Cruise Ship Anchors – How Big Are They? (and More)

Have you ever wondered if modern cruise ships have anchors and if so, where are they stored, and how big are they?

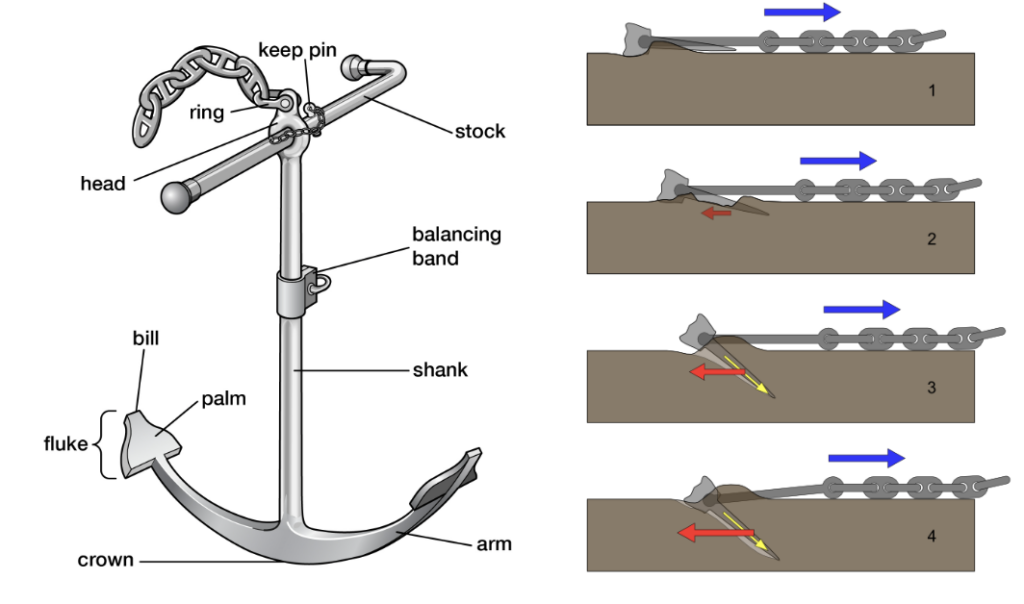

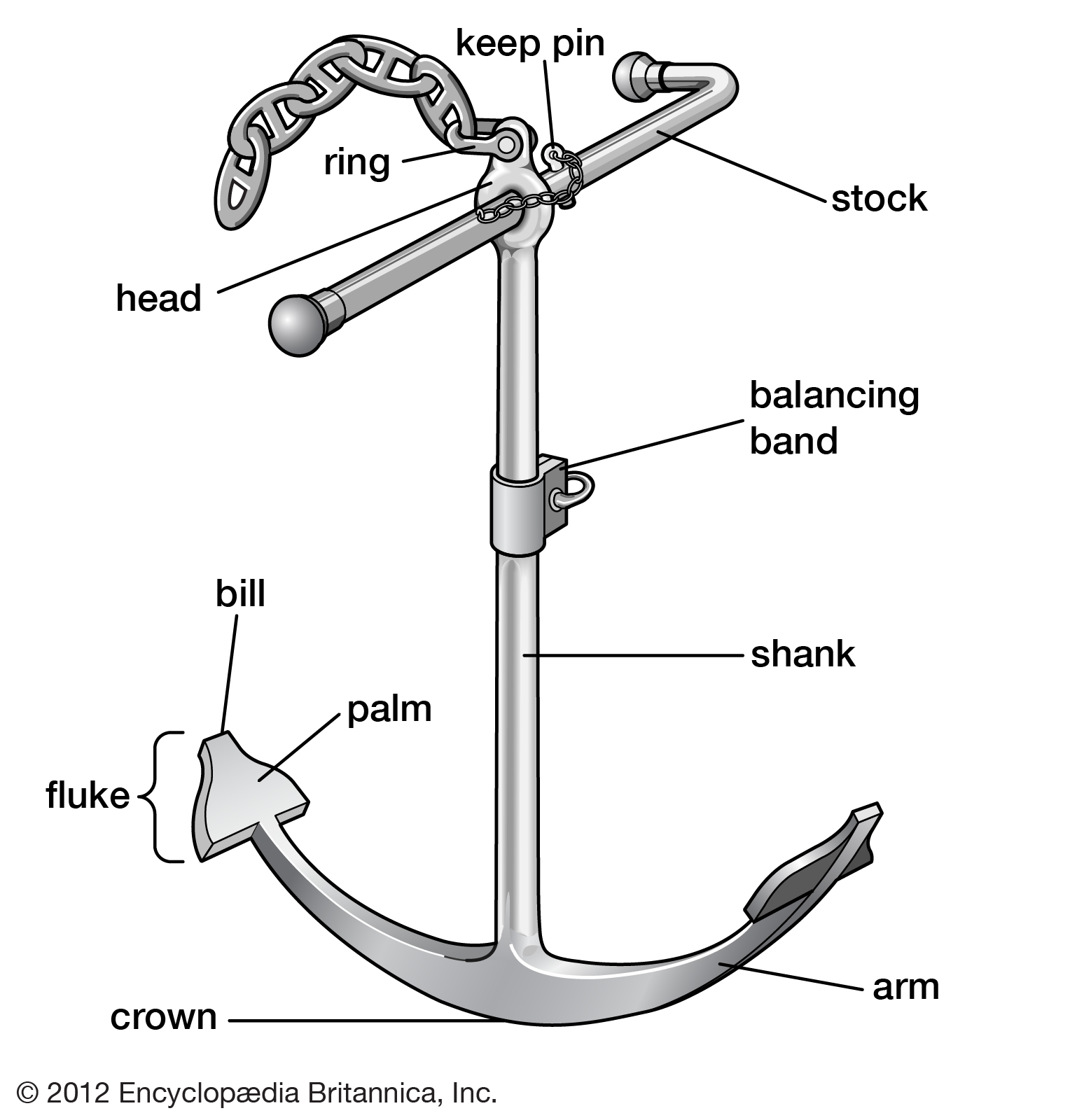

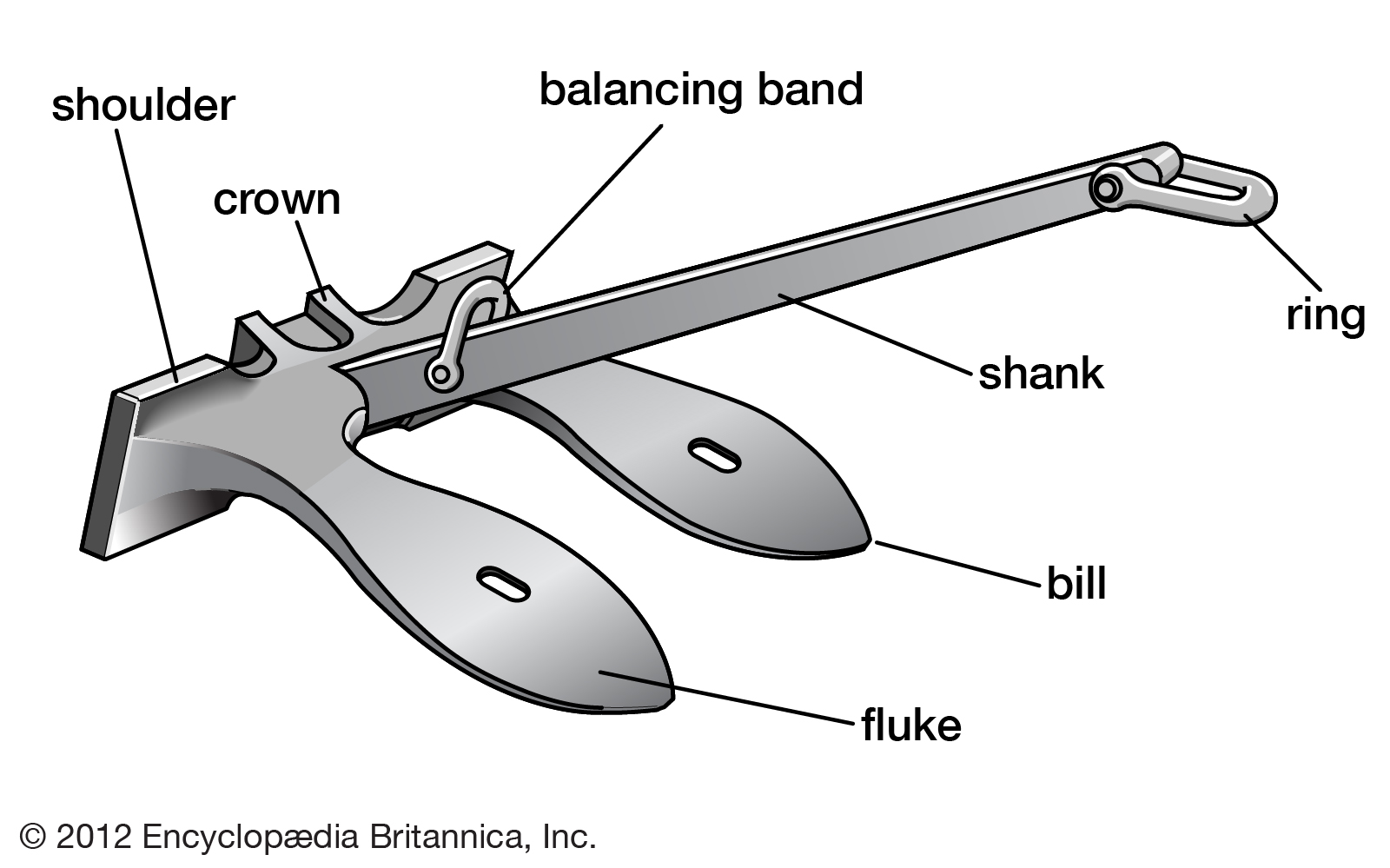

Modern cruise ships have what’s known as a stockless or patent anchor . This type of anchor is suitable for a wide range of different sea bed types, which cruise ships need as they travel through different waters and varying ports.

They are called stockless anchors because they don’t have a horizontal stock across the top of the shank.

Do Cruise Ships Have Anchors?

Like most ships, cruise ships have anchors. Anchors are required for holding a ship in place and preventing it from drifting due to winds and currents.

Anchors come in various shapes and sizes. Cruise ships have stockless anchors. This is a design of anchor that has particularly heavy flukes which are connected to a shank. These heavy flukes can dig into the seabed.

Do Cruise Ships Have More Than One Anchor?

Most cruise ships have two anchors, one port side and one starboard side at the front of the ship , although they are not often deployed at the same time.

One anchor is sufficient to keep a ship in position, although two can have their uses in specific circumstances.

Having two anchors means there’s always a backup should one ever be required. There is a lot of machinery and chain involved in the anchoring process and if any were to become damaged or required maintenance the other anchor could be used.

How Big Is A Cruise Ship Anchor?

Cruise ship anchors can be up 15ft to 20ft in height and 10ft to 15ft wide. Anchors are generally proportional to the size of the cruise ship. The larger and heavier the cruise ship, the larger the anchor can be expected to be.

The largest oasis-class Royal Caribbean cruise ships are some of the largest in-service ships sailing today and can be expected to have the largest anchors on any cruise ships.

The new Royal Caribbean icon-class cruise ships will be larger still and so will the anchors.

How Much Does A Cruise Ship Anchor Weigh?

Cruise ship anchors are somewhat proportional to the size of the ship. The larger the ship, the larger the anchor. A typical cruise ship anchor can weigh 10 to 15 U.S tonnes (9000 to 13600 kilos).

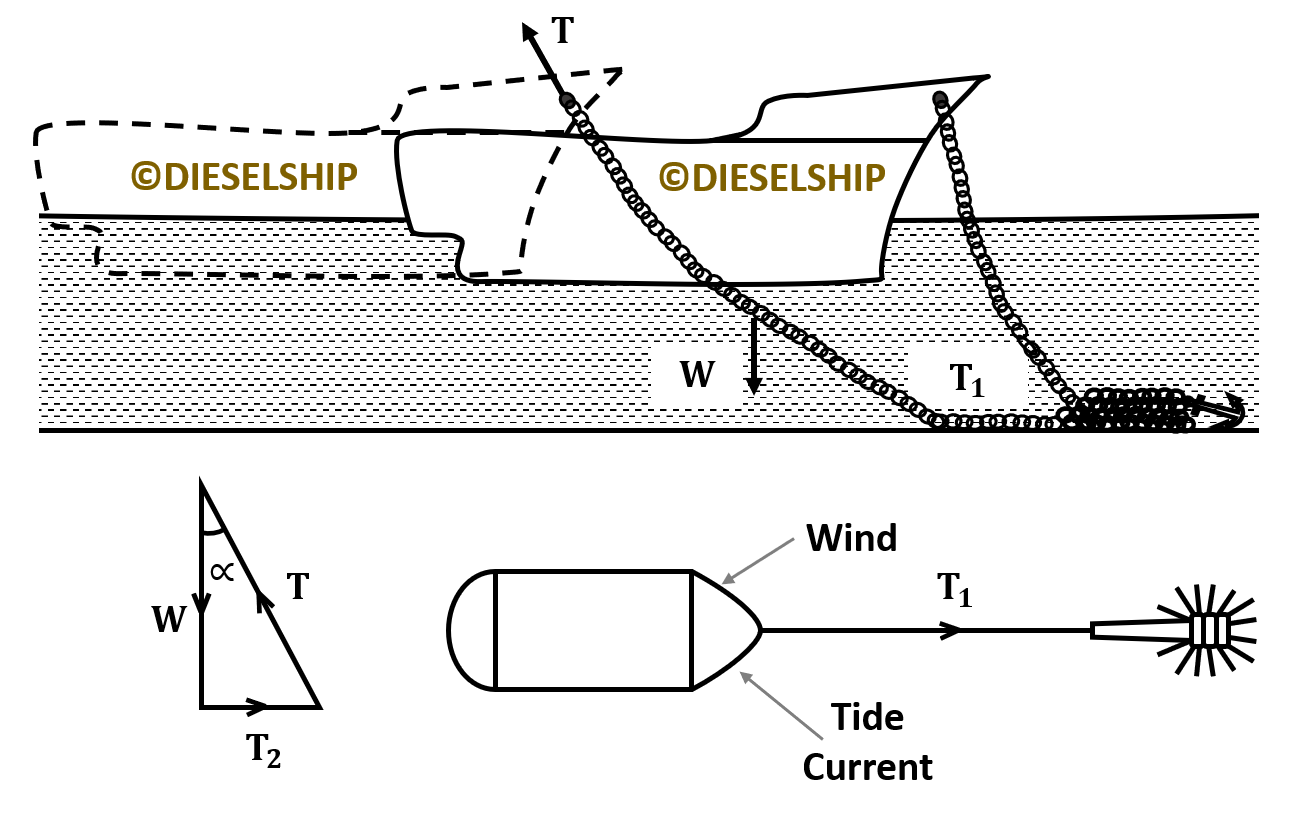

However, the weight of the chains is far heavier and much more of a factor in holding a ship’s position when it’s anchored offshore.

It’s the weight of the chain that holds the ship’s position, while the anchor acts to hold the end of the chain, preventing it from being pulled along the seafloor.

Ship Anchor Compared To Human

Cruise ship anchors can be 2 to 3 times an average human height of 5ft 9inches.

Assuming an average human weight of 80kg, an anchor weighing 10000 to 13500 kilos would be 125 to 168 times heavier.

In the photo below, you can see a human and cruise ship anchor comparison. Two maintenance workers underneath the anchor of Norwegian Cruise Line’s ship Norwegian Jewel , which was raised for maintenance.

In our post about the bottom of a cruise ship , we highlight a video clip of an anchor being freshly painted, and you can see it is about three times the height of the man doing the painting.

How Long Are Cruise Ship Anchor Chains?

The weight of anchor chains plays an important role in holding a cruise ship in position, much more so than the weight of the anchor itself.

When an anchor digs into the seabed, there must also be a sufficient length of anchor chain also lying on the sea bed. This provides extra weight and slack to the chain, which can absorb forces from the ship’s movement.

When a ship is properly anchored, the amount of anchor chain released should be 5 to 7 times longer than the depth of the water.

If the water depth was 50 ft (15m) the anchor chain released would need to be 250ft to 300ft (75m to 105m).

The anchor chain lies horizontally from the ship to the embedded anchor. Much of it is flat on the bed of the water.

The ship will not be sitting directly above the anchor but rather drawn away from it by wind and water currents.

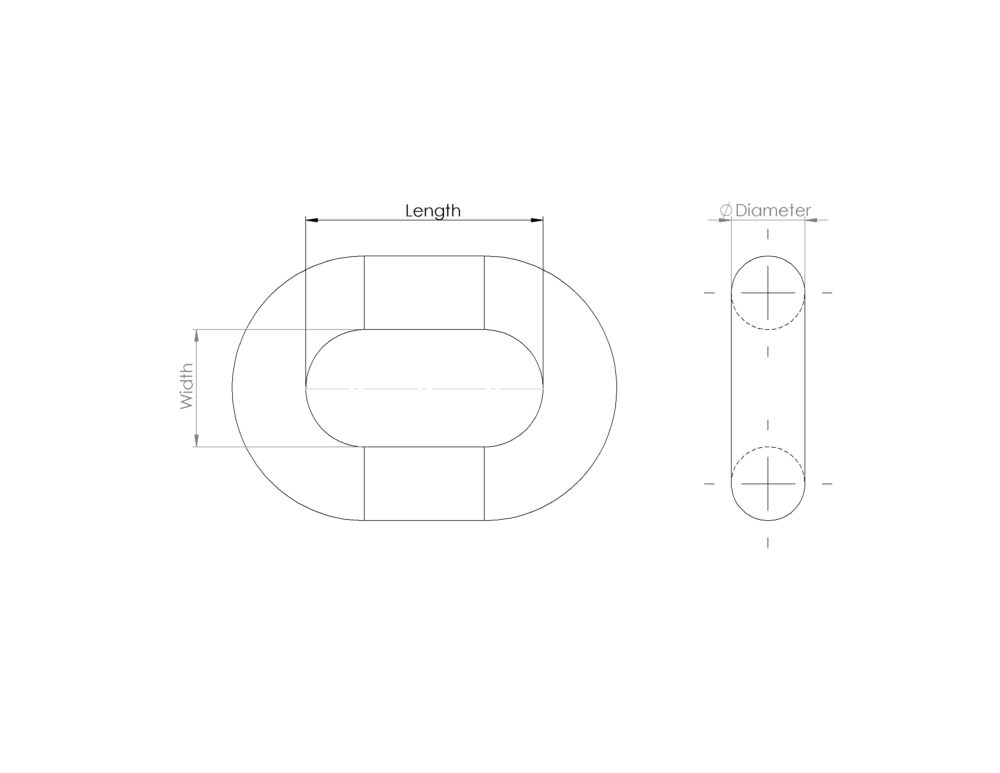

Each individual link on the anchor chain weighs a considerable amount in its own right. This weight of the chain causes it to sag into a curved shape from the anchor chain on the sea bed up towards the ship. This is referred to as a catenary, a flexible hanging chain.

Markings on Anchor Chain

To indicate the length of the anchor chain released are markings on the actual chain, individual chain links of a different color, usually a red shackle, and white links on either side.

These markings indicate every 90ft (27.4m) of chain released.

The way it works is for every 90ft extra links, and either side of the red shackle will be painted white.

For example, a 360ft chain would be indicated with four links painted which either side of the red shackle (4 x 90ft = 360ft).

When do Cruise Ships Use Anchors?

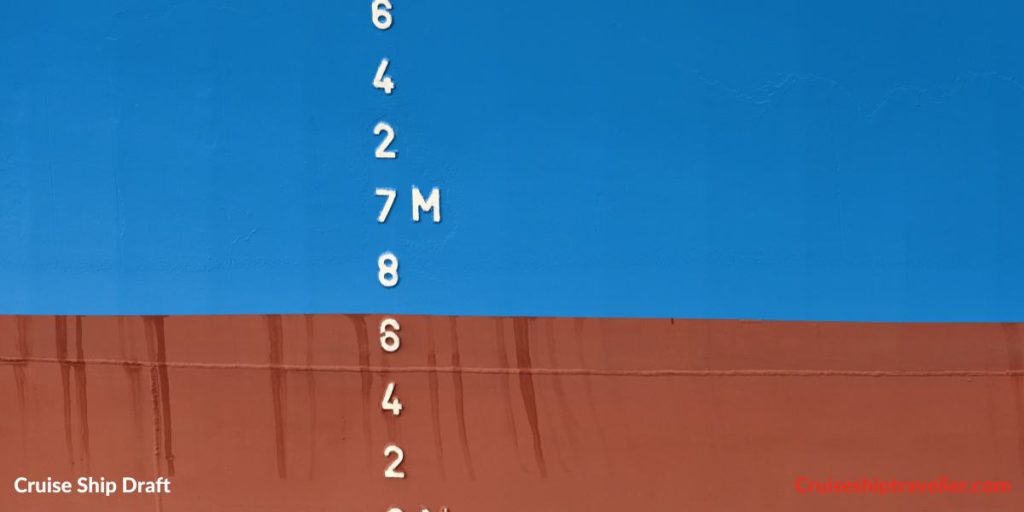

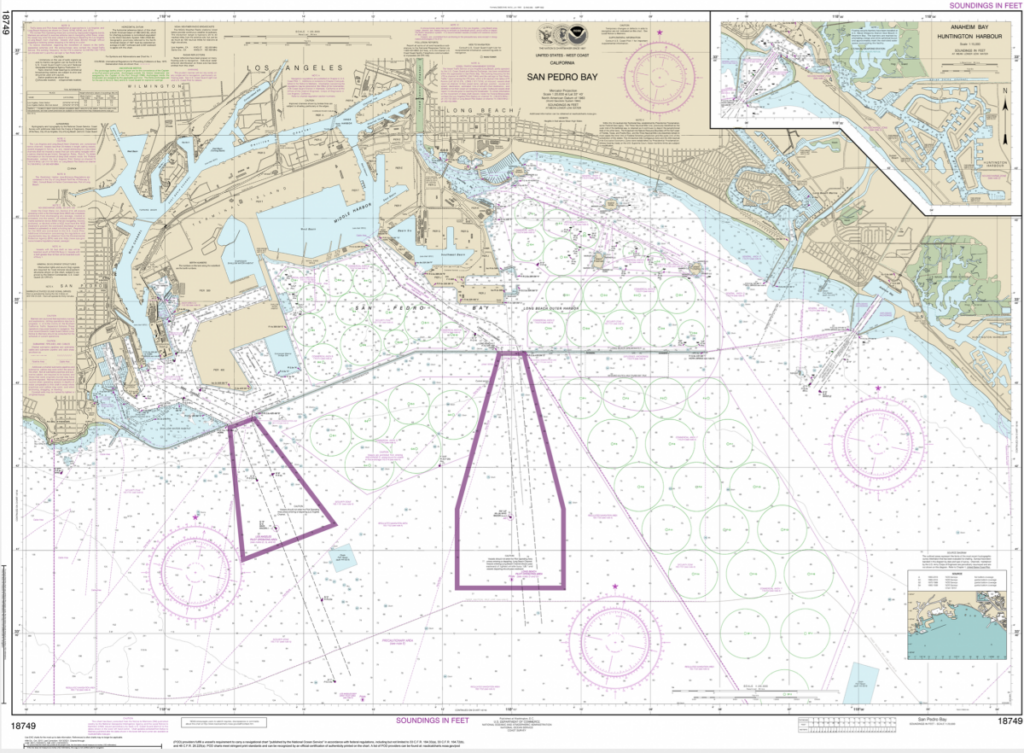

If the draft of a cruise ship is too deep for a shallow port and waters, this prevents the cruise ship from docking. The cruise ship will have to anchor offshore in deeper waters, and passengers will have to be tendered to port.

Reasons a cruise ship might need to anchor include:

- Port waters too shallow

- Waiting to berth (park)

- Holding position during a storm

- Waiting for port channels to clear

How Does A Ship Anchor Work

An anchor can be dropped in one of two ways.

- Engage in gear and walk back at desired pace or drop released for faster

- Release manual break for emergency release

The manual brake can be released in an emergency to release the anchor as quickly as possible.

When the anchor hits the seabed, the bridge crew will use the bow thrusters to maneuver the ship, causing the flukes of the anchor to dig in to the seabed.

With large cruise ships, it’s not so much the size and weight of the anchor that holds it in place, it’s more the total weight of the chain .

The anchor holds the end of the chain in position while much of the chain lays along the seabed before rising up to the cruise ship when forces such as wind are applied.

If there is no pull on the chain, and it’s slack, then there is no weight on the chain.

As the cruise ship moves, the chain’s slack changes when it’s slowly stretched and becomes taunter.

Depending on the stage of slack it will be referred to as:

- Lightweight

- Medium weight

- Heavyweight

At medium weight, the ship will have moved away from the anchor, and some of the chain will have been lifted from the seabed.

When the chain is deemed heavyweight, there is no slack in the chain. At this point, the anchor is acting to keep one end of the chain in position.

As a ship moves away from the anchor, the anchor chain gently extends as some chain is lifted from the seabed, absorbing some of the force that’s moving the ship. The force is not directly transferred to the anchor.

Whenever the forces subside, the chain slackens, and some of it falls back on the seabed as the ship eases back toward the anchor.

This is why anchor chains are so long. The longer the chain, the more force it can take before breaking the anchor free of the seabed.

If ships had short anchor chains that were just long enough for the anchor to bed down with a much shorter and tight chain, as soon as any excessive force is applied to moving the ship, it would be applied directly to the anchor, possibly causing it to break free.

Cruise Ship Dropping Anchor

To understand how a cruise ship works, we found this video which shows the Princess Cruise vessel, the Coral-class Island Princess cruise ship dropping an anchor .

To give you an idea of scale Island Princess is a mid-sized cruise ship, 91,627 gross tonnes with a capacity for 2200+ passengers and 900 crew.

Some of the biggest cruise ships are 2 to 2.5 times bigger, and the anchor and chains would be proportionally larger too.

Island Princess Dropping Anchor

The video shows:

- 0.40 – Anchor lowered to water level

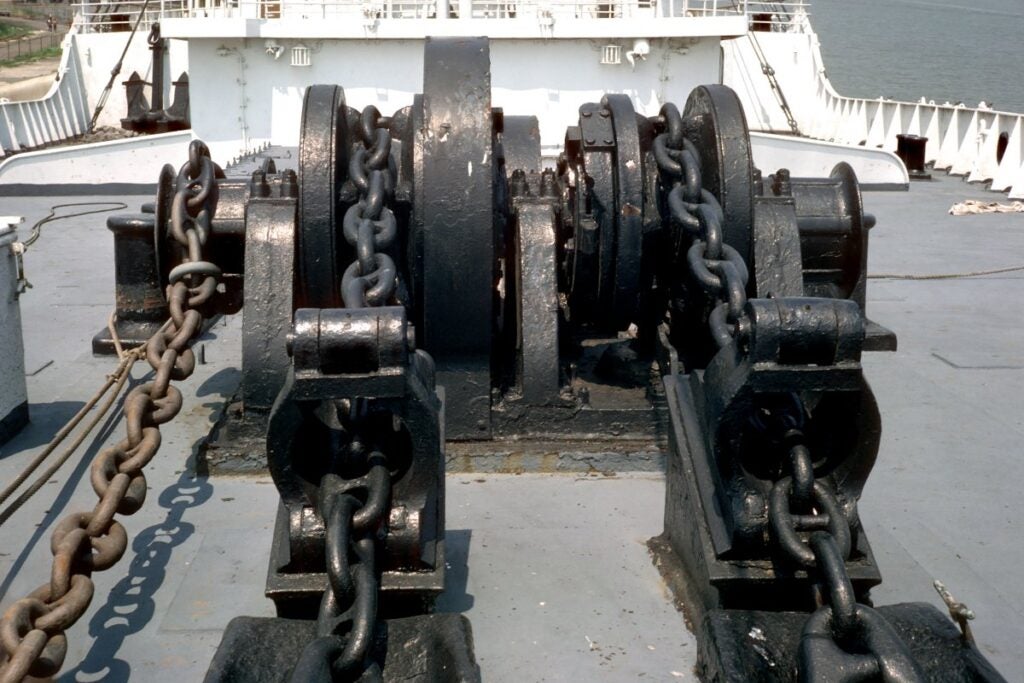

- 1.05 – Port side windlass

- 2.05 – Anchor starts dropping

- 4.03 – Brought up to a port anchor of 5 and a quarter in the water.

Do Modern Cruise Ships Need Anchors?

While cruise ships, in theory, can use the dynamic position system that utilizes a combination of computer technology and GPS and to automatically control the propellors and bow thrusters, keeping the ship in the desired position by acting against the forces of the sea and winds.

Although this would involve keeping the ship’s engine running, using lots of fuel and keeping the crew busy overseeing it all.

An anchor is a much more efficient process, including much less fuel.

More importantly, a cruise ship can always use an anchor in the event of a loss of power, which, in some situations, could be vital.

Basic Anchor Terms:

- Anchor aweigh – means to take up the anchor from the waters bed

- Bed down – anchor on the seabed

- Bosun – operates the windlass and anchor

- Brought up -when the ship’s way has stopped and is riding to her anchor. There’s an equilibrium between the weight and forces on the ship and the weight of the anchor cable.

- Forecastle raised deck front part of the ship

- Flukes – projection of anchor that digs into the seabed

- Hawse pipe -where the anchor is stored

- Heave – a strong pull

- Rode – anchor chain

- Windlass – a type of winch used especially on ships to hoist anchors

Frequently Asked Questions

What’s the largest anchor in the world.

The biggest anchor in the world belongs to the largest ship in service, Pioneering Spirit . The ship has a gross tonnage of 403,342 far greater than the next largest ships by gross tonnage .

One of the largest anchors in the world now on land is that of the Seawise Giant It is 36 tonnes and is on display at the Hong Kong Maritime Museum.

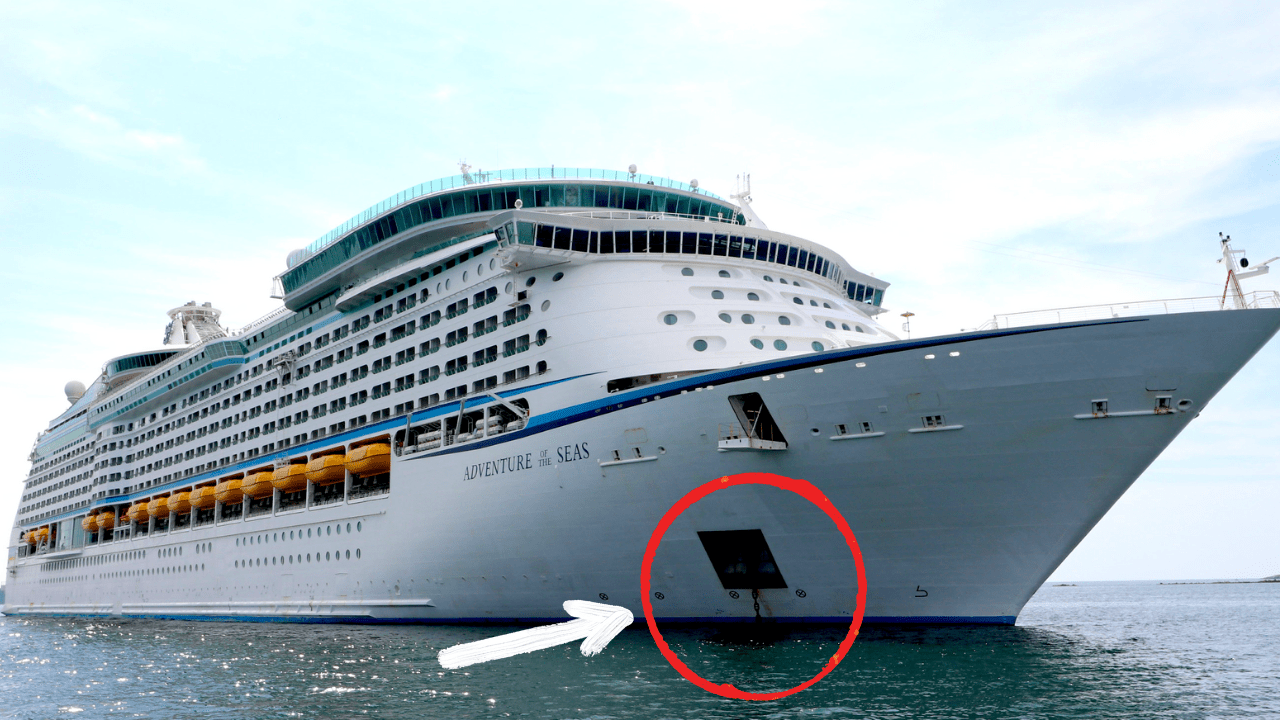

Why is Water Coming From A Ship Anchor?

When an anchor chain is lying on the seabed, it picks up all sorts of debris and mud, which must be cleaned to prevent the chains from seizing up.

The anchor chain is heaved up through the hawsepipe at the bow of the ship , while at the same clean, powerful jet sprays within the hawsepipe clean the anchor chain.

What Happens if an Anchor Gets Stuck?

If an anchor became stuck in the seabed, such as being caught on a rock, the cruise captain would try to maneuver the ship in various ways to try and break it free.

As a last resort, the anchor chains would have to be cut, leaving the anchor on the seabed. Rather than lose the anchor, a buoy could be attached to the last piece of the chain so it could be recovered later.

What Would Happen if a Cruise Ship Lost its Anchor?

There are usually two anchors on a cruise ship, one on the port side and one on the starboard side. If one was lost, the other could be used.

We have this post if you need ways to remember port and starboard side .

If all anchors were lost, the ship would have to use propulsion and bow thrusters to maintain position.

If power was also lost, the ship would be at the mercy of the forces of wind and waves, which would cause it to drift. In this instance, the captain would have to call for assistance.

Do Cruise Ship Anchors Touch The Ocean Floor?

Cruise ship anchors need to reach the floor of the seabed. More than that, they need to dig into the seabed to maintain a grip and have enough chain links to be laying on the seabed to absorb any weight-pulling forces.

Can a Cruise Ship Anchor in the Middle of the Ocean?

Cruise ships can only anchor in seas where the anchor can comfortably reach the bottom of the sea bed and still have enough chains left to lay on the seabed.

If the cruise chain is too taunt, any pressure moving the ship would put too much pressure on the anchor and possibly break it free from the seabed.

There are ocean depths that cruise ship anchors cannot reach. This is because they are primarily designed for anchoring in shallower coastal waters. Excess anchor rode is not on board because it takes up too much space and is rarely required.

If the anchor cannot reach the seabed, it is serving no purpose and is simply a weight dangling from the ship into the sea.

How Much Does A Cruise Ship Anchor Cost?

The cost of an anchor mostly depends on its size and weight.

There are also the logistics of transporting such a heavy item and the additional costs of installing the anchor.

As ship anchors are not commercially available for sale, it isn’t easy to estimate a price, but for a large cruise ship anchor on its own without a chain, it could be expected to cost a six-figure sum.

Related Posts

What is the Draft of a Cruise Ship? (and Why Does it Matter?)

How Many Doors on a Cruise Ship? (Yes, I Counted)

Leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Cruise Ship Anchors – Function, Size, Weight, and Uses

If you have seen a cruise ship you may be wondering if they have anchors. The majority of boats and ships do but with the vast size of cruise ships are anchors needed in the same way?

Cruise ship anchors usually can’t be seen from the shore and if you’ve been on a cruise ship it’s unlikely that you have spent too much time wondering about how the cruise ships stay in one place.

I recently saw a replica of the Titanic’s anchor which made me wonder if modern ships still have anchors.

Do Cruise Ships Have Anchors?

Modern cruise ships do have anchors. Dynamic positioning technology has reduced the need for traditional anchors but has not eliminated their use completely. Cruise ship anchors are usually between 10-20 feet in length and weigh between 10 and 20 US tons. Most modern cruise ships will have more than one anchor.

Cruise ship anchors are used to keep the cruise ship in a stationary position. This is often needed when a ship stops out to sea.

Do Cruise Ships Have Multiple Anchors?

The majority of ships have more than one anchor. It is common for ships to have two anchors, one on the port side and one on the starboard side of the ship.

There are a few reasons for this:

- In certain circumstances it makes sense to use an anchor that is on one side of the ship over the other.

- If an anchor became damaged, broke or was lost the ship needs to have another anchor that can be used as backup.

In addition to two working anchors, some ships will have a third backup anchor. This may not be the full size or weight of the main anchors.

When a ship uses both anchors at the same time and they are both anchored ahead, this is known as an open moor.

The below photo shows the Marella Discovery 2 using both anchors.

When do Cruise Ships Use Their Anchors?

Anchors are used to hold a ship in place. If a ship is unable to dock in a port due to shallow water it may be necessary for the ship to hold a position out to sea and to transport its passengers using tender boats.

Having to take a tender boat to land is a very common part of cruising. Guests are usually able to see ahead of time if the ports that they are visiting will require tendering.

I do enjoy tendering when I cruise but on occasion, it can mean long wait times. Tendering into port also increases the chance of a port being cancelled if the weather is bad. Cruise ships cannot risk tendering their passengers to land if they are unsure that they’ll be able to get them back later.

To learn how to spot tender ports and how to make the process as efficient as possible, check out this post: Cruise Ship Tendering – 5 Tips You NEED to Know .

How do Cruise Ship Anchors Work?

Cruise ship anchors dig into the seabed and provide a contact point for the ship.

When it comes to large ships, it isn’t just the anchor that holds the ship in place. The anchor is on the end of a long and heavy chain and the weight of this chain on the seabed helps to hold the ship in place. Each piece of the chain can be incredibly heavy.

The longer the anchor chain the more movement the ship can withhold. If the anchor chain was very short and a the ship slightly this may cause the anchor to break free. With a long chain the ship is able to move slightly without the anchor needing to come out of the seabed. The chain will simply become less slack.

Will Cruise Ships Always Need Anchors?

Modern technology has reduced the need for anchors but hasn’t completely eliminated it. Many modern cruise ships have ‘dynamic positioning’ meaning that they use propulsion and thrusters instead of anchors to maintain a steady position.

There are many benefits to using dynamic positioning over traditional anchoring including:

- Increased manouverability

- Quick to set up (and to stop)

- Seabed conditions and water depth don’t matter

Maintaining the position of a ship in this way may be better for the seabed as an anchor doesn’t have to be dropped but it does use more fuel and therefore produce more emissions. The initial cost to install this technology is also high.

Dynamic positioning was created in the 1960s for offshore drilling but it is a relatively new piece of cruise ship technology.

How Big are Cruise Ship Anchors?

Cruise ship anchors usually range from 10ft to 20ft in length. The Titanics anchor was 18ft 6 inches in length and the cast steelhead of the anchor was 10ft 9 inches.

In most cases, the size of the anchor directly correlates with the size of the ship.

How Much do Cruise Ship Anchors Weigh?

As a general rule cruise ship anchors tend to weigh between 10 and 20 US tons. The Titanics anchor was 16 US tons and many of the large modern large ships have anchors that weigh vastly more.

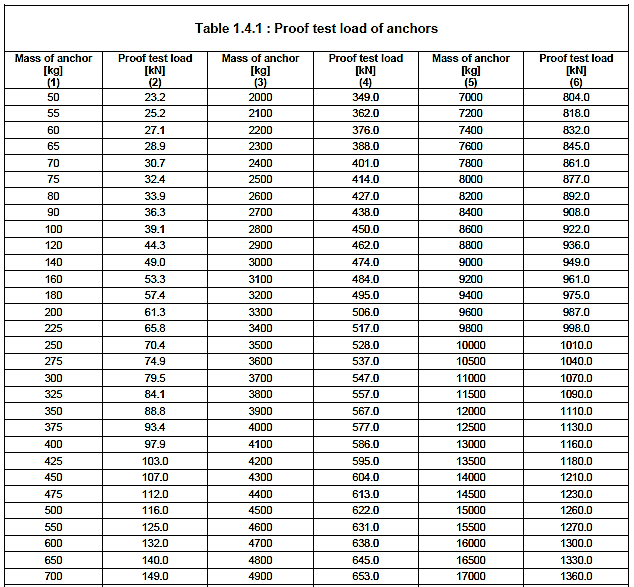

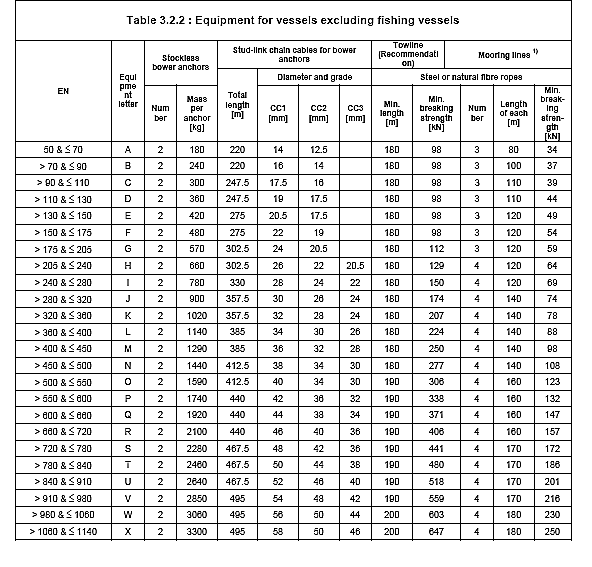

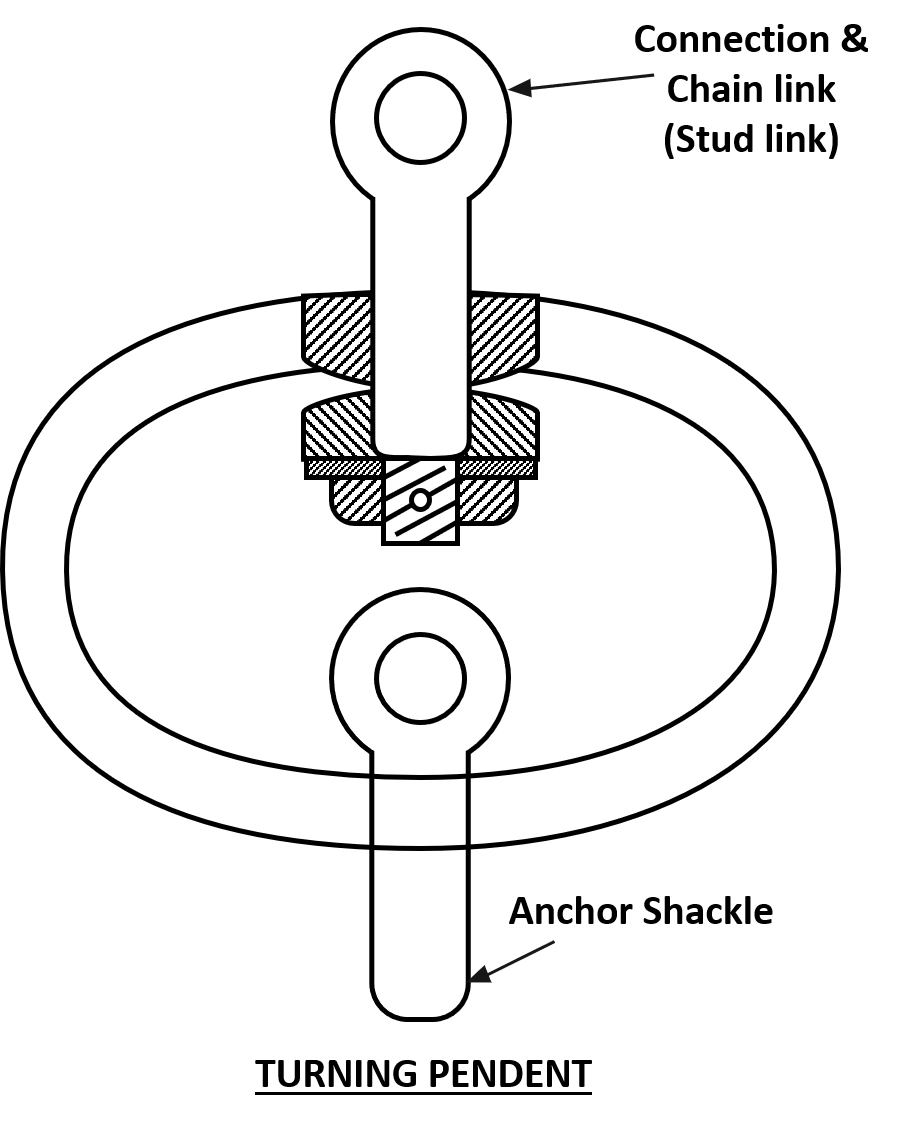

The largest ship detailed by the iacs equipment number calculation would require a 46,000kg anchor. A ship with a 46 metric ton anchor would need an anchor chain of at least 770 metres.

To put that into perspective the largest elephants weigh around 5 tons, so that’s over 9 elephants!

The below table shows the correlation between anchor weight and chain length.

Note, metric tons are different from US tons.

1 metric ton is 1000 KG.

1 US ton is 907 KG.

What Would Happen if a Cruise Ship Lost it’s Anchor?

The majority of cruise ships do have more than one anchor and would be able to maintain their position using just one. Many modern cruise ships would be able to use dynamic positioning if all anchors were lost for some reason.

It’s worth noting that anchors very rarely get lost.

If a ship had lost all of its anchors and was unable to dynamically position the ship would be unable to maintain a position when out to sea.

In this situation, the ship would be either forced to dock in port or to keep sailing.

Cruise Ship Anchor Impact in 2020 and 2021

Due to the 2020 cruise industry shut down a number of cruise ships had to anchor out to sea for long periods of time. The long lengths of time that the ships would be at sea meant that anchoring was a necessity.

One area that was affected by this was the south coast of England. There are no laws that say that cruise ships cannot drop anchor when out to sea and as a result this is how most ships spent the year.

It was too expensive to keep the ships docked and there wasn’t enough dock space in many places to accommodate the number of ships without anywhere to go.

The impact of the ships anchoring out to sea is still being investigated.

Cruise Ship Anchors (Sometimes) Have New Lives!

In the majority of cases, when a cruise ship is scrapped the anchor is scrapped along with the ship. There are a few examples though where cruise ship anchors have found new lives after their ship was scrapped.

Due to the weight and size of cruise ship anchors, it is difficult to use them for another purpose. One use of anchors has been as monuments or statues.

An anchor from the Queen Elizabeth 2 (1 of 2 anchors) currently is a landmark in Southampton. The anchor is 4.3m (14ft) by 2.7m (9ft) and weighs 13 tons.

Free Insiders Cruise Line Guide

Ever wondered how the mainstream cruise lines compare? Cruise lines won’t tell you this, but I will.

This FREE guide shows you everything you need to know to find your perfect cruise line.

Enter your email address below:

Cruise Ship Anchors: Everything You Need to Know

Disclosure: This post may contain affiliate links. We may receive compensation when you purchase via my links at no cost to you. See my disclosure for more information.

Today’s massive cruise ships are some of the most technologically advanced vehicles on the planet. Yet, they still use the ancient invention, anchors.

You’d think that an invention dating back to 592 BC is out of the window, but anchors still play an essential role for cruise ships.

This article will show you everything you need to know about cruise ship anchors. We’ll compare them to the modern ship stabilizing thrusters, and we’ll also compare the size and weight of one of the most famous ships in the world.

Table of Contents

Cruise Ship Anchors

Cruise ships use anchors to hold the ship in place. Cruise ship anchors are commonly used in tender ports, where the ship cannot moor to a land-based dock.

The first known use of ship anchors dates back to Ancient Greece, around 592 BC.

Despite advances in technology, cruise ship anchors remain essential in ship construction.

Modern ships have advanced positioning systems that keep them in place using engines and thrusters. This allows ships to remain in place without drifting.

The technology uses GPS and the cruise ship’s engines to keep the vessel stationary and counter the ocean currents and waves.

Dynamic positioning systems are commonly used when ships must remain in deep water , where an anchor may not be long enough. While the chain length limits the use of anchors, the dynamic positioning systems don’t have any limitations. They can be used in water of any depth and are often used to keep ships positioned in the deep ocean.

They also pose less risk to coral reefs, where an anchor might disturb the reef.

Despite the advantages of dynamic positioning systems, the new technology doesn’t eliminate the need for anchors.

Ship stabilizing thrusters consume fuel and are liable to malfunction and damage. While they don’t impact coral reefs like the anchor, burning fuel has its own environmental impact.

On the other hand, anchors are much more economical when keeping the ship in place since they consume no fuel.

How Do Cruise Ship Anchors Work?

Cruise ship anchors work by extending down to the seabed of shallow water and using their weight to hold the ship in position.

Anchors rest against the sea bed and utilize their heavy weight to keep the ship stationary. They counter the effect of currents and waves, holding the ship in its position.

Utilizing the sea bed is why cruise ships can’t rely on anchors in deep or open water. These anchors’ chains have a limited length; if the anchor can’t reach the sea bed, it can’t perform its function.

How Big Are Cruise Ship Anchors?

Cruise ship anchors range between 10–20 feet long and average 8–15 feet wide. An anchor’s size is directly proportional to the size of the vessel.

Larger and heavier ships require larger and heavier anchors.

The Titanic had an 18 foot 6 inches long main anchor, and it was the largest anchor made at the time.

Let’s not forget about the chains that hold these anchors. These chains have various lengths and thicknesses. The chains’ length depends on the anchor they’re supposed to carry, and the thickness depends on the ship they’re supposed to hold.

How Heavy Are Cruise Ship Anchors?

The average weight of cruise ship anchors ranges between 10–20 US tons . The weight can go considerably higher to accommodate the largest ships. However, it’s unlikely to go lower because it would be difficult for it to stabilize a ship with a lower weight.

The Titanic had an anchor that weighed around 16 US tons. Even back then, that was mighty impressive.

Despite the anchor’s weight, it merely acts as a point of contact with the seabed. The anchor’s chain is far heavier and vital in keeping the ship stationary.

Anchor Chains

Nautical engineers use various methods to calculate the chain length. Generally, heavier anchors require heavier chains.

The weight of the chain helps hold the cruise ship in place.

Longer chains can withstand more movement, unlike short chains, which can cause the anchor to lose contact with the seabed during rough seas.

When an anchor is lowered into the ocean, sufficient slack must be in the chain, which rests on the seabed. The slack provides a greater surface area of contact with the seabed, which absorbs more movement.

Here’s a sample table to show you the correlation between the lengths of chains based on their anchors’ weight.

Remember that we’ll use US tons, which are slightly lighter than metric tons. 1 US ton is around 907 kg.

Regarding thickness, there are three primary sizes of chains.

Smaller vessels use 1/4 inch thick chains, medium ships use 5/18 inch chains, and the biggest cruise ships use 3/8 inch chains.

How Many Anchors Do Cruise Ships Have?

Most modern cruise ships have two anchors, with one on the port side and the other on the ship’s starboard side.

Cruise ships occasionally use both anchors if the waters are rough or there’s a strong current. Most of the time, however, the cruise ship uses only one anchor and keeps the other one for backup.

Some larger cruise ships are equipped with a third backup anchor . The third anchor is often smaller and weighs less than the primary two anchors. It’s primarily used as a backup if one of the primary anchors breaks or malfunctions.

Can a Cruise Ship Stay Idle Without Anchors?

It’s unlikely for a modern cruise ship to lose its anchors. Many cruise ships also have two anchors. So, if one becomes unusable for some reason, the second will act as backup .

If, for some reason, the ship loses all functioning anchors; it can still rely on its thrusters to keep it stable.

In the improbable scenario that both the anchors and dynamic positioning systems also get damaged, the cruise ship will be at the mercy of the moving water as long as it’s not sailing.

In other words, the cruise ship could still get from point A to point B, but it won’t manage to stay idle without anchors or dynamic positioning systems.

The only solution would be to dock and have the issues repaired.

Do Cruise Ships Still Use Anchors?

Cruise ships generally avoid using the anchor due to the environmental impact on coral reefs and the seabed.

But dropping anchor also impacts guests.

Staterooms located near the ship’s bow are some of the worst on a cruise ship. One reason is the sound of the chain when the ship drops anchor.

Cruise ships often arrive at ports of call in the early morning. And no guest wants to be woken by what sounds like a freight train at 5 am while the ship drops anchor.

So what do cruise ships do instead?

Some cruise ports, such as Labedee, Haiti, offer fixed mooring points . The mooring points allow ships to remain stationary at sea within a reasonable distance of the port. This allows the vessel to remain idle without using the anchor.

If no fixed mooring points are available, some cruise lines will opt to use dynamic positioning systems to keep the ship idle using the ship’s engines . The bridge simply inputs the coordinates, and the system takes care of the rest.

But, dynamic positioning systems come at a cost .

They require significant amounts of fuel to power the engines. Not only are fuel costs a primary consideration for cruise lines, but they also impact the environment.

Some cruise ports have local laws prohibiting the use of anchors to protect coral reefs. But if there are no laws regarding anchors, it’s up to the captain to decide whether to use the dynamic positioning system or drop anchor.

Below is a visible of the cruise ship Island Princess dropping anchor.

Final Thoughts

Cruise ships are built with impressive engineering and enriched with fantastic technology, but they’re still humble enough to remain loyal to their anchors.

Anchors excel in stabilizing large cruise ships in shallow waters as long as they’re heavy enough to do the job. They’re also a great backup solution if modern positioning systems cease to function for any reason.

However, anchors can only work if their chains are long enough for them to reach the seabed, rendering them useless in open water.

Marcello De Lio

Leave a Reply Cancel Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Add Comment *

Save my name, email, and website in this browser for the next time I comment.

Post Comment

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Trending now

Cruise Ship Anchors: What You Need to Know

Cruise Ship Anchors: Some of the world’s most technologically advanced automobiles are the enormous cruise ships of today. However, they continue to use the antiquated anchor invention.

You would think that an idea that dates back to 592 BC would be obsolete, but cruise ships still depend heavily on anchors.

You will learn all there is to know about cruise ship anchors from this article. In addition to contrasting them with contemporary ship stabilizing thrusters, we’ll also weigh and dimension one of the most well-known ships in history.

Cruise Ship Anchors

As passengers tender into the port of call, Princess Cruises’ cruise ship is anchored in the Caribbean. Anchors are used by cruise ships to keep them stationary. In tender ports, where the ship is unable to moor to a land-based dock, cruise ship anchors are frequently utilized.

Ship anchors were originally used, as far as is known, in Ancient Greece in 592 BC.

Cruise ship anchors are still a crucial component of ship construction, even with technological advancements.

With the use of thrusters and engines, modern ships maintain their position thanks to sophisticated positioning systems. As a result, ships can stay still and not wander.

Utilizing GPS and the cruise ship’s engines, the system maintains the ship’s motion while fending off waves and currents in the water.

In situations where ships must stay in deep water and an anchor might not be long enough, dynamic positioning devices are frequently utilized. The chain’s length limits the use of anchors; however, dynamic positioning systems are unrestricted. They are frequently employed to maintain a ship’s position in the deep ocean and can be utilized in any depth of water.

Additionally, they lessen the possibility of an anchor disturbing coral reefs.

Even with dynamic positioning systems’ benefits, anchors are still necessary in this modern world.

Ship-stabilizing thrusters use fuel, which can also malfunction or sustain damage. Burning fuel influences the ecosystem even though it doesn’t affect coral reefs like the anchor does.

However, because they don’t use any fuel, anchors are far more cost-effective for keeping the ship stationary.

Cruise Ship Pilot: What is their Role and Responsibility?

How Do Anchors on Cruise Ships Operate?

In order to keep the ship in place, cruise ship anchors extend down to the shallow seafloor and use their weight.

Anchors use their substantial weight to keep the ship motionless while they rest against the ocean floor. They maintain the ship’s position by opposing the effects of waves and currents.

Cruise ships cannot rely on anchors in deep or open water because they must use the sea bed. The chains on these anchors have a finite length; the anchor cannot work if it is not able to reach the sea bed.

How Big Are Anchors on Cruise Ships?

Chris Allen’s replica of the Titanic’s anchor, available on Wikimedia Commons under CC BY-SA 2.0 The normal size of a cruise ship anchor is 8 to 15 feet wide, with a length of 10 to 20 feet. The size of an anchor is closely correlated with the size of the vessel.

Larger and heavier ships need anchors that are also larger and heavier.

The main anchor aboard the Titanic was the longest anchor ever manufactured at the time, measuring eighteen feet and six inches.

Remembering the chains that secure these anchors is important. The thicknesses and lengths of these chains vary. The thickness of the chains and the anchor they are intended to hold determine their length and thickness, respectively.

How Heavy Are the Anchors on Cruise Ships?

Cruise ship anchors typically weigh between ten and twenty US tons. The largest ships can be accommodated by significantly increasing the weight. It would be impossible for it to stabilize a ship with a lower weight, thus it is unlikely to go lower.

An anchor on the Titanic weighed about sixteen tons in US currency. That was really impressive even then.

The anchor serves only as a point of contact with the seafloor despite its weight. The chain of the anchor is much heavier and is essential to keeping the ship motionless.

What is the cost of fueling a cruise ship?

Anchor Chains

To determine the chain length, nautical engineers use a variety of techniques. In general, larger chains are needed for heavier anchors.

The weight of the chain helps to keep the cruise ship in place.

In contrast to short chains, which may allow the anchor to lose contact with the seafloor in choppy conditions, longer chains can tolerate greater movement.

The chain, which rests on the seafloor, needs to have enough slack when an anchor is lowered into the water. More surface area of contact with the seafloor is made possible by the slack, which absorbs more movement.

This sample table illustrates the relationship between chain lengths and the weight of their anchors.

Keep in mind that US tons, which are somewhat lighter than metric tons, will be used. 907 kg is around one US ton.

There are three main sizes of chains in terms of thickness.

Large cruise ships utilize 3/8-inch thick chains, whereas smaller ships use 1/4-inch thick chains and medium-sized ships use 5/18-inch thick chains.

What is the number of anchors on a cruise ship?

Upon docking in Rhodes Island, Greece, the Costa Fascinosa displays two cruise ship anchors. The Costa Fascinosa displays two anchors. The majority of contemporary cruise ships feature two anchors: one on the starboard side and one on the port side.

On rare occasions, when there is a strong current or heavy seas, cruise ships will employ both anchors. However, the cruise ship often only utilizes one anchor, saving the other for emergency usage.

Larger cruise ships may have a third backup anchor installed. Usually lighter than the other two anchors, the third anchor is smaller. Its main purpose is to serve as a backup in case the main anchor fails or malfunctions.

Can an Anchored Cruise Ship Remain Idle?

A contemporary cruise ship is not likely to lose its moorings. In addition, many cruise ships have two anchors. As a result, the second will serve as a backup in case the first breaks down for any reason.

The ship’s thrusters can keep it stable even if it loses all of its moorings for whatever reason.

The cruise ship will be at the mercy of the moving sea as long as it is not sailing, in the unlikely event that both the anchors and the dynamic positioning systems sustain damage.

Stated otherwise, the cruise ship could still get from point A to point B, but in the absence of anchors or dynamic positioning systems, it would not be able to remain still.

Docking would be the only way to get the problems fixed.

Are Anchors Still Used on Cruise Ships?

The anchor chain is visible, while Carnival Freedom is anchored off the coast of a Caribbean cruise port. Because anchoring has a negative environmental impact on the seabed and coral reefs, cruise ships usually avoid utilizing it.

The falling anchor, however, also has an impact on the visitors.

On a cruise ship, the staterooms closest to the bow are among the worst. The sound of the chain dropping anchor is one of the causes.

Early morning is when cruise ships typically dock at places of call. Furthermore, nobody wants to wake up at five in the morning to the sound of a freight train as the ship drops anchor.

What then, do cruise ships do differently? Fixed mooring places are available at certain cruise ports, such as Labedee, Haiti. Ships can stay still at sea as long as they are moored within a reasonable distance of the port. As a result, the ship can continue to move without deploying the anchor.

Some cruise lines choose to use dynamic positioning systems, which use the ship’s engines to keep the ship idle, if there are no fixed mooring locations available. All the bridge has to do is enter the coordinates; the system handles the rest.

However, there is a price for dynamic positioning systems.

To keep the engines running, they need a lot of gasoline. Cruise companies not only prioritize fuel expenses, but they also have an environmental impact.

Local rules in several cruise ports forbid using anchors to save coral reefs. The captain must choose whether to drop anchor or employ the dynamic positioning system if there are no regulations on anchors.

Related Posts

Royal Caribbean Cruises, History, Destinations and Itineraries

Ambassador Cruise Line: Ownership and History

Leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

Understanding Anchor Chain

- By Steve D'Antonio

- Updated: October 2, 2019

All chain’s the same, right? Well, no. There’s actually a variety of types and grades of anchor chain that cruising sailors should know about. What follows is a primer on understanding anchor chain and how to use it properly.

Types of Anchor Chain

Your Chain Explained

The most popular varieties of galvanized-steel windlass chain include high-test or grade 40 (usually marked HT, G4, or HT4); triple B or grade 30 (marked as BBB or 3B); and proof coil, also grade 30 (often marked PC, PC3, or G3). Each has attributes and shortcomings. BBB and proof coil are made from low-carbon steel; heat-treated high-test is made from a high carbon-manganese alloy.

HT chain is widely used because of its “strength-to-link” factor: Its working load limit is nearly twice that of BBB chain, and it has the highest weight-to-working load ratio. In other words, it allows the use of a thinner link, which means more chain can be stored in a given chain locker. Its links are also windlass calibrated, which means that they should fit any wildcat with an “HT” designation. Such links also tend to resist tangling in the locker.

Most PC chain is designated as “non-calibrated for windlass use.” This means it’s not designed to be used with a windlass wildcat. Period. Unfortunately, this caveat is unlikely to be stamped directly on the chain, so you can never be certain if the chain falls into this category. (If chain is verifiably approved for your windlass, it may be used for anchor rodes.) PC chain has roughly the same working load as BBB chain and the same number of links per foot as HT; for 3/8-inch chain, the ratio is 9.8 links per foot of chain. It’s worth noting that some windlass manufacturers, for obvious reasons, don’t offer a PC wildcat. If someone offers you a pile of cheap PC chain, beware.

Most high-quality chain from reputable manufacturers is embossed with a designation indicating the grade. Without one, you’ll be guessing about the chain’s strength. Failing to use chain designed for a specific windlass wildcat can lead to potentially dangerous overrides (above). This chain is in no-man’s land: It can’t be lowered or raised.

At one time, though not the strongest option for a given link size, BBB was the most popular anchor chain because it’s specifically calibrated for windlasses. But its primary attribute is its weight. A 100-foot length of 3/8-inch BBB weighs approximately 165 pounds, while identical lengths of HT and PC weigh 153 and 140 pounds, respectively. With anchor rodes, weight is critical. Every additional pound increases a chain’s catenary, the sag induced by the deployed chain. Still, many builders and sailors choose HT over BBB because, for the same tensile strength, they can fit more of it into cramped chain lockers. And, again, it’s less prone to tangle.

Maintaining Your Marine Chain

Inspect your marine chain carefully and regularly. Make certain that the links fit evenly into each recess of the wildcat and that the wildcat is equipped with a stripper, a steel bar that separates tensioned chain from the wildcat as it’s being retrieved. If the stripper is absent or bent, jams are more likely to occur. Finally, be sure that the bitter end of the chain is attached to the vessel via a spliced-on section of line that’s long enough to reach the deck. The splice should fit easily through the chain hawser. If you’re dragging onto a lee shore or you’re about to be run down, this line acts as a safety valve allowing you to quickly cut the boat free from the ground tackle.

To read more monthly maintenance tips, click here.

- More: boat maintenance , How To , maintenance

- More How To

Adding Onboard Electronics? Here’s How To Get Started

7 Boating Safety Tips for Summer Cruising

How to Prep for a Diesel You Can Depend On

Anchoring in Paradise

Now For Sale: Leopard 45

The Long Way Around

Sailing to the Land of Shrimp

Swallow Tattoos and Sailors

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Marine Anchor Chain – A Complete FAQ Guide

Table of contents.

Anchor chains play an essential role in the marine industry – with them, ships and vessels can stay safe and securely halted throughout their journey. If you want all the essential information regarding an anchor chain and how it works, this is the perfect place to start.

This FAQ guide will provide a comprehensive idea of the advantages, types, and other details of marine anchor chains.

1. What is a Marine Anchor Chain?

Figure 1 Marine Anchor Chain

Marine anchor chains keep your ships safe. This heavy-duty chain is made to withstand the rough conditions out at sea: salt water, changes in temperature and salinity, and extreme pressure changes due to waves or rapid currents.

An anchor chain helps ensure that vessels stay in one place – whether used for travel, recreation, commercial fishing, or cruising. The chain is constructed from thick steel links connected using pins.

In some cases, additional pieces, such as shackles, might be added to parts of the chain for enhanced safety and strength. This chain is essential to make sure you can confidently head out onto the open ocean without worrying about getting swept away!

Figure 2: Chain Parts

2. What is the Importance of the Marine Anchor Chain?

A marine anchor chain – also known as an anchor rode – is a crucial component of the vessel’s anchoring system. Its purpose is to securely attach the anchor to a part of the boat so that it may be quickly and easily lifted in times of need.

Furthermore, this chain plays an essential role in deflecting specific forces away from the anchor head and main structure. When faced with extreme weather conditions such as storms or strong currents, a ship or offshore rig may tilt and heel uncontrollably, severely damaging its hull if not adequately protected.

Figure 3: Anchor Chains

Anchor chains are designed to absorb pressure placed on them, reducing the force exerted upon them. It allows for a potential decrease in damage caused by heavy weights as anchor chains and cables are manufactured to withstand substantial forces without harm or distortion.

3. Write Some Benefits of Using Marine Anchor Chain?

Marine anchor chains are a lifesaver in keeping a vessel safe while it is out at sea. The chain connects the ship and the anchor, ensuring the boat remains safe from harm. Anchor chains are incredibly strong, allowing your boat to remain stationary amidst all weather conditions. Not only do they offer maximum strength, but they also feature an impressive level of corrosion resistance due to their construction with high-grade steel.

Figure 4: Anchor Chain in Water

In addition to this, marine anchor chains do not need to be replaced frequently like some other materials, making them cost-effective in the long run.

4. What are the Important Factors to Consider While Selecting the Marine Anchor Chain?

When selecting or creating the anchor chain, several essential elements must be considered.

- Firstly, the highest permissible load should be taken into account.

- Secondly, storage ease must be considered.

- Finally, the rode’s expected length should also be considered when selecting an anchor chain.

When it comes to rode designs, it is essential to factor in convenience and ease during storage. Anchor chains need to be placed away carefully so that the hull of the boat is not damaged as a result of an anchor chain being left hanging down too much or entangling itself with other elements around it.

Every ship or offshore station has a good understanding of the depths of their working areas and can therefore determine the length at which the anchor rode should be securely attached.

The scope is a ratio that expresses the relationship between the amount of anchor rode paid out to the actual depth of the water body. It reflects a balance between how much vertical force an anchor exerts on a vessel and how much drift it experiences.

The scope of a ship’s anchor chain will usually range from a 5:1 to a 7:1 ratio, meaning that for every one foot of depth in the water, there will be five to seven feet of anchor line. Shorter chains are better at holding the vessel in place since they contain less slack, which helps prevent the waves’ natural motions from moving the boat away.

When the chain is released, and the angle between the anchor rode, and the bottom of the vessel is greater than 90 degrees, any sudden impacts or jerks are quickly transferred to both the rode and boat. This means that a more extensive range of motion can be achieved, and any force acting on the boat will begin to reduce in intensity. As a result, this allows it to drift into an area far more expansive than initially anticipated.

Check the video for some important tips to choose the right anchor chain:

5. Why Can You Use Cable and Anchor Chains Combination?

If the design of a system involves both, it may be able to overcome some of the issues that arise due to the large number of variables involved in each design.

Figure 5: Combination of Chain and Cable

A cable and chain rode combination is commonly used in large cruise ships and offshore structures. This concept works because the chain components of the anchor rode are more suitable for use in areas with rougher seabeds, where cables cannot be used. The steel links within the chain sections have a higher tensile strength required to resist pulling force on the anchor and the ship, thus preserving the integrity of its position.

A typical anchor rode consists of a length of cable, usually made up of galvanized steel or stainless steel wire rope, connected to a short section of chain and then onto an anchor stock. For this reason, joining both types of rodes necessitates utilizing specialized techniques. It is at this junction between cable and chain where most failures occur due to its heightened fragility.

The junction between the cable and chain is covered with a galvanized connection, allowing for a secure and reliable interlocking of the two elements. The cable fibers are partially linked to the chain, creating an even stronger bond. It is further enhanced by being able to connect the cable to the chain as well directly.

Using this combination of cable and chain has numerous advantages. However, if not using such a combination in such conditions, then the single heavy chained element won’t stay on the seafloor due to its lack of weight anchoring it down. In addition, due to its sturdiness when connected, this combination can easily withstand strong waves or winds without coming apart or getting displaced from its anchored position at the seabed.

6. What is Marine Anchor Chain Marking?

The importance of an anchor chain’s scope cannot be understated, as it is necessary to maintain a balance between the movements of the vessel and the strain that is placed on the cable or chain during anchoring. This means it is absolutely essential to be aware of how much anchor rode has been used. To this end, painted sections and plastic markers are strategically positioned along the anchor rode in order to help those involved in anchoring operations, such as the operator, identify quickly how much rope they have put into use.

Compared to traditional painting and other methods of marking the water, plastic rope markers have the advantage of having a longer life on the seas. The paid-out rope length can be typically shown by colored zip ties having different knots at various uniform intervals. These intervals lie between 25 feet and 7.5 meters.

As part of nautical norms, the colors used for length indicators tend to be white, red, and blue. Moreover, they can disintegrate if they come into contact with tethering spools and hawse pipes frequently.

7. How to Store Marine Anchor Chain Properly?

The anchor chain serves an essential purpose in providing extra stability to the anchor, which is often made of metal. But due to being exposed to the harsh environment, these materials are prone to rust and wear over time, making them increasingly vulnerable. This is why it’s essential that when boats bring their anchors back onboard, they must scrutinize them for any signs of damage.

For this, appropriate storage facilities must be constructed so that the rode may be quickly retrieved for maintenance.

Inside the ship’s hull lies the chain locker: an enclosure specially designed to provide ventilation and store anchor chains when they are not in use. This space is typically reinforced with additional materials to support the heavy load of the metal rope and accompanying anchor that is often stored there. As needed, engineer staff can access the locker for regular inspections or maintenance services.

The locker itself is strong enough to withstand immense pressure and strain exerted by the heavy weight of the chain and its elements. Its walls are often made from thick steel plates or reinforced concrete, ensuring it will remain secure during harsh ocean conditions.

Figure 6: Chain Locker Location

It is critically important that the anchor storage equipment on a vessel is set up incorrectly, as it can lead to considerable danger if mechanical problems occur with the windlass. This windlass may offer power to raise or lower the anchor chain, so having an organized arrangement of port and starboard side anchors is essential. If this equipment is not set up correctly, there could be an unforeseen issue with the raising and lowering of the anchor chain.

Marine Cable

- Marine Power Cable

- Marine VFD Cable

- Marine Telephone Cable

- Marine Flex Wire

Offshore Cable

- Offshore Power Cable

- Offshore VFD Cable

- Instrumentation Cable

- Offshore Wire

More Products

Quick Contacts

NO.1299, East Section of Yinxian Avenue,Yinzhou Dist, Ningbo, Zhejiang, China

- Carnival Cruise News

- Royal Caribbean News

- Disney Cruise News

- Travel News

- Casino News

- Cruise News

The Anatomy of a Cruise Ship Anchor Chain

While it may seem like a relatively simple piece of equipment, a cruise ship’s anchor is a marvel of modern engineering. When you consider the incredible size and weight of a modern-day cruise ship, you begin to realize what an incredibly difficult task is to ensure they are secured in place while they are in the harbor.

Today, we will take an in-depth look at cruise ship anchor chains. Not only will we break down how they work, but we also explore what they are made from, the various components of the chain, and the incredible engineering that goes into ensuring that they can hold a cruise ship in place.

So, if you are ready to learn everything you need to know about a cruise ship anchor chain, let’s get started!

While it may seem pretty self-explanatory, a cruise ship anchor chain plays a complex and incredibly important role in ensuring the overall safety of a cruise ship voyage. These massive chains need to withstand the incredible forces exerted on the cruise ship’s anchor when the cruise ship is in the harbor.

To withstand the immense pressure generated by holding a heavy cruise ship in place against tides, waves, and ocean currents, the anchor chain and cables need to be immensely strong, and incredibly flexible. The individual chain links look just like any other type of chain, but they are on a massive scale.

Each link in the chain is made from high-grade steel with incredible tensile strength. While the chain size will vary depending on the size and weight of the cruise ship, they are all incredibly large and heavy.

Read Also: What is the Draft of a Ship?

In some cases, the waters the cruise ship traverses can also be a factor when determining how large the anchor chain needs to be. For example, large ships that traverse deep waters with strong currents need a much larger anchor and anchor chain than small boats on shallow water that stay close to the coastline.

The traditional anchor chains of a cruise ship may seem like they have a relatively simple design, but they are made up of many different parts, which all have to be made to an extremely high standard.

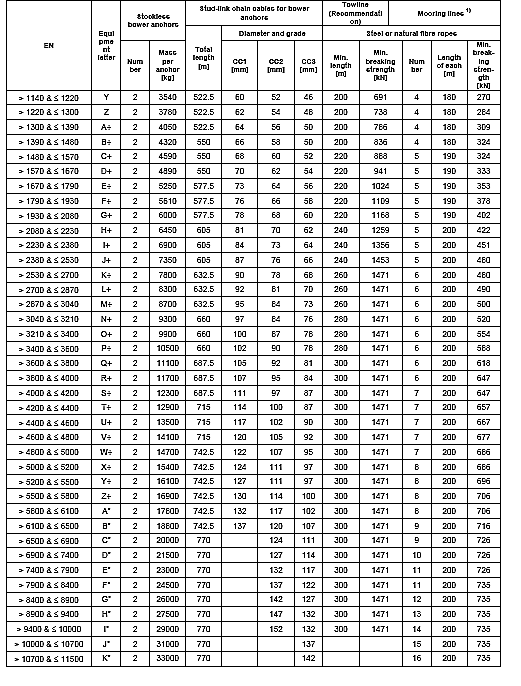

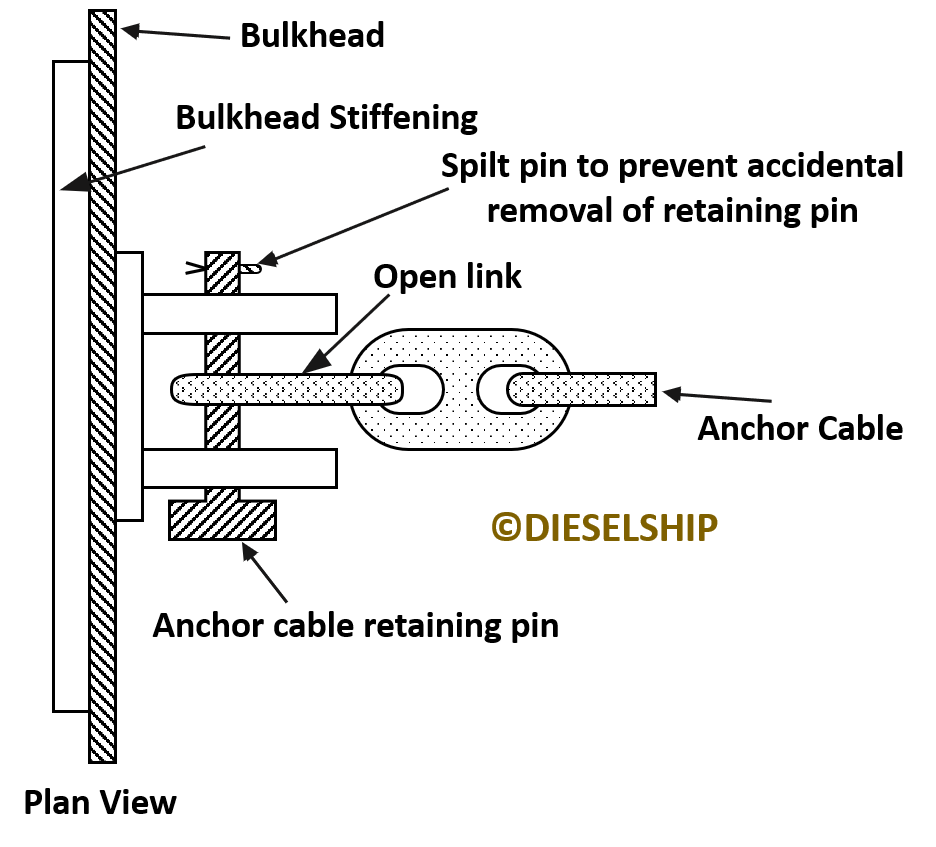

Here are the main components of a cruise ship anchor chain:

The most prominent component of a cruise ship anchor chain is the series of interconnected links that make up the bulk of the chain. These links are massive in scale, and they need to be constructed of high-tensile, high-strength steel.

The chain design allows for the perfect combination of strength and flexibility, which is necessary when holding a heavy anchor in place against the tremendous forces of a large body of water and heavy vessels.

Each link in the chain will look like an elongated oval, or it can be designed to have more of a “D” shape. These two shapes allow the chains to be connected in a way that maintains their strength but can still move smoothly.

All links within the chain are also designed to be the exact same size. They also need to be precisely spaced so that each link has the same freedom to move as the next. If this was not the case, dropping and retrieving the anchor would be much rougher. The chain could also become damaged over time.

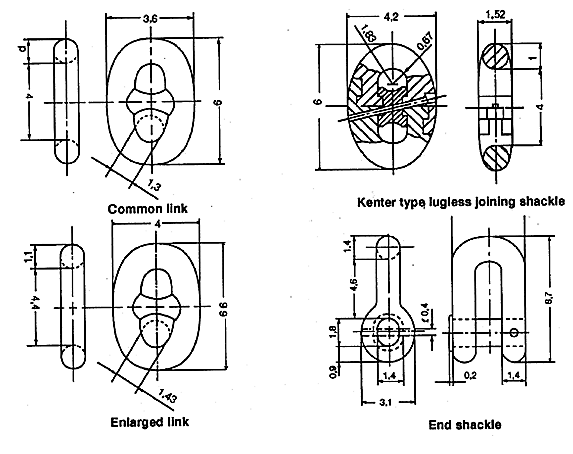

The individual links within the chain are joined together using a detachable mechanism. Basically, this mechanism consists of a connector and an anchor shackle.

Not only does this make it possible to put the chain together, it also makes it possible to remove damaged or corroded links within the chain without completely replacing the entire anchor chain.

Most cruise ship anchor chains also feature depth markings at evenly spaced-out intervals. These allow crew members to easily determine how much of the chain has been released by the anchor windlass. Typically, these markings are made with bright, scratch-resistant paint; however, they can be made by stamping impressions into the metal.

To learn more about the anchor of a cruise ship, rather than just the chain that connects it to the ship, we recommend reading about how big a cruise ship anchor is . This straightforward guide explains how big these enormous anchors need to be and provides other helpful information on how modern anchors work.

As mentioned, the anchor weight, chain length, and size of a cruise ship’s chain can vary depending on the weight and dimensions of the cruise ship itself.

That said, the general range for a single link of the anchor’s chain tends to be between 11 lbs (5 kg) to about 290 lbs (130 kg). The longer the chain length, the more it weighs.

Worth Reading: How Much Does a Cruise Ship Weigh?

With individual links weighing so much, the anchor chain’s overall weight can easily be measured in tons. When you think about the weight of a cruise ship and the immense forces sea and ocean water can exert, it only makes sense that the chains need to be incredibly heavy.

Cruise ship anchor chains need to be made from high-strength steel. Steel is the only suitable choice, as it offers the durability and strength required to withstand such immense forces. The high-strength steel alloys used to make these enormous anchor chains are also resistant to corrosion caused by lengthy exposure to saltwater.

To enhance the corrosion resistance of the anchor chain, most are given additional coatings and surface treatments to enhance the anchor chain’s corrosion resistance. Galvanization and various types of specialized coatings are used for the individual links of the anchor chain.

These surface treatments can not only delay corrosion, they can also help prevent scratching as the chain links rub against each other and even the hull.

Not only do cruise ship anchor chains need to be heavy, strong, and incredibly durable, they need to be flexible. Flexibility is essential for the following reasons:

Even when a cruise ship is anchored in a harbor, the anchor chain must be capable of adjusting to fluctuations in water conditions. The tide can change the depth of the water rapidly, so if the chain is not flexible, it would be under much more tension.

This could damage the anchor and the ship itself. By remaining flexible, the anchor chain can also absorb sudden forces caused by large waves and storms.

A flexible anchor chain creates far less noise when the ship moves. For passengers to have a more comfortable experience while they are on board the ship, flexible anchor chains reduce creaks and other noises that could be disturbing.

The chain’s flexibility is essential when it comes to dropping and retrieving the anchor. When the anchor is dropped or lifted, the chain flows through a chute on the side of the ship’s bow.

As you may know, a seabed in one area can differ in composition from one area to the next. While some are sandy and easy for an anchor to dig into, others are uneven and rocky. By having a strong but flexible anchor chain, the anchor can have a much more stable hold.

Currently, the world’s largest anchor chain belongs to the Oasis Class cruise ships owned and operated by Royal Caribbean International. These anchor chains weigh between 130 and 160 tons!

Although extremely rare, cruise ship anchor chains have been known to break. Typically, this is due to corrosion and long-standing exposure to salty seawater. Overloading the anchor chain by dropping anchor in rough seas can also cause wear and tear. Eventually, this damage could result in the chain breaking.

Read about an anchor lost after getting stuck near San Juan for an example of how and why large vessels could be forced to cut its anchor loose.

While the exact frequency of inspections will depend on the particular policies of each cruise line, most anchor chains are inspected as part of the cruise ship’s regular inspection and maintenance procedures. This means a visual inspection usually occurs before each voyage.

More in-depth inspections are typically conducted at least once a year. During these inspections, each chain link is checked for signs of damage and corrosion. As you would expect, the frequency and closeness of inspections can increase if the crew suspects that the anchor chain could be damaged.

While casual cruise-goers often overlook them, there is an incredible amount of engineering that goes into making and maintaining a cruise ship anchor chain. Not only is the scale of the individual links impressive, but the ability of the chain to withstand immense forces is also truly a marvel of maritime engineering.

RELATED ARTICLES MORE FROM AUTHOR

See how Princess Cruises Alaska Sailing Impacted By Propulsion Problems

See how Holland America Line Unveils 132-Day and 93-Day World Cruises from US

See how Residential Cruise Line Offers New Retirement Program for Up To $499,999

Leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

Don't Miss

Check out port operator announces expansion plans at caribbean destination, check out costa ship sets sail on last cruise before joining carnival, take a look at what to do if your cruise ship leaves without you..., see how the world cruise that sold out in 30 minutes begins 180-day..., even more news.

See how Holland America Line Unveils 132-Day and 93-Day World...

See how Residential Cruise Line Offers New Retirement Program for...

Popular category.

- Cruise News 2310

- Disney Cruise News 253

- Carnival Cruise News 74

- Casino News 68

- Royal Caribbean News 68

- Travel News 33

- Visit our Youtube page!

Sign up now for our WhatsApp newsletter and receive a FREE SVB set of playing cards!

Get the latest SVB news via WhatsApp and/or SMS!

- Spare parts

- SVB@Youtube

- My SVB Account

- Compare list

Are you missing items that you have already placed in your shopping cart? Log in to see your saved items.

- Anchoring & Mooring Correctly

Anchor chains and lines

In this comprehensive guide to anchor chains and anchor lines, we hope you'll find all the answers to the most important questions and plenty of helpful tips! As any skipper will tell you, every boat must have reliable, quality anchor equipment at its disposal. Not only is this essential when moored in a quiet and idyllic bay, but even more so when there is wind or swell. Making the right choice will therefore not only make your life easier on board, it is also paramount to ensuring the safety of your boat and its crew. Anchor chains can come in various grades and types, and each has its own specifications and features that enhance effectiveness. The wide range of products is sure to satisfy all requirements. However, one thing is true for all chains: the breaking load of an anchor chain must be such that it is able to withstand individually acting forces caused by the current, wind and swell in any situation, and this also depends on the boat's size, depth of the water and anchorage. The weight of your anchor chain is also an important factor to consider, as is how easy it is to handle on board. It may therefore be worthwhile looking at chain and rope combinations when choosing anchor rode.

The right choice

- Choosing an anchor chain

- DIN or ISO?

Anchor chain thickness

Anchor line or anchor chain, selection criteria & properties, length of anchor chain or line, chain fore-runner, anchor buddy (weight), attaching, using and caring for your anchor chain, finding the right anchor chain, how to choose the right anchor chain.

Finding the right anchor chain depends first and foremost on your type of boat and the area you sail in. Hot-dip galvanised steel chains are widely used in northern latitudes. "This type of chain is reasonably cheap, but also has properties you should be aware of," explains Dietbrecht, equipment expert at SVB. "Because of its rough surface, silt or algae tend to stick to it. Furthermore, the zinc coating could eventually rub off on the seabed, which could cause rust to occur on damaged areas."

What's more, when raising anchor, this kind of chain doesn't flow as compactly into the locker as well as others. The chain can form a pyramid, meaning that the hanging part won't be heavy enough to pull the chain down into the locker. This is not the case with smooth stainless-steel chains, also called Niro chains, but these are around three to four times more expensive and some alloys have little or no corrosion resistance in warm water areas (Caribbean or Mediterranean). The salt water literally eats into the steel and forms holes, which, if they remain unnoticed, can cause the chain to break unexpectedly under load. High-quality, so-called high-strength steel or duplex steel is supposed to prevent such a scenario, but other products also offer corrosion resistance.

Anchor chains: DIN or ISO?

What does din and iso mean.

In Germany, chains are manufactured according to the industry standard DIN 766. Chains from other European countries often correspond to the ISO standard 4565. DIN sizes correspond to uniform dimensions that have been established according to the German Institute for Standardisation (DIN). The International Organisation for Standardisation, ISO for short (from Greek isos = equal), is a corresponding international standardisation organisation. Outside Europe, chains are commonly measured in inches.

"If using a windlass on board, the size of the anchor chain must match that of the gypsy," says Dietbrecht. "If the links in the chain are the wrong size, it will jump and not run through smoothly." By conforming to strict calibration standards such as ISO or DIN, most anchor chains and chain links will run reliably through the windlass. According to DIN and ISO, round steel chain links with a thickness of six and eight millimetres are identical in terms of link length and internal link dimensions. Differences in classification only exist from a size of ten millimetres of steel chain. This information is usually indicated on the winch. However, these industry standards do not say anything about the material of the chain steel and the alloys can have very different properties. Steel chains of the designations 1.4401, AISI 316, V4A, 1.4404, AISI 316L are not considered suitable for seawater in warm areas. The benchmark here is the material 1.4462 (AISI 318LN).

Overview ISO anchor chain

Din chain characteristics.

Which anchor chain thickness should i have?

There are no legal guidelines on chain thickness, so responsibility here lies with the owner or skipper. You'll have to decide for yourself which is the best anchor chain for your boat. Many specifications and recommendations for skippers are based on safety guidelines issued by yacht associations or the Germanischer Lloyd (GL) classification society. From a purely economic point of view, an anchor chain should of course only ever be as thick as it needs to be. However, experienced boaters do tend to choose chains that are a little thicker, to be on the safe side in case of an emergency. The required chain link thickness is determined by the size of the vessel, i.e., the boat weight and the breaking load of the anchor chain, and varies depending on the chain material. Some specifications base the calculation of the breaking load of an anchor chain on the displacement of the boat, which corresponds to the boat weight in relation to its mass. The average breaking load value for ten-millimetre chain steel is about 80 Kn. The minimum breaking load according to DIN 766 is 4.0 t for a 10 mm round steel chain. The most common thickness for recreational boats is eight, ten and twelve millimetres. An alternative recommendation is provided by Germanischer Lloyd, which refers to the length of the ship (GL recommendation): up to 8 metres boat length = 6 millimetres chain steel, up to 10 metres = 8 millimetres, up to 12 metres = 10 millimetres, up to 14 metres = 12 millimetres and up to 16 metres = 13 millimetres. " You can't tell what loads an anchor chain can take by looking at it from the outside, so a new anchor chain should always have a test certificate from the manufacturer," recommends Dietbrecht, sailor and boating expert.

This is the only way you can be sure that the specified breaking load and gauge accuracy (i.e. exact adherence to the specified dimensions) is correct, and you won't be in for any nasty surprises when at anchor. The price of an anchor chain can vary considerably and depends on the design, quality and length you need. This can range from a few hundred to several thousand euros.

TIP: „Breaking loads on galvanised chains and Nirosta chains are the same. They just have different surface finishes. Hence the difference in price."

Anchor chain

Should i use Anchor line or anchor chain?

Because of its high tensile strength, many skippers prefer an anchor chain. But on dinghies, inflatable boats or small motor yachts (up to 1.5 t weight), you can use an anchor line and it does offer some advantages. Due to its light weight, an anchor line is easier to handle; moreover, the weight of an anchor chain will affect the trim and increase hobby-horsing if stowed in the bow. Furthermore, anchor lines can also have considerable breaking loads, about eight tonnes at 22 millimetres thick, and in adverse conditions with waves or wind they are actually superior to a chain because of their elasticity. Because the line is more flexible, it can absorb dynamic load peaks better, whereby an anchor chain would "jolt" hard. This jerking happens when a wave hits the bow while the chain is taught. The risk here is that the anchor could be ripped free from its hold, or anchor equipment, such as a windlass or cleat could become damaged.

From boat sizes with a weight of 1.5 t, the thickness of an anchor line should be at least twelve millimetres. 10-millimetre lines should be chosen for smaller boats as they are better to handle. Any thinner and lines can cut easily into the hand when being hauled in. The ideal material for an anchor line is nylon or polyester with square braid. Polyethylene lines are not suitable as anchor lines because they do not absorb water and tend to float as a result. Likewise, mooring lines are not suitable for use as anchor lines. Mooring lines must be UV resistant, flexible and have good stretch and abrasion resistance.

Anchor lines, on the other hand, should be relatively stretch-free, but still elastic enough to prevent jerking. Disadvantage of an anchor line: Unlike a chain, it does not self-stow in the chain locker when anchoring and because you need a longer length than a chain, it takes up more space. When using a line, it is essential to note that the swing circle is larger. When a ship is at anchor, it rarely stays fixed at one point: changes in wind conditions or current direction cause it to move in an arc around the anchor. The ship's movement around the anchored position is called the anchor swinging circle. It's important to make sure there are no obstacles within the circle. A wide range of variants available on the market also includes leaded anchor lines. These lines are mostly used with a second anchor.

Anchor lines & anchor line systems

What length of anchor chain or line do i need?

The vessel size, current and swell are all factors that can determine what length anchor chain you should choose. In general, the longer the anchor chain or anchor line, the better the anchor will hold. The angle of pull is important here, and it should not exceed eight degrees. For optimal mooring of a sailboat or a motor yacht, a chain length corresponding to 5 to 7 times the water depth is usually sufficient. If an anchor line is used instead of an anchor chain, a good rule of thumb is that the line length should be at least ten times the water depth.

What do I need a Chain fore-runner for

A chain fore-runner is recommended to be used with anchor lines on boats that are above a certain weight. A fore-runner chain is a length of anchor chain that pulls down the anchor shaft by its own weight, thereby increasing the static friction on the bottom and thus the effectiveness of the anchor. A chain fore-runner will also protect the anchor line from rubbing and sheathing on rocky seabed. From a boat weight of 1.5 t, a chain fore-runnner of three metres in length is sufficient according to GL recommendations. The German Sailing Association (KA), on the other hand, recommends a chain fore-runner of at least six metres in length.

Chain fore-runners

In some situations, an anchor weight on the chain fore-runner is useful. This extra weight is lowered down on a shackle on the anchor chain and does two things: Firstly, the anchor chain is held down to the ocean bed, so that more chain pulls along the surface on the bottom. And because boat swing is reduced, this is advantageous in crowded anchorages. Secondly, an anchor buddy is useful in strong winds, as it relieves pull on the anchor chain and can prevent the anchor from breaking free. Ropes are available from retailers and suppliers by the metre, but for chains usually only in thicknesses up to 13 millimetres, and above that only in so-called "chain lengths" of about 27 metres. The length of the anchor chain on board should be at least 70 to 120 metres, depending on the sailing area, and correspondingly more for an anchor line or combination of line and chain. Some boaters insist on spare rode consisting of anchor and chain. This can be useful in difficult conditions, but again requires storage space and adds weight on board. Normally, spare rode is not necessary if you check the condition of your chain on a regular basis.

Anchoring in tidal waters presents a particular challenge. Sufficient chain must be deployed to ensure that at least five times the water depth is still out at high tide. In addition, the larger swing circle must be taken into account at low tide.

It is advisable to attach an anchor chain to the anchor with a rotating shackle. This prevents the chain from twisting. The end of an anchor chain should be attached to the boat in the chain locker with a rope lashing or strong strop so that it can be easily cut in an emergency. Always shackle a line to the chain. Don't use a sailor's knot like an anchor bend - the knot won't hold reliably in the smooth, synthetic rope. In addition, each knot causes a weak point that reduces the breaking strength of the line by about half. Above a certain boat size, the use of an electric windlass is recommended because the anchor rode is simply too heavy. If the windlass fails, you can sail towards the anchor when retrieving, thus reducing the load. In fact, this is generally advised when using a windlass because it reduces strain on that piece of equipment.

As anchor lines are not very heavy, they can usually be hauled in by hand easily. However, some windlasses have a special capstan fitted to them for this purpose. On sailing yachts, an additional capstan on the foredeck is more likely to be a nuisance and, besides, there are usually enough winches there for hauling. Special care is not required for an anchor chain and can be used for several years, depending on how much wear it is subject to. Nevertheless, it won't hurt to rinse the anchor chain and chain locker with fresh water every now and then to clean.

TIP: If your boat is winterised on land, you must take out the entire chain, including the anchor. Just let your windlass run down and that’s it. This will prevent the chain from rotting away inside the damp and salty chain locker.

Accessories for anchor chains & anchor lines

Share our guide on social media

What are you looking for?

Suggested search.

Container vessel “Maersk Kowloon” at anchor on the Great Bitter Lake in the Suez Canal. Photo: Tim, CC BY-NC 4.0 via Flickr.

16. Vessel Anchoring

Author: Dr. James A. Fawcett, USC Sea Grant Maritime Policy Specialist/Extension Director (retired) Media Contact: Leah Shore / [email protected] / (213)-740-1960

An anchor has two common definitions. Its first meaning is defined as “a heavy device that is attached to a boat or ship by a rope or chain which is dropped into a body of water to secure a boat or ship in place.” Yet, it is also defined as, “a person or thing that provides strength and support”[1] While each of these definitions is useful, they tell only a part of the story about the function of an anchor. For a ship’s anchor, it is only part of the system that secures a ship. Let’s start from the beginning below and explore the details about the importance, purpose, components, and use of a ship’s anchor.

Purpose of a Ship’s Anchor

If we think of a ship as a sort of “bridge” that connects either cargo or people from one location to another, it’s clear that the vessel is a temporary floating intermediate link between those two shorelines. After all, only in the case of Wagner’s opera Der fliegende Holländer (the “Flying Dutchman”) is the ship cursed to sail the seas indefinitely. But, at times, reaching a destination does not mean that the vessel is immediately able to enter the port to be moored to a berth. For many reasons, the vessel may be required to use an offshore anchorage, securing itself in one location for a period of time. In busy harbors, “alongside space”–the common nautical term for a spot along the wharf or where a ship can unload–is often at a premium; ships must wait for their turn to embark or discharge cargo and passengers.