SRAM GXP FITTING IN A BB90 BOTTOM BRACKET

- All Categories

- 18.2K BikeRadar team

- 183.8K Road cycling forum

- 137.2K Mountain biking forum

- 28K Commuter cycling forum

- 1.3K Family & kids cycling forum

- 2.9K Stolen & found bikes

- 9.4K Buy & sell

Site footer

- Facebook White

- Terms & conditions

- Privacy policy

- Cookies policy

- Manage Privacy Settings

Hambini Pressfit Bottom Bracket Installation

Introduction.

This guide takes you through the fitting process of a Hambini Bottom Bracket. It supplements a video guide which is available below. I recommend you familiarize yourself with both before purchasing a Hambini Bottom Bracket. If you have any questions, please e-mail me and I will be on hand to answer them. [email protected]

Hambini Bottom brackets are much stiffer than any other bottom bracket that is commonly available, please install with caution to avoid damaging your bike frame. Hambini will not be liable for any frame damage caused by the installation of a Hambini BB

Crankset compatibility

- Shimano – all hambini BB’s are a direct drop-in for Shimano Hollowtech 2 systems.

- BB30 Extended / BB386 – Hambini BB’s place the bearings at a nominal 90.5mm spacing. If your axle length is shorter than this, it will not work. Hambini BB30 extended BB’s ARE NOT SUPPLIED WITH SHIMS. You may need some BB30 shims to take up any free play. It is impossible for this guide to cover every incarnation of BB30 and BB30 extended as there are many variations in the marketplace.

- SRAM GXP – Please see the dedicated section below.

- SRAM DUB – Please see the dedicated section below

Installation Video

The videos below shows you how to install a Hambini Bottom Bracket, there are some subtle differences between each bottom bracket depending on the application but the overall principle remains the same. Please view these in conjunction with the text below. The Text below always takes precedence as it’s up to date. YouTube does not allow videos to be updated once uploaded

This video shows a Hambini BB86 bottom bracket being installed in a Winspace bike frame.

Pre-Requisites

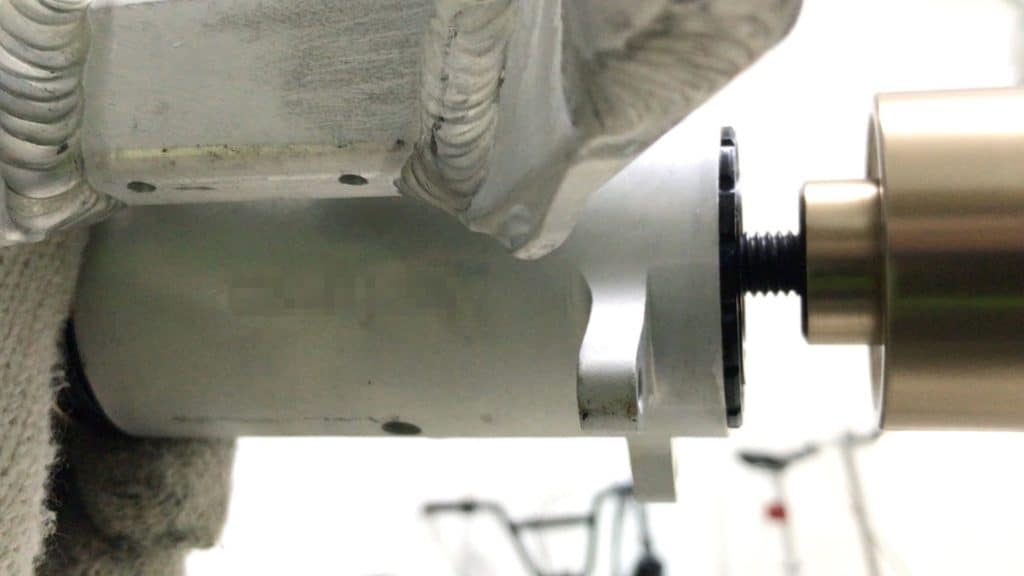

All Hambini Bottom Brackets press in from the drive side (chain side) of the bike frame. They are designed in this way to maintain an accurate chainline that is within manufacturer (Shimano, SRAM etc) tolerances. The following need to be observed:

- The bottom Bracket hole needs to be free of obstructions, usual obstructions are Di2 wires and bolts holding cable guides

- The fitting tools that come with Hambini BB’s are designed to be used with M12 studbar or presses. M12 or 1/2″ studbar and nuts are acceptable, a press makes the job easier. Note: Park Tools professional press is approximately 16mm in Diameter and would require the Hambini adaptors to be drilled.

- The usual respect for wearing safety equipment applies.

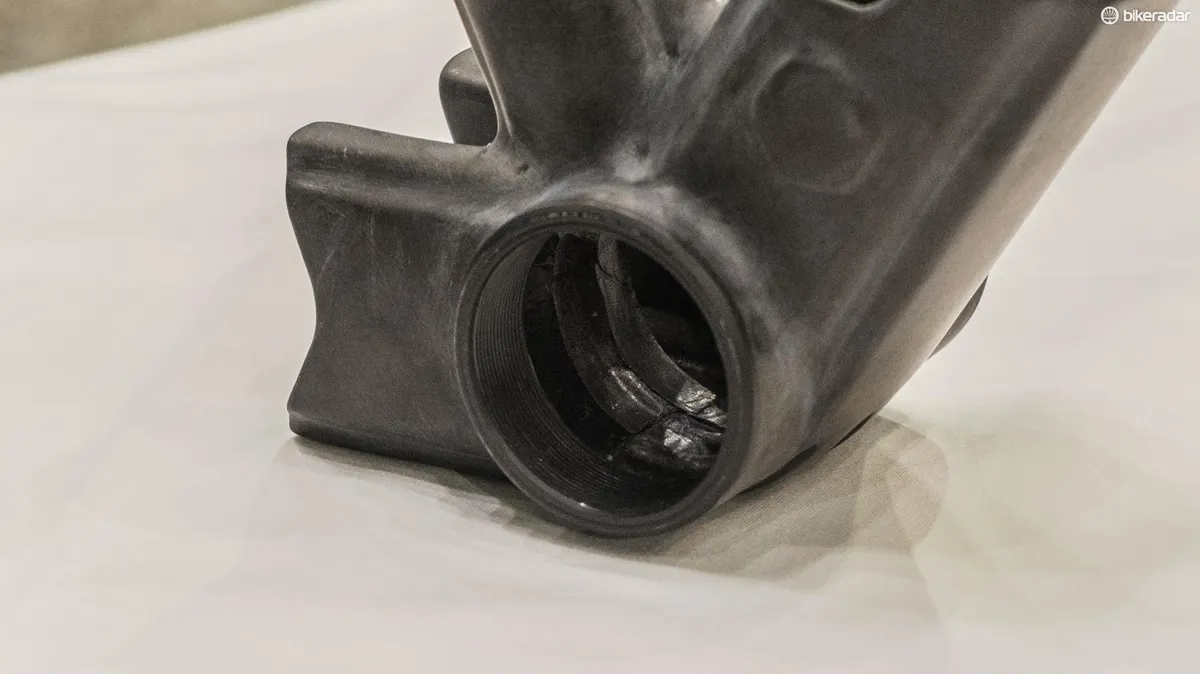

- Any double-lipped bottom bracket holes are unsuitable, this is usually only older model BB86 bike frames that have this issue, BB30/BB30A/PF30/PF30A/BBright usually meet this requirement. The picture below shows a double-lipped bottom bracket, note the lip approximately 10mm into the bottom bracket shell

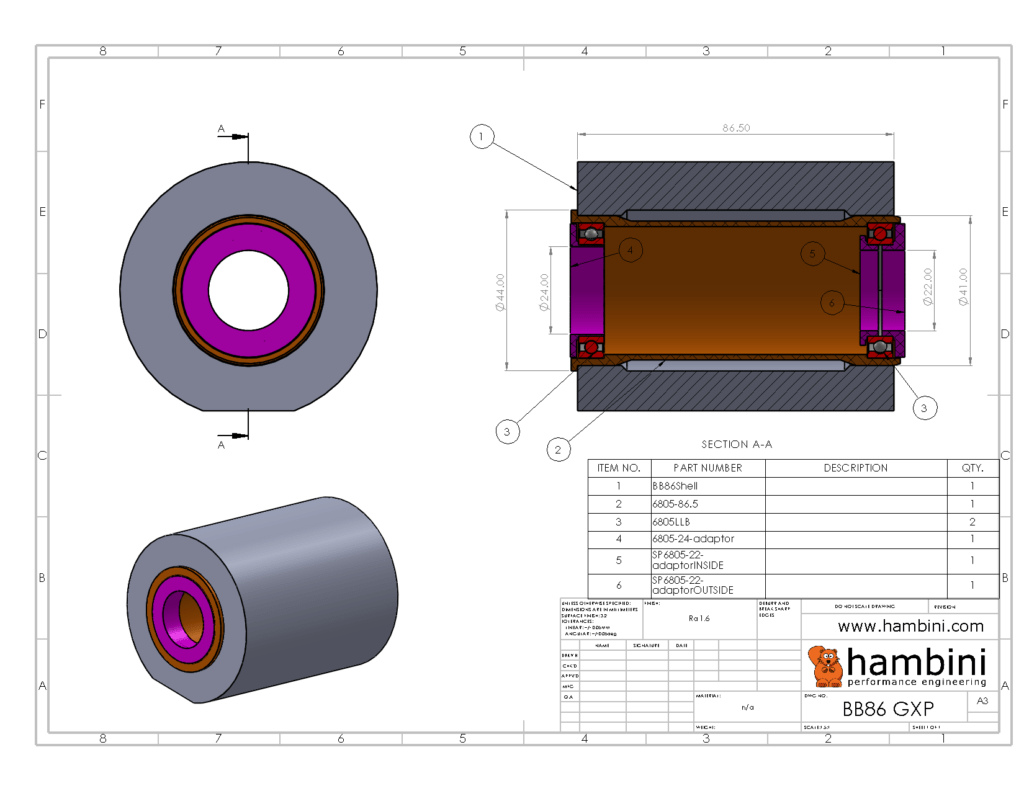

Mechanical Overview and replacement parts

All Hambini Bottom brackets have the same mechanical methodology. They consist of a one-piece sleeve that is made of aluminium or a proprietary alloy, a pair of bearings and Delrin spacers/sleeves. The bottom brackets use standard-sized bearings which are designed to be replaced as and when they wear out. The bearings that are used are shown in the table below. The choice of bearing is dictated by the bottom bracket shell and not the crankset

If you have a custom hambini bottom bracket, please contact me and I will advise

Pre-Installation

It is highly recommended that the crankset is tried in the bottom bracket cartridge before the cartridge is inserted into the bike frame. Any issues with shimming can be identified at this stage rather than when the cartridge is in the bike frame.

Please ensure you measure the bottom bracket hole in the bike before installation. Hambini BB’s are designed to fit into published specifications and fitting the Bottom Bracket into a frame that is out of specification can lead to diminished performance or frame cracking. Sizes for apertures are as follows:

The following bike frames often need whiffling (see troubleshooting):

Cervelo, Factor, Ridley, Canyon, Cannondale, OPEN, Argon 18, Giant

Installation Method

- Bottom bracket shells are often slightly tapered, the edges of the bottom bracket are tigher than the insides, when the bottom bracket gets passed the first location landing, the press will go slack (this is normal)

- During installation, there may be some creaks or popping heard (especially on carbon frames). IF THE INSTALLATION BECOMES EXCESSIVELY TIGHT, PLEASE STOP AND CONTACT ME. The bottom brackets are designed to meet published specifications, however, a lot of manufacturers make their apetures too tight or too loose

- **All Hambini Bottom brackets require approximately 250km of riding to bed in, they may feel slightly notchy or jittery before bedding in and this may vary from side. THIS IS NOT A FAULT** This applies to full and non contacting seals but is more noticeable on full contact seals.

Loctite activator and retaining compound require 48 hours to achieve 98% of the full cure strength, hence it is recommended that the bike is not ridden for 48 hours if any combination of activator and retaining compound has been used.

SRAM GXP Systems General Note

An Engineering guide for SRAM GXP is available here . It is recommended the user reads this information before commencing of crank installation.

SRAM GXP Systems (2020 Onwards)

SRAM GXP systems have a 24mm drive side axle diameter and a 22mm non drive side axle diameter. The non-drive side bearing is clamped between a shoulder and the non-drive side pedal arm by way of a “crank bolt”.

Hambini bottom brackets should be assembled as per SRAM instructions, the use of a wave washer on the drive side is mandatory. The wave washer is not included with the bottom bracket. The wave washer can be sourced from SRAM approved dealers, it is typically 24mm ID and 36mm OD.

A schematic showing a generalized GXP setup is shown below. The key feature is a pair of inserts on the non-drive side. One insert is on the inside of the bottom bracket, the other is on the outside.

You may need some additional 22 or 24mm spacers, SRAM axle lengths and tapers do vary. These are not included.

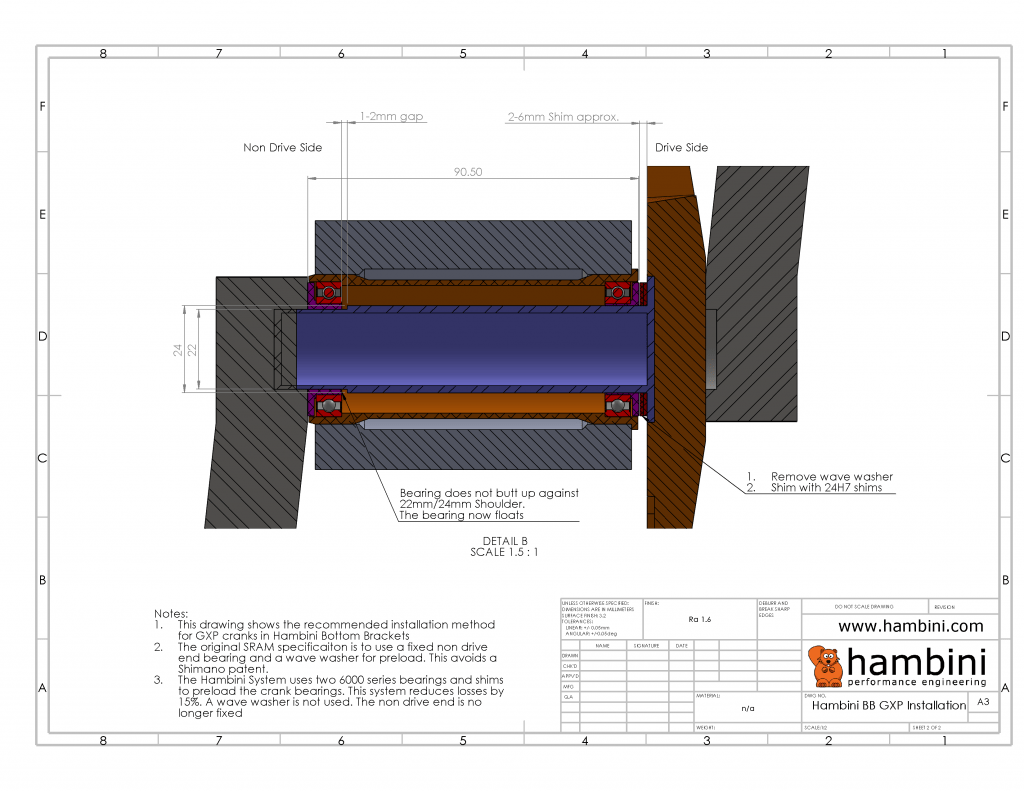

SRAM GXP Systems (Prior to 2020)

SRAM GXP – Hambini BB’s use a two bearing floating system as opposed to the OEM SRAM system of having the non-drive side bearing fixed. SRAM used a fixed Non drive End bearing to avoid a Shimano patent infringement. To allow for the floating nature, Hambini BB’s require preload to be adjusted by shimming. The crankset should be installed so there is just enough tightness on the crank axle bolt to prevent any play. Overtightening will destroy the bearings. Two methods of installing a Hambini BB in GXP systems are shown below. The first does not use a wave washer and is the preferred method used by a number of racing teams. This does require more frequent maintenance as the preload shims have to be adjusted as the bearing clearance increases. The second method functions like most standard bottom bracket/crankset combinations, both bearings are restrained in one direction, and preload is by means of a wave washer. Please note Hambini GXP Bottom Brackets ARE NOT SUPPLIED WITH A WAVE WASHER

SRAM DUB axles are 28.99mm, for all intents and purposes these are actually 29mm but for patent issues, it’s 28.99mm.

Practically, SRAM axles vary in length between crank arms. Hambini Bottom Brackets are made to conform to the bottom end of the tolerance and may require additional 29mm shims. For the end user, it is much easier to add a few shims than potentially having to machine the bottom bracket.

Additional Shims are available from Hambini and a number of other sources. It should be pointed out that you may not need them, it is totally dependent on the distance between the crank arms of your particular crankset.

Additional Information is available here

Troubleshooting Tight and Gritty bottom Brackets (Whiffling)

The most common issue is bearings that feel excessively gritty when the bottom bracket is installed – Some of this is because they are not bedded in but excessive grittiness is caused by a fit problem, Usually, the frame being undersized.

The ideal method of fixing this is to use a boring machine, this can be expensive. An alternative is to use a whiffler to enlarge the hole. The procedure for improving the fit is detailed here .

If you have any further questions, please use the contact form

Review Cart

No products in the cart.

BB92 (&86) – Complete Guide to Installation and Removal

- by Johnson Li

Welcome to your complete guide to BB86 & BB92 bottom brackets.

What are they? What are the differences?

And how do you install and/or remove this type of bottom bracket?

You’ll find all the answers here.

If you are just looking to fast-track removal or installation, the jump to the installation and removal section right here .

- From Threaded to Press Fit

- What are the Differences Among BB86, BB90, & BB92?

- Are BB92 and PF92 the Same?

- What Cranks Fit BB92?

- Will BB30 Fit BB92?

- Unique BB92 Removal & Installation Tool

Installing BB86 & BB92

- Removing BB86 & BB92

FROM THREADED SIMPLICITY to PRESS FIT COMPLEXITY

The press fit revolution has produced a variety of innovations and particular specifications.

BB30 kicked it off with PF30 quickly following. Both took the spindle diameter – 30mm – as their measure.

PF30 Bottom Bracket—The Complete Guide

The press fit standards which followed made it possible to use 24mm spindle cranks in a press-fit environment.

A complicating factor is that the bottom bracket shell diameter of each standard is different: 41mm BB86/92); 42mm (BB30); 46mm (PF30).

And that is just for the most common variants. Individual brands have their own specifications alongside of these.

The latest chapter in the press-fit saga is SRAM’s DUB system.

SRAM DUB Toolset—The Only One of its Kind

You get the advantages of a 30mm crank (28.99mm to be exact) and either a threaded or press-fit bottom bracket to fit the range of the most common (41,42,46mm) bb shell diameters.

Also check out our Bottom Bracket Tool post, covering bottom brackets and the tools you need to install, remove, and maintain them .

WHAT ARE THE DIFFERENCES AMONG BB86, BB90, BB92?

BB86 vs BB92? No difference. They are one and the same bottom bracket.

Well, BB86 refers to road bikes with their 86.5mm shell; BB92 refers to mountain bikes with their 91.5mm BB shells.

BB90 is Trek’s proprietary standard and is the odd one out here .

Like BB30, the bearings sit directly in the bottom bracket shell. Neither BB90 nor BB30 is as widely used as the others. BB90 is obviously brand specific. BB30’s issues has seen it long since overtaken by PF30.

BB86 and BB92 enjoy widespread adoption these days probably because they strike a compromise between a radical break from the past vs a degree of continuity.

And, of course, they are the standard offerings from the market leader, Shimano.

BB86 & BB92 Examples

This is a typical BB86 / BB92 bottom bracket.

It fits into a 41mm diameter bottom bracket shell and has aluminum bearing cups (with a choice of ceramic bearings for greater efficiency).

Shell widths range from maximum 92 mm on down.

Or, more accurately, this bottom bracket design will adjust to fit a BB shell inside that limit.

The sleeve’s rubber O-ring seals against the entire length of the non-drive side bearing cup’s inner diameter. The sleeve slides along the bearing cup as you press the cup in with the seal in place at that position.

This variant has the same options. The difference is the bearing cups/adapters are nylon.

A self-installing, self-extracting model like this is the way to go should you be looking to avoid having to use a dedicated toolset.

A Shimano 16T wrench is all you need.

Mount both sides into the bottom bracket shell. Then turn the drive side with the tool. The internal threads draw each side into the BB shell.

Extract it by turning the drive side BB cup counter clockwise.

We demonstrated the mechanism and technique in relation to the GP30, FIRST’s self-installing, self-extracting PF30 bottom bracket .

Before we get to the subject of installing and removing a BB86/BB92 bottom bracket unit, let’s briefly cover several Frequently Asked Questions.

ARE BB92 and PF92 the SAME?

Yes. It’s a matter of manufacturers’ technical terminology vs the cycling public’s way of speaking.

“PF” 92 is perhaps more accurate since it references the intrinsic nature of the bottom bracket—that it presses into the frame.

A common way to also reference BB92 is “Shimano Press Fit”.

WHAT CRANKS FIT BB92?

If you are thinking of upgrading from your current mountain bike with its 73mm bottom bracket shell/external bearing setup, you’re in luck.

This is a good move, by the way. The idea behind the BB92 standard is creating a beefier frame around a 24mm standard drive train.

- upgrade to a superior rig and

- reuse your existing crank and chainrings into the bargain.

WILL BB30 FIT BB92?

Two different things entirely—apples to oranges if you like.

BB30 refers to the spindle diameter, specifically:

- 42mm BB shell diameter

- bearing with a 30mm internal diameter

- 30mm diameter spindle on the crank

BB92 refers to the bottom bracket shell width, specifically:

- 41mm BB shell diameter

- bearing with a 24mm internal diameter

- 24mm diameter spindle on the crank

BB92 REMOVAL (& INSTALLATION) TOOL

Removing or installing a BB86 or BB92 bottom bracket is a breeze if you’ve got the right tools.

In this section I cover both installation and removal on a mountain bike.

Do I Need an Impact Tool?

A very important point: avoid employing an impact tool to remove a press-fit bottom bracket

This is the “business end” of the tool.

You run the shaft, blunt end first, through the bottom bracket.

The flanges on the other end compress into the bottom bracket then “pop” open as they expand, having moved past the bearing cup.

You grab a hammer and bang away on the blunt end. The flanges brace against the bearing cup enabling you to “tap” it out.

The longer the bottom bracket has been in place, the harder the removal . Ok, not necessarily. But as a rule of thumb, that’s the way it usually goes.

“Tapping”, then, won’t be sufficient. You’ll have to let loose with several solid thumps.

Even if you are able to simply tap the BB free, there’s certainly going to be damage to the bottom bracket bearing cup.

In this day and age we don’t have to resort to this type of blunt-force trauma to maintain or upgrade our bikes .

Precisely machined tools, comprised of CNC-honed components, enable quick and gentle bottom bracket removal including BB92 along with all other types of press fit bottom bracket.

The video demonstrates in fine detail how to carry out installation or removal quickly and easily. For a summary keep on skimming down the page, or check out the video for detailed coverage of the procedure .

First up, a simple grease preparation procedure is important.

Applying a light smear of grease to both the bottom bracket bearing cups and the bottom bracket shell is advised.

Installation and, maybe more importantly, removal becomes easier.

Additionally, any minute movement (which will depend on the manufacturing precision of the frame maker’s BB shell) may generate a press-fit creak, not an uncommon complaint for this type of bottom bracket.

There is is no particular method of application. I would make the point though, that if you mess around with bikes a lot, you will be in frequent contact with a variety of chemicals in the oil, grease, and de-greasers you use over the years.

Over the long term your skin will continually absorb tiny amounts. Over the long term that adds up.

In the interests of reducing the odds of damage to your health somewhere down the track, keeping a barrier between your skin and these chemicals is beneficial.

Smearing grease on with a fine brush – a toothbrush will do the job – or fingers (nitrile gloves are recommended) is enough.

All you need is a light smear across the 10mm where the bearing cup sits inside the BB shell.

This tool is housed in a robust plastic shell with hard and durable – and flexible – closing clasps.

The retaining cup is used for both installing and removing a BB92 bottom bracket.

Its thread takes the bolt used to press-in a bottom bracket and also serves as the capturing vessel when you remove a bottom bracket.

This piece presses against, as well as inserting into, the bearing cup.

The 22mm surface faces out. The other side’s 24mm surface inserts directly into the bottom bracket—24mm is the spindle diameter of course.

The 16cm bolt inserts through the piece and into the retaining cup. This piece presses the bottom bracket into position.

The retaining cup helps to keep it square so the bearing cups are pressed into position on the correct plane.

The piece also aligns perfectly with the bottom bracket’s outer diameter. Once the pressure is applied, this disc guides the BB squarely into position.

There will sometimes be a tiny bit of sideways BB drift as soon as you begin turning the bolt. But the tool’s design straightens the bearing cup.

Screwing the retaining cup into its direct connection with the BB shell ensures this 3-piece ensemble (press-fit piece, bolt, & retaining cup) is perfectly square to the BB shell.

Getting the bolt finger-tight is enough. Provided the retaining cup is snug against the BB shell on the opposite side, you are good to go.

A few turns of the supplied 8mm allen wrench quickly moves the bearing cup into position.

When you’ve got to this point, the drive side installation is complete.

Fractionally turn the the bolt in the opposite direction to loosen the assemblage. Then simply unscrew the retaining cup from the bolt.

Mount the non-drive side BB92 bottom bracket cup onto the press piece and bolt.

The procedure is exactly the same installing the non-drive side.

Installation is complete ready for crank installation.

Removing BB86-BB92

We need a few more components to assist in removal.

Installing is simpler as we apply the force required to press-in a BB92 (again, any press-fit bracket for that matter) from outside.

With removal, the force comes from inside . The trick is to install the components allowing this to happen.

We take away the press-piece (bracket used to press the BB into position). They include the

- retaining cup ring

- the split steel-hitch

The split steel-hitch is a bracket comprised of two equal pieces kept together by an elastic rubber grommet.

This component enables the gentle transfer of force from the driver to the bottom bracket without stressing or damaging it.

The split steel-hitch sits on the driver like so, expanding over the end. Under tension, the rubber grommet keeps it firmly in place.

The driver and the split steel-hitch, as a unit, press the BB92 bearing cup out of the BB shell.

The driver’s diameter is 24mm. The fit is snug as you slide it through, although not quite as close as a crank spindle. There is no need to apply grease as it easily slides through.

- The technique is turn the split steel-hitch slightly sideways.

- Slide the driver back into the BB shell.

- Slide the steel-hitch inside the bearing cup then push it over the end of the driver.

- The rubber grommet expands allowing the steel-hitch to grip the driver.

- Slide it back into position then move the driver forward so that the split steel-hitch’s edge contacts the bearing cup’s inside edge.

Here we see the split steel-hitch fully expanded around the driver, fitting firmly and precisely inside the bearing cup’s 24mm bottom bracket.

You use the retaining cup, again, not just as the “nut” to the bolt, but also as a receptacle that holds the bearing cup once it is pressed out of the bottom bracket shell.

The retaining cup won’t connect neatly with the bottom bracket shell. Hence the ring.

The ring is machined to fit exactly to the bottom bracket shell on one side, and the retaining cup on the other.

Slide the bolt through the driver from the opposite side and screw it into the retaining cup until the cup becomes firm against the ring.

The bolt is through as far as it can go without putting pressure on the bearing cup.

The driver side is ready for the 8mm allen wrench.

As you turn the bolt, the driver moves into the bottom bracket shell.

5 or 6 turns pushes the bearing cup (on the opposite side) out. It “gives” at the point where the bearing cup exits the BB shell completely.

The removed bearing cup sits in the retaining cup but also remains positioned on the driver.

You remove the whole lot in one clean movement.

Retrieve the bottom bracket from the retaining cup.

Remove the split steel-hitch from the driver.

You are ready to remove the drive side.

The difference this time around is that with one BB86-BB92 bearing cup removed, the driver no longer has support of the (now removed) bearing cup.

Despite appearances, that won’t be a problem.

Once the bolt engages the retaining cup “nut”, the driver squares up.

Turn the bolt as with the previous bearing cup removal. The right side bearing comes out just as quickly and easily.

WRAPPING UP Upgrading, maintaining or replacing a BB92, BB86, or BB30 bottom bracket is quick and easy with this toolset.

Yes. An aspect I did not mention is that this works with a BB30 system as well .

Here’s a question:

- Is your press-fit bottom bracket system the bee’s knees?

- Or would you go back to a threaded bottom bracket in a heartbeat?

Like this post? Please share!

2 thoughts on “BB92 (&86) – Complete Guide to Installation and Removal”

This is literally one of the best press fit bb instructions i have seen on the internet. Thanks!

I’m new to the ‘press fit’ bottom bracket technology, due to having a threaded system on my relatively old frame (2011). However, I’ve just inherited a carbon frame with a press fit system. I had difficulty just removing the crankset; it needed a fair whack. I’ve never been a fan of press fit parts. So yes, I would elect for threaded in a heartbeat. It seems so much simpler to me.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

SIGN ME UP!

Unique B2B insights from inside the Taiwan Bike Industry.

- Forum Listing

- Marketplace

- Advanced Search

- Mountain Bike Manufacturer Forums

- Bike Manufacturers

Trek BB90/GXP problems

- Add to quote

I have a new 2011 Trek 9.8 hardtail. It uses a BB90 bottom bracket and I use Sram cranks. So I purchase the Sram bearing kit and get home to put it on and there is alot of lateral movement. The non drive side crank bearing won't even stay in. I am using a brand new Sram X9 10 speed crankset. I can/will not buy a new crankset or bearings after I just bought a new set. Has anyone else had this problem with the Sram crankset? and how did you fix it, if you can at all. I am to the point of just selling the frame. I also will attempt to call Trek tomorrow and see what kind of run around they will give me.

I had a similar problem with my Madone. Sram Red crank was "loose" on the non-drive side. Sram said spindle was in spec, bearings were in spec, but spindle was on the small side and bearing on the large side, so ended up with a sloppy fit. I ended up selling it and getting a Rotor crankset. Rotor crank meshed perfectly with the bearings. I can't recall how tight the bearings were in the frame, but they could be removed/installed without tools or extreme hand pressure.

Did you install the Rotor cranks into the same BB, or did you buy a different one? SRAM uses a 22mm ID bearing on the NDS while Shimano/Rotor use a 24mm ID bearing on the NDS. They both use a 24mm ID bearing on the DS.

There is a specific bearing/spacer kit for this that most shops don't have in stock-- need from trek. With the spacers/bearings you have, they cranks would likely work fine in a bb95 (vast majority of trek mtbs). I have a pic of the spacer kit and trek product number, will try to post shortly on break from work

My guess is you installed your GXP crank in your hardtail mtb bb90 with kit 404700, which resulted in play. Note that 404700 is for GXP with BB95. You need kit 415734; which contains bearings (same as other kit I think) with different spacers, specifically for gxp mtb cranks with BB90 bottom brackets. your trek hardtail, and my carbon top fuel, have bb90 bottom brackets... so I went through this same issue. Good luck.

Attachments

Thank you that is good to know, Sadly the Trek dealer said these were the ones I needed. I fixed the problem by installing a drive side bearing out of my GXP BB on the non drive side and installed the washer to fix the spacing. I will definitely will order the bearings to get is correct. the funny thing it list the carbon hardtail to work as well. UPDATE: Trek does not have this part in any warehouse in the country and no time frame in getting any. I called 15 different dealers to find one and finally the Trek Superstore in San Diego had it. Thank god for him.

The bearing set included both with the new frame. So swapped out the Sram bearing for the Shimano with the Rotor crank.

Ah, okay. Just making sure. I've just never heard of the problem you were having. The SRAM and Shimano bearing sets also use different bearing shields, but if you were using the Shimano shields on the SRAM bearings, the setup would be way too tight axially instead of too loose radially.

Basically my lbs sold me the wrong bottom bracket kit for my bike and I needed a different kit that is know where to be found in the WHOLE country. The Trek superstore also sent me the same kit I already had. In short just get a bike with a standard threaded BB. So I have a brand new frame that is hanging in my garage that is useless until I get the correct bearing spacer kit from trek.

Finally got the correct BB kit from Trek and it bolted up perfectly. Thanks rfxc for the tip, I honestly think my local shop did'nt have a clue about which kit I needed. Surprising the mechanics didn't even know this. I will take her on her maiden voyage tomorrow.

Sorry to dredge up an old thread. But I'm having the same problem with a 2010 TREK Elite XC carbon hardtail frame. The BB is def. a BB90 and i'm installing a SRAM GXP MTB crank. If you think it's hard to find this kit in USA then its basically impossible in South Africa. So i'm trying to work another solution. Can you remember if the NDS bearing from this kit was a normal bearing or did it also have the extended inner race like the other BB95 kits. The standard bearing in kit 405700 was a 22 ID X 37 OD with the outer race being 8mm and the inner race extended to 11.5mm. The only solution I can do is to use a standard 22 X 37 X 8 bearing without the extended inner race.

Hi guys, I'm jumping on the thread as I have just bought a Trek Elite 9.6 (2013) I sold all the deore running gear as I have SRAM X9 shifters and Mechs I wanted to use. I am either going to get a X9 or XO crank depending on price/availability. I assume I'm going to need the same kit 415734 to run either of these GXP cranksets? cheers......

Yes you will need the 415734 kit, I have an X9 crankset on my Trek and have not had a problem since I installed them. Dan

cheers, I have asked my LBS to source it from TREK as I can't find it online anywhere.. Dan

I used a ceramic bearing kit from CRCBike. Fit perfectly and have not had a problem in 1500+ miles. My next frame will have the same bearings in it.

- ?

- 15.5M posts

- 517.9K members

Top Contributors this Month

- MAGAZINE OFFERS

- BIKE INSURANCE

- Best Products

- Maintenance

- Accessories

- Long-Term Reviews

- BikeRadar Podcast

- First Look Friday

- Bike of the Week

- Tech Features

- Routes and Rides

- Bike Galleries

- BikeRadar Bargains

- Buyer's Guides

- Fitness & Training

- Sizing & Fit

- Mountain Biking UK

- Cycling Plus

- Bike of the Year 2024

The complete guide to bottom bracket standards

Want to know your BSA from your BB90?

Jack Luke / Immediate Media

Benedict Pfender

This comprehensive guide tells you everything you need to know about bottom brackets — from a breakdown of all the bottom bracket systems available and their compatibility with one another to how a bottom bracket works and how to stop a bottom bracket creaking, this guide has it all.

It wasn't long ago that the only major bottom bracket decisions you had to make were shell width, spindle length, and, in rare cases, English (BSA) or Italian threading. These days, it can feel as though there are as many 'standards' as there are bike brands, with every one of them supposedly being the best option.

Below we rundown each of the major bottom bracket systems currently available, along with advantages, disadvantages, notes on compatibility, and some input from their proponents on why they exist.

- What is a bottom bracket?

- BikeRadar' s complete guide to headsets

- Conventional/BSA threaded

- BB90 and BB95

- PF86 and PF92

- OSBB (road)

BB30A and BB30-83 Ai

- OSBB (mountain)

PF30A and PF30-83 Ai

- Threadfit 82.5

Before we get stuck into the nitty-gritty of each standard though, we've put together this helpful crib sheet that runs through all of the key specifications.

- The ultimate creaky bottom bracket fix

- Road bike groupsets: everything you need to know

Bottom bracket standards and compatibility

Iso threaded internal.

Proprietary? No BB shell inner diameter 1.37in x 24 TPI Bearing inner diameter N/A, internal BBs have integrated spindle BB shell width 68mm road, 73mm mountain, 83mm downhill, 100/120mm fat bike Installation Threaded internal bearings Compatibility Square taper, Octalink, ISIS Other names BSA or BS threaded Other notes Bottom bracket must be specced with correct shell width and spindle length

ISO threaded external

Proprietary? No BB shell inner diameter 1.37in x 24 TPI Bearing inner diameter 24mm (Hollowtech II), 24/22mm (GXP), 25mm (Ultratorque/Powertorque) BB shell width 68mm road, 73mm mountain, 83mm downhill, 100/120mm fat bike Installation External cups Compatibility n/a Other names BSA or BS threaded Other notes External cups now exist that will take 30mm spindles

Italian threaded

Proprietary? No BB shell inner diameter 1.375in (34.92mm) x 24 TPI Bearing inner diameter 24mm (Hollowtech II), 24/22mm (GXP), 25mm (Ultratorque/Powertorque) BB shell width 70mm Installation External or internal Compatibility n/a Other names n/a Other notes Can be prone to undoing itself because non-driveside is a standard thread

Proprietary? Yes (Trek) BB shell inner diameter 37mm Bearing inner diameter 24mm BB shell width 90mm road, 95mm MTB Installation Pressed bearings with stepped BB shell Compatibility Designed specifically for 24mm spindles, no 30mm option Other names n/a Other notes The extra width of the BB cups is replaced with more frame real-estate

Proprietary? No BB shell inner diameter 41mm Bearing inner diameter 24mm BB shell width 86.5mm road, 91.5mm MTB. Other widths may be named according to shell dimensions: 89.5mm, 104.5mm, 107mm, 121mm, 132mm Installation Bearings pressed in cups Compatibility Originally designed for 24mm spindles, but some BBs that fit a 30mm spindle are available Other names PF41 (Hope – refers to BB shell diameter), PF24 (Chris King – refers to spindle diameter) Other notes Similar to above, but a non-proprietary version with less stringent tolerances

Proprietary? No (open Cannondale standard) BB shell inner diameter 42mm Bearing inner diameter 30mm BB shell width 68mm road, 73mm MTB Installation 6806 bearings pressed into frame with circlips to locate in BB shell Compatibility Designed for specific BB30 cranks, 24mm step-down spacers available Other names n/a Other notes Narrow overall width means longer spindles can be used with appropriate spacers

Proprietary? Yes (Cannondale) BB shell inner diameter 42mm Bearing inner diameter 30mm BB shell width 73mm (BB30A), 83mm (BB30-83) Installation 6806 bearings pressed into frame with circlips to locate in BB shell Compatibility n/a Other names n/a Other notes Asymmetric BB shell which is wider on non-driveside. Wider overall shell is also claimed to improve bearing support

Proprietary? No (SRAM) BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 68mm road, 73mm MTB Installation 6806 bearings in cups Compatibility Originally designed for BB30 cranks Other names n/a Other notes Analogous to BB30 above, but uses pressed cups (with identical bearings) for relaxed manufacturing tolerances

OSBB (Road)

Proprietary? Specialized BB shell inner diameter 42mm Bearing inner diameter 30mm BB shell width 68mm Installation Pressed 6806 bearings with circlips in BB shell Compatibility Designed for specific BB30 cranks Other names n/a Other notes OSBB for Specialized Road bikes appears to just be BB30. An older Pressfit 61x46mm BB appears to be obsolete

OSBB (Mountain)

Proprietary? Specialized BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 73mm Installation 6806 bearings in cups Compatibility Originally designed for BB30 cranks Other names n/a Other notes OSBB for mountain bikes appears to be PF30 (post 2010). An older 84.5x46mm BB appears to be obsolete.

Proprietary? Yes (Cannondale) BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 73mm (BB30A), 83mm (BB30-83) Installation 6806 bearings in cups Compatibility n/a Other names n/a Other notes Essentially the Pressfit version of BB30A and BB30-83

BBRight (Direct Fit)

Proprietary? No (Cervélo) BB shell inner diameter 42mm Bearing inner diameter 30mm BB shell width 79mm (road only) Installation 6806 bearings pressed into frame with circlips to locate in BB shell Compatibility BBRight cranks and wider Other names n/a Other notes Similar asymmetric concept as Cannondale Ai, but the shell is wider

BBRight (Press Fit)

Proprietary? No (Cervélo) BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 79mm (road only) Installation 6806 bearings in cups Compatibility BBRight cranks and wider Other names n/a Other notes Similar asymmetric concept as Cannondale Ai, but the shell is wider

Proprietary? No (FSA) BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 86.5mm road Installation 6806 bearings in cups Compatibility Will take 386EVO cranks and traditional external BB cranks Other names n/a Other notes Matches the wide bearing spacing of a BSA external BB with a large 30mm spindle

Proprietary? No (FSA) BB shell inner diameter 46mm Bearing inner diameter 30mm BB shell width 91.5mm MTB Installation 6806 bearings in cups Compatibility Will take 386EVO cranks and traditional external BB cranks Other names n/a Other notes Matches the wide bearing spacing of a BSA external BB with a large 30mm spindle

Proprietary? No (Chris King & Argonaut Cycles) BB shell inner diameter M47 x 1 Bearing inner diameter 30mm BB shell width 68mm road, 73mm MTB Installation Threaded cups with bearings Compatibility Cross compatible dependent on spindle length Other names Thread Fit 30i Other notes Aims to solve creaking issues of press fit systems. Essentially an oversized BSA external BB

Thread Fit 82.5

Proprietary? Yes (Colnago) BB shell inner diameter 41mm (when shell is fitted) Bearing inner diameter 24mm (30mm) BB shell width 86.5mm road Installation Threaded BB shell takes aluminium shell, which is then fitted with BB86 bearing cups Compatibility Originally designed for BB86 cranksets and bearings. New integrated CeramicSpeed BB fits 30mm spindle cranks Other names n/a Other notes Threaded shell can be made with better tolerances and can be replaced if it wears out. CeramicSpeed now offers a fully integrated bearing (akin to T47) that will fit 30mm spindles

We've also included a section on how you can (or can't as the case may be) change between different bottom bracket standards and an explainer on why there are so many standards in the first place.

Conventional/ISO/BSA threaded bottom brackets

Modern, external cup threaded bottom brackets are among the most common of standards. Square taper bottom brackets also fit in most shells designed for external cup bottom brackets, but to keep things simple, we will only cover the modern standard here.

The idea is simple, by moving the bearings outboard of the shell, you can then use a much larger spindle. Currently, 24mm is the accepted norm compared to square-taper's relatively minuscule 17mm diameter.

External bottom brackets for 30mm spindles do exist, such as those from White Industries , allowing modern 30mm-diameter axle cranks to be used.

Shimano popularised the concept as Hollowtech II, with the introduction of the XTR M960 group in 2003 — even now it's still arguably the gold standard for bottom brackets. In fact, companies such as Santa Cruz continue to stand by it despite the plethora of other options now available.

- The ‘new’ bottom bracket standard we can all get behind

"Threaded bottom brackets are compatible with the largest range of cranks [and] some press-in bottom brackets have a reputation for creaking," Santa Cruz global marketing manager, Will Ockelton, tells BikeRadar .

"Press-in bottom brackets require special tools, which most consumers don't have [and] they can only be installed a few times before it's recommended that you replace the bearings [or cups — ed.]. Most of our bikes come with ISCG tabs, but for the few that don't, a thread-in bottom bracket still allows for chain guide mounting.

"A threaded bottom bracket is great because it isolates the bearing from the frameset," adds Matt Harvey, president of bearing, seal and bottom bracket maker Enduro .

"Because you have aluminium threads and surfaces, you can face the shell with a cutter and make it parallel if it is not. The bearing bores are usually round already, with aluminium cups, because it is a machined surface, and if the bearing bores are too tight you can sand them out and get the fit just right for the bearings before you thread them into the frame. You cannot use a facing or cutting tool that I know of in a carbon shell."

- Pros : Easy at-home service; interface surfaces can often be machined; huge selection of parts and accessories

- Cons : Heavier than press-fit systems; frame design limited by relatively small-diameter and narrow shell

- Crank designs that will fit : Standard 24mm external type (Shimano Hollowtech II, SRAM GXP, Campagnolo Ultratorque and Powertorque, FSA MegaExo, Race Face X-Type, etc), square taper, ISIS, BB386EVO, BB392EVO many others. Crucially external cups that fit 30mm spindles do exist.

A note on other threaded bottom bracket standards

To make matters even more confusing, there exists a number of other threaded bottom bracket standards.

Excluding the relatively new T47 standard (more on that later), the one you're most likely to come across is the Italian threaded bottom bracket.

To keep matters simple, we've put together a simple explainer on this slightly esoteric of standards here .

- What is the difference between an Italian and BSA bottom bracket?

BB90 and BB95 bottom brackets

Trek introduced the proprietary BB90 standard in 2007 on the revamped Madone and soon followed with the mountain bike-specific BB95.

Instead of bearing pressed into aluminium cups that were then threaded into the frame, Trek pressed the bearings directly into the frame.

Bearing seats were moulded into the carbon frame structure to save weight, and bottom bracket shell width ballooned to 90mm on road bikes and 95mm on mountain bikes, creating more real estate for frame tubes and suspension pivots.

Effectively, the space previously taken up by the bearing cups can now be used as frame real-estate, allowing larger (and stiffer) tubes to be used.

- Is Trek all-in on T47? | Why I won’t miss BB90, the worst bottom bracket standard

"The most significant [advantage] is a stiffer frame," says Trek mountain bike product manager John Riley. "Secondarily, BB90/95 offers a lighter overall solution by replacing traditional alloy bearing cups with integrated carbon bearing bores. It also provides a simplified installation process."

Aside from omitting the cups, the BB90/95 setup is functionally identical to conventional threaded bottom brackets, in that it uses the same bearings and the same bearing locations as before. Crankset compatibility is thus unchanged, although you do lose the ability to run chain guides that sandwich between the driveside cup and frame.

This system is not without its issues however, with shells becoming oversized (due to wear) being a relatively common problem (leading Trek to release the very slightly oversized V2 bearings to compensate).

Perhaps partly due to these issues, Trek has, in fact, recently abandoned this bottom bracket standard on its Domane endurance road bike platform for 2020 , in favour of the T47 threaded standard. It will be interesting to see if this trend carries over to future models in its range.

- Pros : Lighter than conventional setups but retains compatibility with 'legacy' cranksets; creates a wider BB shell without affecting crank width

- Cons : Can't use cup-mounted chain guides; shell is wider but still small in diameter; requires a separate bearing puller and press for service, bearing bores can wear out and loose tolerances

- Crank designs that will fit : Standard 24mm external-type only. A GXP conversion kit is also available

BB86 and BB92 bottom brackets

Very closely related to Trek's BB90/BB95 system is the BB86/BB92 standard used by Scott , Giant , Pivot , and many others.

Once again, the bearings and their locations are identical to those of conventional threaded bottom brackets, only they're mounted in small composite cups before being pressed into the frame.

The advantages are similar to those for Trek's BB90/95; a wider bottom bracket shell that doesn't otherwise affect crank width, plus lighter weight compared with threaded alloy cups.

From a manufacturing standpoint, BB86/92's dimensional tolerances aren't as stringent as BB90/95's, and it's easier to adapt the system into alloy frames. So long as you have a concentric bore of the right diameter, parallel faces, and a proper shell width, you're good to go.

"Because of this technology, we're able to improve pedalling stiffness [by about] 10% on some of our frames, over traditional threaded bottom brackets," says Giant global marketing director Andrew Juskaitis. "[PF86/92 is] less subject to tolerances, too, and is able to take up +/- 0.5mm of [shell width] discrepancy."

Scott US marketing and PR director Adrian Montgomery touts similar reasons for his company choosing BB86/92 over other standards:

"We can create frames with a wider bottom bracket shell, thus adding stiffness to the entire structure as the adjoining tubes can also be wider. We can do this without creating our own crank spindle standard because it adheres to the same spindle that a threaded BB uses. It's also lighter than a threaded BB because we've removed the alloy material that held the bearings outside the shell [and] it costs less to do a press-fit bottom bracket in regards to manufacturing. Disadvantages? None that I can see."

The road standard has an 86.5mm shell width (hence BB86) whilst the mountain bike standard has a 91.5mm shell width. A number of other shell widths may also exist, though they all use the same bearing cups.

More recently, bearings have shown up that allow a 30mm spindle to be used. The dimensional restriction mean the bearings are generally quite small, as the system was designed around 24mm spindles. This can lead to reduced bearing lifetimes.

This system has a number of different names depending on who you talk to. It is also called PF86, PF92, PF24 (Chris King) and PF41 (Hope).

- Pros : Same as BB90/95

- Cons : Same as BB90/95 in theory, but in practice there are generally less issues experienced due to the less stringent tolerances

- Crank designs that will fit : Standard 24mm external-type, 30mm spindle bottom brackets are available for e.g. BB386 EVO, BB392EVO

BB30 and OSBB bottom brackets

Several companies have dabbled in alternative bottom bracket standards over the years (Gary Fisher, Klein, and Merlin, to name just three) but it wasn't until Cannondale released its then-proprietary BB30 system as an open standard in 2006 that something actually stuck.

BB30's bearing cartridges press directly into a precision-fit shell, as with Trek's BB90/95 system — albeit with the additional aid of two pairs of snap-rings/C-Clips.

But here it's the shell and spindle diameters that increase in size, not the shell width.

The key benefits are lighter weights owing to the larger, 30mm-diameter aluminium spindle and the elimination of separate bearing cups. Plus, because the shell is still just 68mm wide, the cranks can also be made to provide more heel clearance — or, depending on the crank design, an even a narrower stance width (commonly referred to as Q factor).

"The idea was that, since Cannondale had control of both the frame and crank manufacturing, we could use system integration to design a superior solution, even if that meant not relying on a traditional industry standard," says Cannondale vice president of R&D, Chris Peck. "[Advantages are] a lighter and stiffer crank with the 30mm alloy spindle; more room in the bottom bracket area to attach larger down tubes, seat tubes, and chainstays; and very low bottom bracket weight."

"[Our] Hollowgram SiSL2 crank with SpideRing weighs 484g. By comparison, Dura-Ace 9000 weighs around 678g [we recorded 637g in our review – ed]. In addition to weight, another BB30 advantage is stiffness. By increasing the spindle diameter, you increase its resistance to twisting, which is where the bulk of the deflection in a crankset comes from. Roughly 70% of total deflection measured at the pedal comes from axle twist."

BB30 shells, however, do require more stringent dimensional tolerances to work well, meaning that they're more expensive to manufacture. Moreover, with the notable exception of Felt , which uses a carbon tube, BB30 also usually employs an alloy shell insert that has to be bonded or co-moulded into an otherwise carbon frame.

Specialized's uses this standard for some of its high-end road bikes, but calls it OSBB.

- Pros : Lighter weight; more resistant to axle twist; more heel clearance; larger-diameter shell and spindle; potential for narrower pedal stance width

- Cons : Shell still just 68mm wide; metal-on-metal interfaces can be prone to creaking; requires a separate bearing puller and press for service; requires high manufacturing tolerances; bearing seats can't easily be faced post-manufacturing

- Crank designs that will fit : BB30, BB386 EVO, standard 24mm external-type, Specialized OSBB, BBRight. Can be adapted to almost any standard with suitable adapters.

BB30A and BB30-83 Ai bottom brackets

More recently, Cannondale announced a variant of BB30 called BB30A. This uses a shell that's 5mm wider than the original but it's an asymmetrical layout that only adds those extra millimetres on the non-driveside. According to Cannondale, this allows for wider bearing spacing and better spindle support (which should improve bearing longevity).

Other critical dimensions, such as bearing outer diameter and thickness, remain unchanged and there's also no difference in pedal stance width or ankle clearance (in most cases).

That extra 5mm can complicate crank compatibility, however. BB30-compatible cranks that feature axle spacers on the non-driveside (such as from Cannondale and SRAM) will work just fine because all you'll have to do is remove spacers as needed to accommodate the extra width, but BB30 cranks without such spacers (such as from FSA and Specialized) won't work.

Thankfully, many newer BB30-compatible cranks now feature extra-long spindles for wider compatibility and those will install just fine.

Cannondale also introduced another bottom bracket standard in the form of BB30-83 Ai.

First used on the brand's SuperX 'cross bike, the standard works in exactly the same way as BB30A, but sees the shell ballooned out to 83mm wide, improving tyre clearance and, supposedly, stiffness.

- Cons : Metal-on-metal interfaces can be prone to creaking; requires a separate bearing puller and press for service; requires high manufacturing tolerances; bearing seats can't easily be faced post-manufacturing; not all BB30 cranks will fit

- Crank designs that will fit : BB30 (some), BB386 EVO, standard 24mm external-type, BBRight

PF30 and OSBB bottom brackets

SRAM addressed BB30's stringent dimensional tolerances and associated manufacturing costs with the advent of PressFit 30 in 2009. Just as with PF86/92, PF30 is analogous to BB30 in that the bearings and bearing locations are identical, but with the addition of intermediary composite cups that allow for looser frame tolerances.

Not surprisingly, then, PF30 has gained widespread traction in the industry, particularly with smaller manufacturers who can't afford high reject rates.

Specialized uses PF30 for its high-end mountain bike, confusingly also calling it OSBB though it is a different standard to the OSBB standard found on its road bike.

"I think it's more about the simplicity of the manufacturing process," says Drew Guldalian of Pennsylvania-based custom builder Engin Cycles . "Boring out a [standard] BB30 is not impossible, but in my opinion it's an unrealistic task from a manufacturer's standpoint that needs to do something to make money.

"With the PressFit 30, they're using the same technology with the larger bearings and the same technology with the bearings living inside the frame, but they're utilizing the nylon to their advantage where you have a more realistic tolerance."

"PressFit 30 fundamentally provides all the most significant advantages of BB30 but requires much less precise machining of the bottom bracket shell area, as the bearings come inserted into plastic cups that are easier to fit into the frame and less delicate than standalone bearing," adds SRAM drivetrain product manager Chris Hilton . "PF30 bottom brackets also have an integrated sealing system, which helps prolong bearing life."

Cannondale's Chris Peck provided BikeRadar with specific details. While BB30's bearing bore tolerances are 41.96 +0.025/-0mm (meaning the bore can be slightly oversized but not undersized), PF30's requirements are 46.00 +0/-0.05mm – exactly half as rigorous.

Specialized 's OSBB system is nearly identical to BB/PF30 but with a few key differences, according to the company's director of advanced research, Chris D'Aluisio.

- Interview: SRAM's Chris Hilton

"The 30mm bearing is a good choice when using thinwall aluminium spindles," he says, "and the narrow bearing stance (relative to outboard bearings) works perfectly with our carbon arm design needing to make the turn into the spindle. The OSBB is basically the same as BB30 but with a little tighter tolerances and a 0.5mm difference in the clip-to-clip dimension. Cranks of both systems are compatible with each other."

D'Aluisio even argues that OSBB offers alignment advantages compared with threaded shells:

"The tolerances are not too different but the way they're measured is. They both have the same needs for concentricity and placement relative to the frame. The threads are at a disadvantage in that they need to be machined from both sides and have a hard time sharing a centerline, whereas our OSBB is machined from one side all at once — and round holes are easy to measure."

- Pros : Same as BB30 but with lower costs, easier assembly, and the potential for additional bearing seals integrated into the cup/bearing assembly

- Cons : Standard-width shell; requires a separate cup remover and press for service

- Crank designs that will fit : BB30, BB386 EVO, standard 24mm external-type, Specialized OSBB, BBRight

PF30A and PF30-83 Ai bottom brackets

This is essentially the same as the BB30A and BB30-83 Ai Cannondale system described above, except that it uses bearing cups rather than bearings pressed directly into the frame.

Similarly, it's largely based on the PF30 design, though with a 5mm wider, asymmetric bottom bracket shell — 73mm for PF30A and 83mm for PF30-83.

- Pros : As for BB30A and BB30-83 Ai

- Cons : Similar to BB30A and BB30-83 Ai, though press-fit design relaxes tolerance requirements

BBRight bottom brackets

Most bottom bracket fitments incorporate bearings that are symmetrically positioned about the frame's centerline. Much like the Cannondale design, Cervélo tipped that apple cart in 2010, however, with the introduction of BBRight.

BBRight shares its 30mm-diameter alloy spindle, cartridge bearings, and driveside bearing location with PF30 — in fact, the bottom bracket cups are identical to PF30.

However, the non-driveside bearing is pushed outward by 11mm — the same as conventional threaded, BB90, and PF86 bottom brackets. This makes it something of a hybrid between the two widely accepted systems.

"BBRight uses the 11mm space occupied by an external bottom bracket’s left bearing cup to let the designer widen the frame tubes that connect to the bottom bracket shell: down tube, left chainstay and seat tube," says Cervélo race engineer Damon Rinard. "All these can be 11mm wider now. In the case of the chainstay, that’s nearly double the width at an important and highly loaded point — the junction with the bottom bracket — which has a several-fold beneficial effect on stiffness."

"The resulting increase in moment of inertia has gained us so much stiffness and strength that the left chainstay weighs less than the right, despite being stiffer and stronger," he continues. "Because stiffening either chainstay stiffens the frame, the net result is a substantial increase in the frame’s bottom bracket stiffness, together with a small reduction in frame weight."

Rinard insists this revised bearing spacing comes with no functional downsides, either:

"This performance boost comes with no other changes to basic dimensions: the left bearing stays in the same spot; the aluminium cup is simply replaced with carbon frame now. And since the bearing’s in the same spot, the lateral position of the left crank isn’t changed at all, so Q-factor is also unchanged. Your feet are in exactly the same place as before."

BBRight is available in two incarnations. The direct fit version uses the same 6806 bearings from a BB30 bottom bracket, which are pressed directly into the frame.

The press fit version uses removable bottom bracket cups, similar PF30 and is used on all other Cervélo frames and has also been adopted by some 3T designs.

From the outset, Cervélo introduced BBRight as an open standard that anyone could jump onto. While it seems to make good engineering sense, however, other bike companies have been slow to come on board.

- Pros : Stiffer than BB/PF30, in theory, without impacting other attributes; good crank compatibility, cheaper to manufacture than threaded or BB30

- Cons : Questionable longevity; requires a separate cup remover and press for service

- Crank designs that will fit : BBRight, BB386 EVO, standard 24mm external-type

BB386 EVO & BB 392 EVO bottom brackets

BB386 EVO and BB392 EVO, introduced in 2011, take the oversized principle to extremes. The bearings have the same 86/92mm spacing, width-wise, as conventional threaded external BB, BB90/95, and PF86/92 formats, but it uses BB/PF30's bigger 30mm diameter spindle.

As stiffness is directly tied to cross-sectional size it's no surprise that, theoretically, BB386 EVO has the most to offer, with both the added shell width and diameter that many frame-makers yearn for.

In addition, it uses the same bearings and cups as PF30 and BBRight and, thus, the same manufacturing tolerances and required tools.

"[BB386 EVO] allows us to go wider, which in turn opens up big opportunities in terms of stiffness and strength in the bottom bracket/chainstay area," says BH president and CEO Chris Cocalis (Cocalis holds the same position with Pivot Cycles, whose frames are built around the more mountain bike-friendly PF92 format). "With bigger cross-sections driving stiffness, we also have more flexibility in being able to tune ride quality with the carbon layup."

"For us, there are no disadvantages versus a threaded design or a standard BB30. We are able to have a full carbon shell with no metal bonded into the frame, which makes for a stronger, lighter frame structure.

"With our manufacturing methods, we also have no issues holding tolerances. [BB386 EVO] wasn’t designed as a cost reduction, but not having to post bond an aluminium shell into the frame and make sure the facing and threads are correct is slightly less expensive and much more reliable."

Crank compatibility is another BB386 EVO strongpoint. Despite the bulbous dimensions, the shell will accept most modern crankset fitments save for dedicated BB30/PF30 and BBRight designs.

"The BB386 EVO cranks are compatible with almost every BB shell standard (BSA, BB30, PF30, BB86)," says Jason Miles of FSA . "We currently make bottom brackets and adaptors for BSA, BB30, and PF30 frames and are working on BB86 bottom brackets. Frames with BB386 EVO shells should be able to run almost any crank. We currently make adaptors to fit Shimano, Campagnolo , and SRAM 24mm spindle cranks."

While the surrounding frames should be stiffer than those built around narrower BB/PF30 or threaded shells, Miles admits that the BB386 EVO crankset actually takes a slight step back in that regard, but only when viewed independently of the entire system. The straighter arms also have less ankle and heel clearance than those narrower formats.

"Because the crank arms are straighter, we can make them lighter than BB30 ones," he says. "But because the BB386 EVO spindles are longer than BB30 ones, they aren't as stiff. Total stiffness is not a measure of crank stiffness alone, though. When you factor in the stiffness gains from a wider shell, the overall stiffness will be highest when BB386 EVO frames meet BB386 EVO cranks."

- Pros : Theoretically the best in terms of frame stiffness; reduced manufacturing costs; generous crankset versatility

- Cons : Heel clearance isn't as good as BB30; requires a separate cup remover and press for service

- Crank designs that will fit : BB386 EVO/BB392 EVO specific, standard 24mm external-type (can be adapted), BBRight, BB30 (axle width dependant),

T47 bottom brackets

Designed in conjunction with Chris King and Argonaut Cycles, T47 – announced in 2015 – is the most recent offering hoping to become the next standard. T47 bottom brackets, aka Thread Fit 30i, use the same 46mm internal diameter as PressFit 30, but they thread into frames rather than being pressed in.

This standard is also sometimes known as Threadfit 30i.

The design comes about as a solution to the well documented creaking issues associated with oversized press-fit systems. While these issues are near always the result of poor tolerances, the T47 standard promises to fix the creaking issue without sacrificing the benefits of an oversized interface.

As it stands, this new standard may just become the hot new thing among smaller manufacturers of metal bikes.

The need for a heavier metal interface looked like a limiting factor for mass-produced carbon bikes, but with a manufacturer like Trek on now on board (as mentioned above, its 2020 Domane features a T47 BB ) that could all be about to change.

- Pros : Vast crankset compatibility, open standard, threaded design easy to service and prevent from creaking, same dimensions as PF30

- Cons : New tooling needed for manufacture, requires metal threads, weight

- Crank designs that will fit : All (dependent on axle width)

Colnago ThreadFit 82.5 bottom brackets

Threadfit 82.5 is not really a new standard in that it is compatible with BB86 cranksets and bearings.

Rather than press the BB86 bottom bracket directly into the frame, the ThreadFit system threads an aluminium shell into the frame first, which provides the interface for the bearings to sit in.

According to Colnago, this allows dimensions and tolerances to be controlled more accurately. Additionally, it allows the bottom bracket interface to be replaced easily if it wears over time or after multiple bottom bracket replacements.

With the release of the C64 bike , Colnago, in collaboration with CeramicSpeed, designed a ThreadFit 82.5 bottom bracket that fits the bearings directly into the shell that threads into the frame — effectively a proprietary T47 design. This also allows a larger 30mm spindle crank to be installed.

- Pros : As for PF86

- Cons : As for PF86

- Crank designs that will fit : Standard 24mm external-type, Shimano, SRAM GXP, Campagnolo and 30mm spindle cranks for CeramicSpeed bottom bracket

SRAM DUB bottom brackets (Durable, Unifying Bottom Bracket)

DUB (Durable, Unifying Bottom bracket) may sound like a new standard, but really it’s a new axle diameter specification for mountain bike cranks (in 2019, SRAM also started rolling out DUB cranksets in the road line-up).

SRAM claims that the focus on optimising the bearings resulted in a spindle diameter of 28.99mm. This places is right between SRAM's old 24mm GXP cranks and 30mm spindles of modern cranks.

Thankfully DUB has been designed with major bottom bracket standards in mind, allowing the cranks to be fitted to the most common designs with the choice of the appropriate bottom bracket.

DUB is compatible with BSA threaded, PF86, PF92, BB30 (73mm shell) and PF30 (73mm shell) bottom brackets and cranksets are completely interchangeable between the different standards.

This is achieved by placing the bearings at the same axial location along the bottom bracket axis — in the case of BB30 and PF30 bottom brackets, that results in the bearings being located outboard of the frame.

- Pros : Claims of improved sealing and durability, compatible with major BB standards, cross-compatibility for DUB cranksets

- Cons : Proprietary system

- Crank designs that will fit : DUB

Will my cranks fit my bike?

While cranks designed specifically for your bottom bracket will fit, at some point you may want or need to adapt ‘non-standard’ cranks to your bottom bracket. It’s hard to confirm compatibility without looking at the specific combination of crankset and bottom bracket, but there are some rules of thumb we can apply.

Generally, your replacement cranks may have the same or smaller spindle diameter, and the same or longer spindle length than the system your bottom bracket is designed around.

For example, a BB30/PF30 bottom bracket has the narrowest shell width of any of the standards, whilst being designed for large 30mm spindles. That means it should be able to take most cranks with appropriate adapters and spacers to take up the ‘space’ of a narrower and/or longer spindle.

However, it’s worth bearing in mind that using a stack of spacers may not be the optimum solution for performance (read stiffness) and reliability.

On the other hand, a BB30 crankset, being specifically designed for a BB30 bottom bracket is generally not adaptable to many other systems, due to the short spindle length matching the narrow shell width. Newer BB30 cranks have started using longer spindles to make them a bit more versatile.

At the other end of the spectrum, Trek’s proprietary BB90/BB95 bottom bracket is designed around a wide shell and narrow spindle, meaning it is limited to traditional 24mm spindle cranks.

Various other bottom bracket standards lie between these two extremes. Take these guidelines with a pinch of salt and always be sure to double check what you can fit before committing to a new crankset.

How do I change to a different crankset?

As you've likely noticed in the footnotes above, most of the bottom bracket standards offer a fairly wide range of options in terms of crankset choice. And, not surprisingly, several companies are at the ready to help you make those changes.

Current players in the mix-and-match field include Wheels Manufacturing , Rotor , Praxis Works , Enduro Bearings and even house brands of third-party distributors such as Quality Bicycle Parts ' Problem Solvers.

Changing between setups typically requires some type of adapter. Or, in ideal cases, bottom bracket bearing assemblies that directly convert from one system to another, such as Praxis Works' BB/PF30-to-24mm assembly.

In general, though, the guideline is the same: try to minimise the number of parts involved. More parts added on top of each other results in greater tolerance stack-ups, plus more interfaces that could potentially creak.

Why are there so many bottom bracket standards?

There's nothing wrong with threaded bottom brackets, per se, and it's worth noting that none of the proponents of alternative systems cast threaded systems as being fatally flawed. They do, however, note the system's inherent limitations in terms of frame design, which is why more companies — particularly ones striving to be on the cutting edge — continue to embrace non-threaded formats.

How companies decide to go about that — and precisely what design features they want — is the real issue, because everyone seems to have their own ideas on how to achieve the same goals (less weight, more stiffness, and lower manufacturing costs).

"The explosion of bottom bracket standards reflects the various design objectives and manufacturing competencies of individual frame and component brands," says Eric Doyne, US PR representative for Shimano. "Shimano sees and values the importance for consumers to be able to easily source a frequent consumption article like the bottom bracket.

"The explosion of standards is not good for consumers or dealers," Doyne continues. "The bottom line is that bike companies are driving the standards. Threaded systems have very few limitations — they are easily cleaned and repaired at the shop level, and they do not affect the bearing fit."

In concept, at least, all of the standards we've covered are functionally sound. But the realities of relaxing tolerances can create other issues.

For example, save for Shimano, Rotor, Specialized, and some FSA models that use adjustable effective crank arm-to-crank arm distance, most of these alternative systems require wave washers or compressible spacers to account for inherent shell width variability (Magic Motorcycle used precision micro-shims back in the day, and some third parties offer similar systems for modern cranksets).

Things work okay if the installation is done correctly. But, if not, you could still end up with lateral play under load (possibly resulting in dropped chains) or bearings that are too heavily preloaded (decreasing bearing lifespan).

Weather-sealing can be a problem, too. Integrated cup and bearing systems at least have the potential for good barriers against dirt and moisture, depending on the design, but bottom bracket standards that rely solely on bearings pressed directly into the frame sometimes have to make do with the typically inadequate seals on the bearing cartridges themselves.

Some designs even offer discipline-specific advantages. For example, BB30 offers the narrowest potential Q-factor, while wider shells allow for greater chainstay spacing, for more tire clearance on mountain bike hardtails and cyclocross frames.

Finally, there are aesthetic considerations. Road companies often gravitate towards BB30 for the sleek, narrow form factor, while smaller builders dealing primarily in steel might prefer the more proportional look of a threaded shell. Carbon companies looking to maximise their stiffness (or stiffness-to-weight) figures generally just want to go bigger in some way.

As to which bottom bracket standard is 'best', the answer is undeniably straightforward: it depends.

This article was first published in March 2013 and was most recently updated in January 2020

Share this article

- Terms & Conditions

- Subscribe to our magazines

- Manage preferences

Your cart is empty

Revolvr BB90/95 Thread-Together Bottom Bracket

- SRAM, BB90/95

- Shimano, BB90/95

- Replaces standard BB90/95 press in bearings commonly found on Trek bicycles with a solid, unified thread-together bottom bracket interface

- Thread-together bottom brackets provide a secure and stable shell interface for smoother operation and extended bearing life

- Low-friction dual seals protect the bearings from harmful contaminants

- Sealed premium bearings are serviceable

- Models available for both Shimano HTII 24mm and SRAM GXP 22/24mm spindles

- Requires a special tool for installation (J&B# 610756)

You may also like

Recently viewed.

- Road Bottom Brackets

- MTB Bottom Bracket

- Parts, Kits, Bearings

- Service Tools

- Clothing and Hats

- Engineering

- The BBInfinite Story

- Testimonials

- Your Cart is Empty

You have a Shimano crankset. What bottom bracket standard is your bike?

Determine which of our Shimano road bottom brackets is the most compatible with your bike by using this selection guide. BBInfinite’s modules are compatible with all Shimano HollowTech cranksets on the market. Engineered with a one-piece design, these BBs fix bicycle creaking while providing cyclists with consistent shifting and drivetrain performance. Additionally, these road bike bottom brackets feature dual polymer bearing shields to prevent dirt and debris from getting into the precision bearings. Our Shimano bottom brackets are fully compatible with crank-based power meters.

Now that you have selected a Shimano road crank set for your bike, or you intend to install on your bike, you may select the appropriate road bottom bracket standard of your bike to jump directly to the Shimano bottom bracket you desire:

For ALL Shimano HollowTech II road crank sets, double or triple, standard or compact, select the compatible frame bottom bracket standard button above.

The possible Shimano road bottom bracket standards are:

BBRight (79mm)

BB86 (86.5mm)

T47 Internal

T47 External (68mm)

BSA English Threaded (68mm) 1.37 x 24TPI

Italian Threaded (70mm) 36mm x 24TPI

PressFit30 (68mm)

PressFit30A (73mm)

BB30 (68mm)

BB30A (73mm)

BB386EVO (86.5mm)

Specialized OSBB (61mm)

Note: If you have any questions, or need help identifying your bottom bracket standard, please call our Customer Service line: 866.865.3335.

Or email us: [email protected]

Now, please select the appropriate Shimano bottom bracket above. Thank you.

- 1-866-865-3335

- View our Privacy Policy Here

Sign up to get the latest on sales, new releases and more…

© 2024 BBInfinite . Powered by Shopify

Bottom Bracket Selection Guide

- Remember me Not recommended on shared computers

Forgot your password?

- Manuals, Tutorials, Guides and Tips

I need to know how to reinstall the game

By Taxman November 22, 2020 in Manuals, Tutorials, Guides and Tips

Recommended Posts

Some how during the latest update my career's got goofed up. For example I cannot fly the Hurricane on the Moscow map even though I have purchased it. -DED-Rapius from support has tried to work with my current install but there is no fix. His recommendation is to do reinstall the game, but I so far cannot find any good instructions on how to reinstall. Also I presume I should back up all my career's and input folders. I do have lots of space on my hard for a second install.

Link to comment

Share on other sites.

Any help out there?

III./SG77-K_Bobo

Hi Taxman, I'll try to help.

First you need the IL2_setup_Great_Battles.exe file, that should be in your C:\Program Files (x86)\1C Game Studios\IL-2 Sturmovik Great Battles folder.

Save that file in a safe place along with your account, input, startup and skins/campaign/career stuff you want to carry over.

Then uninstall the game. Once uninstalled, re-install it with the IL2_setup_Great_Battles.exe file you tucked away. Run the launcher and it will update to current. Then replace all your saved files you tucked away and resume playing.

You say you have room for a second install. If doing the above makes you feel insecure, use the IL2_setup_Great_Battles.exe file to do a second install, then transfer your vital info to the second install, then uninstall the original or try to fix it.

Good luck and have fun! It just takes some time.

So I just looked at my GB folder and there seems to be no exe file that I can find. What I do have in bin>game is Il-2 application @ 16.503 kb, is that what your are referring too?

Again thanks

No_85_Gramps

Go to the web site, log into your account, click on profile, then downloads, and download the installer. The installer, IIRC, is not found withing the games folder structure.

That's true! I saved mine to the games folder after my re-install. Get it from your account page, the installer is 168 mb

Thanks Gramps!!

Thanks No_85_Gramps, will do.

Again thanks to_ BoBo

Ok got it and it is the same size as you posted _BoBo. Now on my desk top.

Quick up date. Success, some minor tweaks but all working now.

Thanks to everyone who help me.

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Already have an account? Sign in here.

- Existing user? Sign In

- All Activity

- Great Battles

- Flying Circus

- Cliffs of Dover

- Create New...

Moscow ML is a light-weight implementation of Standard ML (SML), a strict functional language used in teaching and research

View the Project on GitHub kfl/mosml

- Download ZIP File

- Download TAR Ball

- View On GitHub

- Download PKG File

- Get DEB File

- Download Win. Installer

The current version 2.10.1 of Moscow ML

- implements the full Standard ML language, as revised 1997, including Modules and some extensions

- yet is backwards compatible with versions prior to 2.00

- implements large parts of the new SML Basis Library

- implements separate compilation

- can produce compact stand-alone executables (a la Caml Light)

- supports quotations and antiquotations, useful for metaprogramming

- supports dynamic linking of external functions under Linux (x86, ARM, and Alpha), FreeBSD, NetBSD, Solaris, Digital Unix, HP-UX, MacOS, and MS Windows’95/98/NT/XP/Vista and possibly also 7 and 8.

New in version 2.10.1 of Moscow ML

- This is a minor update, mostly just for various clean up.

- ML Server Pages added to examples

- Build system cleaned up a bit

New in version 2.10 of Moscow ML

- Support for dynamic linking and callback from C also under MacOS X

- There may now be 2 G globals (string literals etc) instead of 64 K

- The HTML files generated for mosmllib now have valid URLs

- Substring.app more efficient

- Recursive structure compilation (elabRecSigExp) fixed

- Several errors in Mosmlcookie

- Misplaced double quote in Msp.ahrefa

- Exception Option wasn’t available at top-level

- Linker did not check stamps of linked-in units

- Hash function now much faster on very long strings

- Double alignment constraints now correct with gcc-3.2 and Solaris

- Bug in Polyhash.filter

- Socket library returned only first 16 bytes of UDP datagram

- String and Substring : added concatWith , isSuffix , isSubstring , full

- ListPair : added zipEq , appEq , mapEq , foldlEq , foldrEq , allEq

- Added ArraySlice and VectorSlice structures, also for Char and Word8

- Added find , findi , all , exists , collate to vector, array and slice structures

- Added collate to List

- Added update to vector structures

- Path.{mkRelative,mkAbsolute} now take record arguments

- Negative Time.time values allowed

- OS.Process : new functions sleep and isSuccess ; status not eqtype

- Listsort : added eqclasses , merge , mergeUniq

- Path : added functions isRoot , fromUnixPath , toUnixPath , and exception InvalidArc (bug report by Henning Niss)

- TextIO : inputLine now have type instream -> string option

- Array : added type abbreviation vector (bug report by Andrzej Wasowski)

- FileSys : type access renamed to access_mode (bug report by Henning Niss)

- Byte : unpackString{,Vec} now uses vector slices (bug report by Henning Niss)

- Unix : added functions fromStatus , textInstreamOf , binInstreamOf , textOutstreamOf , binOutstreamOf , exit , and added phantom types to proc (bug report by Henning Niss)