skilled workforce, it requires knowledge and understanding of the terrain. Excavators are exceptional tools and when being manned by experienced operators they are an excellent machine to use on slopes. Here are a number of tips to help operate machinery on an incline a lot safer.

Examine the conditions of the hill

One of the first tasks to be carried out is to assess the job site and the involved in the project. Various weather conditions can impact the safety and stability of a slope as factors such as snow, ice, mud, and rain can jeopardise the machines’ ability to operate. It is best practice to stay updated on the weather conditions and keep in mind what the terrain may be like the days after a downpour. Although projects can have a tight deadline, waiting a day or two to allow the ground to improve will help avoid any possible risks of slips or overturns.

Use the right machine

It is important in any situation to use the correct machine for the job. When it comes to excavators a long reach excavator is the better option for slopes and angled digging. This means the machine can stay on the flat and stable ground whilst the long digging arm does the work making them the perfect machine for the task. Another option is the spider excavator, designed to conquer the difficult terrain of the Alpine slopes this machine was created for a steep decline.

Use the 70% rule

Even excavators have their limitations and a principle to bear in mind is the 70% rule. A 70% slope grade is the equivalent to a 35-degree angle, and an excavator should not be operated on such terrain to avoid slips or overturns. If the hill is steep enough to make you question it get a professional to survey it.

Use experienced operators

Operating a machine on a slope is a skill that comes with time and experience, it is not a task for the new guy. The expertise it takes to manoeuvre and coordinate an excavator is best left to the professionals, if you are not comfortable do not operate. When operating an excavator on a slop focus and attention to detail is a must as there is a lot of coordination and thinking involved as the operator uses their feet to move the travel motors while using their hands to navigate the machine.

Chose the right track and direction

Ensuring your tracks are pointed in the correct direction is crucial, they must be pointed up and down not sideways when operating on a slope. Ideally, you want more weight behind you to balance the heavy motor drive. Idlers bear the force of the energy generated when digging therefore they need to be pointed down the slope.

Protect your engine

The usual engine configurations are limited to a 30-degree incline due to lubrication, ensure you do not surpass that gradation for extended periods of time. Operating on a decline makes it harder for the engine to pump oil to the top of the motor which leads to starvation and lowers the lifespan of the equipment.

Check the equipment positioning

When travelling uphill positioning the boom & arm correctly can help massively. Stretching out the arm and keeping the boom low to the slope distributes the weight of the excavator and keeps it balanced when travelling up. You can also put the bucket teeth into the ground and use the arm to help you climb.

At Omnia Machinery, all of our heavy plant machinery is inspected before being prepared for shipment enabling you to buy in confidence. Browse our wide selection of excavators below from leading brands such as Liebherr , Hitachi , Hyundai and Komatsu . If you have specific requirements for your excavator that are not shown below, please do not hesitate to contact our knowledgeable team who can help to source the perfect machine for you. Before shipment, we always ensure that our machines are up-to-date and are fully tested. Should you require something more specialist, please contact us and our expert team will aim to source the machine required for your project.

Privacy Overview

- Buying Resources

How to Properly Transport Your Compact Excavator

Posted on August 28, 2018

Transporting compact excavators from one jobsite to another sounds simple. But, it involves several steps that shouldn't be overlooked, such as using the right-sized trailer as well as correctly loading, positioning and securing equipment.

If you follow these four hauling techniques and the recommendations in your Operation & Maintenance Manual, transporting your equipment can be easier than you think.

Select the Right Transport Vehicle

Your excavator cannot get to the jobsite without a safe, reliable way to haul it. Before transporting your excavator, properly match the transport and towing vehicle, such as a trailer, to the equipment.

Most smaller excavators can be transported on a 10,000-pound trailer, while larger equipment may need a 20,000- to 30,000-pound trailer or larger. If you are transporting oversize loads, such as an excavator and an attachment, you will likely need a larger trailer with a larger weight rating to handle the load. A transport vehicle’s load rating can be found on its identification plan or in the equipment owner’s manual if you are unsure how much you can safely haul.

All states and local municipalities have regulations based on gross vehicle weight rating. Load ratings vary in each state, so always check federal, state and local laws and regulations regarding weight, width, length and height of a load before transporting your machine. Special approvals or permits may be required for oversize loads along your planned route.

Load the Machine Properly

Once you have selected the right transport vehicle, it’s time to load your excavator. Always load your machine as outlined in your Operation & Maintenance Manual to ensure critical actions are not missed.

You should also follow these basic loading procedures:

- Check that the trailer is parked on firm and level ground.

- Secure the parking brakes and block the wheels of the transport vehicle.

- Use ramps that are the correct length and width and can support the weight of the machine.

- Use metal loading ramps with a slip resistant surface.

- Travel up the ramp with the heaviest end up when you are loading the equipment onto the trailer.

Disengage the auto idle feature and move the two-speed travel to the low range position.

Secure It Before Transport

Next, lower your excavator’s bucket or attachment to the floor of the trailer and stop the engine. All doors and covers should be locked before transport.

Chocks, cradles, wedges or other blocks should be placed in front of and behind each track to prevent rolling or shifting during transport. Then, install tie-downs at the front and rear tie-down positions, as identified in your Operation & Maintenance Manual.

Most manufacturers recommend at least four tie-down positions to prevent any movement. Some transport devices have D-rings, chain slots or built-in strap rails that allow you to easily connect your excavator to the trailer. Always use the recommended connection points and securements to minimize damage

At this time also inspect the tie-down points and tie-down equipment used to secure your machine. All pins and connection points should be secure and the hooks still functional. If you see any cracks, stretches or fatigued links, remove the tie-down equipment.

Don’t Forget Attachments

Whenever possible, the attachment should be connected to your excavator before transport. If that isn’t possible, set the attachment on the trailer so it can be secured by chain straps. Buckets and other attachments should be properly secured to the transport device, especially when transporting smaller excavators.

If your excavator is equipped with hydraulic attachments, make sure the hoses are routed in an orientation where they are not interfering with the machine on the trailer. For instance, hoses should not be laying underneath the machine, located in the way of a tie-down or connected where they could become disengaged.

Transporting your excavator doesn’t have to be difficult. By following these four tips and instructions along with recommendations in your owner’s manual, you can minimize loading challenges the next time you need to transport your machine.

- PRO Courses Guides New Tech Help Pro Expert Videos About wikiHow Pro Upgrade Sign In

- EDIT Edit this Article

- EXPLORE Tech Help Pro About Us Random Article Quizzes Request a New Article Community Dashboard This Or That Game Popular Categories Arts and Entertainment Artwork Books Movies Computers and Electronics Computers Phone Skills Technology Hacks Health Men's Health Mental Health Women's Health Relationships Dating Love Relationship Issues Hobbies and Crafts Crafts Drawing Games Education & Communication Communication Skills Personal Development Studying Personal Care and Style Fashion Hair Care Personal Hygiene Youth Personal Care School Stuff Dating All Categories Arts and Entertainment Finance and Business Home and Garden Relationship Quizzes Cars & Other Vehicles Food and Entertaining Personal Care and Style Sports and Fitness Computers and Electronics Health Pets and Animals Travel Education & Communication Hobbies and Crafts Philosophy and Religion Work World Family Life Holidays and Traditions Relationships Youth

- Browse Articles

- Learn Something New

- Quizzes Hot

- This Or That Game

- Train Your Brain

- Explore More

- Support wikiHow

- About wikiHow

- Log in / Sign up

- Cars & Other Vehicles

- Driving Vehicles

How to Drive an Excavator

Last Updated: April 29, 2024 References

This article was co-authored by wikiHow Staff . Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards. There are 16 references cited in this article, which can be found at the bottom of the page. This article has been viewed 85,178 times. Learn more...

An excavator is a large piece of machinery used to dig dirt and debris out of construction sites. Using one on a construction site requires operator training and a state operator license. [1] X Research source To get started, become familiar with the controls. Learn how the right and left joysticks control the cab, boom, stick, and bucket. Then drive the excavator with its foot pedals. Finally, combine all of these motions to complete your first dig.

Starting the Machine

- Change the control pattern if it isn’t in the setting you want. Some excavators have a button or switch in the cab that makes this change. Look on the display screen for a button to switch the control pattern.

- On other excavators, the control pattern lever is in the back near the engine. Open the back section and look for a blue or red lever. It should have a mark for each pattern setting. Slide the lever from one setting to the other to switch the pattern.

- Always consult your owner’s manual before changing the control pattern so you follow the right procedure.

- If you’re just learning how to drive an excavator, learn in ISO pattern. This is more common in excavators. [3] X Research source

- If you won’t be running the excavator with the door open, then also shut the door. Most excavators have a handle that locks the door, so secure this before starting the machine.

- Most operators run their machines with the door closed to keep debris out. Sometimes operators keep the door open to communicate with other workers.

- Let the machine run in idle for 5-10 minutes before operating it to warm up.

- If the weather is cold, run the hydraulic controls through a few cycles before doing any digging.

Moving the Boom and Cab

- Never unlock your controls before checking around you to make sure no people or objects are nearby.

- If someone approaches the cab or you get close to an object you don’t want to damage, flip the lever back down until your cab is clear again.

- Instructions are given in ISO because this is a more common excavator setting. For SAE, reverse the controls to the opposite side.

- Use smooth motions when operating the stick and boom. These use hydraulic systems, so the machines will move as fast as you pull the joysticks.

- Don’t suddenly let go of the joysticks or the machine will rock quickly.

- The cab moves freely and can complete a 360-degree turn. If you hold the joystick in one direction, the cab will keep spinning.

Driving the Excavator

- If you’re a beginner, driving with your hands may be easier.

- Most expert operators prefer using their feet to drive.

- If you’re using your feet, rest them on the top of the pedals and push down there.

- Always make sure no one is around you before moving the excavator in any direction.

- An excavator’s stop speed is around 8 mph (13 km/h), so even if you press down as hard as you can, you won’t move very fast.

- If you’re using your feet, press on the bottom of the foot pedals to move backward. Shift your feet down with your heels on the floor of the cab. Then press down with your toes touching the bottom of the pedals.

- Always check behind you before reversing. Some newer excavators have cameras on the back to help while you reverse.

- If you’re already moving, ease off one of the pedals rather than letting go with both and pressing one again. This results in smoother driving.

- The same rules apply whether you’re turning backward or forward. Press the left pedal back to move back and to the right. Press the same pedal forward to move forward and to the right.

Digging with the Excavator

- Most excavators will stay stable if you dig when they aren’t perfectly centered, but while you’re a beginner, always make sure the cab is square until you gain more experience.

- Once you’ve gotten to the desired position, remove your feet from the foot pedals so you don’t accidentally move while you’re digging.

- Don't try to drive and dig at the same time until you’re an experienced operator.

- Experienced operators can dig with the stick in different positions. While you’re still learning, however, extend the stick completely before digging.

- Don’t try to dig with the bucket fully extended. This drives dirt and debris into the joints and could damage the machine over time.

- Only enter the dirt about halfway up the bucket. Any more and you won’t get an effective scoop.

- Leave the dirt nearby in case you need to backfill the hole.

- Repeat this process as many times as you need to finish the dig.

- Watch your step when exiting the cab. Injuries from falls are common on construction sites.

Expert Q&A

- In most cases, you only need a high school diploma or GED and a driver’s license to get a job operating an excavator. Check with local regulations to see if you need other certifications. Thanks Helpful 15 Not Helpful 0

- Always follow the safety regulations when operating heavy equipment. Thanks Helpful 9 Not Helpful 0

- Never drive or move the excavator while people are within reach of the arm. Thanks Helpful 7 Not Helpful 0

You Might Also Like

- ↑ https://study.com/articles/Become_an_Excavator_Education_and_Career_Roadmap.html

- ↑ https://construction.papemachinery.com/blog/how-to-change-the-control-pattern-on-a-john-deere-excavator

- ↑ https://youtu.be/kUs6G5iBGP0?t=345

- ↑ https://www.labour.gov.hk/eng/public/os/B/excavator.pdf

- ↑ https://youtu.be/uutTJgY7Br0?t=234

- ↑ https://youtu.be/uutTJgY7Br0?t=266

- ↑ https://youtu.be/uutTJgY7Br0?t=277

- ↑ https://youtu.be/uutTJgY7Br0?t=303

- ↑ https://youtu.be/kUs6G5iBGP0?t=623

- ↑ https://youtu.be/uutTJgY7Br0?t=457

- ↑ https://youtu.be/kUs6G5iBGP0?t=610

- ↑ https://youtu.be/uutTJgY7Br0?t=630

- ↑ https://youtu.be/uutTJgY7Br0?t=640

- ↑ https://youtu.be/uutTJgY7Br0?t=684

- ↑ https://youtu.be/uutTJgY7Br0?t=689

- ↑ https://youtu.be/uutTJgY7Br0?t=710

About This Article

- Send fan mail to authors

Reader Success Stories

Timothy Ndimba

Jun 13, 2021

Did this article help you?

Featured Articles

Trending Articles

Watch Articles

- Terms of Use

- Privacy Policy

- Do Not Sell or Share My Info

- Not Selling Info

wikiHow Tech Help Pro:

Level up your tech skills and stay ahead of the curve

- Checkout Now

LIMITED LIFETIME WARRANTY

On new and rebuilt final drive motors.

- Give us a chance to beat any advertised price.

- We are the experts in mini final motor rebuilding

- Shop Talk Blog

Five Reasons Your Final Drive Lacks Power

Dec 21st 2017

5 Potential Causes of a Weak Travel Motor

Lack of power is a common complaint when a final drive or travel motor is in need of service. It reveals itself when your machine can’t climb a steep grade or keeps steering to one side. There are six potential causes behind a lack of power, and not all of them are the fault of the final drive.

Reason #1: Lack of Pressure

One major cause behind a weak final drive or travel motor is simply a lack of hydraulic pressure. This can be detected by checking the hydraulic pressure at the final drive. You can refer to your manufacturer’s guidelines for the expected pressure reading you should obtain.

Reason #2: Excessive Friction

The second potential cause behind a lack of power is high friction. When high friction is present, more power is required to overcome it. Excessive friction can be caused by issues with the track chain tension or by rollers and idlers that are in poor condition. This, in turn, can cause key components, including your final drive, to wear out prematurely.

Reason #3: High Speed Mode

Sometimes the machine steers to the side because one of the travel motors is trapped in high-speed mode. This can also cause problems with climbing steep grades. In that case, the issue most likely lies with the speed control system and not the final drive. Check the speed control system before you send in your travel motor for repairs or inspection.

Reason #4: Weak Charge Pump

If your final drive is making a screeching noise along with a lack of power, the problem is most likely the charge pump . If the charge pump isn’t providing enough pressure, the internal brake on the travel motor won’t be released and is equivalent to driving with the emergency brake on. If this goes on unresolved, your travel motor will be badly damaged.

Reason #5: Worn Out

There is another potential cause behind a lack of power: the gearbox or the final drive itself is just worn out and in need of repair or replacement . All parts have a finite life, and will eventually wear out. You can slow down that process with regular maintenance, but wear can never be 100% prevented.

Possible Problem May Not be Final Drive

If your final drive seems weak, keep in mind that the problem may not be your final drive. Possible causes include low pressure, high friction, high-speed mode control issues, a weak charge pump, or worn out parts and components.

- #final drive

- #final drive charge pump

- #final drive components

- #final drive friction

- #final drive lacks power

- #final drive motor

- #final drive parts

- #final drive speed

- #final drive weak charge pump

- #final drive worn out parts

- #travel motor

- #weak final drive

- #weak travel motor

Share This Article

"Shop Talk Blog" Email Updates

Join our mailing list for special offers, recent posts.

Posted at Apr 12th 2024

Posted at Mar 21st 2024

Posted at Feb 2nd 2024

![excavator travel direction Final Drive Cores and the Remanufacturing Revolution [VIDEO]](https://cdn11.bigcommerce.com/s-lbnln0ppxx/images/stencil/original/uploaded_images/final-drive-cores-and-the-remanufacturing-revolution.png?t=1705357426)

Posted at Jan 15th 2024

Posted at Dec 2nd 2023

Posted at Sep 13th 2023

Shop by Brand

- Caterpillar

- New Holland

- View all Brands

A JavaScript enabled browser is required to use this calculator. If you see this message, enable JavaScript and re-load the page.

This JavaScript applet calculates distances and directions from one location on the surface of Earth towards another, both the ‘ as the bird flies ’ surface distance, and the ‘ as the neutrino flies ’ straight-line distance.

Azimuth refers to the compass heading when leaving your location traveling towards another along a great circle path (shortest surface route), where North=0°, East=90°, South=180° and West=270°. Back azimuth refers to the initial heading when leaving the distant location to come to where you are.

Inclination refers to the angle below horizontal of the straight line path to a distant location, where 0° is horizontal & local, and 90° points straight down through the center of the Earth to the antipode.

The straight line direction to another location on Earth may be pointed out with the two angles of azimuth and inclination.

Calculations assume Earth to be spherical with a 6366.707 km radius. If you come across any errors or have some ideas of how to improve the code, feel free to pass along your observations. This is Version 0.11, so everything might not work as well as it could…

Check trip elevation

Please enable JavaScript

Looking for a way to avoid mountains on a long road trip? Find alternate routes that are smoother and explore ways to bypass the Rocky Mountains or cut through on major highways. An easier drive will have less elevation change and avoid small roads that may climb to high altitude.

Google maps can show you the elevation for a bike route, but if you're planning a cross country road trip in an RV, you may want to explore the flattest travel routes across America in any state or country. Check out the flattest state in the U.S.

You can also use this site to find the highest elevation point in any city, state, or country. Check the "steepness" score to find interesting uphill hikes to summit, hilly streets to drive, or the fastest downhill mountain biking trails.

If you prefer a steady path without steep grades, use the flat route finder to get the least elevation change. Create an elevation map for your next trip. If you're not driving, switch to the flattest cycling route or the flattest route for running .

If you're driving south, you can research the flattest route from Michigan to Florida , the flattest route from Washington to Texas , or the flattest route from Ohio to Florida . If you're driving across America, try some of the alternate routes to find the elevation from Chicago to Los Angeles or the flattest route from Albuquerque to Phoenix . You can also check your current elevation .

Also check out the Flattest Route demo video by Creativity RV. Thanks Robin!

Traffic snarled as workers begin removing I-95 overpass scorched in Connecticut fuel truck inferno

Workers have begun removing a bridge over a Connecticut highway that was damaged in a fiery crash involving a gasoline tanker truck

Work crews began demolishing a bridge damaged in a fiery crash that kept Interstate 95 in Connecticut closed for a second day Friday, as motorists’ nerves continued to fray in hours of traffic jams on and around the main artery linking New England and New York.

“It’s crazy,” said Marco Ortiz, a tattoo artist at Javier Eastman Tattoo Studios in Norwalk on Connecticut Avenue, one of the detours jammed bumper-to-bumper. “I’ve seen people beeping, trying to cut other people off, making faces, hand gestures. It’s not good. You’ve got to be patient. What else can we do? It was a really bad accident.”

- Election 2024

- Entertainment

- Newsletters

- Photography

- Personal Finance

- AP Investigations

- AP Buyline Personal Finance

- AP Buyline Shopping

- Press Releases

- Israel-Hamas War

- Russia-Ukraine War

- Global elections

- Asia Pacific

- Latin America

- Middle East

- Election Results

- Delegate Tracker

- AP & Elections

- Auto Racing

- 2024 Paris Olympic Games

- Movie reviews

- Book reviews

- Personal finance

- Financial Markets

- Business Highlights

- Financial wellness

- Artificial Intelligence

- Social Media

Traffic snarled as workers begin removing I-95 overpass scorched in Connecticut fuel truck inferno

Workers begin removing a bridge over Interstate 95 in Connecticut. The overpass was damaged in a fiery crash involving a gasoline tanker truck

A tanker truck filled with gasoline burst into flames in a three-vehicle crash on Interstate 95 in Connecticut. The wreck closed the East Coast’s main north-south highway Thursday and caused major traffic jams, but the state’s governor said there were no serious injuries.

In this photo made from video, a demolition crew begins work on tearing down the Fairfield Avenue bridge, Friday, May 3, 2024, in Norwalk, Conn. Workers have begun removing the bridge over I-95 that was damaged in a fiery crash involving a gasoline tanker truck on Thursday. The demolition is expected to keep both sides of Interstate 95 in Norwalk closed through the weekend. (WABC TV via AP))

- Copy Link copied

In this image provided by the Connecticut Governor’s Office, emergency personnel work at the scene of a fiery early morning crash that left both sides of Interstate 95, the East Coast’s main north-south highway, shut down in southwestern Connecticut., Thursday, May 2, 2024, in Norwalk, Conn. (Norwalk Fire Department/Connecticut Governor’s Office via AP)

This image provided by the Norwalk Police Department shows the scene of a tanker fire on I-95 in Norwalk, Conn., Thursday, May 2, 2024. Both sides of I-95, the East Coast’s main north-south highway, were shut down following the early morning crash involving a passenger car, a tractor-trailer and a tanker truck carrying 8,500 gallons (about 32,000 liters) of gasoline. (Norwalk Police Department via AP)

Work crews began demolishing a bridge damaged in a fiery crash that kept Interstate 95 in Connecticut closed for a second day Friday, as motorists’ nerves continued to fray in hours of traffic jams on and around the main artery linking New England and New York.

“It’s crazy,” said Marco Ortiz, a tattoo artist at Javier Eastman Tattoo Studios in Norwalk on Connecticut Avenue, one of the detours jammed bumper-to-bumper. “I’ve seen people beeping, trying to cut other people off, making faces, hand gestures. It’s not good. You’ve got to be patient. What else can we do? It was a really bad accident.”

The highway remained shut down in both directions after Thursday morning’s three-vehicle wreck, in which a gasoline tanker burst into flames that engulfed the Fairfield Avenue overpass above I-95 in Norwalk and damaged the structure.

Gov. Ned Lamont said plans to reopen all six lanes before rush hour Monday morning appeared to be on track.

“And here we are more than 24 hours later, that bridge is going to be down very soon,” Lamont said at a news conference in Norwalk on Friday. “The sheers are coming in to lift off the final piece of this. Get the asphalt back in place. And hopefully ... we get I-95 going in both directions on Monday.”

About 160,000 vehicles travel that section of I-95 in both directions daily, officials said. Detours on local roads added up to an hour or more to trips through the area for some motorists, while others sought alternate routes far from the scene.

John Blair, president of the Motor Transport Association of Connecticut, said the trucking industry group has been working with state police and the DOT to get the word out to truckers across the Northeast about safe alternate routes, which include I-84.

He said there were problems over the past 24 hours with tractor-trailer drivers who don’t know Connecticut well striking low bridges or taking down power lines on local roads as they try to drive around the closure. State police said they were aware of only one incident where a commercial vehicle struck a bridge overpass in New Canaan on the Merritt Parkway, which bans tractor trailers because of low bridge heights.

Blair said his group has been trying to get long-haul truckers to avoid that part of state.

“We are pushing them up north as best as we can,” Blair said. “We’re trying to get to them before they get to Connecticut and have them avoid 95 completely.”

Workers started tearing down the bridge on Friday morning using excavators — one on each side of the highway — armed with jackhammers. Bucket loaders scooped up the debris that fell on the highway below and dumped it in containers that were hauled away by trucks.

The sheers Lamont spoke of are special heavy equipment that will be used to cut down the metal support components of the bridge beginning Saturday morning, officials said. That should take about 24 hours, and then the damaged parts of the highway will be repaired by milling and repaving, according to the state transportation commissioner, Garrett Eucalitto.

The crash happened at around 5:30 a.m. Thursday on the southbound side of the highway.

State police said a car was merging from the right lane when it struck the gas truck, which was carrying 8,500 gallons (32,000 liters) of fuel. The truck then hit a tractor trailer in another lane and caught fire. Nobody was seriously injured, and no charges have been filed.

On Friday afternoon, the state Department of Transportation said the travel time was nearly 90 minutes for the 16 miles (26 kilometers) from the New York border to Route 7 in Norwalk on I-95 north.

Jillian Mauro, a press aide with the Connecticut House Republicans, said she noticed many more tractor trailers during her commute from Danbury to Hartford along I-84, as well as fender benders with the stop-and-go traffic.

“There’s definitely a steady parade of trucks,” said Mauro, whose commute to the Capitol on Friday took 90 minutes instead of the usual hour.

The bridge removal and road repairs could cost about $20 million, said U.S. Sen. Richard Blumenthal, a Connecticut Democrat. He and other members of the state’s congressional delegation sent a letter asking the Federal Highway Administration for emergency funds to pay all the expenses. Lamont has declared a state of emergency, which could expedite the funding.

“Swift reopening of I-95 is extremely critical to flow the vehicular and truck traffic through New England,” the delegation wrote in a letter to Transportation Secretary Pete Buttigieg.

The Merritt Parkway, which is open only to passenger vehicles, saw 13-mile-long delays Friday morning, the letter noted, while trucks and other commercial vehicle have been forced to take “much longer alternate routes.”

The accident was reminiscent of a deadly one last year in Philadelphia when a tractor-trailer carrying gasoline along I-95 lost control and caught fire, destroying a section of the highway.

Thursday’s crash also came just over a year after a fatal wreck on I-95 in Connecticut in April 2023, when a fuel truck caught fire after colliding with a stopped car on the Gold Star Memorial Bridge between New London and Groton.

Associated Press writer Susan Haigh in Hartford, Connecticut, contributed to this report.

COMMENTS

heavy equipment operator. Mar 11, 2015. #2. Convention (Scrub Pullers words) dictates sprockets downhill.You will get some other opinions on this but I have never read otherwise in any operators manuals,Caterpillar included.That should be the digging or operating profile too.Pull against the idlers.The direction of travel would be intuitive ...

Keep the bucket low to the ground and close to the machine. Reduce operating speeds to avoid tipping or slipping. Avoid changing direction when traveling on grades. Never attempt to travel across a grade steeper than 15 degrees if crossing the grade is unavoidable. Reduce swing speed as necessary when swinging loads.

Pay close attention to the direction of travel. An excavator allows the upper housing to be rotated 360 degrees. However, the undercarriage tracks in the same direction, regardless of which way ...

Link-Belt 220 X4S Excavator Brings Heavy Digging Performance to Jobsites Get an overview of the 220 X4S and see how it can make your projects and efforts more productive, even in tough ...

Tip #5: When moving the excavator around the job site, select a route that is as flat as possible. Steer the machine as straight as possible and only make small gradual changes in direction when turning is needed. Tip #6: Travel directly up slopes vertically instead of diagonally.

Offering a maximum digging depth of 19.1 ft (5.8 m), the new straight boom excavator features a maximum vertical reach of 40.9 ft (12.48 m) - 8.0 ft (2.45 m) higher than a standard Cat 330 ...

1) Use the Right Machine. When operating a machine on a slope, or when operating a machine in general, always make sure you are using the correct machine. For excavator operation, a long reach excavator may work well for slopes and angled digging. This way, the actual machine can remain on stable ground while the extra long digging arm ...

When trenching, start at the top and work down in layers. Don't dig from the bottom and fill your bucket by raking up the face. Digging from the bottom up is much harder and extends your cycle, because you'll be going all the way to the bottom of the trench on each pass. Set your excavator facing the work area. Avoid digging over the side.

Allowing one track to rest on the fill while the excavator digs is dangerous. As the tracks rock, they are compressing and loosening the fill zone. The risk is that the fill will collapse, and the excavator will tumble over the slope. Go Small A smaller machine, such as a compact excavator with a dozer blade, provides more stability on a slope.

When operating an excavator on a slop focus and attention to detail is a must as there is a lot of coordination and thinking involved as the operator uses their feet to move the travel motors while using their hands to navigate the machine. Chose the right track and direction. Ensuring your tracks are pointed in the correct direction is crucial ...

For those heavy equipment operators, this is a follow-up to our popular "How to Operate an Excavator" video. We are back with "How to Operate an Excavator -...

Your excavator cannot get to the jobsite without a safe, reliable way to haul it. Before transporting your excavator, properly match the transport and towing vehicle, such as a trailer, to the equipment. Most smaller excavators can be transported on a 10,000-pound trailer, while larger equipment may need a 20,000- to 30,000-pound trailer or larger.

Basic Operating Instructions for Volvo C-Series Crawler Excavators. Part 4 of 15: TrackingThis section is giving you information about how to travel/track wi...

4. Press 1 pedal at a time to turn the excavator. The pedals each control 1 of the excavator's tracks. When you want to turn, press down the pedal on the opposite side that you want to turn. Pressing the left pedal turns the excavator right, and pressing the right pedal turns it left.

Two hydraulic motors rotate in the same direction, the excavator will travel in a straight line; If only one hydraulic motor is fed with oil and the other hydraulic motor is braked, the excavator ...

Basic Excavator skills. Running an excavator, Control patterns, operation & more for beginners. Step by Step Heavy equipment skills. BIG THANKS to Volvo for ...

5 Potential Causes of a Weak Travel Motor. Lack of power is a common complaint when a final drive or travel motor is in need of service. It reveals itself when your machine can't climb a steep grade or keeps steering to one side. There are six potential causes behind a lack of power, and not all of them are the fault of the final drive.

Official MapQuest website, find driving directions, maps, live traffic updates and road conditions. Find nearby businesses, restaurants and hotels. Explore!

This JavaScript applet calculates distances and directions from one location on the surface of Earth towards another, both the 'as the bird flies' surface distance, and the 'as the neutrino flies' straight-line distance. Azimuth refers to the compass heading when leaving your location traveling towards another along a great circle path (shortest surface route), where North=0°, East=90 ...

Official MapQuest - Maps, Driving Directions, Live Traffic

Google maps can show you the elevation for a bike route, but if you're planning a cross country road trip in an RV, you may want to explore the flattest travel routes across America in any state or country. Check out the flattest state in the U.S. You can also use this site to find the highest elevation point in any city, state, or country.

Powerful storms roared across parts of southern Oklahoma Tuesday night and produced dangerous and unusual tornadoes, including one incredibly rare type.

About 160,000 vehicles travel that section of I-95 in both directions daily, officials said. ... Workers started tearing down the bridge on Friday morning using excavators — one on each side of ...

About 160,000 vehicles travel that section of I-95 in both directions daily, officials said. John Blair, the president of the Motor Transport Association of Connecticut, which represents the trucking industry, said the group has been working with the state police and DOT to get the word out to truckers across the Northeast about safe alternate ...