Please choose region and language

Germany, Austria, Switzerland

International

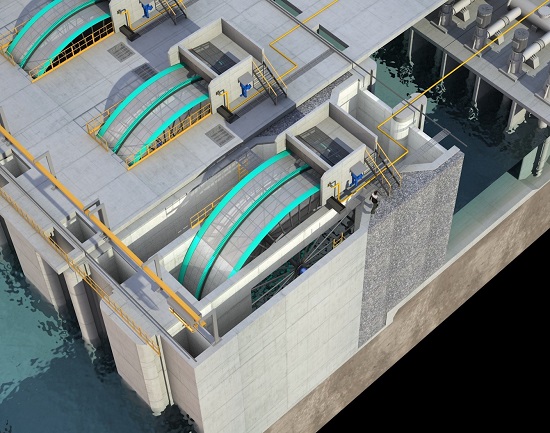

Travelling Band Screens and MultiDisc ® Travelling Water Screens High-Capacity Drum Screens

Reliable Technologies powered by our brand Geiger

- Water Intakes and Pumping Stations

- Open Water Intakes - Screening and Filtration of Surface Water

For decades, Geiger ® fine screening machines have been successfully implemented on a global scale in the water intake structures of power plants, petrochemical plants, desalination, LNG, pulp & paper, potable water, irrigation and other processing plants. One of our main features is the high throughput capacity with reduced channel sizes.

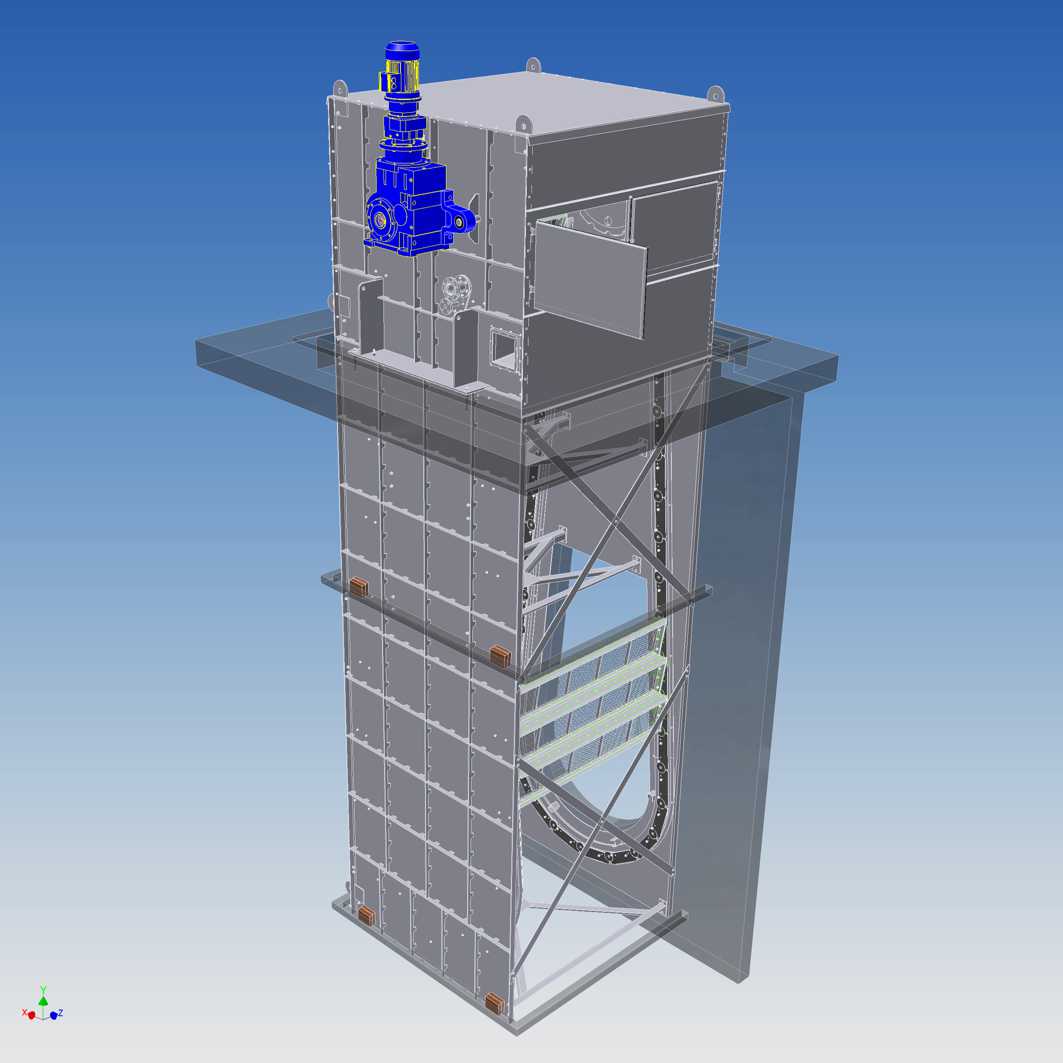

Looking for a completely new concept and in view of modern requirements, we developed the renowned Geiger ® MultiDisc ® screen which has been successfully installed hundreds of times worldwide.

The advantages of Geiger ® MultiDisc ® are:

- Its compact design allowing significant cost reductions in civil structure volume

- Its fast and simple plug-in installation

- Its low operating costs:

- a) Only one maintenance-friendly bar chain

- b) Easy maintenance; mesh panels can be changed at operator’s floor level (no need for channel dewatering)

- Lower head loss: water only passes through the screen once

- Optional fish protection (EPA clean Water act – section 316b pre-approved technology) – intensive and efficient cleaning of the mesh panels

- Zero carry-over of debris to the clean water side

- Shorter channels

Executed projects have proven that the Geiger ® Multi-Disc ® can be retrofitted into existing water intake structures within 24 hours, including removal of the old through- flow band screen, installation of the Geiger ® MultiDisc ® and commissioning. Both the Geiger ® MultiDisc ® and our Travelling Band screens are available project-specifically with plastic or stainless steel mesh ranging from 0.2 – 10 mm. Furthermore, for special applications we offer micro drum screens with a mesh size down to 15 microns.

Product Overview

Geiger ® MultiDisc ® Screen with Fish Return System

Geiger MultiDisc ® Screens are available with specially designed fish buckets and fish return systems. They are widely used where strict requirements in terms of fish protection have to be fulfilled.…

Geiger ® Centre-Flow Travelling Band Screens

For decades, Geiger ® and Passavant ® Centre-Flow (In-to-Out) Travelling Band Screens have been operating successfully in water intake systems in power stations, petrochemical and sea water desalination…

Geiger ® Dual-Flow (Out-to-In-Flow) Travelling Band Screens

For decades, Geiger ® Dual-Flow (Out-to-In-Flow) Travelling Band Screens, have been operating successfully in the water intake systems of power stations, petrochemical plants and sea water desalination…

Geiger ® High-Capacity Drum Screens

The Geiger ® large rotating Drum Screens are typically installed in cooling water intake systems downstream from trash rakes or coarse bar screens. Debris is removed by efficient filtration at Geiger…

Geiger ® MultiDisc ®

Efficient fine screening is essential to protect pumps, condenser tubes, heat exchangers and other critical equipment, and is the last cleaning stage in the water intake process. Geiger…

Next-generation Water Screen Technology

Hydrolox is changing the way facilities think about intake screen performance.

View Solutions

Hydrolox engineered polymer traveling water screens are easy to install in existing intake structures, require virtually no maintenance, and address the needs of water-extracting facilities across all industries. These durable solutions are field- and lab-proven to last five times longer than traditional screens while ensuring full compliance with regulations for aquatic life.

Water Screen Solutions

Yes, it is a paradigm shift to think that an intake screen can provide a low-maintenance experience—and we did more than think it.

Driven by Industry Expertise

We’ve already dramatically reduced maintenance costs and increased productivity across many industries—and we’re ready for the rest.

Engineer-Procure-Construct Ready

Our screens can be built wider than traditional technologies and can handle more flow—meeting your project goals with fewer screens and simpler layouts.

World-Class support Trusted Innovation and Customer Service

Backed by Intralox's award-winning support, Hydrolox experts guide you through every stage of your project, from ordering and installation to ongoing maintenance and technical support.

About Hydrolox

Our Customers

Your industry's trusted leaders trust Hydrolox water screens.

Service Spotlight Partner with Hydrolox for EPC Projects

Hydrolox experts have extensive experience delivering challenging projects in fields ranging from municipal drinking water to nuclear power. We’re ready to help your Engineer, Procure, and Construct (EPC) firm deliver any large infrastructure project it's contracted for at lower CapEx and with products superior to alternative technologies.

News & Insights

Keep up with the latest from Hydrolox

Removing Limitations from the Oil and Gas Industry

Our experts discuss the future of oil and gas, traditional solutions’ shortcomings in that future, and what effect Hydrolox technology is having on the industry.

Fueling the Nuclear Renaissance

The future of nuclear power, how Hydrolox technology is fueling it, and what the next generation of water screen technology is doing for nuclear operations around the world.

A Future Dependent on Desalination

Hydrolox team experts discuss the current state of the desalination industry, its future, and how our paradigm-shifting water screen technology can ensure the success of these crucial plants worldwide.

TRAVELING BAND SCREENS

Automatic band screen or traveling band screen with a mesh size from 0,5 mm to 10mm, that is designed to remove all fine solids (algae, plastics, leaves, jellyfish, branches, etc).

Each band screen is comprised by a head section, a set of guides and a series of chain-linked filtration baskets.

Heavy duty design, with unitary flow from 1.000 m³/h to 150.000 m³/h.

It can be designed to comply with very strict material specifications.

Optionally, it can include a fish protection system

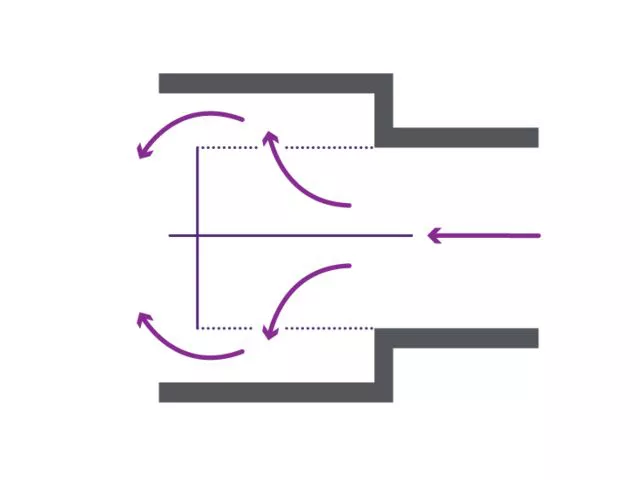

THROUGH FLOW TYPE >>

DUAL FLOW TYPE >>

CENTER FLOW TYPE >>

THROUGH FLOW TYPE

Once through design

Uniform laminar flow

Covers the whole width of the channel

Self-supporting unit

SPECIFICATIONS

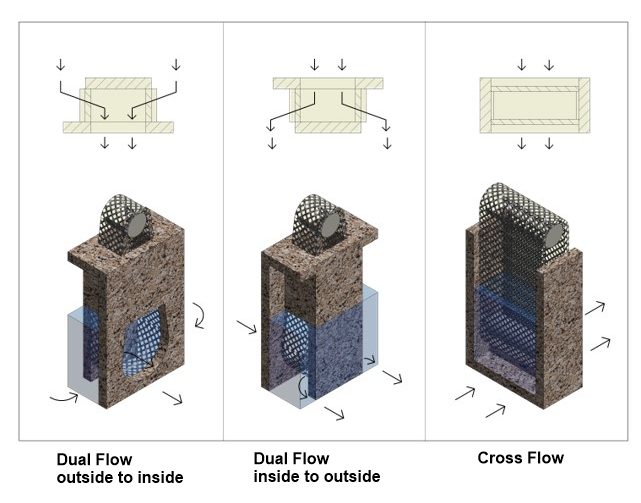

DUAL FLOW TYPE

Lateral water inlet and central outlet

Has a larger surface area for the same basket width as a equivalent through flow unit

Totally removes debris carryover

Requires a back civil works wall to support the unit

Can be designed as self-supporting unit or with no structure

Optionally designed with a frontal deflector plate

CENTER FLOW TYPE

Central water inlet and lateral outlet

Requires front and back civil works wall to install the anchored guides

Traveling Water Screens

International water screens is the industry leader for traveling water screens, debris removal screens.

Multiple options for debris collection and removal from canals, aqueducts, rivers and more. Learn more

Cooling Tower Screens

IWS Screens will filter water prior to your pumps, keeping your condenser tubes clean. Learn more

Fish Screens

Large scale screens designed for debris-free water without harming aquatic life. Learn more

Inline Canal Water Screens

Engineering, design, manufacturing and installation for inline canal solutions worldwide. Learn More

Vertical Water Screens

We design, manufacture and install vertical traveling water screen solutions. Learn More

Moss Removal Screens

Moss is a terrible problem, causing trash racks to be plugged and creating a labor nightmare. Learn more

We are a leading manufacturer of traveling water screens worldwide. We design, build and install custom traveling water screens for a wide variety of customers.

Industries include: Agriculture , Geothermal Power Plants , Hydroelectric Power Plants , Municipal , and Nuclear Power Plants

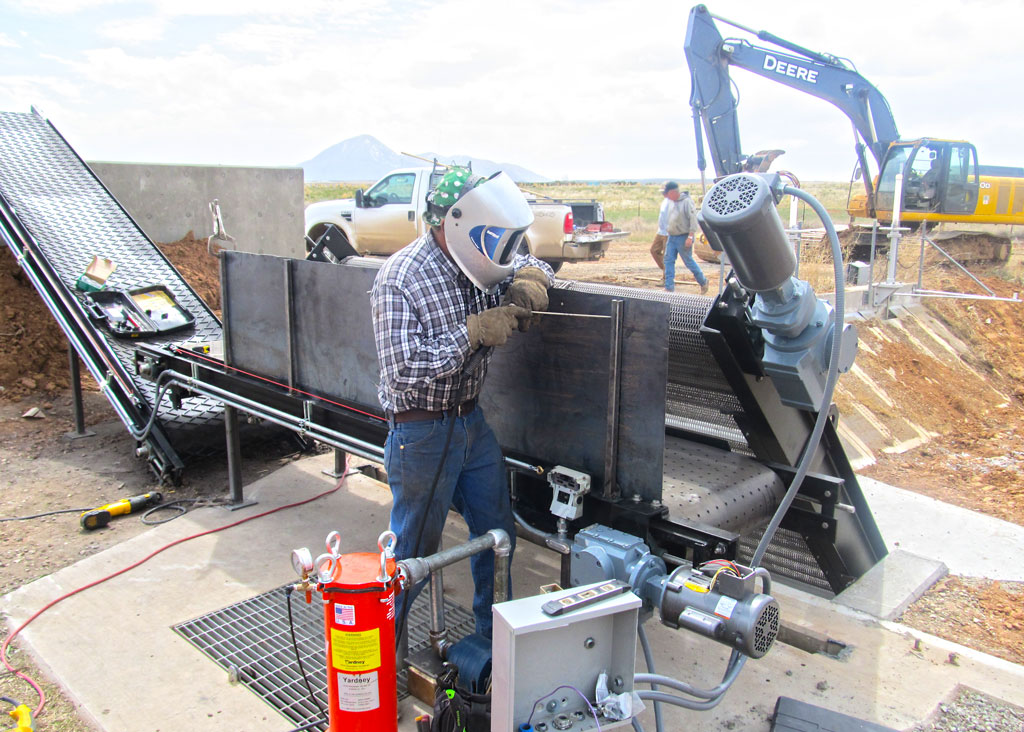

We offer many traveling screen features for your water screen needs

Our traveling water screens are custom designed for the location in question. Water screen construction of heavy duty materials. Stainless steel 304, 316 and 317 are available.

Water screen frames can also be made of aluminum or mild steel appropriately coated for your location. All traveling water screen wear surfaces covered with UHMW for long life. Traveling water screen with internal spray bar with high pressure water that removes the debris from the back side of the traveling water screen.

A complete traveling water screen system could include:

- Variable speed motor

- Trough or conveyor

- Submersible pump

- Control panel

- Differential level control

- Adjustable timer

- Hand/off/auto controls

- Belt openings as tight as 3/31’ and open as 3”

Other traveling screen features include:

Generator Powered Screens

Traveling water screen with spray bar

Traveling water screen hoods

Traveling water screen conveyor/elevator

Traveling water screen debris collection

Algae and aquatic plant removal

Multiple ways to collect debris

Hydroranger for both level and volume measurement

Stationary Trash Rack

Customized trash rack

Care to Share?

- Moss removal water screens

- Vertical traveling water screens

- Inline canal water screens

- Fish screens

- Cooling tower water screens

- Debris removal screens

- Agriculture

- Chemical & Processing Plants

- Hydroelectric

- Nuclear Power Plant

- Our Services

- Eight screens on California Aqueduct

- Idaho Water District’s New Hydroelectric Project

- Saskatchewan fish catch a break when IWS catches debris

- Inline Traveling Water Screen Keeps Canal Clean

- Contra Costa, California’s Mossy Mess Cleaned

- Great Lakes Nuclear Power Plant Keeps Intakes Clean

- Pump Station on the Snake River, Oregon

- Southern California Geothermal Plant Protects Pumps

- Vertical Traveling Water Screen Project for Pittsburgh, CA

- Columbia River Gets a Vertical Fish Screen

- Chemical Processing Plant Gets a Cool Cooling Tower

You are using an outdated browser. Please upgrade your browser to improve your experience.

- HUBER Report

- Australia - www.huber-technology.net.au

- Brazil - www.huber-technology.com.br

- Bulgaria - www.huber.bg

- China - www.huber.cn.com

- Chile - www.huber-technology.cl

- Finland - www.huber.fi

- France - www.huber.fr

- Germany - www.huber.de

- Great Britain - www.huber.co.uk

- Hungary - www.huber-technology.hu

- Italy - www.hubertec.it

- Mexico - www.huber.mx

- Norway - www.huber.no

- Poland - www.huber.com.pl

- Russia - www.huber-technology.ru

- Sweden - www.hubersverige.se

- Switzerland - www.picatech.ch

- Spain - www.huber.es

- South Africa - www.hubersa.com

- Czech Republic - www.hubercs.cz

- Turkey - www.huber.com.tr

- United Arab Emirates - www.huberme.com

- HUBER worldwide

- About HUBER

- ROTAMAT® Screens

- Perforated Plate and Bar Screens

- STEP SCREEN®s

- Complete Plants

- Ultra Fine Screens

- Sewage Sludge Screens

- Screen Basket

- Microscreens

- Active Carbon Filter

- Longitudinal Grit Traps

- Circular Grit Traps

- Grit Classifiers

- Grit Washing Plants

- System Components

- Grit Feeding Arrangement

- Grit Treatment Systems

- Screenings Treatment

- Sludge Screening

- Sludge Thickening

- Sludge Dewatering

- Sludge Drying

- Combined Sewage Screens

- Pumping Station Screens

- Stainless Steel Equipment

- Manhole Equipment

- Technical Doors

- Drinking Water Storage

- Energy from Wastewater

- Membrane Filtration (MBR)

- Mechanical Pre-Treatment

- Sedimentation Tanks

- Microscreening / Filtration

- Quaternary Treatment

- Sludge Treatment

- Green Buildings

- Meat Processing

- Pulp & Paper

- Textile / Leather

- Organic Waste Processing

- Sand and Grit Slurry

- Other Industries

- Conditioning

- Distribution

- Municipal Wastewater

- Industrial Wastewater

- Grit Treatment

- Stormwater Tanks

- Local Cycles

- Sewers – Sources of Energy

- Heat from WWTP Eflluent

- Sewage Sludge Treatment

- Sludge Disinfection

- What we provide

- HUBER Lifecycle Service

HUBER Service Edge℠ Provides Security

We know that customer loyalty is not only built on superior product quality, but also on the motivation of a producer to offer life-long product assistance.

- Our Mission

- Our Philosophy

- Our Manufacturing Quality

- Our Parent Company

- Tradition - Innovation - Progress

- Research and Innovation

- "HUBER TV": Videos

The HUBER Group

Innovative high qualitative machines, plants and stainless steel equipment for municipal and industrial water, wastewater and sludge treatment.

Competent in stainless steel - leading in wastewater technology - more than 50,000 installations worldwide.

- People and Companies

- Information Requests

Close to the Customer - World-wide!

In this section you may get comprehensive information about your contacts and the wordwide subsidiaries, offices and representatives within the HUBER group or you may send direct online information requests free of charge.

- Huber Technology USA News

- Huber Group International News

- HUBER Technology Blog

- Trade Fairs and Exhibitions

- Press Downloads

HUBER US – New Headquarters and New Capabilities

The journey began in 2016, as HUBER US started searching for a new facility to increase its office space and manufacturing capabilities.

We need YOU

HUBER has over 45,000 operating installations at an international level. Due to our continued success and growth, we are seeking energetic and dedicated individuals. We offer you interesting jobs that require independent work within a motivated and committed team.

- Screens and Fine Screens

HUBER Multi-Rake Bar Screen RakeMax®

- Grit Separation and Treatment

- Micro Screening / Filtration

- Storm & Sewer Equipment

- Safe Access Solutions

- Product & Solution Finder

- Centralized Wastewater Treatment

- Drinking Water Supply

- Water ReUse

- Heating and Cooling with Wastewater

- Sewer and Stormwater

Huber Technology Inc.

1009 Airlie Parkway Denver, NC 28037 USA

Member of the HUBER group

> Headquarters

> Service

> Aftermarket Sales

Huber representatives

Reliable, sturdy travelling screen

- Very high screenings discharge capacity

- Low headloss

- Low installation height above ground level even in deep channels

- Control-independent safety system

The RakeMax® Screen is perfectly suited to both municipal and industrial wastewater and process water screening. The cleaning elements, attached to the chain system, can easily be adjusted to suit different requirements.

Read more... close

These elements can be conventional rakes, or brushes, or plastic wipers. As the cleaning elements are changeable, the screenings discharge capacity is then adjustable. This is especially favourable for high solids loads.

The installation height of the RakeMax® above ground level is very small and only dependent, even in case of deep channels, on the installation height of screenings transport or washing units.

Both ends of the cleaning elements are connected to drive chains. Each chain is driven by a sprocket on a common shaft and a flange mounted gear motor. Furthermore, defined meshing of the cleaning rakes with the bar rack ensures a high operating reliability. If the screen operation is blocked, a mechanical overload protection interrupts the operation.

The option RakeMax®-J offers additional extra high hydraulic throughput capacity and the advantage of screenings removal from the bar rack starting straight at the channel bottom, in addition to all the well known benefits of the proven RakeMax®, i.e. reliable solids separation and high screenings discharge capacity.

The benefits of the RakeMax® Screen at a glance:

- Very low headloss - high separation efficiency

- Defined meshing of the cleaning rakes with the bar rack ensures a high operating reliability.

- Screen installation possible without a bottom step

- Compact design with a low installation height above ground level

- Completely odour-encased screen with easy to remove covers

- Easy-to-retrofit into existing channels, installation without channel recesses possible

- The screen consists of a self-supporting folded stainless steel profile so that it can easily be lifted out of the channel.

- Not hindered by gravel or grit

- Simple and easy-to-access chain tensioning unit

- All parts in contact with medium (except the chain, drive and bearing) are made of immersion

- Pickled stainless steel, optional stainless steel chains

- High screenings discharge capacity through adjustable cleaning elements

- Independently replaceable rake and comb plates

- Optional screenings removal from the bar rack starting straight at the channel bottom plus extra high hydraulic throughput capacity with "J" option

- Brochure: HUBER RakeMax® Multi-Rake Bar Screen [pdf, 421 KB]

- Brochure: HUBER Detection System Safety Vision for impurity detection [pdf, 300 KB]

Case Studies

- HUBER expands activities in the field of water extraction: clean water through innovative system solutions for seawater and river water extraction

- The HUBER Multi-Rake Bar Screen RakeMax® – a success story with more than 3000 installed machines

- Unique innovation from the market leader: HUBER Detection System Safety Vision

- HUBER Safety Vision increases the availability of machines

- Refurbishment project: regional STP Linz-Asten

- Case Study: Improvement of the Maer Lane STW Inlet Works

- Flawless operation and longevity make the RakeMax® Multiple Rake Screen invaluable to Guelph’s Screening Process

- Major order: 12 HUBER Multi-Rake Bar Screens RakeMax® for Vienna

- Meadowhead STW Wastewater Case Study

- HUBER supplies the equipment for a major sewage treatment works in Berlin

- Huber Technology upgrades the Inlet works at Duncrue Street, Belfast - a Wastewater case Study

- Three HUBER RakeMax® screens for STW Magdeburg / Gerwisch

- HUBER supplies the machines for the mechanical treatment stage of the worlds’ largest wastewater treatment plant project

- Great HUBER Bar Screens and Wash-Presses in Dublin

- Up to 400 million litre capacity: HUBER successfully commissions 18 RakeMax® screens in the Madrid-Butarque stormwater retention basin

- Multi-Rake Bar Screen 2.0: the HUBER RakeMax® CF, an all-rounder with powerful hydraulics

Design Sketch

- Mobile Hamburger Menu

Traveling Raw Water Intake Screens

Traveling water screen overview.

Traveling water screens are one of the most cost-effective means for fine screening of raw water. They are used in all types of applications where continuous raw water intake screening is required and protection of downstream equipment is critical.

Debris in the flow can overwhelm and damage rotating screens or cause serious condenser issues. Leaves, trash, marine organisms, and aquatic vegetation can blind various systems. Review of the source water is critical to the proper selection of the flow pattern, screen panel (basket or tray) design, mesh apertures, rotation speeds, and materials of construction.

WTR® Traveling Water Screens are designed to automatically and reliably filter incoming water and discharge recovered debris or marine life into the appropriate handling trough. Screens can be designed to handle typical water-borne debris as well as unusual grasses, seaweed, jellyfish and many different types of debris.The screens are available in various flow patterns including thru flow (TF), dual flow conversion (DFC), dual flow (DF), and center flow (CF).

The dual or center flow pattern is recommended to eliminate debris carry-over. Filtration is through two faces simultaneously, with total separation of influent from effluent. Screens can be provided as a dual flow for new civil works or as a dual flow conversion to convert existing thru flow sites to a dual flow pattern, typically with no civil modifications. Duty types include standard debris handling, jellyfish handling, or fish screens.

All flow patterns are available as fish recovery and return to meet the EPA’s 316(b) environmental requirements. Specialized water tight, hydraulically stabilized fish recovery buckets allow for the quick recovery of juvenile marine life. Organisms are elevated to the head section where gentle sluice sprays aid in discharging them into a return trough for reinsertion to their indigenous environment. After the fish sprays, the screen continues rotation past higher pressure debris sprays, washing the captured screenings into a separate debris trough for discharge or further disposal.

WTR Engineering, LLC, is a wholly owned subsidiary of WesTech Engineering, as of April 1, 2017. WTR designs and supplies mechanical water filtration equipment, such as raw water and wastewater screening for large flows, for both the municipal and industrial markets, including the power industry.

Benefits and Features

- Screens built to site specifics for flow, mesh aperture, panel style, debris, or marine handling

- Materials of carbon steel or stainless steel (304L, 316L, Duplex or other)

- Variable Frequency Drive (VFD) motors incorporate multiple speeds

- Shaft-mounted drive reduces maintenance and eliminates sprockets, chains, and guards

- Oversized carrier chain rollers, pins, and bushings are non-lubricated and extend chain life

- Full rim sprockets drive the carrier chain via the sidebars extending chain life

- Dual spray headers provide positive overlapping coverage and reduce required pressure

- Reduced height head section allows for easy internal viewing and routine maintenance

- Chain tensioning from deck level gives instant access for adjustment

- Framed freestanding design eliminates costly civil requirements

- Roll around boot section delivers positive tracking while eliminating submerged sprockets

- Dual flow, dual flow conversion, or thru flow patterns

- Fish recovery and return to meet 316(b) for all flow patterns

- Anti-friction take up bearings for continuous duty

- Panel-to-panel and frame-to-panel seals for fine mesh applications

- Manual or automatic self-flushing debris headers

- Replaceable track and wear bars for future overhauling

- Emergency bypass doors on dual flow for debris surges

- Control systems with ultrasonic or radar differential control

- HMI touchscreen control or DCS monitoring

- Complete elimination of carry over with dual flow pattern

- Adaptable to existing sites

- Variable speeds for dynamic site conditions

- No drive sprockets, driven sprockets, or drive chains to maintain

- Reduced horsepower from oversized chain components

- Extended chain life for continuous (24/7/365) operation

- High impact spray nozzles for debris removal

- Chain tensioning and drive gear accessible from deck level

- No complex tracks to embed for framed design

- No foot sprockets to maintain deep below the surface

- Positive tracking roll around boot is virtually jam free

- Power plant raw water (fossil and nuclear)

- Industrial raw water (petrochemical plants, pulp and paper, steel mills, etc.)

- Pumping stations

- Irrigation for water distribution

- Potable water intakes

- Water parks

Related Pages

Cup & Drum Screens

Effective Industrial Water Screening Starts With Choices

Fish Recovery & Return Screens

Stationary Screens

WTR® Talon Rake® & Bar Screens

Get the latest industry and westech news, choose from our newsletters below.

Get the info you need to more effectively design, manage, and maintain your operations.

- About Ovivo

- Board of Directors

- Global Offices

- Company News

- À propos d’Ovivo

- Conseil d’administration

- Bureaux mondiaux

- Commercial & Private Development

- Electronics

- Food & Beverage

- Metal Production & Finishing

- Municipal Drinking Water

- Municipal Wastewater

- Petrochemicals

- Pharmaceuticals & Life Sciences

- Power Generation

- Pulp & Paper

- View all 12 industry solutions

- Biogas Systems

- Biological Treatment

- Biosolids Management

- Clarification

- Condensate Polishing

- Condenser Optimisation

- Demineralisation

- Grit Removal

- Healthcare Solutions

- View All Our Technology Solutions

- Chemicals & Consumables

- Parts & Services

- Product Rentals

- Digital Plant Monitoring

- View all services

- Resources Centre

- CONTACT AN EXPERT

Brackett Green ® CF100 ® Band Screens

Highly refined through decades of experience, the brackett green cf100 range of screens can efficiently remove large volumes of debris and protect downstream equipment for wastewater and cooling water applications..

The Brackett Green CF100 travelling band screen collects, conveys and discharges debris directly into a deck mounted gulley. Incorporating a patented tapered-hole mesh design, it provides fully automated operation and 24-hour coverage.

Features & Benefits

How it works, technical information.

- Related Products

Ideal for new or retrofitted wastewater and cooling water intakes

The Brackett Green CF100 Band Screen is supplied as a single fully assembled solution, enabling a rapid, risk-free installation.

The Ovivo team works closely with all partners to assist with their debris removal needs by providing:

- Feed studies

- Design optimisation (cost engineering)

- Life cycle cost analysis

Fully customisable for a range of water intake requirements

Brackett Green CF100 Band Screens are fully customisable and offer a range of benefits that put this product ahead of the competition, such as :

- Uniform centre flow distribution to eliminate carryover

- Patented Propapanel® technology to eliminate hairpining and blinding

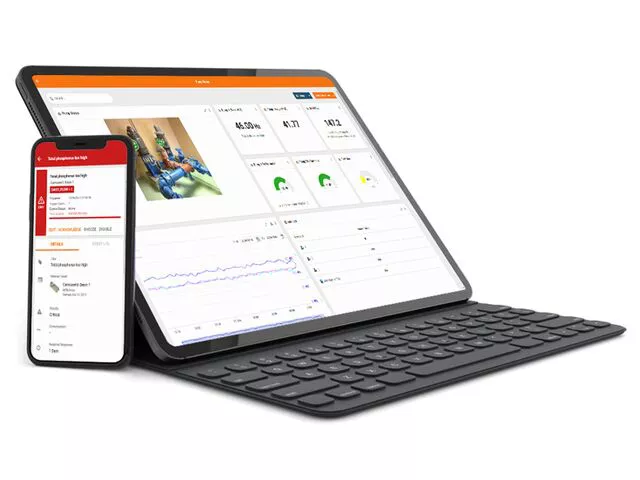

- opsCTRL™ enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

- Low noise operation for urban sites.

Downloadable Resources

Eliminating debris bypass

The water enters the center of the screen, and then flows through the mesh panels to the outside of the screen. The debris is collected on the inside of the patented Propapanel and is then lifted above deck level by a shaft mounted electric drive unit, where it is washed directly into the gulley by wash-water jets. This flow pattern ensures the ‘dirty’ side of the mesh is never exposed to the ‘clean’ flow, and therefore prevents debris carryover.

The mesh guides and head frame assembly (complete with drive gear) are supported by a fabricated steel frame, which is assembled in sections and is freestanding in the screen chamber. This style of frame construction allows for removal of the screen in sections for major maintenance, reducing space requirements for headroom.

Monitor your plants activities from wherever you are

opsCTRL™ can be supplied with all CF100 Band Screens, enabling remote monitoring, Ovivo service engineer contact, storage of O&M manuals and predictive maintenance tracking.

The CF100 has been successfully installed in hundreds of applications worldwide. The design has been refined over the years, resulting in a patented product that includes several key partner benefits:

- Pre-engineered options or customised to partner specifications.

- Mesh aperture size from 2 to 10 mm.

- Fully customisable for depths from 0.7 to 9.7 m (2 ft 4 in to 29 ft 10 in)

- Capability to handle a wide range of flow rates

- Stainless Steel 304L frame with Polypropylene panels (alternatives materials available)

Privacy Overview

You are in:

- United Kingdom

- Central Europe

BANDGUARD - Centre Flow Band Screen

BANDGUARD TM is a high efficiency dual flow traveling fine screen used in inlet works of a wastewater treatment plant. The high efficiency band screen prevents screenings accumulation and its exceptional capture rate significantly reduces maintenance costs in downstream equipment.

With the BANDGUARD TM screening is achieved by passing the sewage through a vertical band shaped screen curtain. It comprises an assembly of plastic perforated panels, clipped and fastened into stainless steel frames which are fastened to stainless steel conveyor chains that form two endless loops.

The screenings enter the centre of the screen, inside of the screen curtain where solids are retained and transported out of the flow by driving the band, moving the dirty panels from the screening zone to the panel cleansing area.

The band is sprocket driven via a motor and gearbox. A spray bar fed by final or primary effluent is used to clean dirty panels before the panels are re-submerged. The cleaning system is orientated to achieve full panel cleaning whilst depositing all debris in the internal launder system, which feeds out through the side of the screen.

Each panel has replaceable side seals manufactured from UHMWPE fitted between the chain and panel to effect a close tolerance seal with the chain guide fitted to the screen structure.

The main structural side plates are designed and manufactured for strength and rigidity.

The high strength chains run in steel and UHMWPE guides and are driven by sprockets attached to the head shaft running in adjustable bearing units.

The drive is from a close coupled motor and gearbox. Variable or Dual speed drives are available as options and the screens can be supplied to suit ATEX Zone 1 environments.

The BANDGUARD TM is fully guarded by covers fastened to the main screen structure thus encasing odours and wash water aerosol. The screen can be supplied with odour extraction pipework flanges where requested.

The BANDGUARD TM can be inched forward and reverse, in case of mechanical stoppage.

Technical details

- Screen widths of up to 4m (13ft) and depths of 20m (65ft) can be provided.

- Panels with 2mm to 6mm diameter holes are available.

- 2mm Ø perforated panel has an estimated SCR from 95 to 98% .

- 3mm Ø perforated panel has a certified average SCR of 95% [UK Water Industry Research (UKWIR) – National Screen Evaluation Facility (NSEF)].

- 5mm Ø perforated panel has an estimated SCR from 88 to 89%.

- 6mm Ø perforated panel has a certified average SCR of 85% [UK Water Industry Research (UKWIR) – National Screen Evaluation Facility (NSEF)].

- Stainless steel and carbon steel construction is available.

- 200mm, 300mm and 450mm chain options.

- Typical Hydraulic flows of 43l/sec (1 MGD) and higher.

BANDGUARD screens for drinking water

Inlet Works WWTP

Product benefits.

- Thick & durable Ultra-high-molecular-weight polyethylene (UHMWPE) panels minimize carry over and hair-pinning.

- Available with integral washing compactor.

- Highly efficient side sealing arrangement.

- Maintenance can be undertaken above the channel.

Recent News

Join us at the Water Equipment Show on May 16, 2024, from 8:30 AM to 5:00 PM at the Telford International...

The IFAT trade show will be held in Munich from May 13 th to 17 th , 2024. You can find...

All screw conveyors are the same. We beg to differ. Since 1976 SPIRAC has installed thousands of...

At a crucial stage of a £43M upgrade, with an additional 430 liters per second (l/s) coming in from a...

A high-efficiency dual-flow traveling fine-screen made by SPIRAC has been installed at the world-renowned...

The Water Industry Operators Association (WIOA) Exhibition in Bendigo is an eagerly anticipated event for...

In a groundbreaking initiative to enhance sustainability and combat climate change, residents and...

Shaftless Spiral Conveyors showcase remarkable capabilities in efficiently managing extended runs with...

SPIRACs engineers had an uncompromising commitment to develop and manufacture a leading inlet works solution within time and budget, allowing us to develop a sustainable plant for the future Mr. Davie Goondiwindi, Aufsichtsrat/Entwicklungsberater

Great system. We have it onsite at Rubyanna WWTP, recommend them for any plants for the future or even retrofitting! Flawless and easy! Also recommend SPIROTAINER. Less than 5 minutes from entering site with one and leaving with a full one! Great idea guys. Sean Watteau Downer, Kläranlagen Treatment Plant Manager

Equipment works wonderfully at our plant to move biosolids for processing. No problems found so far, clean and low maintenance. Jacob Colins Lystek Fairfield - Anlagenbetreiber / Produktkoordinator

You're in Good Hands.

Five Points that define Our Reliability.

- Market Leader since 1970

- Positive Results within Deadlines

- 100% Reliability & Guarantee

- Dedicated Professional Team of 100+

- Unmatched After Sales Support

- Air & Climate

- Drinking Water

- Environmental Management

- Health & Safety

- Monitoring & Testing

- Soil & Groundwater

- Waste & Recycling

- Water & Wastewater

- Water Monitoring

- Water Pumping

- Air & Climate

- Acid Gas Emissions Control

- Activated Carbon Air Treatment

- Activated Carbon Gas Treatment

- Activated Carbon Treatment

- Activated Carbon VOC Treatment

- Aerobiology

- …and more

- Applications

- Atmospheric Water Generation

- Bottled Water

- Bottleless Water

- Communal Water

- Developing Countries Water

- Domestic Drinking Water

- Acoustic Bird Control

- Air Modeling

- Air Quality Reporting

- Aquatic Waste Collectors

- Archaeology

- Asbestos Compliance

- Health & Safety

- Absorbent Polymers

- Accident Compliance

- Accident Monitoring

- Accident Regulations

- Accidental Release

- Acid Safety

- Monitoring & Testing

- 3D Measurement

- 3D Scanning

- Absorptiometers

- Absorption Monitoring

- Accelerometers

- Acetonitrile Monitoring

- Soil & Groundwater

- 3D Groundwater

- Acid Mine Drainage

- Airborne Geophysics

- Anaerobic Bioremediation

- Aquifer Characterization

- Aquifer Monitoring

- Waste & Recycling

- Acid Recycling

- Acoustic Cleaning

- Aerobic Biodegradation

- Aerobic Waste

- Aerosol Cans Disposal

- Water & Wastewater

- Acidic Wastewater Treatment

- Activated Carbon Filtration

- Activated Carbon Water Treatment

- Activated Sludge

- Activated Sludge Monitoring

- Air and Water Quality Monitoring

- Algae Bloom Monitoring

- Aquatic Monitoring

- Automatic Water Sampling

- Ballast Water Monitoring

- Axial Pumps

- Backwashing Pumps

- Balancing Valve

- Booster Pumps

- Cavity Pumps

- … and more

- Environmental XPRT Search

- List your business

- Email marketing

- traveling band screen

Only show results in USA ? Ok

Traveling Band Screen Equipment

TARNOS - Model THROUGH FLOW - Traveling Band Screens

Automatic band screen or traveling band screen with a mesh size from 0,5 mm to 10mm, that is designed to remove all fine solids (algae, plastics, leaves, jellyfish, branches, etc). Each band screen is comprised by a head section, a set of guides and a series of chain-linked ...

TARNOS - Model DUAL FLOW - TRAVELING BAND SCREEN

TARNOS - Model CENTRE FLOW - Traveling Band Screen

H+R - Traveling Band Screen

The traveling band screen is a fully automatic debris removal equipment. It can remove the debris both floating on water surface and submerged in water from inlet channel in order to prevent the followed mechanism from clogging and damage. The equipment is specially designed for debris removal purpose in the intake channel of power ...

GMW - Travelling Band Screen

Raw water from rivers and sea inlet contains large floating objects, foreign material, and other foreign objects, which needs to be filtered out. Since 1983, we have installed screening equipment for a variety of applications including power plants, water treatment plants and irrigation projects. These Screens can work in automatic ...

Hubert - Travelling Band Screen

A Hubert water intake travelling band screen is also called ‘ travelling water screen ’. A travelling band screen or traveling water screen is a self-cleaning fully automatic screen suitable to filter ...

Profilter - Travelling Band Screens

The new generation of PROFILTER’s travelling band screens is the result of many years of experience in the field of water treatment for communal water intakes, large industrial plants such as power plants and combined heat and power plants, the chemical industry and others. Our first attempts to use rubber belts in place of steel chains ...

Mesh - Ultrafine Traveling Band Screens

Claro is pleased to offer the CF ultra-fine traveling band screen designed specifically for water and wastewater screening applications that require an exceptionally high degree of screenings debris capture. The CF unit is ideally suited for the protection of very sensitive process equipment such as membrane ...

Beaudrey - Thru-Flow Travelling Band Screens

Installed across a channel in which the water to be cleaned flows through. The screen consists of a set of rectangular screening mesh panels, carried by two endless chains. The downstream panels travel down into the water, around the bottom and up again along the upstream side. The water flows across the upstream and then the downstream ...

Model MR 15 and MR 36 - Traveling Band Screen and Rotating Screen

The DAGA self-cleaning traveling - screen consists of a series of overlapping self-draining screen -trays which are fastened to two lateral steel chains mounted on a structural drive. The solids captured on the screen -trays are washed from the screens by high-pressure overlapping water sprays across the back of ...

Ovivo NEW Brackett Green - Dual Flow Traveling Band Screens

Brackett Green® Dual Flow Traveling Band Screens are compliant with most of the new Environmental Protection Regulation around the world including the US’s EPA 316(b) with the highest debris-capture ratios in the industry. With over 200 years of industry experience, Ovivo can custom design for your specific application, and optimize your ...

Geiger - Centre-Flow Travelling Band Screens

For decades, Geiger and Passavant Centre-Flow (In-to-Out) Travelling Band Screens have been operating successfully in water intake systems in power stations, petrochemical and sea water desalination plants, steel works and other industrial plant all over the ...

Ovivo Brackett Green - Dual Flow Traveling Band Screens

Dual flow band screens offer maximum throughput and the highest debris-capture ratios in the industry. The superior performance of our screens is due to their design, which avoids the disadvantages of conventional through flow models, reducing fouling of downstream equipment and minimizing maintenance costs as well as plant down time. ...

Perrier Sorem - Model GRF - Dual Flow Traveling Band Screen

The GRF travelling band screen is designed for the protection of hydraulic power packs. All its constituent parts have been studied and dimensioned so as to allow for accidental over loading without any interference to its ...

Brackett Green - Straight Through Traveling Band Screens

Brackett Green straight through traveling band screens can be installed as a single system or as part of a two or three-stage system for raw water intakes, where continuous and efficient methods of removing floating and suspended solids are required to protect pumps, heat exchangers and other critical equipment. Mesh aperture sizes can vary ...

Beaudrey - Dual-Flow Travelling Band Screen

Installed in a channel in which flows the water to be cleaned, the screen consists of a set of rectangular screening mesh panels carried by two endless chains. The panels travel up and down again between an upstream wall plate and a downstream partition with a central, outlet aperture set across the ...

Beaudrey - Center-Flow Travelling Band Screen

Installed in a channel in which the water to be cleaned flows, the screen consists of a set of rectangular screening mesh panels carried by two endless chains. The panels travel up and down again between an upstream partition set across the channel, with an inlet central aperture and a downstream wall set across the channel. The water ...

Brackett Green - Dual Flow Travelling Band Screens

Ovivo is proud to announce the latest development of the proven Brackett Green® dual flow bandscreen, which has become the global reference design for the screening of large power and industrial water intakes. The newly re-engineered and optimized design is the result of over 100 years of experience and know-how while retaining the ...

Geiger - Dual-Flow (Out-to-In-Flow) Travelling Band Screens

For decades, Geiger Dual-Flow (Out-to-In-Flow) Travelling Band Screens , have been operating successfully in the water intake systems of power stations, petrochemical plants and sea water desalination plants, steel works and other industrial plants all over the ...

SISMAT - Travelling Band Water Screens

This type of screen is utilised for very fine screening following the coarse screen in stream- or sea-water intake structures. It relies on the principle of collecting screenings on sieve modules mounted on a chain and then expelling them through back-washing with pressurised water. In general, the conveyor ...

Need help finding the right suppliers? Try XPRT Sourcing . Let the XPRTs do the work for you

ABOUT OUR COMPANY

Our background.

Beaudrey is a world leader in the design, installation and service of fully customizable water screening and condenser protection equipment used in cooling water intake structures. Beaudrey screens have been supplied to over 85 countries worldwide.

Designed to minimize operational costs, environmental protection and maintenance needs, Beaudrey offers a complete range of high quality, efficient and economical solutions to all water screening needs, all of which are custom designed for our clients' needs.

Beaudrey has global coverage with offices in Europe, The United States and Asia

Industries Served:

- Fossil plants

- Nuclear power plants

- LNG terminals

- Desalination plants

- Irrigation facilities

- Water treatment plants

- Oil and Gas facilities (refineries)

With over 100 years of experience in a wide variety of applications, BEAUDREY is undoubtedly one of the main suppliers in its field of activity.

A LITTLE HISTORY

A family business turned global.

1912: Company created by Eugène Beaudrey. The first travelling screens are built. From then on BEAUDREY has pioneered all the major screening and condenser cleaning systems now used worldwide.

1921: First on-line condenser tube-cleaning system. Hundreds have been sold since.

1922: First self-cleaning, backwashed, pressure-line strainer. A best-seller to this day.

1924: First export order. Since then, BEAUDREY has exported between 50 and 90% of its production to over 80 countries worldwide.

1926: Invention of the dual-flow band screen followed by the drum screen (1927). The most widely-used machines in the world.

1936: Condenser inlet debris filters. Over 1200 sold since. The design culminates with the regularly-refined "W" type.

1951: First microstrainer. Over 100 in service.

1953: Large-diameter drum screens (+11m). 76 are supplied for the French Nuclear Program from 1974 to 1988), 69 are installed in Saudi Arabia from 2000 to 2015.

1956: The first French nuclear power plant uses 5 Beaudrey travelling screens.

1966: World’s largest travelling band screen (86 000 m3/h) installed in Le Havre, France.

1968: Beaudrey invents the water-flushed trash rake.

1976: Beaudrey introduces the “C” type filter for essential service nuclear circuits.

1980: Invention of the "Scoop-a-fish" device providing high rates of fish survival.

1984: First Beaudrey screens installed in the USA.

1989-2000: Partnership with Marusei and Marubeni in Japan, over 80 debris filters retrofitted into existing power plants

2006: Development of the WIP (Water Intake Protection) for fish protection. Rated as best-available technology by the EPA.

2006: Beaudrey American Services opens to the US market.

2007: World's largest drum screen (24 m diameter x 10 m wide) for the EPR nuclear plant in France.

2014: Beaudrey Asia (1043444-T) is created in Kuala Lumpur to serve our customers in South East Asia

2015: Beaudrey Portugal is formally opened.

- Dual Flow Traveling Water Screens

- Raw Water Intake Screen Solutions

- Traveling Water Screens

ATLAS-SSI manufactures “zero-carryover,” Dual-Flow Screens and Dual-Flow Conversion Screens that are built to last.

ATLAS-SSI Dual Flow traveling water screens are heavy-duty and require very little maintenance. They provide clean and debris-free water while minimizing marine life impacts.

The dual-flow design is positioned parallel with the water flow, which means no debris can “carry over.” The roll around lower section requires no sprockets or shafts, thereby reducing maintenance and eliminating issues that may arise from having rotating parts below the water’s surface.

- Low maintenance

- SmartScreen Technology® interface

- Dual-Flow design

- No debris carryover

- Clean water

- We don’t sub out the work—ATLAS manufactures all of our screens at our facility in the U.S.

- 316(b) Compliant (with optional Ristroph fish handling collection basket assembly)

- ATLAS-SSI tech is fully accepted by the EPA. There’s no need to undergo further compliance testing

- Our technicians and certified diving crews can travel all over the U.S. for service

- We’re a one-stop-shop and can service all of your needs—including manufacturing replacement parts for any type of screen (even our competitor’s equipment) or factory rebuilds of existing equipment

- We off a total package solution and our delivery times are some of the shortest in the industry

Frequently Asked Questions About Dual Flow Screens

What are the material options for ATLAS Dual Flow Screens?

We can manufacture dual flow screens out of carbon steel coated with immersion-rated epoxy or stainless steel.

What basket options does ATLAS offer?

We offer baskets that meet 316(b) and manufacture them out of coated carbon steel, stainless steel, or pultruded fiberglass.

Related Resources

Water intake screen brochure, screen rebuild at a power plant [case study], east river generating station [case study].

- 31, Sector-C, Industrial area, Sanwer Road, Indore - 452015, M.P., India

- Send us a mail [email protected]

- Call us +91-731- 2720143, 2721143

Screening Equipment

Manual bar screens.

- August 12, 2021

- No Comments

TRASH RACK SCREENS

J type trash screen, multi rake screens, step screens, per-scalator, travelling band screens, drum screen, static screens.

Markets and Applications

About Hubert

- Case Studies

Water Intake Systems

Travelling Band Screen

A Hubert water intake travelling band screen is also called ’travelling water screen’

A travelling band screen or traveling water screen is a self-cleaning fully automatic screen suitable to filter large flow rates in a water intake at a relatively fine filtration degree as a secondary step.

Every project intake location is different. Excavating and civil engineering cost vary from site to site and have a important influence on the choice of screening system, where the choice is often made between a travelling band screen or a drum screen .

Hubert hubert supplies his own designs where possible, however all systems are engineered as per your project specifications. If you prefer a different design, we can of course also supply this. We are happy to advise you to make the best choice and flow pattern for your project. When renovating existing installations (which have been in operation for many years), (dated) designs are often used or, if possible, the civil construction is adapted to a modern design.

Below you will find an explanation of frequent applied travelling band screens. See Wikipedia .

Hubert – Water Intake Systems

Our specialization: water intake systems for cooling, drinking and process water.

Hubert is specialized in water intake systems for cooling, drinking and process water. These systems can be found in power stations, petrochemical plants and refineries, desalination plants, drinking water and irrigation plants and industrial production plants requiring a huge demand of process water.

We supply complete complete ‘ screening trains’ including all additional equipment, like controls and cathodic protection. This movie includes an animation of a typical water intake, showing the water flow from the suction from the sea to the arrival at the pumps. See also Markets and Applications.

You will find our projects in both new construction (EPC) projects and renovation and optimization of existing water intakes.

Hubert is specialized in water intake systems for cooling, drinking and process water. These systems can be found in power stations, petrochemical plants & refineries, desalination plants, drinking water & irrigation plants and industrial production plants requiring a huge demand of process water.

We supply complete complete ‘ screening trains’ including all additional equipment, like controls and cathodic protection. This movie includes an animation of a typical water intake, showing the water flow from the suction from the sea to the arrival at the pumps. See also Markets & Applications

You will find our projects in both new construction (EPC) projects and renovation & optimization of existing water intakes.

Travelling Band or Water Screen

A hubert travelling band screen has a compact design.

The Hubert travelling band screen is the ‘heart’ of the ‘screening train’, often used used for (sea)water intakes as part of power plants and desalination plants, where big tidal differences can also play a role. It is more compact than a vertical drum screen, but it has still a high capacity. Quite common flow rates are 15.000 m3/h per screen, depending on customer requirements and the local situation at the intake. Today, a lot of Duplex and Super Duplex (PREN > 40) is used for screens.

A travelling band screen is typically installed in water intake systems downstream from coarse bar screens .

Woven mesh with a diameter of about 2-10 mm is used as relative fine filter medium.

The Hubert travelling band screen is the ‘heart’ of the ‘screening train’, often used used for (sea)water intakes as part of power plants and desalination plants, where big tidal differences can also play a role. It is more compact than a vertical drum screen, but it has still a high capacity. Quite common flow rates are 15.000 m3/h per screen, depending on customer requirements and the local situation at the intake. Today, a lot of duplex and super duplex (PREN > 40) is used for screens.

Design, Construction and Operation

Hubert travelling band screens require only a small installation area due to the vertical construction. This type of screen is used in places where the construction area of the total cleaning installation is limited or where big differences occur between water levels.

The band water screen operates on a conveyor belt principle. The ‘conveyor belt’ is composed of mesh panels which are mounted between two endless heavy duty transport chains. The chains are driven by 2 sprockets.

The debris, trapped on the screens is removed by spray water jets and discharged through a flushed chute. The drive unit, flushing mechanism and debris hopper are located at deck level. The upper section above decl level is fitted with a metal or reinforced polyester composite cover.

Hubert traveling band sceens are available for different flow patterns.

Special designs can be provided with facilities for removing and discharging other debris like jellyfish and seawead. If this is not or insufficiently covered by the coarse screens in front of the screening system.

Skid or Embedded Configuration

Hubert travelling band screens can be configurated as a skid, which minimizes on-site mounting. The band screen can also be part of the civil construction and assembled on site (embedded).

Features and Benefits

- Large flow capacity

- No debris carryover

- High screening efficiency (99%)

- Minimal construction space required

- Big tidal differences

- High quality and reliable

- Maintenance free

- Long lifetime (30 years or more)

- Resistant to abrasive water

- (Sea) water lubricated bearing

- Heavy duty chains

Fish Friendly - Fish Recovery System

Hubert’s traveling band screens can be supplied with a fish recovery gutter or channel that allows trapped fish to be removed in a gentle and effective way. T hese recovery systems are tailor-made for each project. See also this movie .

Standard Dimensions and Materials

- Width up to 4 m

- Pit depth up to 20 m

- Mesh opening 2/ 10 mm

- Materials can be (partly) coated carbon steel, stainless steel, duplex and super duplex (PREN > 40)

Travelling band screen: different flow patterns

Hubert supplies all common applied flow patterns, depending on a number of things including channel width / available space, etc. Cross flow or Thru-flow screens are relative expensive when large mesh areas are required. Dual-flow screens perform better than thru-flow screens. They are smaller and have more capacity with same mesh surface. Please contact us for advice!

Customer Stories

Project: Replacement of gutter and clearing bridge settling tank at WWTP Birdaard

The elaboration of the drawings with accompanying calculations in the preparation phase were well worked out. The construction of the new gutter and bridge was installed satisfactorily by employees and especially the foreman. The project was completed on time, both financially and in the delivery of product certificates and revision. A great project and end result was achieved through synergy between client and contractor.

Wetterskip Fryslan, Netherlands, mr. R.T. van der Zee, Design coordinator - Director

Hubert: no. 1 supplier for screening!

Interested in working with us, our clients.

More Hubert

Privacy Statement

Cookie Policy

Wastewater Treatment

Service and After Sales

High-Spec Steel Assemblies

Coarse Screen

Drum Screen

Rotary Drum Filter

Ancillary Equipment

Mussel Filter

Screening Services

Flow Patterns Drum Screen

Waste Water Treatment

TRAVELLING BAND SCREEN

Travelling band screen is designed for the protection of hydraulic power packs. All its constituent parts have been studied and dimensioned so as to allow for accidental over loading without any interference to its running.

- self supporting frame or without any supporting frame

- construction in carbon steel, SS304 or SS316

- drive unit, flushing mechanism and debris hopper located on deck level

- mesh size up to 1mm

- panel construction type either as perforated panel or weaved wire mesh

- Debris trapped removed by high pressure spray nozzles and option for brush which effectively clean the mesh/perforated panel from clogging.

- Enclosed, safe & hygienic with easy to open access doors.

- option for sprocket in Stainless steel

Travelling Band Screen

- Location Near Me

Traveling Band Screens

Sankalpa enterprise.

Nibra, Howrah Howrah Amta Road, Kantalia, Champatala, P. O. Nibra, Nibra, Howrah - 711409, Dist. Howrah, West Bengal

Verified Supplier

Macmet Engineering Limited

Kolkata 10- B, O C Ganguly Sarani, Kolkata - 700020, Dist. Kolkata, West Bengal

Traveling Band Screens Filtration

Sureflo techcon private limited.

Andheri East, Mumbai A 101, New India Chambers, Cross Road A Off MIDC, Andheri East, Mumbai - 400093, Dist. Mumbai, Maharashtra

Travelling Band Screens

Macmet india limited.

Camac Street, Kolkata No. 27 B,, Camac Street, Kolkata - 700016, Dist. Kolkata, West Bengal

FLOW THROUGH SCREEN (CGMP)

Hindustan vibrotech private limited.

Vasai, Dist. Palghar Unit No 5 Navghar Vora Industrial Estate No.4, Vasai - 401210, Dist. Palghar, Maharashtra

GMW Private Limited

Noida, Dist. Gautam Buddha Nagar 11 7a/1108 Sector-142, Gautam Buddha Nagar, Noida - 201304, Dist. Gautam Buddha Nagar, Uttar Pradesh

- Tell us what you need, and we’ll help you get quotes Tell us what you need Receive seller details Seal the deal Pay with IndiaMART Tell us what you need, and we’ll help you get quotes I agree to the terms and privacy policy -->

TRENT-TBS TRAVELLING BAND SCREEN FOR MARINE

Parchure engineers pvt. ltd..

School Pune 411004 , Maharashtra. Office Line, Pune Office 502 / 503 Shriniwas Apartments , Sr. No. 10,14/4 ,16/6 & 23A , CTS No. 906 Patwardhan Baug ,E, School Pune 411004 , Maharashtra. Office Line, Pune - 411038, Dist. Pune, Maharashtra

Makarpura Industrial Esate, Vadodara Plot No 885 G I D C, Makarpura Industrial Esate, Makarpura G I D C, Makarpura Industrial Esate, Makarpura, Makarpura Industrial Esate, Vadodara - 390010, Dist. Vadodara, Gujarat

Vadodara Plot No 885 G I D C Makarpura Industrial Esate Makarpura, Vadodara - 390010, Dist. Vadodara, Gujarat

Otoklin Global Business Ltd.

Mumbai Ambernath, Mumbai - , Dist. Mumbai, Maharashtra

Have a Question? Ask our expert

Please enter your question.

PVC Band Screen

Ghazi trading co..

Jali Kothi, Meerut 91/76, Purwa Fateh Nagar, Jali Kothi, Jali Kothi, Meerut - 250002, Dist. Meerut, Uttar Pradesh

Jeetpur Baheri, P.O. Kadh, Una 37 & 38, Industrial Area, Jeetpur Baheri, P.O. Kadh, Jeetpur Baheri, P.O. Kadh, Una - 264776, Dist. Una, Himachal Pradesh

CHOK MEDICAL COLLEGE ROAD, POST, Gorakhpur 1209, 12TH, GEMINI PARADISE ESTATE, SALEMPUR ALIAS MUGHALPUR, MUGLAHA, CHOK MEDICAL COLLEGE ROAD, POST, Gorakhpur - 273013, Dist. Gorakhpur, Uttar Pradesh

General Mechanical Works

Sector 142, Noida, Dist. Gautam Buddha Nagar Sector 142, Sector 142, Noida - 201304, Dist. Gautam Buddha Nagar, Uttar Pradesh

Sarani, Kolkata No. 10- B, OC Ganguli, Sarani, Sarani, Kolkata - 700020, Dist. Kolkata, West Bengal

Temsonn Travelling Water Screen Spares

Type : Travelling Water Screen Spares

Brand : Temsonn

Temsonn Veselex India Private Limited

Gurgaon, Dist. Gurugram D-38, Sector 11, Noida Phase - I, Gautam Budh Nagar, Gurgaon - 201301, Dist. Gurugram, Haryana

Travelling Water Screen Spares

Temsonn veselex india pvt. ltd..

Noida, Dist. Gautam Buddha Nagar D-38, Sector 11, Noida - 201301, Dist. Gautam Buddha Nagar, Uttar Pradesh

Traveling Water Screen Spares

Sector 11, Noida, Dist. Gautam Buddha Nagar D-38, Sector 11, Sector 11, Noida - 201301, Dist. Gautam Buddha Nagar, Uttar Pradesh

Sureflo Clean Technologies

Andheri Area, Mumbai Andheri Area, Andheri Area, Mumbai - 400001, Dist. Mumbai, Maharashtra

O C Ganguly Sarani, Kolkata No. 10- B, O. C. Ganguly Sarani, O C Ganguly Sarani, Kolkata - 700020, Dist. Kolkata, West Bengal

General Mechanical Works Private Limited

Jayanagar, Bengaluru No. A-306, 3rd Floor, Oakyard Apartments, 38th Cross, Eastend ¿¿¿¿¿¿B¿¿¿¿¿¿ Main Road, Jayanagar, 9th, Jayanagar, Bengaluru - 560011, Dist. Bengaluru, Karnataka

GMW Pvt. Ltd.

Makarpura Gidc, Vadodara 885, GIDC Estate, Makarpura, Makarpura Gidc, Vadodara - 390010, Dist. Vadodara, Gujarat

Kolkata Mac Met India Ltd 27-B Camac Street, Kolkata, Kolkata - 700016, Dist. Kolkata, West Bengal

G.M.W. Engineers Private Limited

Hyderabad Flat No- 311 Laxmi Plaza Apt S Jafar Ali Bagh E, Hyderabad - 500082, Dist. Hyderabad, Telangana

Gmw Pvt Ltd

Thousand Lights, Chennai Thousand Lights, Thousand Lights, Chennai - 600006, Dist. Chennai, Tamil Nadu

G.M.W. Engineers Pvt. Ltd.

Vadodara 309-310, Por-ramangamdi G I D C Industrial Estate, Por, Vadodara - 391243, Dist. Vadodara, Gujarat

Vadodara Plot No 885 G I D C, Makarpura Industrial Esate Makarpura, Vadodara - 390010, Dist. Vadodara, Gujarat

Makarpura, Vadodara 885, GIDC Estate, Makarpura,, Makarpura, Vadodara - 390010, Dist. Vadodara, Gujarat

- Manufacturer

Have a requirement? Chat with us

IMAGES

VIDEO

COMMENTS

flow band screen, installation of the Geiger ® MultiDisc ® and commissioning. Both the Geiger ® MultiDisc ® and our Travelling Band screens are available project-specifically with plastic or stainless steel mesh ranging from 0.2 - 10 mm. Furthermore, for special applications we offer micro drum screens with a mesh size down to 15 microns.

Hydrolox engineered polymer traveling water screens are easy to install in existing intake structures, require virtually no maintenance, and address the needs of water-extracting facilities across all industries. These durable solutions are field- and lab-proven to last five times longer than traditional screens while ensuring full compliance ...

Atlas-SSI traveling water screens will help reduce maintenance issues, minimize ecological impact, and provide debri-free clean water. ATLAS-SSI is the right partner to provide faster solutions and help you reduce your system downtime. We can custom-manufacture new water intake screens, water intake screen rebuilds that offer factory warranties ...

Evoqua's Thru-Flow traveling water screens are the most specified screen in the water intake industry and have been setting the standard for more than 100 years. The Thru-Flow screen incorporates a non-metallic basket frame with stainless steel mesh. Because the baskets are non-metallic, they won't rust or corrode, making them ...

TRAVELING BAND SCREENS. Automatic band screen or traveling band screen with a mesh size from 0,5 mm to 10mm, that is designed to remove all fine solids (algae, plastics, leaves, jellyfish, branches, etc). Each band screen is comprised by a head section, a set of guides and a series of chain-linked filtration baskets.

We offer many traveling screen features for your water screen needs. Our traveling water screens are custom designed for the location in question. Water screen construction of heavy duty materials. Stainless steel 304, 316 and 317 are available. Water screen frames can also be made of aluminum or mild steel appropriately coated for your location.

Automatic band screen or traveling band screen with a mesh size from 0,5 mm to ... REQUEST QUOTE Tarnos S.A. is a company that has specialised in the design, manufacture, and sale of vibrating equipment for the dosing, transport, and classification of all types of bulk material since it opened its facilities in Torrejón de Ardoz (Madrid) in ...

Also referred to as band screens or travelling screens. The travelling band screen is a self-cleaning screen with millimetric mesh apertures that removes all types of debris from the water to be screened so as to protect the downstream industrial applications from being obstructed (heat exchangers, drinking water and desalination plants, chemical and LNG plants, irrigation networks, etc.).

The benefits of the RakeMax® Screen at a glance: Very low headloss - high separation efficiency. Defined meshing of the cleaning rakes with the bar rack ensures a high operating reliability. Screen installation possible without a bottom step. Compact design with a low installation height above ground level. Completely odour-encased screen with ...

Traveling water screens are one of the most cost-effective means for fine screening of raw water. They are used in all types of applications where continuous raw water intake screening is required and protection of downstream equipment is critical. Debris in the flow can overwhelm and damage rotating screens or cause serious condenser issues.

The Brackett Green CF100 travelling band screen collects, conveys and discharges debris directly into a deck mounted gulley. Incorporating a patented tapered-hole mesh design, it provides fully automated operation and 24-hour coverage. ... Brackett Green CF100 Band Screens are fully customisable and offer a range of benefits that put this ...

Download Brochure. The BEAUDREY thru-flow travelling band screen is installed across a channel to arrest small debris in industrial or power plants. It has a large debris-handling capacity, is fully-automatic and self-cleaning. It can be provided with fish-friendly options for environmental protection.

Atlas-SSI is the largest full-service traveling water screen manufacturer in North America. We'll provide your facility with comprehensive engineering, manufacturing, and installation capabilities for new water intake screens and rebuilds. Our service teams offer nationwide coverage with certified commercial divers specializing in raw water ...

Screen widths of up to 4m (13ft) and depths of 20m (65ft) can be provided.; Panels with 2mm to 6mm diameter holes are available.; Highest Screen Capture Ratio's (SCR%) of any band screen in the world.. 2mm Ø perforated panel has an estimated SCR from 95 to 98%.; 3mm Ø perforated panel has a certified average SCR of 95% [UK Water Industry Research (UKWIR) - National Screen Evaluation ...

Description. Our Dual Flow traveling water screens have become the industry standard design for Intake screening. This design completely eliminates debris carryover, offers nearly twice the screening area of a Thru-Flow screen and is ideal for high water volumes and heavy debris removal. Building on the legacy of Rex® and Link-Belt® products ...

Automatic band screen or traveling band screen with a mesh size from 0,5 mm to ... REQUEST QUOTE Tarnos S.A. is a company that has specialised in the design, manufacture, and sale of vibrating equipment for the dosing, transport, and classification of all types of bulk material since it opened its facilities in Torrejón de Ardoz (Madrid) in ...

Automatic band screen or traveling band screen with a mesh size from 0,5 mm to ... By Tarnos, S.A. based in Madrid, SPAIN . from Water Intake Systems Product line

1956: The first French nuclear power plant uses 5 Beaudrey travelling screens. 1966: World's largest travelling band screen (86 000 m3/h) installed in Le Havre, France. 1968: Beaudrey invents the water-flushed trash rake. 1976: Beaudrey introduces the "C" type filter for essential service nuclear circuits.

ATLAS-SSI manufactures "zero-carryover," Dual-Flow Screens and Dual-Flow Conversion Screens that are built to last. ATLAS-SSI Dual Flow traveling water screens are heavy-duty and require very little maintenance. They provide clean and debris-free water while minimizing marine life impacts. The dual-flow design is positioned parallel with ...

Dual flow travelling band screen is a sturdy self-cleaning fine screen provided with endless band of perforated plates or woven wire mesh to prevent medium to fine sized floating waste from travelling further into pumping stations or treatment plants. The screen is provided with heavy duty stainless steel sprockets & chain but no sprocket and ...

A travelling band screen is typically installed in water intake systems downstream from coarse bar screens. Woven mesh with a diameter of about 2-10 mm is used as relative fine filter medium. A travelling band screen is used in a water intake. It is designed and engineered as per your application. We manufacture in our own factory!

Travelling band screen is designed for the protection of hydraulic power packs. All its constituent parts have been studied and dimensioned so as to allow for accidental over loading without any interference to its running. Design and Constructions. Type of Travelling Band Screen. self supporting frame or without any supporting frame.

More Manufacturers and Suppliers of Travelling Band Screen. Travelling Band Screen RLT Engineering Verified Supplier. Vadodara Gidc Plot No 485/486/a-77 Makarpura Makarpura,vadoda Vadodara, Vadodara - 390014, Dist. Vadodara, Gujarat. View Mobile Number +91-8062245119. Contact Supplier.